Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

13 viewsAT840 Steel Cladding Methodology

AT840 Steel Cladding Methodology

Uploaded by

John Rheynor MayoSteel cladding is attached to concrete using epoxy grout. The concrete surface is prepared, steel plates are installed with anchor bolts, and then epoxy grout is injected through ports in the steel plates to fully fill the space between the concrete and steel. Once cured, excess bolts and ports are cut off.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Weld Built Up ProcedureDocument4 pagesWeld Built Up ProcedureMohd Shafuaaz KassimNo ratings yet

- Method Statement Bundwall GSUT Spare Unit 3Document4 pagesMethod Statement Bundwall GSUT Spare Unit 3MarhendraNo ratings yet

- 4.0 FOREBAY - OkDocument6 pages4.0 FOREBAY - Okjarabos8609No ratings yet

- Bulletin Description: Escoweld 7505E/7530 Grout InstallationDocument6 pagesBulletin Description: Escoweld 7505E/7530 Grout InstallationECCNo ratings yet

- Repair of Concrete Pavement Using High Pressure InjectionDocument3 pagesRepair of Concrete Pavement Using High Pressure InjectionJohn Rheynor MayoNo ratings yet

- 1600e Epoxy Grout InstallationDocument6 pages1600e Epoxy Grout InstallationAli Mari BalochNo ratings yet

- Continuously Reinforced Concrete PavementDocument7 pagesContinuously Reinforced Concrete PavementtanujpadhyNo ratings yet

- 1.MS - FoundationDocument11 pages1.MS - FoundationMalik BilalNo ratings yet

- 03 315 06 FT Epóxico Proanchor - EliteDocument22 pages03 315 06 FT Epóxico Proanchor - EliteJose TorresNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- Ofs Light PavingDocument14 pagesOfs Light PavingMorgan SidesoNo ratings yet

- 7 Cracking in Epoxy GroutDocument7 pages7 Cracking in Epoxy GroutNicolas Enrique Palma Pereira100% (1)

- Size Cased (If Contract Documents Specify The Cased Method.)Document7 pagesSize Cased (If Contract Documents Specify The Cased Method.)jmpkumaraNo ratings yet

- 440 SbceilingsDocument2 pages440 Sbceilingsscribdatapinky.comNo ratings yet

- Epoxy Injection Specification: Low Temperature Low Mod InjectionDocument5 pagesEpoxy Injection Specification: Low Temperature Low Mod InjectionHarms GundamNo ratings yet

- Repairs of D-Wall Exposed ReinforcementDocument7 pagesRepairs of D-Wall Exposed Reinforcement陈勇No ratings yet

- Bridge Rehabilitation: Maintaining and Repairing Existing StructuresDocument114 pagesBridge Rehabilitation: Maintaining and Repairing Existing StructuresAyu Eki MaharatriNo ratings yet

- Plugs and ProfilesDocument43 pagesPlugs and ProfilesTariq SaydawiNo ratings yet

- 06 Specification Section036000 GroutingDocument4 pages06 Specification Section036000 GroutingOtceliban SarlNo ratings yet

- PosiTestAT C AddendumDocument4 pagesPosiTestAT C AddendumKatherine CamposNo ratings yet

- Electrofusion Welding HDPE PipeDocument4 pagesElectrofusion Welding HDPE PipeTRISTAR TEKZONENo ratings yet

- WaboElastoFlex Park 0408Document4 pagesWaboElastoFlex Park 0408Cristhian Alfonso Mandujano PérezNo ratings yet

- FloroBuild PT HT ArchSpec 1Document6 pagesFloroBuild PT HT ArchSpec 1Edwin MorochoNo ratings yet

- Project - Sport CityDocument30 pagesProject - Sport CityAdmin DepartmentNo ratings yet

- Ess Building Crack Repair Work Procedure For SBFS 02Document4 pagesEss Building Crack Repair Work Procedure For SBFS 02timothy ogbechieNo ratings yet

- New Home Inspections: Pre-Pour Slab Inspection Report and Defects ListDocument7 pagesNew Home Inspections: Pre-Pour Slab Inspection Report and Defects ListKEMARNo ratings yet

