Professional Documents

Culture Documents

Glazing Risk Assessment

Glazing Risk Assessment

Uploaded by

Karen OlivierOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glazing Risk Assessment

Glazing Risk Assessment

Uploaded by

Karen OlivierCopyright:

Available Formats

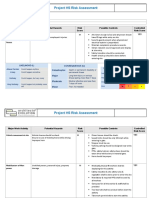

Risk Assessment

Project: Activity: Sheet: 1 of 5 Completed By: Date:

Glazing Sept/ Oct

Project Name People affected / at risk of being harmed: ? Our operatives and other trades

No Hazards Possible Affects / Harm Pre Control Risk Rating Required Controls Post Control Risk Rating

High Medium Low High Medium Low

Injury caused to other An exclusion zone to be formed around the works area

1 Third party trades and or members YES prior to any works commencing. Signage warning of the YES

interface of the public exclusion zone and warning of the works occurring is to be

posted on the barriers. Should any authorised personnel

breach the exclusion zone, works are to cease immediately

until the persons are removed.

Injury caused by poor Whenever possible, manual handling is to be avoided.

2 manual handling When this is not possible, mechanical aids are provided if

techniques when YES appropriate and when it is not possible to use mechanical YES

Manual moving tools, equipment aids, employees are provided with information on safe

handling or manoeuvring trolleys manual handling techniques.

or manually. Tool boxes have wheels on them to reduce the level of

effort require to move them.

Tool box talks on manual handling are to be regularly

completed to reaffirm the message.

Slips trips and Injury caused by slips, A take 5 is completed at the start of each work shift and at

3 falls trips and falls due to YES the start of each section of work. Good standards of

poor housekeeping. housekeeping are maintained at all times with tools and

equipment and other trip hazards being kept clear of traffic

routes. Where trailing cables have to be routed across a YES

traffic route, they are suspended using skyhooks or are

protected by a cable cover or hazard tape.

Waste materials are placed in the appropriate site skip.

Standards of house keeping are checked during the weekly

hazard spotting checks carried out by the supervisor and

the monthly site inspections carried out by the project

manager. Records of the checks are to be kept in the safety

file.

SIGN THE BACK IF REQUIRED

Risk Assessment

Working at Injury caused by falling Each task will be subject to an assessment to ascertain if YES

4 height YES work at height can be avoided, and if not, the necessary

collect protection and personal protection measures to

reduce the risk of a fall, and minimise the distance and

consequence should a fall occur. Any potential fragile

surfaces to be identified and pointed out to the main

contractor and eliminated prior to carrying out the task. Or

if not eliminated MC to put out clearly marked WARNING

signs. Supervisor to monitor weather forecast / conditions

and cease work should weather conditions create a risk to

the task involved. Make sure there are NO exposed edges,

missing handrails or area’s un guarded or inadequate

guarding. Any of these MUST be reported back to the main

contractor NOT left. Exclusion zones below our working

area to be provided by the main contractor to prevent other

trades or members of the public walking or accessing

below. NO ONE to be working below. No loan working.

Loss of Suction and

Power sucker power YES Only trained personnel to operate. Ensure the plant has up YES

5 to date test certificates, ensure pads are clean and free

from splits or debris and that the battery is charged enough

to carry out the task at hand. When lifting the first piece of

glass let it hang slightly above the floor and above timber

blocks, leave it for 5 minutes as a test.

Only qualified and experienced personnel to operate.

6 Glass boy Falling or tipping YES Ensure all wheels are in good order and complete, make YES

Lifting device sure adequate counter weights are used, all areas must be

clear with level surfaces.

Collapse of structure Ensure scaffold is based out and tied correctly, a

7 Use of access Falls of persons, YES competent person to inspect every 7 days and records

Scaffold materials & Tools maintained, tags and certificate available for inspection,

tags visible. YES

1, Users of scaffold must carry out safety checks prior to

accessing, checking, handrails, intermediate toe boards

must be in position and secure. Ladders must be secured

and positioned correctly, The ladder must be the correct

way up and have sufficient rungs on for handrail.

Correct PPE must be worn.

Eye injury Ensure tools are in good working use and in good

8 Hand Tools Bodily harm YES condition, fit for purpose. Wear appropriate task specific YES

Improper use PPE including gloves and goggles, Steel toe capped safety

SIGN THE BACK IF REQUIRED

Risk Assessment

boots. Adequate training for the use of hand tools, ongoing

visual checks and inspections.

