Professional Documents

Culture Documents

Stps 340

Stps 340

Uploaded by

Mariusz KaźmierczakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stps 340

Stps 340

Uploaded by

Mariusz KaźmierczakCopyright:

Available Formats

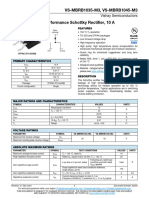

STPS340

Datasheet

40 V, 3 A power Schottky rectifier

Features

• Very small conduction losses

• Negligible switching losses

• Low forward voltage drop

• Low thermal resistance

• Extremely fast switching

• Surface mount package

• Avalanche rated

• ECOPACK2 component

Applications

• Telecom power supply

• Set-top box power supply

• TV power supply

• Battery charger

Description

Single chip Schottky rectifier suited for switch mode power supplies and high

frequency DC to DC converters.

Packaged in SMA Flat Notch, SMB, SMB Flat, SMC and DPAK, the STPS340 is ideal

Product status for surface mounting and used in low voltage, high frequency inverters, free wheeling

and polarity protection applications.

STPS340

Product summary

Symbol Value

IF(AV) 3A

VRRM 40 V

T j(max.) 150 °C

VF(typ.) 0.52 V

DS0792 - Rev 13 - October 2019 www.st.com

For further information contact your local STMicroelectronics sales office.

STPS340

Characteristics

1 Characteristics

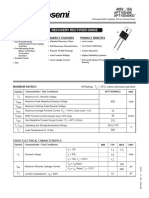

Table 1. Absolute ratings (limiting values at 25 °C, unless otherwise specified)

Symbol Parameter Value Unit

VRRM Repetitive peak reverse voltage 40 V

IF(RMS) Forward rms current DPAK 6 A

SMA Flat Notch TL = 105 °C

SMB TL = 95 °C

IF(AV) Average forward current, δ = 0.5, square wave SMB Flat TL = 115 °C 3 A

SMC TL = 105 °C

DPAK TC = 135°C

SMA Flat Notch 105 A

IFSM Surge non repetitive forward current tp = 10 ms sinusoidal

All others 75 A

PARM Repetitive peak avalanche power tp = 10 µs, Tj = 125 °C 90 W

Tstg Storage temperature range -65 to +150 °C

Tj Maximum operating junction temperature(1) +150 °C

1. (dPtot/dTj) < (1/Rth(j-a)) condition to avoid thermal runaway for a diode on its own heatsink.

Table 2. Thermal resistance parameter

Symbol Parameter Max. value Unit

SMA Flat Notch 20

SMB 25

Rth(j-l) Junction to lead

SMB Flat 15 °C/W

SMC 20

Rth(j-c) Junction to case DPAK 5.5

For more information, please refer to the following application note :

• AN5088 : Rectifiers thermal management, handling and mounting recommendations

Table 3. Static electrical characteristics

Symbol Parameter Test conditions Min. Typ. Max. Unit

Tj = 25 °C - 20 µA

IR(1) Reverse leakage current VR = VRRM

Tj = 125 °C - 2 10 mA

Tj = 25 °C - 0.63

IF = 3 A

Tj = 125 °C - 0.52 0.57

VF(1) Forward voltage drop V

Tj = 25 °C - 0.84

IF = 6 A

Tj = 125 °C - 0.63 0.72

1. Pulse test: tp = 380 µs, δ < 2%

DS0792 - Rev 13 page 2/19

STPS340

Characteristics

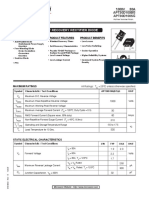

To evaluate the conduction losses, use the following equation:

P = 0.42 x IF(AV) + 0.050 x IF2(RMS)

For more information, please refer to the following application notes related to the power losses :

• AN604: Calculation of conduction losses in a power rectifier

• AN4021: Calculation of reverse losses on a power diode

DS0792 - Rev 13 page 3/19

STPS340

Characteristics (curves)