- Method Statement For The Installation of The Additional Steel Beam (For Mep Hangers and Ceiling Networks) Along Roof Beam in Main Terminal BuildingDocument2 pagesMethod Statement For The Installation of The Additional Steel Beam (For Mep Hangers and Ceiling Networks) Along Roof Beam in Main Terminal Buildingmd_rehan_2No ratings yet

- Method Statement Slip Form KerbsDocument4 pagesMethod Statement Slip Form KerbsEric Isidore AgossouNo ratings yet

- Spalling Is Break Away of Concrete Surface Which Often Extends To The Top Layers of Reinforcing SteelDocument6 pagesSpalling Is Break Away of Concrete Surface Which Often Extends To The Top Layers of Reinforcing SteelJasmi HusseinNo ratings yet

- Fabric Joint Installation ManualDocument3 pagesFabric Joint Installation ManualPato AltavillaNo ratings yet

- The Strong Internally Threaded Anchor With Unique 4-Way Expansion For Fixings in Aerated ConcreteDocument2 pagesThe Strong Internally Threaded Anchor With Unique 4-Way Expansion For Fixings in Aerated ConcreteSunil YadavNo ratings yet

- SMSGutter System Installation SpecificationDocument13 pagesSMSGutter System Installation SpecificationChristan Daniel RestorNo ratings yet

- TamRez 220-220TG (Epoxy Binder and - Injection Resin) MS R00 (1) - 1 - 1Document2 pagesTamRez 220-220TG (Epoxy Binder and - Injection Resin) MS R00 (1) - 1 - 1Patrick manuelNo ratings yet

- Access FittingDocument7 pagesAccess Fittingchakrapani vagish chandra pandeyNo ratings yet

- Method of Bored Piling Work Botanica Residence Project: Proposal Bore PileDocument3 pagesMethod of Bored Piling Work Botanica Residence Project: Proposal Bore PileNurfandy DewantoNo ratings yet

- Solar Car Park CanopyDocument6 pagesSolar Car Park CanopyAnish BabuNo ratings yet

- Basic Info TK-U.B.I Sleeves3Document17 pagesBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyNo ratings yet

- Tech SpecsDocument13 pagesTech SpecsZidd PerezNo ratings yet

- Defect Forensic Science-2Document45 pagesDefect Forensic Science-2Anonymous SwsxW9No ratings yet

- Section 514-Epoxy Coated Steel Reinforcement: 513.5 PaymentDocument4 pagesSection 514-Epoxy Coated Steel Reinforcement: 513.5 PaymentSuranga ManuNo ratings yet

- Formatrac Bendable Track - Specifications Ipc.1196 Rev8Document2 pagesFormatrac Bendable Track - Specifications Ipc.1196 Rev8sr2011glassNo ratings yet

- 8 Verti Crete Spec SheetDocument6 pages8 Verti Crete Spec SheetRobert R. TiinNo ratings yet

- Nitoflor ET Slurry PDFDocument4 pagesNitoflor ET Slurry PDFriverwilliamsNo ratings yet

- 330 Infiltration System Rev1703Document3 pages330 Infiltration System Rev1703Jovenal TuplanoNo ratings yet

- Final CIDCO Schedule (10-11)Document187 pagesFinal CIDCO Schedule (10-11)deepakhartalkarNo ratings yet

- Meramec Instructions 08Document11 pagesMeramec Instructions 08lian9358No ratings yet

- General Requirements and SOP For STOPAQ-EGS InstallationDocument7 pagesGeneral Requirements and SOP For STOPAQ-EGS InstallationNithin MathaiNo ratings yet

- Tks RP Retrieval Tool: Installation, Operation & Maintenance InstructionsDocument30 pagesTks RP Retrieval Tool: Installation, Operation & Maintenance Instructionssaiful anwarNo ratings yet

- Section 606 Bridge Restoration and Waterproofing With Concrete OverlaysDocument12 pagesSection 606 Bridge Restoration and Waterproofing With Concrete OverlaysSuranga ManuNo ratings yet

- Bolted Water Tank SpecsDocument7 pagesBolted Water Tank SpecsMakulay Ang BuhayNo ratings yet

- Florock Seamless Flooring Systems: Page 1 of 6 Florock Architectural Specification - Floroshop 8/16Document6 pagesFlorock Seamless Flooring Systems: Page 1 of 6 Florock Architectural Specification - Floroshop 8/16shashibagewadiNo ratings yet