Falling over , trapping Strongly recommended that safety harness should be

9 MEWPS causing crushing. YES worn. ONLY qualified personal to operate the machine. YES

Ensure the working area is clear and flat free from

obstacles on the ground and up high, do NOT move the

machine while the basket is extended.

Before lifting and carrying glass always check the YES

Handling, Cuts and crushing YES surrounding area for trip, hazards and obstacles.

10 storage of glass When lifting glass only experienced persons who are used

and breakage. to the handling of glass, always wear relevant task specific

PPE.

The storage area: Always be in a pre designated and safe

area provided by the main contractor, clear of all debris

and ease of access.

Storing of glass. ALWAYS check that the grounds are

suitable to take weight, solid walls and floors are ideal, if

raised flooring there may be a need to spread, always

make sure the area is not is a hazardous area where others

can trip, fall or come into contact with exposed edges. glass

must be placed on timber or equally suitable blocks these

ideally should be place on the floor, 2 No. one to be place at

approximately 75mm in from each end, the glass is laid

back against the wall at an angle of approximately 75

degree’s.

Glass will need to be bound with suitable straps/webbing, to

prevent the glass falling.

In the event of a breakage, the glass must be cleared up

using brooms and shovels and put into plastic bins or

rubble bags. Being toughened glass any panel which breaks

will break in a safe manner for example small fragments as

listed out in BS6206 on this particular ob the glass is

toughened laminated and will hold together safely and can

be hand carried out whole.

SIGN THE BACK IF REQUIRED

Risk Assessment

Collapse of structure YES Only qualified personnel holding current PASMA

Mobile towers Falls of persons, certification to erect and dismantle.

materials & Tools Before erecting .

Check all components are in good condition

Check wheels for effective rotation.

Check breaks and locking devices working correctly. YES

Check floor finish and bearing capacity.

Before use

Ensure tower is square & vertical, wheels must be locked.

Outriggers are secure and set correctly.

Ensure fully boarded , if the tower is over 2000 including

toe boards.

Erected tower.

Never climb up the outside of a tower use the internal

ladder.

Follow manufactures recommendation, width to height

ratio.

Hoist of materials to come through the inside.

Tie the tower to a permanent structure where possible.

Don’t move the tower if persons or tools are on the

platform.

SIGN THE BACK IF REQUIRED

Risk Assessment

Aluminium Cutting of limbs, YES Always trained experience personnel to use the equipment,

cutting Chop blades breaking with visual inspection of all cables, safety guards and blades YES

saw. the risk deep cute prior to use on every occasion. Always use on a adequate

and severe eye injury. work surface flat, being securely fixed down, always ensure

the safety guards are in place and used correctly.

Up to date PAT test stickers.

Working with Risk of fire and burns YES Our heat guns are electric and do not have a naked

heat gun. to skin. flame, no sparks and no hot swarf, we use these to YES

Hot works. de-stabilise UV adhesive on glass to glass joints in

display cabinets, the heat from these guns will NOT

cause the glass to ignite. Always move any flammable

materials clear away from the working area. A

minimum of two operatives, one to carry out the task

and one to act as look out.

In the event of a fire.

Raise the alarm and then call the fire brigade.

Close doors and windows to prevent the spread of

fire.

Evacuate the building or area you are working in.

Fight the fire with extinguishers provided but don’t

put yourself at risk. Don't use water to put out

electrical fires.

SIGN THE BACK IF REQUIRED

Risk Assessment

Risk Assessments must be reviewed regularly.

Signed ...................................................................... .............. Date...................................................................

Signed ...................................................................... .............. Date...................................................................