1.1 Characteristics (curves)

Figure 1. Average forward power dissipation versus Figure 2. Average forward current versus ambient

average forward current temperature (δ = 0.5) (SMB, SMC, DPAK)

PF(AV) (W) IF(AV)( A)

2.5 3.5 DPAK

δ = 0.1 δ = 0.2 δ = 0.5 Rth(j-a) = Rth(j-c)

δ = 0.05

3.0

2.0 SMB

δ=1 2.5 Rth(j-a) = Rth(j-l)

1.5

SMC

2.0 Rth(j-a) = Rth(j-l)

1.0

1.5

0.5 T 1.0 Rth(j-a) = 65 °C/W

T

δ =tp/T tp 0.5

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 δ = t P/T tP Tamb(°C)

0.0

IF(AV)(A) 0 25 50 75 100 125 150

Figure 3. Average forward current versus ambient Figure 4. Normalized avalanche power derating versus

temperature (δ = 0.5, SMB Flat) pulse duration (Tj = 125 °C)

PARM (t p )

IF(AV) (A) PARM (10 µs)

3.5 1

Rth(j-a) = Rth(j-l)

3.0

2.5

0.1

2.0

1.5

1.0 0.01

T

0.5

0.0

δ = t P/T tP t p(µs)

0.001

0 25 50 75 100 125 150

Tamb(°C) 1 10 100 1000

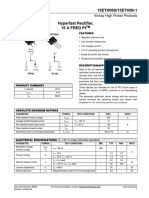

Figure 5. Relative variation of thermal impedance junction Figure 6. Relative variation of thermal impedance junction

to ambient versus pulse duration (SMB) to lead versus pulse duration (SMB flat)

Zth(j-a)/Rth(j-a) Zth(j-l) / Rth(j-l)

1.0 1.0

0.9 0.9

0.8 0.8

0.7 0.7

0.6 0.6

0.5 0.5

0.4 0.4

0.3 0.3

0.2 0.2

Single pulse Single pulse

0.1 0.1

0.0 0.0

1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03 1.E-04 1.E-03 1.E-02 1.E-01 1.E+00 1.E+01

tp(s) tp(s)

DS0792 - Rev 13 page 4/19

STPS340

Characteristics (curves)

Figure 7. Relative variation of thermal impedance junction Figure 8. Relative variation of thermal impedance junction

to ambient versus pulse duration (SMC) to case versus pulse duration (DPAK)

Zth(j-a)/ Rth(j-a) Zth(j-c)/Rth(j-c)

1.0 1.0

0.9 0.9

0.8 0.8

0.7 0.7

0.6 0.6

0.5 0.5

0.4 0.4

0.3 0.3 Single pulse

0.2 0.2

Single pulse

0.1 0.1

0.0

0.0

1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03 1.E-03 1.E-02 1.E-01 1.E+00

tp(s) tp(s)

Figure 9. Reverse leakage current versus reverse voltage Figure 10. Junction capacitance versus reverse voltage

applied (typical values) applied (typical values)

IR(mA) C(pF)

1.E+01 1000

Tj=150°C F=1MHz

VOSC= 30mVR MS

T=j 25°C

Tj=125°C

1.E+00

Tj=100°C

1.E-01 Tj=75°C

100

1.E-02

Tj=25°C

1.E-03

10

1.E-04

1 10 100

0 5 10 15 20 25 30 35 40

VR(V) VR(V)

Figure 12. Thermal resistance junction to ambient versus

Figure 11. Forward voltage drop versus forward current copper surface under each lead (SMA Flat Notch)

IF(A) Rth(j-a) (°C/W)

10.00

200

Epoxy printed circuit board FR4, copper thickness: 35 µm

SMA Flat Notch

Tj=125°C

(Maximum values)

1.00 150

Tj=125°C

(Typical values) 100

0.10 Tj=25°C

(Maximum values)

50

S(Cu)(cm²)

0.01

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 0

VF(V) 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

DS0792 - Rev 13 page 5/19

STPS340

Characteristics (curves)

Figure 13. Thermal resistance junction to ambient versus Figure 14. Thermal resistance junction to ambient versus

copper surface under each lead (SMB) copper surface under each lead (SMB flat)

Rth(j-a) (°C/W)

Rth(j-a) (°C/W)

200 200

Epoxy printed circuit board FR4, eCu = 35 µm SMB flat

Epoxy p ri nted ci rcui t board FR4, coppe r t hi ckness: 35 µm SMB

150 150

100 100

50 50

S(Cu)(cm²) SCu (cm²)

0 0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Figure 16. Thermal resistance junction to ambient versus

Figure 15. Thermal resistance junction to ambient versus copper surface under tab (DPAK)

copper surface under each lead (SMC)

Rth(j-a) (°C/W) Rth(j-a) (°C/W)

160 100

Epoxy p ri nted ci rcui t board FR4, coppe r t hi ckness: 35 µm DPAK

140 SMC 90 Epoxy printed circuit board, copper thickness: 35 µm

80

120

70

100

60

80 50

60 40

30

40

20

20 10

SCu (cm²) SCu (cm²)

0 0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 0 5 10 15 20 25 30 35 40

DS0792 - Rev 13 page 6/19

STPS340

Package information

2 Package information

In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK packages,

depending on their level of environmental compliance. ECOPACK specifications, grade definitions and product

status are available at: www.st.com. ECOPACK is an ST trademark.

2.1 SMA Flat Notch package information

• Epoxy meets UL94, V0

• Cooling method: by conduction (C)

• Band indicates cathode

Figure 17. SMA Flat Notch package outline

DS0792 - Rev 13 page 7/19

STPS340

SMA Flat Notch package information

Table 4. SMA Flat Notch package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Typ. Max. Min. Typ. Max.

A1 0.90 1.10 0.035 0.044

A1 0.05 0.002

b 1.25 1.65 0.049 0.065

C 0.15 0.40 0.005 0.016

D 2.25 2.90 0.088 0.115

E 5.00 5.35 0.196 0.211

E1 3.95 4.60 0.155 0.182

G 2.00 0.079

G1 0.85 0.033

L 0.75 1.20 0.029

L1 0.45 0.018

L2 0.45 0.018

L3 0.05 0.002

V 8° 8°

V1 8° 8°

Figure 18. SMA Flat Notch recommended footprint in mm (inches)

1.20 3.12 1.20

(0.047) (0.123) (0.047)

1.52

(0.060)

5.52

(0.217)

DS0792 - Rev 13 page 8/19

STPS340

SMB package information

2.2 SMB package information

• Epoxy meets UL94, V0

• Lead-free package

Figure 19. SMB package outline

E1

A1

C A2

L b

Table 5. SMB package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Max. Min. Max.

A1 1.90 2.45 0.074 0.097

A2 0.05 0.20 0.001 0.008

b 1.95 2.20 0.076 0.087

c 0.15 0.40 0.005 0.016

D 3.30 3.95 0.129 0.156

E 5.10 5.60 0.200 0.221

E1 4.05 4.60 0.159 0.182

L 0.75 1.50 0.029 0.060

DS0792 - Rev 13 page 9/19

STPS340

SMB package information

Figure 20. SMB recommended footprint

1.62 2.60 1.62

(0.064) (0.102) (0.064)

2.18

(0.086)

5.84

(0.230)