- S04 Specification - PilesDocument4 pagesS04 Specification - Pilesemonson2.projectstechnologiesNo ratings yet

- MS For Sonic Logging - C487Document8 pagesMS For Sonic Logging - C487Anonymous S7Cq7ZDgPNo ratings yet

- Method Statement For Core CuttingDocument5 pagesMethod Statement For Core Cuttingahmedshah512No ratings yet

- DPWHDocument6 pagesDPWHEdwina EgeraNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- How to Build a Simple Three Bedroom Shipping Container HouseFrom EverandHow to Build a Simple Three Bedroom Shipping Container HouseRating: 4 out of 5 stars4/5 (2)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

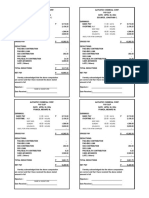

- Payroll 04.15 30.2024 Rheynor Moog - 6Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 6John Rheynor MayoNo ratings yet

- HTML5 Webook Page 24Document4 pagesHTML5 Webook Page 24John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 10Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 10John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 4Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 4John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 7Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 7John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 8Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 8John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 9Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 9John Rheynor MayoNo ratings yet

- Detailed Computation Balaasan BridgeDocument7 pagesDetailed Computation Balaasan BridgeJohn Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 11Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 11John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 3Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 3John Rheynor MayoNo ratings yet

- Acctg. Request Form (Arf)Document1 pageAcctg. Request Form (Arf)John Rheynor MayoNo ratings yet

- Detailed Computation Bucayao BridgeDocument7 pagesDetailed Computation Bucayao BridgeJohn Rheynor MayoNo ratings yet

- Ak 1271Document1 pageAk 1271John Rheynor MayoNo ratings yet

- Detailed Computation Baguin II BridgeDocument7 pagesDetailed Computation Baguin II BridgeJohn Rheynor MayoNo ratings yet

- 200 HardenerDocument3 pages200 HardenerJohn Rheynor MayoNo ratings yet

- PRE U-LOX GP M (New)Document3 pagesPRE U-LOX GP M (New)John Rheynor MayoNo ratings yet

- Daily Progress ReportDocument1 pageDaily Progress ReportJohn Rheynor MayoNo ratings yet

- Construction MethodsDocument1 pageConstruction MethodsJohn Rheynor MayoNo ratings yet

- Ak 3552Document1 pageAk 3552John Rheynor MayoNo ratings yet

- Ak 3511Document1 pageAk 3511John Rheynor MayoNo ratings yet

- U - Coat Base ResinDocument3 pagesU - Coat Base ResinJohn Rheynor MayoNo ratings yet

- Rebound Hammer - Rosario BridgeDocument2 pagesRebound Hammer - Rosario BridgeJohn Rheynor MayoNo ratings yet

- Construction ScheduleDocument1 pageConstruction ScheduleJohn Rheynor MayoNo ratings yet

- Hammer Test FormDocument1 pageHammer Test FormJohn Rheynor MayoNo ratings yet

- Slwo-0000000490 Alphatec Chemical CorporationDocument6 pagesSlwo-0000000490 Alphatec Chemical CorporationJohn Rheynor MayoNo ratings yet

- Contractors EHS Clearance - RevisedDocument2 pagesContractors EHS Clearance - RevisedJohn Rheynor MayoNo ratings yet

- Contractor's Information Sheet UPDATEDDocument2 pagesContractor's Information Sheet UPDATEDJohn Rheynor MayoNo ratings yet

- Rehabilitation Reconstruction of Roads With Slips, Slope Collapse and Landslide, TertDocument2 pagesRehabilitation Reconstruction of Roads With Slips, Slope Collapse and Landslide, TertJohn Rheynor MayoNo ratings yet

- Sample Detailed Manpower LoadingDocument1 pageSample Detailed Manpower LoadingJohn Rheynor MayoNo ratings yet

- Updated Memorandum For COVID 19 Guidelines and ProtocolDocument2 pagesUpdated Memorandum For COVID 19 Guidelines and ProtocolJohn Rheynor MayoNo ratings yet

AT840 Steel Cladding Methodology

AT840 Steel Cladding Methodology

Uploaded by

John Rheynor Mayo0 ratings0% found this document useful (0 votes)

