Professional Documents

Culture Documents

Service Bulletin: M67-5 FAA-DER Approved

Service Bulletin: M67-5 FAA-DER Approved

Uploaded by

Ingenieria SIALASOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Bulletin: M67-5 FAA-DER Approved

Service Bulletin: M67-5 FAA-DER Approved

Uploaded by

Ingenieria SIALASCopyright:

Available Formats

service bulletin

M67-5

FAA-DER Approved

May 2, 1967

TO: Owners and Operators of Continental Aircraft Engines

SUBJECT: Lagging Engine Breather Line on GTSIO-520 Engines.

Gentlemen:

Normal breathing of the GTSIO520 Engine produces some condensation which can cause

sludging in the breather system, especially in colder climates and operation in cold

temperatures at altitude. Heaviest sludging generally accumulates in the area from the

breather elbow, on the prop gear reduction section, back to the connection at the oil filler

neck. Condensation can also collect in the breather separator causing blockage of the

return suction line from the breather separator to the scavenge pump. Partial blockage of

the breather system causes an increase in internal crankcase pressure and can cause oil to

be thrown overboard, showing up as a sudden increase in oil consumption.

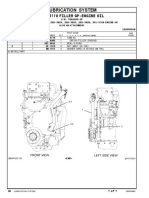

Lagging of all metal portions of the breather line (refer to sketch page 2 )

for the entire length from the breather elbow back to the diaphragm baffle at the

rear of the engine will significantly reduce the amount of condensation build up and

retard sludging. (Rubber hose connectors need not be lagged.) Lagging the line with

regular plumbers fibre glass insulation (or equivalent) covered with tape has proved

effective. The system should be checked for blockage at every 100 hour periodic

thereafter or as often as experience dictates is necessary consistent with the type of

operation and geographic location.

TELEDYNE INDUSTRIES, INC. 1977 TELEDYNE CONTINENTAL MOTORS

Member of GAMA Aircraft Products Division

General Aviation

Manufacturer’s Association

PO Box 90 Mobile Alabama 36601

Page – 2 – M67-5 May2, 1967

You might also like

- Merc Service Manual 17 305 350 EnginesDocument6 pagesMerc Service Manual 17 305 350 EnginesHayduke them100% (1)

- Technical Information Letter: GE PowerDocument10 pagesTechnical Information Letter: GE PowerRichard Puicon PuyenNo ratings yet

- Cessna Seb99 12Document20 pagesCessna Seb99 12Elmer VillegasNo ratings yet

- CSL 1060Document6 pagesCSL 1060oscar horacio floresNo ratings yet

- CFM56-5B SB 72-0865 R03 Dt. 18.03.21Document23 pagesCFM56-5B SB 72-0865 R03 Dt. 18.03.21Pradeep K sNo ratings yet

- Bulletin 6l90 PDFDocument4 pagesBulletin 6l90 PDFAnonymous WzR5h9g8VNo ratings yet

- MALIBU 2010 Brake Light TSBDocument19 pagesMALIBU 2010 Brake Light TSBRenato M FariaNo ratings yet

- Technical Information Letter: Lube Oil VarnishingDocument6 pagesTechnical Information Letter: Lube Oil VarnishingHeryanto SyamNo ratings yet

- SB05 9Document12 pagesSB05 9Alma BravoNo ratings yet

- CFM56 7B27Document4 pagesCFM56 7B27ozmaeNo ratings yet

- G 500Document522 pagesG 500Monika Estevez100% (3)

- GE Lube Oil Varnishing TIL 1528-3Document6 pagesGE Lube Oil Varnishing TIL 1528-3hebishtNo ratings yet

- B777 Inspection Notices Dated 06 Oct 2003Document10 pagesB777 Inspection Notices Dated 06 Oct 2003rofllololNo ratings yet

- Sae J169-1985Document4 pagesSae J169-1985nelliNo ratings yet

- 177 SeriesDocument430 pages177 SeriesaburizqiNo ratings yet

- Homework Oral Assesment A320 CeoDocument2 pagesHomework Oral Assesment A320 CeoShoyashNo ratings yet

- Piper SB 955 Engine Mount Nose Gear AttachmentDocument6 pagesPiper SB 955 Engine Mount Nose Gear AttachmentGeorgios AsimakopoulosNo ratings yet

- Service Bulletin AFS-SB9 Adjustment of Servo Regulators Fitted With AVStar Diaphragms-1Document3 pagesService Bulletin AFS-SB9 Adjustment of Servo Regulators Fitted With AVStar Diaphragms-1Alberto ColinNo ratings yet

- 03-Sistema de LubrificacaoDocument16 pages03-Sistema de LubrificacaoFabio MacielNo ratings yet

- Body Builders Layout Book: Second Unit Body Mounting IndexDocument10 pagesBody Builders Layout Book: Second Unit Body Mounting IndexSPIN2018No ratings yet

- Service Bulletin: Teledyne Continental Aircraft EngineDocument2 pagesService Bulletin: Teledyne Continental Aircraft EngineHuda LestraNo ratings yet

- MEI - Aluminium MIG WeldDocument56 pagesMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- TP-5804 SLO Spec & CriteriaDocument2 pagesTP-5804 SLO Spec & CriteriaCARLOS OLIVEROSNo ratings yet

