Professional Documents

Culture Documents

5.19.3 Job Safety Practices Grouting Works

5.19.3 Job Safety Practices Grouting Works

Uploaded by

Barkat UllahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.19.3 Job Safety Practices Grouting Works

5.19.3 Job Safety Practices Grouting Works

Uploaded by

Barkat UllahCopyright:

Available Formats

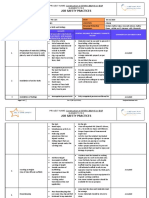

PROJECT NAME: Construction of SPARK 380/115 kV BSP

ELEMENT 5.19.3

JOB SAFETY PRACTICES

DEPARTMENT/DIVISION PE-199 Civil DATE 02/10/2019

EMPLOYEE JOB TITLE Mason LOCATION Abqaiq

Helmet, Safety Glass, Mask, Coverall, Gloves,

Personal Protective

JOB/ TASK TITLE Grouting Works Safety Shoes, visible vest & Harness with 2

Equipment

lanyards

STEPS HAZARDS

IN EACH STEP, WHAT COULD CONTROL REQUIRED TO MINIMIZE/ ELIMINATE

LIST ALL STEPS IN PERFORMING THIS COMMENTS OF JOB OBSERVATION

STEPS # CAUSE INJURY, LOSS DAMAGE, HAZARD

TASK

INTRRUPTION, OR POLUTION?

Struck by vehicle Materials must be secured to prevent it

Fall of materials due to from falling while traveling

unsecured materials and Flagman must be present on forklift at

improper loading to all time to guide the movement of the

Preparation of materials (Shifting vehicle by forklift equipment and prevent anyone to go

1. of Materials from store to work Struck by forklift near the area. Accepted

place by used of vehicle/forklift) Slip, trip and fall Arrange materials properly as per

Back injury due to carrying standard

of heavy load Do not block the access

Do not carry heavy materials by your

own, ask for help.

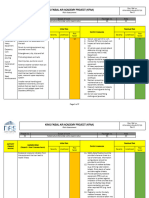

2. Application of Grout The workers are exposed All workers engage in grouting works Accepted

to chemicals (grout, etc.) must be provided with required

during application. personal protective equipment (PPE) at

Contact with the chemicals all ties.

may cause skin and eye Remove all unwanted cables at the site

irritation, pain, de-fatting if not intended to use.

and drying of skin All electrical cables inside the building

Unprotected / unsecured should be properly suspended / hang to

trailing cables in the prevent the tripping hazards.

workplace. All cables must be provide by any

The risk of slip and trip means of protection when passing to

may results to hand and another area.

Page 1 of 3 Rev.2 [08-April-2019] Projects Business Unit

PROJECT NAME: Construction of SPARK 380/115 kV BSP

ELEMENT 5.19.3

JOB SAFETY PRACTICES

physical injuries.

Workers must be trained in working

Fall from Height

height prior to work in elevated area.

Incomplete Scaffold

Wear full body harness with double

Working at Height Workers are not trained in Accepted

3. lanyards and secure 100% tie off.

(Use of scaffold) working at height

Scaffold must be inspected, Green tag

Unsafe erection of

will indicated scaffold is safe to use.

Scaffolding

Area must be clean and materials must

be arrange.

Excess Materials should be return to

Poor housekeeping that store.

Housekeeping can cause trip, slip and fall. Removed scrap materials at site and Accepted

4.

Scattered Scrap materials place it on scrap storage area.

Emergency Response and Arrangements

The injured person should be given first aid immediately.

First aid box shall be made available with required medicines in adequate quantity.

Emergency response team should be available at site.

All personnel on site should be aware on site evacuation procedure, location of muster point.

Emergency Numbers shall be posted at different locations.

One vehicle shall be made available for meeting emergency needs.

All employees shall be explained about the provisions of first aid, assembly point and contact number, etc.