13 views2 pagesSteel cladding is attached to concrete using epoxy grout. The concrete surface is prepared, steel plates are installed with anchor bolts, and then epoxy grout is injected through ports in the steel plates to fully fill the space between the concrete and steel. Once cured, excess bolts and ports are cut off.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSteel cladding is attached to concrete using epoxy grout. The concrete surface is prepared, steel plates are installed with anchor bolts, and then epoxy grout is injected through ports in the steel plates to fully fill the space between the concrete and steel. Once cured, excess bolts and ports are cut off.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

13 views2 pagesAT840 Steel Cladding Methodology

AT840 Steel Cladding Methodology

Uploaded by

John Rheynor MayoSteel cladding is attached to concrete using epoxy grout. The concrete surface is prepared, steel plates are installed with anchor bolts, and then epoxy grout is injected through ports in the steel plates to fully fill the space between the concrete and steel. Once cured, excess bolts and ports are cut off.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

STEEL CLADDING METHODOLOGY

USING ALPHATEC 840 EPOXY GROUT

1. Roughen the concrete surface by grinding and/or chipping. Clean prepared surface using

industrial vacuum or blower to remove dirt, dust and other foreign materials.

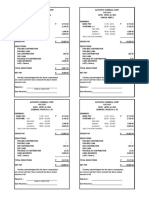

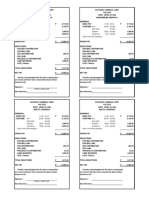

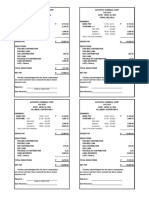

2. Installation of steel plates. (see details below)

Install anchor bolts using Alphatec 940NS (Fast Cure Epoxy Anchor Grout)

Top View

Steel Plate Details

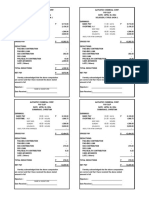

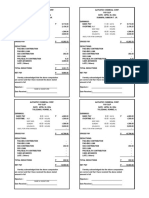

3. Grout injection using ALPHATEC 840.

Start injection on the lowest entry ports.

Once the grout exits the next adjacent entry ports, discontinue the grout injection and

seal the entry ports.

Then place the nozzle on the next adjacent ports and continue the grout injection.

Repeat the steps above until the entire / designed height of the steel cladding is filled with

grout.

Let the epoxy grout cure for 24hrs.

4. Cut the anchor bolts and entry ports using grinder with cutting disc.

You might also like

- Weld Built Up ProcedureDocument4 pagesWeld Built Up ProcedureMohd Shafuaaz KassimNo ratings yet

- Method Statement Bundwall GSUT Spare Unit 3Document4 pagesMethod Statement Bundwall GSUT Spare Unit 3MarhendraNo ratings yet

- 4.0 FOREBAY - OkDocument6 pages4.0 FOREBAY - Okjarabos8609No ratings yet

- Bulletin Description: Escoweld 7505E/7530 Grout InstallationDocument6 pagesBulletin Description: Escoweld 7505E/7530 Grout InstallationECCNo ratings yet

- Repair of Concrete Pavement Using High Pressure InjectionDocument3 pagesRepair of Concrete Pavement Using High Pressure InjectionJohn Rheynor MayoNo ratings yet

- 1600e Epoxy Grout InstallationDocument6 pages1600e Epoxy Grout InstallationAli Mari BalochNo ratings yet

- Continuously Reinforced Concrete PavementDocument7 pagesContinuously Reinforced Concrete PavementtanujpadhyNo ratings yet

- 1.MS - FoundationDocument11 pages1.MS - FoundationMalik BilalNo ratings yet

- 03 315 06 FT Epóxico Proanchor - EliteDocument22 pages03 315 06 FT Epóxico Proanchor - EliteJose TorresNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- Ofs Light PavingDocument14 pagesOfs Light PavingMorgan SidesoNo ratings yet

- 7 Cracking in Epoxy GroutDocument7 pages7 Cracking in Epoxy GroutNicolas Enrique Palma Pereira100% (1)

- Size Cased (If Contract Documents Specify The Cased Method.)Document7 pagesSize Cased (If Contract Documents Specify The Cased Method.)jmpkumaraNo ratings yet