DS0792 - Rev 13 page 10/19

STPS340

SMB Flat package information

2.3 SMB Flat package information

• Epoxy meets UL94, V0

• Lead-free package

Figure 21. SMB Flat package outline

A

c

D

L 2x

L1 2 x

E E1

L2 2 x

Table 6. SMB Flat mechanical data

Dimensions

Ref. Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 0.90 1.10 0.035 0.044

b 1.95 2.20 0.076 0.087

c 0.15 0.40 0.005 0.016

D 3.30 3.95 0.129 0.156

E 5.10 5.60 0.200 0.221

E1 4.05 4.60 0.159 0.182

L 0.75 1.50 0.029 0.060

L1 0.40 0.016

L2 0.60 0.024

DS0792 - Rev 13 page 11/19

STPS340

SMB Flat package information

Figure 22. Footprint recommendations, dimensions in mm (inches)

1.20 3.44 1.20

(0.047) (0.136) (0.047)

2.07

(0.082)

5.84

(0.230)

millimeters

(inches)

DS0792 - Rev 13 page 12/19

STPS340

SMC package information

2.4 SMC package information

• Epoxy meets UL94, V0

Figure 23. SMC package outline

E1

A1

A2

E2

Table 7. SMC package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Max. Min. Max.

A1 1.90 2.45 0.0748 0.0965

A2 0.05 0.20 0.0020 0.0079

b 2.90 3.20 0.1142 0.1260

c 0.15 0.40 0.0059 0.0157

D 5.55 6.25 0.2185 0.2461

E 7.75 8.15 0.3051 0.3209

E1 6.60 7.15 0.2598 0.2815

E2 4.40 4.70 0.1732 0.1850

L 0.75 1.50 0.0295 0.0591

DS0792 - Rev 13 page 13/19

STPS340

SMC package information

Figure 24. SMC recommended footprint

1.54 5.11 1.54

(0.061) (0.201) (0.061)

3.14

(0.124)

8.19

(0.323)

millimeters

(inches)

DS0792 - Rev 13 page 14/19

STPS340

DPAK package information

2.5 DPAK package information

• Epoxy meets UL 94,V0

• Cooling method: by conduction (C)

Figure 25. DPAK package outline

E

A

b4

c2 Thermal pad

L2 E1

D1

D

H R

L4

A1

e b R

e1 c

A2

L1

L

V2

Gauge

0.25 plane

Note: This package drawing may slightly differ from the physical package. However, all the specified dimensions are

guaranteed.

DS0792 - Rev 13 page 15/19

STPS340

DPAK package information

Table 8. DPAK package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Max. Min. Max.

A 2.18 2.40 0.085 0.094

A1 0.90 1.10 0.035 0.043

A2 0.03 0.23 0.001 0.009

b 0.64 0.90 0.025 0.035

b4 4.95 5.46 0.194 0.215

c 0.46 0.61 0.018 0.024

c2 0.46 0.60 0.018 0.023

D 5.97 6.22 0.235 0.244

D1 4.95 5.60 0.194 0.220

E 6.35 6.73 0.250 0.265

E1 4.32 5.50 0.170 0.216

e 2.286 typ. 0.090 typ.

e1 4.40 4.70 0.173 0.185

H 9.35 10.40 0.368 0.409

L 1.0 1.78 0.039 0.070

L2 1.27 0.050

L4 0.60 1.02 0.023 0.040

V2 -8° +8° -8° +8°

Figure 26. DPAK recommended footprint (dimensions in mm)

12.7

6.7 3.0 3.0

A

4.572

6.7

B 1.6

The device must be positioned within 0.05 A B

DS0792 - Rev 13 page 16/19

STPS340

Ordering Information

3 Ordering information

Table 9. Ordering information

Order code Marking Package Weight Base qty. Delivery mode

STPS340AFN A340 SMA Flat Notch 0.039 g 10 000 Tape and reel

STPS340U U34 SMB 0.107 g 2500 Tape and reel

STPS340UF FU34 SMB Flat 0.050 g 5000 Tape and reel

STPS340S S34 SMC 0.243 g 10 000 Tape and reel

STPS340B-TR S3 40 DPAK 0.320 g 2500 Tape and reel

DS0792 - Rev 13 page 17/19

STPS340

Revision history

Table 10. Document revision history

Date Version Changes

Jul-2003 7 Last update.

Feb-2005 8 Layout update. No content change.

08-Feb-2007 9 Reformatted to current standard. Added ECOPACK statement. Added SMBflat package.

10-Feb-2009 10 Updated ECOPACK statement. Corrected Y axis in Figure 10.

23-Apr-2015 11 Updated DPAK and reformatted to current standard.

22-Sep-2016 12 Updated DPAK package information and reformatted to current standard.

08-Oct-2019 13 Added Section 2.1 SMA Flat Notch package information.

DS0792 - Rev 13 page 18/19

STPS340

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2019 STMicroelectronics – All rights reserved

DS0792 - Rev 13 page 19/19

You might also like

- STPS1045D Eng TdsDocument8 pagesSTPS1045D Eng Tdsjohn9999_502754No ratings yet

- STPS2L40: 40 V, 2 A Low Drop Power Schottky RectifierDocument17 pagesSTPS2L40: 40 V, 2 A Low Drop Power Schottky RectifierNirmal NepalNo ratings yet

- Stps 2 H 100Document19 pagesStps 2 H 100WAN MOZESNo ratings yet

- Vs mbrb1035 m3-2897740Document8 pagesVs mbrb1035 m3-2897740Möpar LösungenNo ratings yet

- STPS3150 STMicroelectronicsDocument16 pagesSTPS3150 STMicroelectronicssegundo zapataNo ratings yet

- STTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeDocument15 pagesSTTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeAlex Nicole SanchezNo ratings yet

- STTH1R02 200V 1.5A U-FastDocument15 pagesSTTH1R02 200V 1.5A U-Fastrara221122raraNo ratings yet

- Stps 30100 STDocument9 pagesStps 30100 STDerkis MarcanoNo ratings yet

- STPS745: Main Product CharacteristicsDocument9 pagesSTPS745: Main Product CharacteristicsQadash NeharaNo ratings yet

- STTH 110Document11 pagesSTTH 110Mohamed IsmailNo ratings yet

- Ultrafast Soft Recovery Rectifier Diode: Product Benefits Product Features Product ApplicationsDocument5 pagesUltrafast Soft Recovery Rectifier Diode: Product Benefits Product Features Product Applicationsalaa delewarNo ratings yet

- STTH212: DescriptionDocument11 pagesSTTH212: DescriptionPablo Gonzalez RivielloNo ratings yet

- Stps 40170 CDocument15 pagesStps 40170 CotnielsaririNo ratings yet

- DPAK Surface Mount Package: Semiconductor Technical DataDocument4 pagesDPAK Surface Mount Package: Semiconductor Technical DataJeanpierre H. AsdikianNo ratings yet

- STPS1045Document8 pagesSTPS1045László LósNo ratings yet

- Apt15d40k (G) GDocument5 pagesApt15d40k (G) GmylitalindaNo ratings yet

- Stps1045b-Y - Schottky DiodeDocument7 pagesStps1045b-Y - Schottky DiodePradeep JaganjyothiNo ratings yet

- Diodo Tarjeta Logica Del 1 Disco Duro Wester Digital de 500gb Modelo WD5000AAKX - 083CA1 Del DVR WesrDocument10 pagesDiodo Tarjeta Logica Del 1 Disco Duro Wester Digital de 500gb Modelo WD5000AAKX - 083CA1 Del DVR WesrHernan Vallenilla Rumildo MixNo ratings yet

- tn4050hp 12gy tr-2935903Document11 pagestn4050hp 12gy tr-2935903chawkigenieNo ratings yet

- stps1045b Eng TdsDocument8 pagesstps1045b Eng Tdsjohn9999_502754No ratings yet

- MBR3045ST, MBRB3045CT-1 Switch Mode Power Rectifier: °C Operating Junction TemperatureDocument5 pagesMBR3045ST, MBRB3045CT-1 Switch Mode Power Rectifier: °C Operating Junction TemperatureSandeep KumarNo ratings yet

- B3045G ONSemiconductorDocument6 pagesB3045G ONSemiconductorCristea GabrielNo ratings yet

- Features: Transil™Document10 pagesFeatures: Transil™Tirwanda EdhoNo ratings yet

- TBR3516 Three Phase Bridge Rectifiers: FeaturesDocument3 pagesTBR3516 Three Phase Bridge Rectifiers: FeaturesGabriel MassiminoNo ratings yet

- MBRS140T3 Surface Mount Schottky Power RectifierDocument4 pagesMBRS140T3 Surface Mount Schottky Power RectifierfreddyNo ratings yet

- STTH812Document11 pagesSTTH812rolando ojedaNo ratings yet

- STTH12R06: Turbo 2 Ultrafast High Voltage RectifierDocument11 pagesSTTH12R06: Turbo 2 Ultrafast High Voltage RectifierNitish kumarNo ratings yet

- STTH 102Document12 pagesSTTH 102Abel GaunaNo ratings yet

- STTA1512PI Orgn Diod Conmm inDocument9 pagesSTTA1512PI Orgn Diod Conmm inmylitalindaNo ratings yet

- STTA2512P STTA5012TV1/2: Turboswitch Ultra-Fast High Voltage DiodeDocument9 pagesSTTA2512P STTA5012TV1/2: Turboswitch Ultra-Fast High Voltage DiodeDavid ReyesNo ratings yet

- STPS80H100CY Schottky RectifierDocument10 pagesSTPS80H100CY Schottky RectifierAnonymous oyUAtpKNo ratings yet

- DF005M - DF10M: Bridge RectifiersDocument4 pagesDF005M - DF10M: Bridge RectifiersrubertussNo ratings yet

- DF005M - DF10M: Bridge RectifiersDocument4 pagesDF005M - DF10M: Bridge RectifiersrubertussNo ratings yet

- Apt40dq60b S (G) D PDFDocument4 pagesApt40dq60b S (G) D PDFjhon130296No ratings yet

- MBR1535CT, MBR1545CT Switchmode Power Rectifier: Schottky Barrier Rectifiers 15 Amperes 35 and 45 VOLTSDocument3 pagesMBR1535CT, MBR1545CT Switchmode Power Rectifier: Schottky Barrier Rectifiers 15 Amperes 35 and 45 VOLTSNallbellausNo ratings yet

- By359 1500Document5 pagesBy359 1500RuslanNo ratings yet

- Stps 20 S 100 CDocument12 pagesStps 20 S 100 CEnrico RotaNo ratings yet

- 1N4933GP - 1N4937GP: Fast Rectifiers (Glass Passivated)Document3 pages1N4933GP - 1N4937GP: Fast Rectifiers (Glass Passivated)Zoltán ÁgostonNo ratings yet

- TYN640, TYN840: DescriptionDocument8 pagesTYN640, TYN840: DescriptionNal FivefivetwooneNo ratings yet

- Features: Transil™Document9 pagesFeatures: Transil™m.furqan.q.tsNo ratings yet

- Bat 41Document11 pagesBat 41Tanko SuleNo ratings yet

- STPS20L45C: Low Drop Power Schottky RectifierDocument9 pagesSTPS20L45C: Low Drop Power Schottky RectifierFabio SantanaNo ratings yet

- Product Profile: Ultrafast Power DiodeDocument11 pagesProduct Profile: Ultrafast Power DiodeAndrzej WojtalaNo ratings yet

- MBR3045PT Switchmode Power Rectifier: Schottky Barrier Rectifier 30 Amperes, 45 VoltsDocument4 pagesMBR3045PT Switchmode Power Rectifier: Schottky Barrier Rectifier 30 Amperes, 45 VoltsSaikumarNo ratings yet

- Stps 5 H 100Document10 pagesStps 5 H 100chudungk57No ratings yet

- Datasheet ST S5H100Document5 pagesDatasheet ST S5H100Maria Haro garateNo ratings yet

- 249NQ135-150 (R) - 1 N1208, Dioda 890Document5 pages249NQ135-150 (R) - 1 N1208, Dioda 890diesmirnovNo ratings yet

- Reverse Blocking Triode Thyristors: Semiconductor Technical DataDocument4 pagesReverse Blocking Triode Thyristors: Semiconductor Technical DataYoshiZHNo ratings yet

- Ultrafast Soft Recovery Rectifier Diode: Product Benefits Product Features Product ApplicationsDocument4 pagesUltrafast Soft Recovery Rectifier Diode: Product Benefits Product Features Product ApplicationsEDER RIBEIRONo ratings yet

- 15ETH06S/15ETH06-1: Vishay High Power ProductsDocument8 pages15ETH06S/15ETH06-1: Vishay High Power ProductsPablo AllosiaNo ratings yet

- Byv44 Series PDFDocument7 pagesByv44 Series PDFdraNo ratings yet

- Media 3323329Document6 pagesMedia 3323329Daniel MesiNo ratings yet

- Datasheet PDFDocument9 pagesDatasheet PDFIng MechatronicsNo ratings yet

- STPS10L25: Low Drop Power Schottky RectifierDocument12 pagesSTPS10L25: Low Drop Power Schottky Rectifierjohn9999_502754No ratings yet

- Semiconductor Technical Data: Schottky Barrier Rectifier 20 Amperes 45 VoltsDocument4 pagesSemiconductor Technical Data: Schottky Barrier Rectifier 20 Amperes 45 VoltsalbaromachadoNo ratings yet

- Bta 25Document10 pagesBta 25ingservicioddmNo ratings yet

- STPS3045CT/CG/CR/CP/CPI/CW/CFP: Power Schottky RectifierDocument9 pagesSTPS3045CT/CG/CR/CP/CPI/CW/CFP: Power Schottky Rectifierигорь федотовNo ratings yet

- Diode MSR1560GDocument7 pagesDiode MSR1560G유진No ratings yet

- TN6050-12PI: 60 A, 1200 V Standard SCRDocument11 pagesTN6050-12PI: 60 A, 1200 V Standard SCRluis lopezNo ratings yet

- Upload A Document - ScribdDocument2 pagesUpload A Document - ScribdMariusz KaźmierczakNo ratings yet

- Ren U16498ee1v1an00 Apn 20040501Document56 pagesRen U16498ee1v1an00 Apn 20040501Mariusz KaźmierczakNo ratings yet

- Motor Control Reference GuideDocument56 pagesMotor Control Reference GuideMariusz KaźmierczakNo ratings yet

- P5kpl-Am Se PDFDocument4 pagesP5kpl-Am Se PDFMariusz KaźmierczakNo ratings yet

- Avx BZ05FB682ZSBDocument26 pagesAvx BZ05FB682ZSBMariusz KaźmierczakNo ratings yet

- Laptop Conversion To Raspberry PiDocument42 pagesLaptop Conversion To Raspberry PiMariusz KaźmierczakNo ratings yet

- Series: Shielded Surface Mount Power InductorsDocument2 pagesSeries: Shielded Surface Mount Power InductorsMariusz KaźmierczakNo ratings yet

- Chapter 07 EngineDocument24 pagesChapter 07 EngineAdiya PurevjavNo ratings yet

- Explosion Proof CCTVDocument4 pagesExplosion Proof CCTVAhmad AjiNo ratings yet

- Scheme For Promotion of Electric Vehicles in The StateDocument4 pagesScheme For Promotion of Electric Vehicles in The Statepratik rathodNo ratings yet

- Sustainability 14 15912Document31 pagesSustainability 14 15912AmanuelAlemaNo ratings yet

- DOC665105Document2 pagesDOC665105DeivisNo ratings yet

- Chandler Condensing UnitsDocument40 pagesChandler Condensing UnitsFred SmifNo ratings yet

- Maintenance EngDocument225 pagesMaintenance EngGrazvydas JuzelskisNo ratings yet

- Energy Efficiency For The Transcritical Compression CO2 Cycle With The Use of The Ejector As The Firts Stage of The CompressionDocument9 pagesEnergy Efficiency For The Transcritical Compression CO2 Cycle With The Use of The Ejector As The Firts Stage of The CompressionOnofreHalberNo ratings yet

- Pricelist ASENWARE Conventional Fire Alarm Control SystemDocument4 pagesPricelist ASENWARE Conventional Fire Alarm Control SystemIlham WaskitoNo ratings yet

- 1 Elpress Iws Presentation - enDocument28 pages1 Elpress Iws Presentation - enFábio MaiaNo ratings yet

- Brother in The Land QuestionsDocument2 pagesBrother in The Land QuestionsKhola Munawar - 79431/TCHR/BFBOY0% (1)

- Electrical Conductors and Insulators WorksheetDocument6 pagesElectrical Conductors and Insulators WorksheetMONTYMER HERNANDO MORENONo ratings yet

- Um-Soft31 (DN15,20,25) R1Document17 pagesUm-Soft31 (DN15,20,25) R1Femto BotNo ratings yet

- 3.2 RMR-35 Equipment Operation and Maintenance ManualDocument11 pages3.2 RMR-35 Equipment Operation and Maintenance Manual021804No ratings yet

- Steam Generators Lecture No.-1Document18 pagesSteam Generators Lecture No.-1rathoraryan2003No ratings yet

- E & SIA - Unit - 1 NotesDocument33 pagesE & SIA - Unit - 1 NotesvidhyaNo ratings yet

- 313-311-PROJECTOVERALLTO-As of 09-15-2022Document6 pages313-311-PROJECTOVERALLTO-As of 09-15-2022EvanNo ratings yet

- Chapter 2 Plant-Water RelationsDocument45 pagesChapter 2 Plant-Water Relationsenyew nigussieNo ratings yet

- Commented - HT PANEL 11kV and 33kVDocument8 pagesCommented - HT PANEL 11kV and 33kVGautam MishraNo ratings yet

- Electrical System AnalysisDocument6 pagesElectrical System AnalysisSolarMaxNo ratings yet

- FSG Angular Position Transducers EDocument11 pagesFSG Angular Position Transducers ERachid SmailiNo ratings yet

- UntitledDocument46 pagesUntitledBangali FilmsNo ratings yet

- The Importance of Environmental Conservation in The 21st CenturyDocument1 pageThe Importance of Environmental Conservation in The 21st CenturymonkeyboppopNo ratings yet

- About AA Historic Expansion Ethiopia 2050 Article Aynalem AdugnaDocument34 pagesAbout AA Historic Expansion Ethiopia 2050 Article Aynalem AdugnaAhmedNo ratings yet

- Aipmt Neet Question Paper 2012 183Document36 pagesAipmt Neet Question Paper 2012 183ramNo ratings yet

- Capstone Research Group 5 UnityDocument27 pagesCapstone Research Group 5 UnityMohammad Ryyan PumbagulNo ratings yet

- Minerals 13 00315 v2Document16 pagesMinerals 13 00315 v2王柏昆No ratings yet

- Fabrication of Vertical Axis Wind Turbine and ApplicationDocument5 pagesFabrication of Vertical Axis Wind Turbine and ApplicationIJRASETPublicationsNo ratings yet

- Underground Falut Detector Based On Ardunio: Vii Sem Project Work Phase - 1 and Project Work Seminar (17eep78)Document16 pagesUnderground Falut Detector Based On Ardunio: Vii Sem Project Work Phase - 1 and Project Work Seminar (17eep78)Gowrav KNo ratings yet

- FDB2 Datasheet 2022Document4 pagesFDB2 Datasheet 2022bondsivamaniNo ratings yet