Professional Documents

Culture Documents

ZBS600 Marca ZERMA

ZBS600 Marca ZERMA

Uploaded by

Juan Carlos Ortiz PimientaCopyright:

Available Formats

You might also like

- CNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WDocument16 pagesCNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WSot DesignNo ratings yet

- Manufacturing Process of Speaker EnclosureDocument8 pagesManufacturing Process of Speaker EnclosureShoaib AhmadNo ratings yet

- 3.4 Golden Joint ProcedureDocument9 pages3.4 Golden Joint ProcedureArieNo ratings yet

- De 20220812162629y1ee0Document4 pagesDe 20220812162629y1ee0Raiyre RolandNo ratings yet

- Manual Quickhitch: Issue 1Document23 pagesManual Quickhitch: Issue 1MMM-MMMNo ratings yet

- Machine Introduction & Technical Data Specification: Vertical Machining Center MS-500 Twin PalletDocument8 pagesMachine Introduction & Technical Data Specification: Vertical Machining Center MS-500 Twin PalletCristian PavanNo ratings yet

- E - Product View-PrDocument16 pagesE - Product View-PrJack ReacherNo ratings yet

- Trituradora Manguera Gse300Document2 pagesTrituradora Manguera Gse300grhismakNo ratings yet

- Features & Benefits: Precision Abrasive Waterjet SystemsDocument2 pagesFeatures & Benefits: Precision Abrasive Waterjet SystemsCojanu CozminNo ratings yet

- SeriesISellSheet1330D PDFDocument2 pagesSeriesISellSheet1330D PDFRicardo Alberto Ortegon BenjumeaNo ratings yet

- RASO Series en v001Document12 pagesRASO Series en v001silviolcNo ratings yet

- Numturn 660-1500Document1 pageNumturn 660-1500Frederik HenderwanzaNo ratings yet

- Astro Jaw: Single Toggle Jaw CrusherDocument4 pagesAstro Jaw: Single Toggle Jaw CrusherDanielSantos100% (1)

- Doosan Stump GrinderDocument2 pagesDoosan Stump GrinderAaravGuptaNo ratings yet

- 11 Riveting MachinesDocument4 pages11 Riveting MachinesTecnicas Reunidas de AutomociónNo ratings yet

- TS Spir Class-EnDocument2 pagesTS Spir Class-EnpdiconpNo ratings yet

- LT 12 15 - EnglDocument2 pagesLT 12 15 - EnglEmilian PopaNo ratings yet

- C350 Ipower: Standard Equipment ApplicationsDocument1 pageC350 Ipower: Standard Equipment ApplicationsDein MasterNo ratings yet

- Rittal Busbar Machining Made Easy 5 4635Document12 pagesRittal Busbar Machining Made Easy 5 4635Mohammad Badii MosliNo ratings yet

- Features & Benefits: Precision Abrasive Waterjet SystemsDocument2 pagesFeatures & Benefits: Precision Abrasive Waterjet SystemsCojanu CozminNo ratings yet

- Specs Cat Wheel SawsDocument4 pagesSpecs Cat Wheel SawsEmmanouEl BirikakisNo ratings yet

- SunShine Technology - Presentation - 02082022Document41 pagesSunShine Technology - Presentation - 02082022shashwat.dhaseNo ratings yet

- Manual LathesDocument26 pagesManual LathesBINNo ratings yet

- 2050 Panther LatheDocument2 pages2050 Panther Lathepramod_tryNo ratings yet

- KMT CatalogueDocument13 pagesKMT Cataloguepriyanka.vijayNo ratings yet

- Woodturning LathesDocument24 pagesWoodturning LatheslucibrandusNo ratings yet

- Blades - AEHQ5851-01 08-08Document4 pagesBlades - AEHQ5851-01 08-08Carlo PoliNo ratings yet

- Rack Milling Machine RMDocument4 pagesRack Milling Machine RMAries N. RamadhanyNo ratings yet