- 440 SbceilingsDocument2 pages440 Sbceilingsscribdatapinky.comNo ratings yet

- Epoxy Injection Specification: Low Temperature Low Mod InjectionDocument5 pagesEpoxy Injection Specification: Low Temperature Low Mod InjectionHarms GundamNo ratings yet

- Repairs of D-Wall Exposed ReinforcementDocument7 pagesRepairs of D-Wall Exposed Reinforcement陈勇No ratings yet

- Bridge Rehabilitation: Maintaining and Repairing Existing StructuresDocument114 pagesBridge Rehabilitation: Maintaining and Repairing Existing StructuresAyu Eki MaharatriNo ratings yet

- Plugs and ProfilesDocument43 pagesPlugs and ProfilesTariq SaydawiNo ratings yet

- 06 Specification Section036000 GroutingDocument4 pages06 Specification Section036000 GroutingOtceliban SarlNo ratings yet

- PosiTestAT C AddendumDocument4 pagesPosiTestAT C AddendumKatherine CamposNo ratings yet

- Electrofusion Welding HDPE PipeDocument4 pagesElectrofusion Welding HDPE PipeTRISTAR TEKZONENo ratings yet

- WaboElastoFlex Park 0408Document4 pagesWaboElastoFlex Park 0408Cristhian Alfonso Mandujano PérezNo ratings yet

- FloroBuild PT HT ArchSpec 1Document6 pagesFloroBuild PT HT ArchSpec 1Edwin MorochoNo ratings yet

- Project - Sport CityDocument30 pagesProject - Sport CityAdmin DepartmentNo ratings yet

- Ess Building Crack Repair Work Procedure For SBFS 02Document4 pagesEss Building Crack Repair Work Procedure For SBFS 02timothy ogbechieNo ratings yet

- New Home Inspections: Pre-Pour Slab Inspection Report and Defects ListDocument7 pagesNew Home Inspections: Pre-Pour Slab Inspection Report and Defects ListKEMARNo ratings yet

- Method Statement For The Installation of The Additional Steel Beam (For Mep Hangers and Ceiling Networks) Along Roof Beam in Main Terminal BuildingDocument2 pagesMethod Statement For The Installation of The Additional Steel Beam (For Mep Hangers and Ceiling Networks) Along Roof Beam in Main Terminal Buildingmd_rehan_2No ratings yet

- Method Statement Slip Form KerbsDocument4 pagesMethod Statement Slip Form KerbsEric Isidore AgossouNo ratings yet

- Spalling Is Break Away of Concrete Surface Which Often Extends To The Top Layers of Reinforcing SteelDocument6 pagesSpalling Is Break Away of Concrete Surface Which Often Extends To The Top Layers of Reinforcing SteelJasmi HusseinNo ratings yet

- Fabric Joint Installation ManualDocument3 pagesFabric Joint Installation ManualPato AltavillaNo ratings yet

- The Strong Internally Threaded Anchor With Unique 4-Way Expansion For Fixings in Aerated ConcreteDocument2 pagesThe Strong Internally Threaded Anchor With Unique 4-Way Expansion For Fixings in Aerated ConcreteSunil YadavNo ratings yet

- SMSGutter System Installation SpecificationDocument13 pagesSMSGutter System Installation SpecificationChristan Daniel RestorNo ratings yet

- TamRez 220-220TG (Epoxy Binder and - Injection Resin) MS R00 (1) - 1 - 1Document2 pagesTamRez 220-220TG (Epoxy Binder and - Injection Resin) MS R00 (1) - 1 - 1Patrick manuelNo ratings yet

- Access FittingDocument7 pagesAccess Fittingchakrapani vagish chandra pandeyNo ratings yet

- Method of Bored Piling Work Botanica Residence Project: Proposal Bore PileDocument3 pagesMethod of Bored Piling Work Botanica Residence Project: Proposal Bore PileNurfandy DewantoNo ratings yet

- Solar Car Park CanopyDocument6 pagesSolar Car Park CanopyAnish BabuNo ratings yet

- Basic Info TK-U.B.I Sleeves3Document17 pagesBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyNo ratings yet

- Tech SpecsDocument13 pagesTech SpecsZidd PerezNo ratings yet

- Defect Forensic Science-2Document45 pagesDefect Forensic Science-2Anonymous SwsxW9No ratings yet