JSP Prepared By: Mr. Haitham Abouelella Signature: Date: 02/10/2019

JSP Accepted By: Mr. Mohamed Abdellatif Signature: Date: 02/10/2019

JSP Approved By (SEC / Site): Mr. Ronald Marteja Signature: Date: 02/10/2019

JSP Approved By (SEC- PD): Mr. Abdul Majeed Signature: Date: 02/10/2019

Page 2 of 3 Rev.2 [08-April-2019] Projects Business Unit

PROJECT NAME: Construction of SPARK 380/115 kV BSP

ELEMENT 5.19.3

JOB SAFETY PRACTICES

Page 3 of 3 Rev.2 [08-April-2019] Projects Business Unit

You might also like

- Organization and Management PDFDocument104 pagesOrganization and Management PDFjolina talledo97% (34)

- JSA Maintenance Fire Alarm PDFDocument2 pagesJSA Maintenance Fire Alarm PDFBernath100% (3)

- Hirac - DoleDocument11 pagesHirac - DoleAngela Salumbides50% (2)

- Risk Assessment MicrotunnelingDocument7 pagesRisk Assessment Microtunnelingmohamed ghalyNo ratings yet

- Demand Worksheet PDFDocument2 pagesDemand Worksheet PDFDipti NagarNo ratings yet

- JHA Fabrication WorkDocument4 pagesJHA Fabrication WorkRavi thokalNo ratings yet

- Jsa For Gypsum Fixing & DismentlingDocument5 pagesJsa For Gypsum Fixing & DismentlingSushil Kumar YadavNo ratings yet

- Apollo Medicine InvoiceOct 13 2022-19-37Document1 pageApollo Medicine InvoiceOct 13 2022-19-37mani kandanNo ratings yet

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDocument3 pagesHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834100% (1)

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius Dsouza100% (1)

- 5.19.3 Job Safety Practices Finishing WorksDocument3 pages5.19.3 Job Safety Practices Finishing WorksBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahNo ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Water Proofing WorksDocument3 pages5.19.3 Job Safety Practices Water Proofing WorksBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsDocument3 pages5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionDocument3 pages5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionBarkat UllahNo ratings yet

- Job Safety Practices Backfilling and CompactionDocument3 pagesJob Safety Practices Backfilling and CompactionBarkat UllahNo ratings yet

- R.A FOR Condensate PitDocument5 pagesR.A FOR Condensate PitResearcherNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- Jsa For Admin BuildingDocument5 pagesJsa For Admin Buildingmohamed yasinNo ratings yet

- RMK Jsa.Document49 pagesRMK Jsa.Vaibhav GaikwadNo ratings yet

- Hirarc B-BandDocument3 pagesHirarc B-BandDon McleanNo ratings yet

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoNo ratings yet

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- JSA Additional Lamp Paiton 3Document10 pagesJSA Additional Lamp Paiton 3MarhendraNo ratings yet

- 045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Document7 pages045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Zubair Ahmed KhaskheliNo ratings yet

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- 5.19 JSP ScaffoldDocument4 pages5.19 JSP Scaffoldpoorm879No ratings yet

- Job Safety Practices FirefightingDocument16 pagesJob Safety Practices Firefightingmohammed tofiqNo ratings yet

- JSA of 33KV Bay - Rev001 - 15072020Document3 pagesJSA of 33KV Bay - Rev001 - 15072020Aradhya SinghNo ratings yet

- Hard BarricationDocument3 pagesHard BarricationViron BaxhiaNo ratings yet

- AsasasaDocument2 pagesAsasasahalfy safitriNo ratings yet

- Concrete Placing by Using Mobile Crane Through Concrete Bucket JSA HSE ProfessionalsDocument1 pageConcrete Placing by Using Mobile Crane Through Concrete Bucket JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document2 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- Fixing of Glass at Bridge JSA HSE ProfessionalsDocument1 pageFixing of Glass at Bridge JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- JSA 20-Rev.02 - Finish PaintingDocument2 pagesJSA 20-Rev.02 - Finish PaintinggolusinghdataNo ratings yet

- Cañete Assignment CVODocument17 pagesCañete Assignment CVOKim CañeteNo ratings yet

- Rig Move-JsaDocument1 pageRig Move-JsasNo ratings yet

- JSP 42 Use of Power ToolsDocument6 pagesJSP 42 Use of Power ToolsMuhammad AtifNo ratings yet

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- Bobadilla - Working at HeightsDocument7 pagesBobadilla - Working at Heightscharmainebobadilla27No ratings yet

- Risk Assessement For AAES ProductsDocument4 pagesRisk Assessement For AAES ProductsAzhar Shaikh100% (1)

- Yanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of PipelineDocument3 pagesYanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of Pipelinesam mathewNo ratings yet

- Grouting of Bolts - Pockets JSA HSE ProfessionalsDocument1 pageGrouting of Bolts - Pockets JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Backfilling ENDocument5 pagesBackfilling ENTilalNo ratings yet

- ISLA JHA Mobilization of EquipmentsDocument4 pagesISLA JHA Mobilization of Equipmentsaasafety06No ratings yet

- Safe Work Method StatementDocument12 pagesSafe Work Method StatementJanakiramanNo ratings yet

- Hazard Identification & Risk Assesment (Hira) Ohs-Pr-02-03-F07 Job Safe ProcedureDocument5 pagesHazard Identification & Risk Assesment (Hira) Ohs-Pr-02-03-F07 Job Safe ProcedureMuhammad M KhanNo ratings yet

- Binks Maple 30 3Document24 pagesBinks Maple 30 3HuynhTienNo ratings yet

- Jha 2023Document2 pagesJha 2023Leo TabitaNo ratings yet

- SWP - Opening Railcar Lids and Inspecting InteriorDocument2 pagesSWP - Opening Railcar Lids and Inspecting Interiordaman.sNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- 15 Piping Fabrication & Welding - Rev 3Document7 pages15 Piping Fabrication & Welding - Rev 3Rafael Restituyo LopezNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Cutting DrillingDocument2 pagesCutting DrillingKoneti JanardhanaraoNo ratings yet

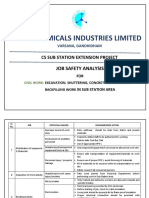

- CS Sub Station JsaDocument4 pagesCS Sub Station JsaEHS Unit IINo ratings yet

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- 5.19.3 Job Safety Practices Welding and CuttingDocument3 pages5.19.3 Job Safety Practices Welding and CuttingBarkat UllahNo ratings yet

- IntroDocument3 pagesIntroBarkat UllahNo ratings yet

- H10-HSE Data For Weekly Report 26 May 23.Document1 pageH10-HSE Data For Weekly Report 26 May 23.Barkat UllahNo ratings yet

- PrefDocument1 pagePrefBarkat UllahNo ratings yet

- HARC For Lowering Raising Mast With Old Bridle LinesDocument1 pageHARC For Lowering Raising Mast With Old Bridle LinesBarkat UllahNo ratings yet

- Saudi Law p1Document30 pagesSaudi Law p1Barkat UllahNo ratings yet

- Over Confidence Safety MomentDocument1 pageOver Confidence Safety MomentBarkat UllahNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Finishing WorksDocument3 pages5.19.3 Job Safety Practices Finishing WorksBarkat UllahNo ratings yet

- R10-H10-KEO-MOM-SU-0026 - TRSP H10 LEED MoM 230509Document18 pagesR10-H10-KEO-MOM-SU-0026 - TRSP H10 LEED MoM 230509Barkat UllahNo ratings yet

- Job Safety Practices Backfilling and CompactionDocument3 pagesJob Safety Practices Backfilling and CompactionBarkat UllahNo ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- Marketing Report LatestDocument25 pagesMarketing Report LatesthelalNo ratings yet

- Foi Mtcu-100025 Bargaining Expenses Thu Aug 26 2010 08-26-27.142-1Document5 pagesFoi Mtcu-100025 Bargaining Expenses Thu Aug 26 2010 08-26-27.142-1Rob HorganNo ratings yet