- DiscSpreader ENDocument14 pagesDiscSpreader ENRavi MistryNo ratings yet

- Hobbing Machines LC 80-180Document8 pagesHobbing Machines LC 80-180Abdisalaam mohamudNo ratings yet

- MB46 T-SlotDocument2 pagesMB46 T-Slotdarkarmy100No ratings yet

- Bridgeport Series I - BrochureDocument2 pagesBridgeport Series I - BrochureVVNo ratings yet

- SJ 410 460 530 - EnglDocument2 pagesSJ 410 460 530 - EnglEmilian PopaNo ratings yet

- NEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Document12 pagesNEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Marlon GilerNo ratings yet

- Petrography EXPDocument16 pagesPetrography EXPYounes KoutayaNo ratings yet

- Tecnotest 5.2 Coring and Drilling PDFDocument8 pagesTecnotest 5.2 Coring and Drilling PDFRyan A.Y.No ratings yet

- Pt0uk Nlx6000 PDF DataDocument48 pagesPt0uk Nlx6000 PDF DataAlexandroNo ratings yet

- DW Series 2015Document20 pagesDW Series 2015kris CadwellNo ratings yet

- 07 - Pump Split Case Pump - enDocument6 pages07 - Pump Split Case Pump - enRizaldi YahyaNo ratings yet

- Samurai 120H BrochureDocument17 pagesSamurai 120H BrochurehoriaNo ratings yet

- Masonry SawsDocument1 pageMasonry Sawspapasote.unoNo ratings yet

- PSA Series EngilshDocument66 pagesPSA Series EngilshTuấn NguyễnNo ratings yet

- Crushing Screening BrochureDocument24 pagesCrushing Screening Brochuredebasish bhowmickNo ratings yet

- ABS Submersible Mixer RW 200, 50HzDocument2 pagesABS Submersible Mixer RW 200, 50Hzalisya.blwsNo ratings yet

- Water Jet PortfoliaDocument7 pagesWater Jet PortfoliaSagar KumarNo ratings yet

- Biko 12 Pag. GBDocument12 pagesBiko 12 Pag. GBMUFİTNo ratings yet

- Lva1 App6891Document53 pagesLva1 App6891Allyth AlqhtaniNo ratings yet

- TF ENGcatalogo2016 TRS 2Document8 pagesTF ENGcatalogo2016 TRS 2James MckerrNo ratings yet

- Router Family BrochureDocument15 pagesRouter Family BrochurealexNo ratings yet

- Minimax Gen. - Rev01 - Jan18 - IngDocument136 pagesMinimax Gen. - Rev01 - Jan18 - IngWagner MenezesNo ratings yet

- Washing and Classifying Brochure EnglishDocument24 pagesWashing and Classifying Brochure EnglishMohammed Alshami GeologistNo ratings yet

- Okamoto Brochure 2Document38 pagesOkamoto Brochure 2Legi YangNo ratings yet

- SMS ColdPilgerMillsDocument8 pagesSMS ColdPilgerMillsSUNILNo ratings yet

- Emery Roller MachineDocument3 pagesEmery Roller Machineinstallationsap1No ratings yet

- Machine Tool LINE-UP (Eng)Document40 pagesMachine Tool LINE-UP (Eng)Mohamed Essam MohamedNo ratings yet

- Auger Compactor - ENDocument4 pagesAuger Compactor - ENEugene Jin LeowNo ratings yet

- PNC 10catalogueDocument2 pagesPNC 10catalogueParlin PasbarNo ratings yet

- ☆ SJ-inclined-screens-technical-specification-山特维克Document8 pages☆ SJ-inclined-screens-technical-specification-山特维克AShuang qinNo ratings yet

- Petrography CatalogueDocument16 pagesPetrography CatalogueMR DaniNo ratings yet

- VTL SeriesDocument10 pagesVTL Seriesxojoga9602No ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- PAINTS INVENTORY Apr.14 2016Document1 pagePAINTS INVENTORY Apr.14 2016Pavel ViktorNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- 1 s2.0 S1044580322004053 MainDocument16 pages1 s2.0 S1044580322004053 MainSree SabariNo ratings yet

- Process Design For The Recycling of Tetra Pak CompDocument5 pagesProcess Design For The Recycling of Tetra Pak CompMostafa AlakhliNo ratings yet

- Cost Accoounting ReviewerDocument19 pagesCost Accoounting ReviewerUNKNOWNNNo ratings yet

- Ground Parallels: To Provide More Convenient Processing For Milling ViseDocument4 pagesGround Parallels: To Provide More Convenient Processing For Milling ViseVinod KumarNo ratings yet

- Automotive Steering-KnuckleDocument4 pagesAutomotive Steering-Knucklefileuse.fNo ratings yet

- Development of Large Diameter V-Belt Pulley Using Coreless Drag and Wire-Reinforced CheekDocument9 pagesDevelopment of Large Diameter V-Belt Pulley Using Coreless Drag and Wire-Reinforced CheekAna MayumiNo ratings yet

- NumberDocument275 pagesNumberHarshana RathnayakeNo ratings yet

- Mastic Asphalt, Asphalt Hot Mix + Grouting Asphalt PavementsDocument44 pagesMastic Asphalt, Asphalt Hot Mix + Grouting Asphalt PavementsMM NNNo ratings yet

- Aluminium / Aluminum Bronze UNS C64200 - Copper Alloy: Topics CoveredDocument3 pagesAluminium / Aluminum Bronze UNS C64200 - Copper Alloy: Topics CoveredakramNo ratings yet

- Singer 221 Featherweight Sewing Macine & Case - Care & MainDocument6 pagesSinger 221 Featherweight Sewing Macine & Case - Care & MainGinny RossNo ratings yet

- High Temperature Behaviour of Concrete Produced With Desert SandDocument4 pagesHigh Temperature Behaviour of Concrete Produced With Desert SandDelahan AbatyoughNo ratings yet

- IS 458 - 2021 Precast Concrete Pipe PipeDocument54 pagesIS 458 - 2021 Precast Concrete Pipe PipeManpal SinghNo ratings yet

- LCC-22012-Shipping InstructionsDocument1 pageLCC-22012-Shipping InstructionsTIEBE SERGESNo ratings yet

- Final BOQ - 2018 - BRPL JAN 2024 RatesDocument21 pagesFinal BOQ - 2018 - BRPL JAN 2024 RatesDarshit VyasNo ratings yet

- E-Catalog & Company Profile PT. Total Solusindo Mesin (FEASpack) - 1Document15 pagesE-Catalog & Company Profile PT. Total Solusindo Mesin (FEASpack) - 1vincentkNo ratings yet

- Indian Standard: Specification For Coarse Aggregate For Water Bound Macadam (Document8 pagesIndian Standard: Specification For Coarse Aggregate For Water Bound Macadam (ar TaNo ratings yet

- BS 1449-1-3 - 1991Document10 pagesBS 1449-1-3 - 1991عمر عمرNo ratings yet

- Development of A Device For Brazing Copper Pipes in HVAC InstallationsDocument8 pagesDevelopment of A Device For Brazing Copper Pipes in HVAC InstallationsJournal of Interdisciplinary PerspectivesNo ratings yet

- SBD en Technical Data SheetDocument8 pagesSBD en Technical Data SheetJonathanFallasNo ratings yet

- Welding Module 1-6Document42 pagesWelding Module 1-6Init Bulan Bituin100% (1)

- Hackathon - Technology - Idea Submission Template 2f5e432Document8 pagesHackathon - Technology - Idea Submission Template 2f5e432SnehlataNo ratings yet

- Alat Pengendali Emisi Dan Hasil Kajian CBADocument9 pagesAlat Pengendali Emisi Dan Hasil Kajian CBAAnnisa DzikriNo ratings yet

- Yonks Tubing A Inox 3-8Document1 pageYonks Tubing A Inox 3-8Fercomil S.A.SNo ratings yet

- DefectologyDocument91 pagesDefectologySivasankaran Raju100% (6)

- Catalogo Domus Wet Cleaning en 2020-142Document7 pagesCatalogo Domus Wet Cleaning en 2020-142Đinh Trọng NghĩaNo ratings yet

- RWF Paper 100232Document6 pagesRWF Paper 100232biswajit.baruah1991No ratings yet

ZBS600 Marca ZERMA

ZBS600 Marca ZERMA

Uploaded by

Juan Carlos Ortiz PimientaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZBS600 Marca ZERMA

ZBS600 Marca ZERMA

Uploaded by

Juan Carlos Ortiz PimientaCopyright:

Available Formats

ZBS

Compact shredder

yy Affordable solution for small lumps

yy simple upgrade for existinggranulation system

yy Easy to move and place

yy Tangential infeed avoids the need for a hydraulic pusher

yy Small footprint

yy Low energty consumption

The shredders use concave ground All ZERMA shredders are equipped The ZBS shredders feature an aggres-

square knives, producing high quality with our E-style flat rotor. The knives sive tangential infeed for easy fee-

output. The cutters can be turned af- are fixed in special knife holders fitted ding without the need for a hydraulic

ter a side is worn out. in machined pockets. system. Lumps of up to 400 mm dia-

meter can be processed easily in this

machine series.

Applications General Description

The ZBS shredders have been desig- The ZBS series shredders are single shaft shredders with a tangential infeed to

ned for in house recycling of small eliminate the need for a hydraulic feeding system. The Space saving and ma-

lumps and purges from injection and neuverable design combined with the ‘plug and play ‘ controls make this ma-

blow molding processes. The Typeical chine very flexible and ready to go in no time. Like its bigger brothers in the ZS

input materials are small and medium series they are equipped with outboard bearings, 310 mm diameter flat E rotors

sized cakes such as head waste. The with 600 or 850 mm width driven by an oversized geared motor. Utilizing the

material can be shred to reduce the proven ZERMA knife holder and knife design. The user friendly design makes

volume or processed further in a gra- cleaning and maintenance work a breeze. The low speed of 60 rpm combined

nulator to be re introduced into the with the compact design of the ZBS shredders makes it possible to shred lumps

production process immediately. The at a relatively low noise level. The machines can be fed manually or by conveyor,

machine also can be used to destroy material discharge can be done via conveyor or into a drop box.

sensitive products or to recycle small

batches of low volume products to

avoid contamination of the main pro-

duct line.

The Home of Size Reduction

E

A F

G H

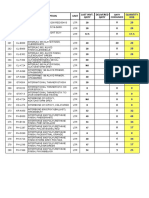

Technical Specifications

Type 600 850

Rotor diameter (mm) 310 310

Rotor width (mm) 560 840

Rotor speed (rpm) 61 61

Drive capacity (kW) 11 18.5

Rotor knives (pcs) 26 40

Stator blades (rows) 1 1

Screen size (mm) > 16 > 16

Effective working area (mm) 490 x 550 490 x 830

Weight approx. (kg) 1400 1500

Technical changes reserved / Ver. 1 - 04/2019 / EN · Pictures in this brochure may also include optional equipment options.

Dimensions

Type 600 850

A (mm) 995 1045

B (mm) 490 490

C (mm) 2255 2255

D (mm) 525 525

E (mm) 1400 2080

F (mm) 550 830

G (mm) 420 470

H (mm) 950 1200

ZERMA Machinery & Recycling Technology (Shanghai) Co., Ltd

5 Xinjie Rd Xinqiao · Township Ind. Park

201612 · Songjiang · Shanghai · China

Phone: +86 21 57645573 · info@zerma.com

You might also like

- CNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WDocument16 pagesCNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WSot DesignNo ratings yet

- Manufacturing Process of Speaker EnclosureDocument8 pagesManufacturing Process of Speaker EnclosureShoaib AhmadNo ratings yet

- 3.4 Golden Joint ProcedureDocument9 pages3.4 Golden Joint ProcedureArieNo ratings yet

- De 20220812162629y1ee0Document4 pagesDe 20220812162629y1ee0Raiyre RolandNo ratings yet

- Manual Quickhitch: Issue 1Document23 pagesManual Quickhitch: Issue 1MMM-MMMNo ratings yet

- Machine Introduction & Technical Data Specification: Vertical Machining Center MS-500 Twin PalletDocument8 pagesMachine Introduction & Technical Data Specification: Vertical Machining Center MS-500 Twin PalletCristian PavanNo ratings yet

- E - Product View-PrDocument16 pagesE - Product View-PrJack ReacherNo ratings yet

- Trituradora Manguera Gse300Document2 pagesTrituradora Manguera Gse300grhismakNo ratings yet

- Features & Benefits: Precision Abrasive Waterjet SystemsDocument2 pagesFeatures & Benefits: Precision Abrasive Waterjet SystemsCojanu CozminNo ratings yet

- SeriesISellSheet1330D PDFDocument2 pagesSeriesISellSheet1330D PDFRicardo Alberto Ortegon BenjumeaNo ratings yet

- RASO Series en v001Document12 pagesRASO Series en v001silviolcNo ratings yet

- Numturn 660-1500Document1 pageNumturn 660-1500Frederik HenderwanzaNo ratings yet

- Astro Jaw: Single Toggle Jaw CrusherDocument4 pagesAstro Jaw: Single Toggle Jaw CrusherDanielSantos100% (1)

- Doosan Stump GrinderDocument2 pagesDoosan Stump GrinderAaravGuptaNo ratings yet

- 11 Riveting MachinesDocument4 pages11 Riveting MachinesTecnicas Reunidas de AutomociónNo ratings yet

- TS Spir Class-EnDocument2 pagesTS Spir Class-EnpdiconpNo ratings yet

- LT 12 15 - EnglDocument2 pagesLT 12 15 - EnglEmilian PopaNo ratings yet

- C350 Ipower: Standard Equipment ApplicationsDocument1 pageC350 Ipower: Standard Equipment ApplicationsDein MasterNo ratings yet

- Rittal Busbar Machining Made Easy 5 4635Document12 pagesRittal Busbar Machining Made Easy 5 4635Mohammad Badii MosliNo ratings yet

- Features & Benefits: Precision Abrasive Waterjet SystemsDocument2 pagesFeatures & Benefits: Precision Abrasive Waterjet SystemsCojanu CozminNo ratings yet

- Specs Cat Wheel SawsDocument4 pagesSpecs Cat Wheel SawsEmmanouEl BirikakisNo ratings yet

- SunShine Technology - Presentation - 02082022Document41 pagesSunShine Technology - Presentation - 02082022shashwat.dhaseNo ratings yet

- Manual LathesDocument26 pagesManual LathesBINNo ratings yet

- 2050 Panther LatheDocument2 pages2050 Panther Lathepramod_tryNo ratings yet

- KMT CatalogueDocument13 pagesKMT Cataloguepriyanka.vijayNo ratings yet

- Woodturning LathesDocument24 pagesWoodturning LatheslucibrandusNo ratings yet

- Blades - AEHQ5851-01 08-08Document4 pagesBlades - AEHQ5851-01 08-08Carlo PoliNo ratings yet

- Rack Milling Machine RMDocument4 pagesRack Milling Machine RMAries N. RamadhanyNo ratings yet

- DiscSpreader ENDocument14 pagesDiscSpreader ENRavi MistryNo ratings yet

- Hobbing Machines LC 80-180Document8 pagesHobbing Machines LC 80-180Abdisalaam mohamudNo ratings yet

- MB46 T-SlotDocument2 pagesMB46 T-Slotdarkarmy100No ratings yet

- Bridgeport Series I - BrochureDocument2 pagesBridgeport Series I - BrochureVVNo ratings yet

- SJ 410 460 530 - EnglDocument2 pagesSJ 410 460 530 - EnglEmilian PopaNo ratings yet

- NEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Document12 pagesNEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Marlon GilerNo ratings yet

- Petrography EXPDocument16 pagesPetrography EXPYounes KoutayaNo ratings yet

- Tecnotest 5.2 Coring and Drilling PDFDocument8 pagesTecnotest 5.2 Coring and Drilling PDFRyan A.Y.No ratings yet

- Pt0uk Nlx6000 PDF DataDocument48 pagesPt0uk Nlx6000 PDF DataAlexandroNo ratings yet

- DW Series 2015Document20 pagesDW Series 2015kris CadwellNo ratings yet

- 07 - Pump Split Case Pump - enDocument6 pages07 - Pump Split Case Pump - enRizaldi YahyaNo ratings yet

- Samurai 120H BrochureDocument17 pagesSamurai 120H BrochurehoriaNo ratings yet

- Masonry SawsDocument1 pageMasonry Sawspapasote.unoNo ratings yet

- PSA Series EngilshDocument66 pagesPSA Series EngilshTuấn NguyễnNo ratings yet

- Crushing Screening BrochureDocument24 pagesCrushing Screening Brochuredebasish bhowmickNo ratings yet

- ABS Submersible Mixer RW 200, 50HzDocument2 pagesABS Submersible Mixer RW 200, 50Hzalisya.blwsNo ratings yet

- Water Jet PortfoliaDocument7 pagesWater Jet PortfoliaSagar KumarNo ratings yet

- Biko 12 Pag. GBDocument12 pagesBiko 12 Pag. GBMUFİTNo ratings yet

- Lva1 App6891Document53 pagesLva1 App6891Allyth AlqhtaniNo ratings yet

- TF ENGcatalogo2016 TRS 2Document8 pagesTF ENGcatalogo2016 TRS 2James MckerrNo ratings yet

- Router Family BrochureDocument15 pagesRouter Family BrochurealexNo ratings yet

- Minimax Gen. - Rev01 - Jan18 - IngDocument136 pagesMinimax Gen. - Rev01 - Jan18 - IngWagner MenezesNo ratings yet

- Washing and Classifying Brochure EnglishDocument24 pagesWashing and Classifying Brochure EnglishMohammed Alshami GeologistNo ratings yet

- Okamoto Brochure 2Document38 pagesOkamoto Brochure 2Legi YangNo ratings yet

- SMS ColdPilgerMillsDocument8 pagesSMS ColdPilgerMillsSUNILNo ratings yet

- Emery Roller MachineDocument3 pagesEmery Roller Machineinstallationsap1No ratings yet

- Machine Tool LINE-UP (Eng)Document40 pagesMachine Tool LINE-UP (Eng)Mohamed Essam MohamedNo ratings yet

- Auger Compactor - ENDocument4 pagesAuger Compactor - ENEugene Jin LeowNo ratings yet

- PNC 10catalogueDocument2 pagesPNC 10catalogueParlin PasbarNo ratings yet

- ☆ SJ-inclined-screens-technical-specification-山特维克Document8 pages☆ SJ-inclined-screens-technical-specification-山特维克AShuang qinNo ratings yet

- Petrography CatalogueDocument16 pagesPetrography CatalogueMR DaniNo ratings yet

- VTL SeriesDocument10 pagesVTL Seriesxojoga9602No ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- PAINTS INVENTORY Apr.14 2016Document1 pagePAINTS INVENTORY Apr.14 2016Pavel ViktorNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- 1 s2.0 S1044580322004053 MainDocument16 pages1 s2.0 S1044580322004053 MainSree SabariNo ratings yet

- Process Design For The Recycling of Tetra Pak CompDocument5 pagesProcess Design For The Recycling of Tetra Pak CompMostafa AlakhliNo ratings yet

- Cost Accoounting ReviewerDocument19 pagesCost Accoounting ReviewerUNKNOWNNNo ratings yet

- Ground Parallels: To Provide More Convenient Processing For Milling ViseDocument4 pagesGround Parallels: To Provide More Convenient Processing For Milling ViseVinod KumarNo ratings yet

- Automotive Steering-KnuckleDocument4 pagesAutomotive Steering-Knucklefileuse.fNo ratings yet

- Development of Large Diameter V-Belt Pulley Using Coreless Drag and Wire-Reinforced CheekDocument9 pagesDevelopment of Large Diameter V-Belt Pulley Using Coreless Drag and Wire-Reinforced CheekAna MayumiNo ratings yet

- NumberDocument275 pagesNumberHarshana RathnayakeNo ratings yet

- Mastic Asphalt, Asphalt Hot Mix + Grouting Asphalt PavementsDocument44 pagesMastic Asphalt, Asphalt Hot Mix + Grouting Asphalt PavementsMM NNNo ratings yet

- Aluminium / Aluminum Bronze UNS C64200 - Copper Alloy: Topics CoveredDocument3 pagesAluminium / Aluminum Bronze UNS C64200 - Copper Alloy: Topics CoveredakramNo ratings yet

- Singer 221 Featherweight Sewing Macine & Case - Care & MainDocument6 pagesSinger 221 Featherweight Sewing Macine & Case - Care & MainGinny RossNo ratings yet

- High Temperature Behaviour of Concrete Produced With Desert SandDocument4 pagesHigh Temperature Behaviour of Concrete Produced With Desert SandDelahan AbatyoughNo ratings yet

- IS 458 - 2021 Precast Concrete Pipe PipeDocument54 pagesIS 458 - 2021 Precast Concrete Pipe PipeManpal SinghNo ratings yet

- LCC-22012-Shipping InstructionsDocument1 pageLCC-22012-Shipping InstructionsTIEBE SERGESNo ratings yet

- Final BOQ - 2018 - BRPL JAN 2024 RatesDocument21 pagesFinal BOQ - 2018 - BRPL JAN 2024 RatesDarshit VyasNo ratings yet

- E-Catalog & Company Profile PT. Total Solusindo Mesin (FEASpack) - 1Document15 pagesE-Catalog & Company Profile PT. Total Solusindo Mesin (FEASpack) - 1vincentkNo ratings yet

- Indian Standard: Specification For Coarse Aggregate For Water Bound Macadam (Document8 pagesIndian Standard: Specification For Coarse Aggregate For Water Bound Macadam (ar TaNo ratings yet

- BS 1449-1-3 - 1991Document10 pagesBS 1449-1-3 - 1991عمر عمرNo ratings yet

- Development of A Device For Brazing Copper Pipes in HVAC InstallationsDocument8 pagesDevelopment of A Device For Brazing Copper Pipes in HVAC InstallationsJournal of Interdisciplinary PerspectivesNo ratings yet

- SBD en Technical Data SheetDocument8 pagesSBD en Technical Data SheetJonathanFallasNo ratings yet

- Welding Module 1-6Document42 pagesWelding Module 1-6Init Bulan Bituin100% (1)

- Hackathon - Technology - Idea Submission Template 2f5e432Document8 pagesHackathon - Technology - Idea Submission Template 2f5e432SnehlataNo ratings yet

- Alat Pengendali Emisi Dan Hasil Kajian CBADocument9 pagesAlat Pengendali Emisi Dan Hasil Kajian CBAAnnisa DzikriNo ratings yet

- Yonks Tubing A Inox 3-8Document1 pageYonks Tubing A Inox 3-8Fercomil S.A.SNo ratings yet

- DefectologyDocument91 pagesDefectologySivasankaran Raju100% (6)

- Catalogo Domus Wet Cleaning en 2020-142Document7 pagesCatalogo Domus Wet Cleaning en 2020-142Đinh Trọng NghĩaNo ratings yet

- RWF Paper 100232Document6 pagesRWF Paper 100232biswajit.baruah1991No ratings yet