SIGN THE BACK IF REQUIRED

You might also like

- IB Chemistry IA: EnergeticsDocument10 pagesIB Chemistry IA: EnergeticsMomina Amjad88% (56)

- Concreting SWMS - 2 PDFDocument10 pagesConcreting SWMS - 2 PDFMD AbdullahNo ratings yet

- Risk Assessment For Wall Panels InstallationDocument5 pagesRisk Assessment For Wall Panels InstallationChristos Loutrakis100% (1)

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- Alfriston School, Beaconsfield, BuckinghamshireDocument8 pagesAlfriston School, Beaconsfield, BuckinghamshireJayant NegiNo ratings yet

- 27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapDocument5 pages27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapprabuNo ratings yet

- RA - Plumbing Works Rev. BDocument8 pagesRA - Plumbing Works Rev. BResearcher100% (1)

- Risk - Assessment - TelehandlerDocument11 pagesRisk - Assessment - TelehandlerCiaraNo ratings yet

- F KG HSE RA Steel Doors Installation 2Document3 pagesF KG HSE RA Steel Doors Installation 2Alvin Badz50% (2)

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 pagesRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanNo ratings yet

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius Dsouza100% (1)

- Valves Training ManualDocument240 pagesValves Training Manualchakkudon75% (8)

- Risk Assessment of Barricading WorkDocument3 pagesRisk Assessment of Barricading WorkGyanendra SrivastavaNo ratings yet

- Risk Assessment For DemolitionDocument10 pagesRisk Assessment For Demolitionadeniyi abiolaNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- Hiradc SF Merge - TilingDocument3 pagesHiradc SF Merge - TilingUDAWSA2 WKENo ratings yet

- Children & Young People's Services RISK ASSESSMENTDocument2 pagesChildren & Young People's Services RISK ASSESSMENThaziq ziqNo ratings yet

- Block Work (Unit Masonary) RISK ASSESSMENTDocument8 pagesBlock Work (Unit Masonary) RISK ASSESSMENTVimal ViswanathNo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Exacavation Job Safety AnalysisDocument1 pageExacavation Job Safety AnalysisNeelakantamNo ratings yet

- Ra 02 - Anti-Termite TreatmentDocument4 pagesRa 02 - Anti-Termite TreatmentHafiz M WaqasNo ratings yet

- JHA - Overhead Power LinesDocument2 pagesJHA - Overhead Power Linesrenee0% (1)

- Risk AssessmentDocument5 pagesRisk AssessmentIshan DankharaNo ratings yet

- Painting WorkDocument8 pagesPainting WorkNisanth Thulasidas100% (1)

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- PCC & ConcDocument4 pagesPCC & Concprasanna okNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (2)

- RA - Risk Assessment - Surveying and Pegging - 2021Document4 pagesRA - Risk Assessment - Surveying and Pegging - 2021Asakundwi Mukhwa100% (1)

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- Risk Assement - (Paint Work)Document6 pagesRisk Assement - (Paint Work)Zohaib TahirNo ratings yet

- (SWMS - 04) Carpentry Work Temporary & PermanentDocument6 pages(SWMS - 04) Carpentry Work Temporary & PermanentPRATEEK SINGHNo ratings yet

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDocument4 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- Project HS Risk AssessmentDocument8 pagesProject HS Risk AssessmentParasNo ratings yet

- 025 - TRA - Grouting Works - Rev 1Document3 pages025 - TRA - Grouting Works - Rev 1Rachel Flores100% (2)

- Thohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFDocument17 pagesThohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFbubele pamlaNo ratings yet

- SWMS Power FloatDocument10 pagesSWMS Power FloatSam LimNo ratings yet

- Risk Assessment GRP Tank InstallationDocument19 pagesRisk Assessment GRP Tank Installationanwer.ahmadNo ratings yet

- Risk Assessment - Plaster WorksDocument3 pagesRisk Assessment - Plaster WorksMahdi DwaikatNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Installation & Testing of Underground Drainage PipingDocument7 pagesInstallation & Testing of Underground Drainage PipingamalNo ratings yet

- Method Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00Document6 pagesMethod Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00bryanNo ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- Pile Cutting / Hacking (Sub-Structure Work)Document2 pagesPile Cutting / Hacking (Sub-Structure Work)Rahmat HariNo ratings yet

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildan100% (1)

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfNo ratings yet

- BMR - Safety PPT Apr-2023Document17 pagesBMR - Safety PPT Apr-2023shamshad ahamedNo ratings yet

- ISLA JHA Removal of BarricadeDocument3 pagesISLA JHA Removal of Barricadeaasafety06No ratings yet

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga Mabhena100% (1)

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationD FiransyahNo ratings yet

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- ENGY-EnG3-MOS-20210603-002 - Method of Statement For Concrete Pavement WorksDocument21 pagesENGY-EnG3-MOS-20210603-002 - Method of Statement For Concrete Pavement WorksTemur LomidzeNo ratings yet

- SWMS - HVAC ShiftingDocument6 pagesSWMS - HVAC ShiftingParas100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document3 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Persons at Risk (Groups) Risk Assessor Appointment Tel. No. Description of Task or ActivityDocument4 pagesPersons at Risk (Groups) Risk Assessor Appointment Tel. No. Description of Task or ActivityAyu Wanda SaraswatiNo ratings yet

- Jannatul Ferdosh: Career ObjectivesDocument2 pagesJannatul Ferdosh: Career ObjectivesNishaNo ratings yet

- CC505 - 2 Slope Deflection Method For BeamDocument34 pagesCC505 - 2 Slope Deflection Method For BeamIzzSyieNo ratings yet

- Gate ValveDocument27 pagesGate ValveYogesh Kumar Bhatnagar0% (1)

- GD&TDocument138 pagesGD&Tأيمن أحمدNo ratings yet

- RT Catalog 2011 - Air Operated Hand ToolsDocument12 pagesRT Catalog 2011 - Air Operated Hand ToolsN.PalaniappanNo ratings yet

- Metaland CatalogueDocument95 pagesMetaland CatalogueTimothy LovettNo ratings yet

- Stat 565: Some Basic Time Series ModelsDocument34 pagesStat 565: Some Basic Time Series Modelsmasudul9islamNo ratings yet

- DC DC Book of KnowledgeDocument287 pagesDC DC Book of KnowledgeJose Simon Bolivar MoranNo ratings yet

- GD50 Slickline Rev 29 May 18Document1 pageGD50 Slickline Rev 29 May 18hoss mosafaNo ratings yet

- G O BaldocerDocument93 pagesG O Baldocerruba herbawiNo ratings yet

- K StageDocument8 pagesK Stagedeco lombNo ratings yet

- Timetable DGD (Fise)Document3 pagesTimetable DGD (Fise)Iqmal KhoirussolehNo ratings yet

- IARPA - Catalyst Entity Extraction & Disambiguation StudyDocument122 pagesIARPA - Catalyst Entity Extraction & Disambiguation StudyImpello_TyrannisNo ratings yet

- Datasheet DiacDocument4 pagesDatasheet DiacOrlandoTobonNo ratings yet

- ANSWER Rule78 SampleExamDocument19 pagesANSWER Rule78 SampleExamrayzlazoNo ratings yet

- Lec-1.pdf Thermodynamics Application - Engineering Thermodynamics-01Document15 pagesLec-1.pdf Thermodynamics Application - Engineering Thermodynamics-01Saurabh GuptaNo ratings yet

- XenoyDocument2 pagesXenoyJuanjo HornoNo ratings yet

- Kleemann News ISSUE #01 (English Version)Document10 pagesKleemann News ISSUE #01 (English Version)Kleemmann Hellas SANo ratings yet

- 8096CRSN3 25 - Factsheet e PDFDocument2 pages8096CRSN3 25 - Factsheet e PDFLuis MirandaNo ratings yet

- 009 (1) .BC415 Communication Interfaces in ABAPDocument228 pages009 (1) .BC415 Communication Interfaces in ABAPChandramouli BalachandranNo ratings yet

- ASME BPVC 2010 - VIII - Division 1 - Rules For Construction of Pressure Vessels - 2011a AddendaDocument860 pagesASME BPVC 2010 - VIII - Division 1 - Rules For Construction of Pressure Vessels - 2011a Addendafabiorenzi86% (7)

- MainframeDocument4 pagesMainframeramanadhampNo ratings yet

- Managing Construction Using UavDocument22 pagesManaging Construction Using Uavsree sreeNo ratings yet

- 2N2369Document6 pages2N2369سعيد الحدادNo ratings yet

- Algorithms in PythonDocument218 pagesAlgorithms in Pythonsarvesh_mishra100% (8)

- Application of Remote Sensing and GIS Analysis in Groundwater Potential Estimation in West Liaoning Province, ChinaDocument3 pagesApplication of Remote Sensing and GIS Analysis in Groundwater Potential Estimation in West Liaoning Province, ChinaMohammed El-khoudryNo ratings yet

- Acropolis Institute of Technology & Research, IndoreDocument19 pagesAcropolis Institute of Technology & Research, IndoreRrr320No ratings yet