- SB-75 (Traffic Advisory System)Document10 pagesSB-75 (Traffic Advisory System)OSCAR RODRIGUEZNo ratings yet

- 3-7L MerCruiser All Service BulletinsDocument83 pages3-7L MerCruiser All Service BulletinsGerrit DekkerNo ratings yet

- Service Bulletin: Single EngineDocument9 pagesService Bulletin: Single EngineHenryNo ratings yet

- Section EE-1: Cummins QSC Engine - Installation and PartsDocument64 pagesSection EE-1: Cummins QSC Engine - Installation and Partsjadan tupuaNo ratings yet

- Interim Change Notice: Ge Industrial Aeroderivative Gas TurbinesDocument6 pagesInterim Change Notice: Ge Industrial Aeroderivative Gas TurbinesRolando Antonio Cuenca PironaNo ratings yet

- Aircraft Maintenance Manual: TASK 12 13 21 610 801 Servicing of The Oil Level of The ACMDocument10 pagesAircraft Maintenance Manual: TASK 12 13 21 610 801 Servicing of The Oil Level of The ACMCHIMONo ratings yet

- Hose Management Guide: SN: Agc Lines Group - AttachmentDocument42 pagesHose Management Guide: SN: Agc Lines Group - AttachmentJose luis Consuegra100% (1)

- Otaq Recall 1999 p1Document1 pageOtaq Recall 1999 p1Muhammad Eitch-BeeNo ratings yet

- Airframe-Mounted Oil-Tank Drain Valve - Removal/InstallationDocument6 pagesAirframe-Mounted Oil-Tank Drain Valve - Removal/InstallationAdrian LauNo ratings yet

- KFS 564aDocument38 pagesKFS 564aWorawit ThipphothongNo ratings yet

- Shaft Selaing System Hydrogen GeneratorDocument12 pagesShaft Selaing System Hydrogen GeneratorIpm Ipm100% (1)

- Oil FilterDocument4 pagesOil FilterRameswar PradhanNo ratings yet

- CSL1060Document6 pagesCSL1060Asep HidayatNo ratings yet

- Lubrication System: 230-4118 Filler Gp-Engine OilDocument19 pagesLubrication System: 230-4118 Filler Gp-Engine OilSidney RodriguesNo ratings yet

- Be Sure To Consider Combustion Air Content When Assessing Air Induction System DamageDocument1 pageBe Sure To Consider Combustion Air Content When Assessing Air Induction System Damagebenjir shuvoNo ratings yet

- Service Bulletin: Teledyne Continental Aircraft Engine Category 3Document5 pagesService Bulletin: Teledyne Continental Aircraft Engine Category 3JacksonNo ratings yet

- Be Sure To Consider Combustion Air Content When Assessing Air Induction System Damage1Document1 pageBe Sure To Consider Combustion Air Content When Assessing Air Induction System Damage1momenshahirajonNo ratings yet

- Sb643c Inspection 100 HrsDocument4 pagesSb643c Inspection 100 HrspaulNo ratings yet

- Relacion de InformacionDocument21 pagesRelacion de InformacionMay MaydayNo ratings yet

- SIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2Document39 pagesSIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2kenji roberto santanaNo ratings yet

- SRV-TSB-23-003 CR246 Spring Installation For Fuel Tank Breather HoseDocument7 pagesSRV-TSB-23-003 CR246 Spring Installation For Fuel Tank Breather Hosecarlos antonio gonzalez abregoNo ratings yet

- Service BulletinDocument2 pagesService BulletinFalgon IslamNo ratings yet

- Operation & Maintenance Manual: Thrustmaster Outboard Propulsion Unit Section 5 Maintenance ProceduresDocument9 pagesOperation & Maintenance Manual: Thrustmaster Outboard Propulsion Unit Section 5 Maintenance ProceduresMohammed BasionyNo ratings yet

- Sabp G 028Document19 pagesSabp G 028Krishnamoorthy100% (1)

- SB658Document3 pagesSB658ricardo novoa saraviaNo ratings yet

- Three Speed Switch 49-60-69Document126 pagesThree Speed Switch 49-60-69Turpial Airlines OMAC-N 683No ratings yet

- Flow and Heat Transfer Simulation in A Splash Lubricated Bell 525 AccessoryDocument10 pagesFlow and Heat Transfer Simulation in A Splash Lubricated Bell 525 AccessoryAnonymous lEX5U51wOANo ratings yet

- SB658Document3 pagesSB658oscar horacio floresNo ratings yet

- TSB 98-23-14 Dual TensionerDocument2 pagesTSB 98-23-14 Dual TensionerhNo ratings yet

- Service Letter: MandatoryDocument6 pagesService Letter: MandatorySantiagoLeonNo ratings yet

- Intervalo de 6000 Horas + Revisão de 2000 - 938KDocument2 pagesIntervalo de 6000 Horas + Revisão de 2000 - 938KMatheus MongesNo ratings yet

- Saes T 631Document10 pagesSaes T 631BM TECHNo ratings yet

- 19D GrommetDocument1 page19D GrommetbtgottliebNo ratings yet

- Ps2-Heat Treatment - Gas CarburizingDocument17 pagesPs2-Heat Treatment - Gas CarburizingMine Bautista SantiagoNo ratings yet

- 1991 Ford Technical Service BulletinsDocument147 pages1991 Ford Technical Service Bulletinsalexander pintoNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet