Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

8 viewsRF slb007 en

RF slb007 en

Uploaded by

JX SCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Comprehensive Guide to Composites: Processes & Procedures from the ProfessionalsFrom EverandA Comprehensive Guide to Composites: Processes & Procedures from the ProfessionalsRating: 5 out of 5 stars5/5 (2)

- The Elements of Boat Strength: For Builders, Designers, and OwnersFrom EverandThe Elements of Boat Strength: For Builders, Designers, and OwnersRating: 5 out of 5 stars5/5 (8)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Decorative Chromium Plating BasicsDocument8 pagesDecorative Chromium Plating Basicsm daneshpour100% (1)

- When Glass meets Pharma: Insights about glass as primary packaging materialFrom EverandWhen Glass meets Pharma: Insights about glass as primary packaging materialNo ratings yet

- Informe No. 3 " Determinación de Aluminio" AnalíticaDocument8 pagesInforme No. 3 " Determinación de Aluminio" AnalíticaDiegou Pinzón100% (1)

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Ceramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsFrom EverandCeramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsWalter KrenkelNo ratings yet

- Membranes for Energy ConversionFrom EverandMembranes for Energy ConversionKlaus-Viktor PeinemannNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Sustainable Renovation: Strategies for Commercial Building Systems and EnvelopeFrom EverandSustainable Renovation: Strategies for Commercial Building Systems and EnvelopeNo ratings yet

- Ceramics Science and Technology, Volume 4: ApplicationsFrom EverandCeramics Science and Technology, Volume 4: ApplicationsRalf RiedelNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- The Methods of Glass Blowing and of Working Silica in the Oxy-Gas Flame For the use of chemical and physical studentsFrom EverandThe Methods of Glass Blowing and of Working Silica in the Oxy-Gas Flame For the use of chemical and physical studentsNo ratings yet

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsFrom EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Dust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopFrom EverandDust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopNo ratings yet

- Metallic Oxynitride Thin Films by Reactive Sputtering and Related Deposition Methods: Process, Properties and ApplicationsFrom EverandMetallic Oxynitride Thin Films by Reactive Sputtering and Related Deposition Methods: Process, Properties and ApplicationsNo ratings yet

- Membrane Technology: in the Chemical IndustryFrom EverandMembrane Technology: in the Chemical IndustrySuzana Pereira NunesNo ratings yet

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- FDS FT Super 10WDocument10 pagesFDS FT Super 10WAlfredo Mamangueño FloresNo ratings yet

- Quimica Geral - EngenhariaDocument9 pagesQuimica Geral - Engenharia299b6z22tzNo ratings yet

- Organisation of The OrganismDocument4 pagesOrganisation of The Organismanotida marambaNo ratings yet

- Caso InnovacionDocument3 pagesCaso InnovacionNorma FillurenNo ratings yet

- Research ProposalDocument14 pagesResearch Proposaldelossantos.blueg8No ratings yet

- Iones Cationes y Aniones TeoriaDocument7 pagesIones Cationes y Aniones TeoriaLidia OrtegaNo ratings yet

- Farmaco DiapositivaDocument1 pageFarmaco Diapositivadaymari ccarolina chirino chirinoNo ratings yet

- Fiche CobaltDocument19 pagesFiche CobaltMPNo ratings yet

- Crudo Caño LimónDocument7 pagesCrudo Caño Limónica zonaorienteNo ratings yet

- Problemas y Generalidades de Electro-Refinación de CuDocument11 pagesProblemas y Generalidades de Electro-Refinación de CuCaroEllNo ratings yet

- 1Document2 pages1roxana madrizNo ratings yet

- Guía de Problemas Sobre Concentración de Soluciones (Resueltos) )Document4 pagesGuía de Problemas Sobre Concentración de Soluciones (Resueltos) )gabriel marcaNo ratings yet

- Chemistry ObservationDocument11 pagesChemistry ObservationMohammed FarhanNo ratings yet

- Radial, Axial or Dual View ICP: Which Do You Choose?: Manny Almeida Teledyne Leeman Labs, Inc. Hudson, NH 03031Document33 pagesRadial, Axial or Dual View ICP: Which Do You Choose?: Manny Almeida Teledyne Leeman Labs, Inc. Hudson, NH 03031Ridwan HarahapNo ratings yet

- Guia de Ejercicios Del Tema I. PPQ - t1-t1 - .Final. 29-04-2012Document8 pagesGuia de Ejercicios Del Tema I. PPQ - t1-t1 - .Final. 29-04-2012gabrielNo ratings yet

- WPS - 170-20 - Smaw-Precalificado para Calificacion de Soldador-1Document1 pageWPS - 170-20 - Smaw-Precalificado para Calificacion de Soldador-1antony bolivar100% (3)

- MisiónDocument16 pagesMisiónPaola CameloNo ratings yet

- Hds - Protector Impermeabilizante e Hidrofugante - MasisaDocument4 pagesHds - Protector Impermeabilizante e Hidrofugante - MasisaRobinson Francisco Torres CandiaNo ratings yet

- S4 - Hidrogeno, Oxigeno, AzufreDocument30 pagesS4 - Hidrogeno, Oxigeno, AzufreJuan Alex Osorio RomanNo ratings yet

- Solsperse Hyperdispersants Overview - 19-179712Document2 pagesSolsperse Hyperdispersants Overview - 19-179712Jose E BatistaNo ratings yet

- Casting Manufacturing Processes Fundamentals of Metal Casting Metals For CastingDocument47 pagesCasting Manufacturing Processes Fundamentals of Metal Casting Metals For CastingarobaidiNo ratings yet

- PPR DigitalDocument10 pagesPPR DigitalcamilaNo ratings yet

- Synthesizing, Characterizing, and Toxicity Evaluating of Phycocyanin-ZnO Nanorod Composites-A Back To Nature ApproachesDocument32 pagesSynthesizing, Characterizing, and Toxicity Evaluating of Phycocyanin-ZnO Nanorod Composites-A Back To Nature ApproachesHossein ShahbaniNo ratings yet

- Semana O4Document450 pagesSemana O4Daniels Felix Tinoco OrihuelaNo ratings yet

- AUBF LAB - Chemical Examination of UrineDocument7 pagesAUBF LAB - Chemical Examination of Urinecdsteenkamp18No ratings yet

- 鳞翅目昆虫肠道微生物的多样性及其与宿主的相互作用Document13 pages鳞翅目昆虫肠道微生物的多样性及其与宿主的相互作用tabaci BemisiaNo ratings yet

- Soja - Fixação BiológicaDocument35 pagesSoja - Fixação BiológicaRafael DelaiNo ratings yet

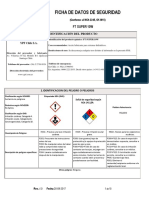

RF slb007 en

RF slb007 en

Uploaded by

JX S0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

rf-slb007-en

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

8 views2 pagesRF slb007 en

RF slb007 en

Uploaded by

JX SCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

CompleteCoat™ corrosion protection

CompleteCoat™

Corrosion-resistant, flexible coating uniformly bonded to all condenser coil surfaces

A condenser coil-coating system makes Trane air-cooled

chillers and Precedent packaged rooftop units the best choice

for an even wider range of applications. Because of the

potential for corrosion of air-cooled condenser coils, certain

environments have traditionally limited the use of air-cooled

chillers and Precedent packaged rooftop units. This includes

coastal applications and a wide variety of industrial

environments. In such areas, there may be airborne corrosive

salts, acids, bases, and/or other chemicals that shorten the

life of air-cooled heat exchangers.

CompleteCoat offers unprecedented protection.

Trane CompleteCoat offers more application

CompleteCoat is a water-based, flexible epoxy polymer

flexibility

coating process engineered specifically for HVAC heat

transfer coils. Electrocoating is the process by which a coil is

Trane has a corrosion-resistant coating available for our

submerged in a paint/water bath where electricity is used to

air-cooled chillers and Precedent™ packaged rooftop units

deposit paint onto it.

that goes beyond the performance and protection of

anything offered in the past. CompleteCoat provides the

Benefits of CompleteCoat factory-applied

corrosion protection you need without the worry of

electrocoating process:

performance degradation or coating breakdown.

•The only process that can guarantee 100% coil coverage

Air-cooled chillers and Precedent packaged rooftop units are

•Proven to stand up to 6,000+ hour salt spray exposure test

increasingly being chosen for a wide range of comfort and

•The coating process will ensure a uniform dry film thickness

process-cooling applications. Unit efficiency continues to

from 0.6 1.2 mils on all surface areas including fin edges

increase with advanced compressor and control designs.

•Excellent corrosion and UV resistance make it suitable for

Trane air-cooled chillers and Precedent packaged rooftop

coastal environments and other harsh environments

units in particular have achieved a reputation for rugged

•The coating protects the coil in temperatures

reliability and efficiency.

from -50°F to +450°F

•Units with the CompleteCoat option keep their UL listing

and do not need to be re-rated

CompleteCoat™ provides the corrosion protection

you need without the worry of performance

degradation or coating breakdown.

Previously, the choices were to either accept the shortened

life of the aluminum heat exchanger or use a variety of

coatings that fell short on corrosion protection and

performance.

Phenolic coatings offer some protection from corrosion, but

provide inconsistent coverage and can break down in

challenging environments. Furthermore, phenolic coatings

significantly reduce the heat-exchange value of the coil

(2 4%), requiring more energy usage and a larger unit to

Another reliability enhancement from Trane.

make up for the peak load performance loss. Because of their

brittle nature, phenolic coatings can deteriorate from thermal

Trane air-cooled chiller and Precedent packaged rooftop

flexing or from an abrasive environment.

units are available with the CompleteCoat coil-coating option.

CompleteCoat is a tough epoxy coating that uniformly covers

The option to spray various coatings on in the field has also

all condenser coil surfaces, including the edges of the fins,

been available. This can provide a first-cost and delivery

coils, heads, and frame, with a 0.6 1.2 mil layer. This

benefit compared to full coatings. However, these options

advanced material is flexible, avoiding the thermal cracking

can be very inconsistent in coverage, and provide protection

problems of phenolics, and avoids bridging problems

mainly on the visible surfaces of the coils, allowing the

encountered with application of earlier, more viscous

interior fins and coils to corrode at the uncoated rate.

coatings.

Another option is epoxy precoated fin stock. This generally

Now you can consider the Trane air-cooled chillers and

provides the largest first-cost and delivery benefit when

Precedent packaged rooftop units for an even wider range of

compared to other coating options. It does provide protection

applications. CompleteCoat opens the door to a range of

in low- to moderately-corrosive environments. The lack of

marine and industrial uses that other coating options could

coating on the edge of the fins, the condenser frame, and the

not handle. With CompleteCoat, thermal breakdown,

coil heads makes this option less desirable when corrosion is a

performance degradation, and incomplete coverage will no

major concern.

longer be your foremost concern. Ask your Trane sales

engineer for additional information on the CompleteCoat coil

protective system. If you have a concern about coil corrosion

from most airborne contaminants, this is the right solution.

© 2010 Trane All rights reserved

RF-SLB007-EN May 03, 2010

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Comprehensive Guide to Composites: Processes & Procedures from the ProfessionalsFrom EverandA Comprehensive Guide to Composites: Processes & Procedures from the ProfessionalsRating: 5 out of 5 stars5/5 (2)

- The Elements of Boat Strength: For Builders, Designers, and OwnersFrom EverandThe Elements of Boat Strength: For Builders, Designers, and OwnersRating: 5 out of 5 stars5/5 (8)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Decorative Chromium Plating BasicsDocument8 pagesDecorative Chromium Plating Basicsm daneshpour100% (1)

- When Glass meets Pharma: Insights about glass as primary packaging materialFrom EverandWhen Glass meets Pharma: Insights about glass as primary packaging materialNo ratings yet

- Informe No. 3 " Determinación de Aluminio" AnalíticaDocument8 pagesInforme No. 3 " Determinación de Aluminio" AnalíticaDiegou Pinzón100% (1)

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Ceramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsFrom EverandCeramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsWalter KrenkelNo ratings yet

- Membranes for Energy ConversionFrom EverandMembranes for Energy ConversionKlaus-Viktor PeinemannNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Sustainable Renovation: Strategies for Commercial Building Systems and EnvelopeFrom EverandSustainable Renovation: Strategies for Commercial Building Systems and EnvelopeNo ratings yet

- Ceramics Science and Technology, Volume 4: ApplicationsFrom EverandCeramics Science and Technology, Volume 4: ApplicationsRalf RiedelNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- The Methods of Glass Blowing and of Working Silica in the Oxy-Gas Flame For the use of chemical and physical studentsFrom EverandThe Methods of Glass Blowing and of Working Silica in the Oxy-Gas Flame For the use of chemical and physical studentsNo ratings yet

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsFrom EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Dust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopFrom EverandDust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopNo ratings yet

- Metallic Oxynitride Thin Films by Reactive Sputtering and Related Deposition Methods: Process, Properties and ApplicationsFrom EverandMetallic Oxynitride Thin Films by Reactive Sputtering and Related Deposition Methods: Process, Properties and ApplicationsNo ratings yet

- Membrane Technology: in the Chemical IndustryFrom EverandMembrane Technology: in the Chemical IndustrySuzana Pereira NunesNo ratings yet

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- FDS FT Super 10WDocument10 pagesFDS FT Super 10WAlfredo Mamangueño FloresNo ratings yet

- Quimica Geral - EngenhariaDocument9 pagesQuimica Geral - Engenharia299b6z22tzNo ratings yet

- Organisation of The OrganismDocument4 pagesOrganisation of The Organismanotida marambaNo ratings yet

- Caso InnovacionDocument3 pagesCaso InnovacionNorma FillurenNo ratings yet

- Research ProposalDocument14 pagesResearch Proposaldelossantos.blueg8No ratings yet

- Iones Cationes y Aniones TeoriaDocument7 pagesIones Cationes y Aniones TeoriaLidia OrtegaNo ratings yet

- Farmaco DiapositivaDocument1 pageFarmaco Diapositivadaymari ccarolina chirino chirinoNo ratings yet

- Fiche CobaltDocument19 pagesFiche CobaltMPNo ratings yet

- Crudo Caño LimónDocument7 pagesCrudo Caño Limónica zonaorienteNo ratings yet

- Problemas y Generalidades de Electro-Refinación de CuDocument11 pagesProblemas y Generalidades de Electro-Refinación de CuCaroEllNo ratings yet

- 1Document2 pages1roxana madrizNo ratings yet

- Guía de Problemas Sobre Concentración de Soluciones (Resueltos) )Document4 pagesGuía de Problemas Sobre Concentración de Soluciones (Resueltos) )gabriel marcaNo ratings yet

- Chemistry ObservationDocument11 pagesChemistry ObservationMohammed FarhanNo ratings yet

- Radial, Axial or Dual View ICP: Which Do You Choose?: Manny Almeida Teledyne Leeman Labs, Inc. Hudson, NH 03031Document33 pagesRadial, Axial or Dual View ICP: Which Do You Choose?: Manny Almeida Teledyne Leeman Labs, Inc. Hudson, NH 03031Ridwan HarahapNo ratings yet

- Guia de Ejercicios Del Tema I. PPQ - t1-t1 - .Final. 29-04-2012Document8 pagesGuia de Ejercicios Del Tema I. PPQ - t1-t1 - .Final. 29-04-2012gabrielNo ratings yet

- WPS - 170-20 - Smaw-Precalificado para Calificacion de Soldador-1Document1 pageWPS - 170-20 - Smaw-Precalificado para Calificacion de Soldador-1antony bolivar100% (3)

- MisiónDocument16 pagesMisiónPaola CameloNo ratings yet

- Hds - Protector Impermeabilizante e Hidrofugante - MasisaDocument4 pagesHds - Protector Impermeabilizante e Hidrofugante - MasisaRobinson Francisco Torres CandiaNo ratings yet

- S4 - Hidrogeno, Oxigeno, AzufreDocument30 pagesS4 - Hidrogeno, Oxigeno, AzufreJuan Alex Osorio RomanNo ratings yet

- Solsperse Hyperdispersants Overview - 19-179712Document2 pagesSolsperse Hyperdispersants Overview - 19-179712Jose E BatistaNo ratings yet

- Casting Manufacturing Processes Fundamentals of Metal Casting Metals For CastingDocument47 pagesCasting Manufacturing Processes Fundamentals of Metal Casting Metals For CastingarobaidiNo ratings yet

- PPR DigitalDocument10 pagesPPR DigitalcamilaNo ratings yet

- Synthesizing, Characterizing, and Toxicity Evaluating of Phycocyanin-ZnO Nanorod Composites-A Back To Nature ApproachesDocument32 pagesSynthesizing, Characterizing, and Toxicity Evaluating of Phycocyanin-ZnO Nanorod Composites-A Back To Nature ApproachesHossein ShahbaniNo ratings yet

- Semana O4Document450 pagesSemana O4Daniels Felix Tinoco OrihuelaNo ratings yet

- AUBF LAB - Chemical Examination of UrineDocument7 pagesAUBF LAB - Chemical Examination of Urinecdsteenkamp18No ratings yet

- 鳞翅目昆虫肠道微生物的多样性及其与宿主的相互作用Document13 pages鳞翅目昆虫肠道微生物的多样性及其与宿主的相互作用tabaci BemisiaNo ratings yet

- Soja - Fixação BiológicaDocument35 pagesSoja - Fixação BiológicaRafael DelaiNo ratings yet