- RA 9208 - Anti-Trafficking in Persons Act of 2003Document13 pagesRA 9208 - Anti-Trafficking in Persons Act of 2003Rocky MarcianoNo ratings yet

- Sonnet Is A 14 Lines Poem Written Iambic PentameterDocument2 pagesSonnet Is A 14 Lines Poem Written Iambic PentameterS ShreeNo ratings yet

- United States v. Albert A. Cortellesso, 601 F.2d 28, 1st Cir. (1979)Document7 pagesUnited States v. Albert A. Cortellesso, 601 F.2d 28, 1st Cir. (1979)Scribd Government DocsNo ratings yet

- Components of Industrial EconomyDocument2 pagesComponents of Industrial EconomyEllis ElliseusNo ratings yet

- FloraPark 1 IntroductionDocument33 pagesFloraPark 1 IntroductionTin TranNo ratings yet

- Customer Satisfaction Survey On Insurance Products of ICICI PrudentialDocument71 pagesCustomer Satisfaction Survey On Insurance Products of ICICI PrudentialSachin90% (31)

- Pointers On SalesDocument19 pagesPointers On SalesDonvidachiye Liwag CenaNo ratings yet

- Law of ContractDocument85 pagesLaw of ContractDebbie PhiriNo ratings yet

- Commissioner of Internal Revenue VsDocument4 pagesCommissioner of Internal Revenue VsKyla BinayaoNo ratings yet

- Career Readiness ReflectionDocument2 pagesCareer Readiness Reflectionapi-597414151No ratings yet

- Nakshatra SwatiDocument1 pageNakshatra SwatinmremalaNo ratings yet

- Introduction and Preface To PFRS and Conceptual Framework: Theory of Accounts Preweek DiscussionDocument20 pagesIntroduction and Preface To PFRS and Conceptual Framework: Theory of Accounts Preweek DiscussionLeisleiRagoNo ratings yet

- List of Successful Candidates For Direct Admission (Bba Program)Document44 pagesList of Successful Candidates For Direct Admission (Bba Program)zunaira khanNo ratings yet

- Accounting For Business DecisionsDocument7 pagesAccounting For Business DecisionsFaizan AhmedNo ratings yet

- Immuniazation AuthorizationDocument1 pageImmuniazation Authorizationsreenivas puttaNo ratings yet

- 2a Marketing ChannelsDocument74 pages2a Marketing ChannelsMahbobullah RahmaniNo ratings yet

- Jay Abraham - The MasterMind Marketing SystemDocument0 pagesJay Abraham - The MasterMind Marketing Systematik103100% (4)

- 2 Specifications: 2-1 Nominal Capacity and Nominal InputDocument1 page2 Specifications: 2-1 Nominal Capacity and Nominal InputBMCNo ratings yet

- Contemporary Issues in Social Studies Ed PDFDocument12 pagesContemporary Issues in Social Studies Ed PDFangiecrazie wellerNo ratings yet

- MOTILALDocument17 pagesMOTILALvinodhji5No ratings yet

- Factors Affecting Contract Management in Public Procurement Sector in Kenya A Case of Kenya Literature BureauDocument11 pagesFactors Affecting Contract Management in Public Procurement Sector in Kenya A Case of Kenya Literature BureauERNEST KAIGENo ratings yet

- Arii 2018Document207 pagesArii 2018Bisa AcademyNo ratings yet

- Put The Verbs Into Past Simple Tense: Written Work (VIII) NameDocument2 pagesPut The Verbs Into Past Simple Tense: Written Work (VIII) NameVelika KaradjovaNo ratings yet

- Lab 8.4.2 Configuring Access Policies and DMZ SettingsDocument17 pagesLab 8.4.2 Configuring Access Policies and DMZ SettingsKasozi BakulumpagiNo ratings yet

- JADON SANCHO - Social Media Marketing ProjectDocument20 pagesJADON SANCHO - Social Media Marketing ProjectNilakashNo ratings yet