- Section 514-Epoxy Coated Steel Reinforcement: 513.5 PaymentDocument4 pagesSection 514-Epoxy Coated Steel Reinforcement: 513.5 PaymentSuranga ManuNo ratings yet

- Formatrac Bendable Track - Specifications Ipc.1196 Rev8Document2 pagesFormatrac Bendable Track - Specifications Ipc.1196 Rev8sr2011glassNo ratings yet

- 8 Verti Crete Spec SheetDocument6 pages8 Verti Crete Spec SheetRobert R. TiinNo ratings yet

- Nitoflor ET Slurry PDFDocument4 pagesNitoflor ET Slurry PDFriverwilliamsNo ratings yet

- 330 Infiltration System Rev1703Document3 pages330 Infiltration System Rev1703Jovenal TuplanoNo ratings yet

- Final CIDCO Schedule (10-11)Document187 pagesFinal CIDCO Schedule (10-11)deepakhartalkarNo ratings yet

- Meramec Instructions 08Document11 pagesMeramec Instructions 08lian9358No ratings yet

- General Requirements and SOP For STOPAQ-EGS InstallationDocument7 pagesGeneral Requirements and SOP For STOPAQ-EGS InstallationNithin MathaiNo ratings yet

- Tks RP Retrieval Tool: Installation, Operation & Maintenance InstructionsDocument30 pagesTks RP Retrieval Tool: Installation, Operation & Maintenance Instructionssaiful anwarNo ratings yet

- Section 606 Bridge Restoration and Waterproofing With Concrete OverlaysDocument12 pagesSection 606 Bridge Restoration and Waterproofing With Concrete OverlaysSuranga ManuNo ratings yet

- Bolted Water Tank SpecsDocument7 pagesBolted Water Tank SpecsMakulay Ang BuhayNo ratings yet

- Florock Seamless Flooring Systems: Page 1 of 6 Florock Architectural Specification - Floroshop 8/16Document6 pagesFlorock Seamless Flooring Systems: Page 1 of 6 Florock Architectural Specification - Floroshop 8/16shashibagewadiNo ratings yet

- S04 Specification - PilesDocument4 pagesS04 Specification - Pilesemonson2.projectstechnologiesNo ratings yet

- MS For Sonic Logging - C487Document8 pagesMS For Sonic Logging - C487Anonymous S7Cq7ZDgPNo ratings yet

- Method Statement For Core CuttingDocument5 pagesMethod Statement For Core Cuttingahmedshah512No ratings yet

- DPWHDocument6 pagesDPWHEdwina EgeraNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- How to Build a Simple Three Bedroom Shipping Container HouseFrom EverandHow to Build a Simple Three Bedroom Shipping Container HouseRating: 4 out of 5 stars4/5 (2)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Payroll 04.15 30.2024 Rheynor Moog - 6Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 6John Rheynor MayoNo ratings yet

- HTML5 Webook Page 24Document4 pagesHTML5 Webook Page 24John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 10Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 10John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 4Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 4John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 7Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 7John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 8Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 8John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 9Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 9John Rheynor MayoNo ratings yet

- Detailed Computation Balaasan BridgeDocument7 pagesDetailed Computation Balaasan BridgeJohn Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 11Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 11John Rheynor MayoNo ratings yet

- Payroll 04.15 30.2024 Rheynor Moog - 3Document1 pagePayroll 04.15 30.2024 Rheynor Moog - 3John Rheynor MayoNo ratings yet

- Acctg. Request Form (Arf)Document1 pageAcctg. Request Form (Arf)John Rheynor MayoNo ratings yet

- Detailed Computation Bucayao BridgeDocument7 pagesDetailed Computation Bucayao BridgeJohn Rheynor MayoNo ratings yet

- Ak 1271Document1 pageAk 1271John Rheynor MayoNo ratings yet

- Detailed Computation Baguin II BridgeDocument7 pagesDetailed Computation Baguin II BridgeJohn Rheynor MayoNo ratings yet

- 200 HardenerDocument3 pages200 HardenerJohn Rheynor MayoNo ratings yet

- PRE U-LOX GP M (New)Document3 pagesPRE U-LOX GP M (New)John Rheynor MayoNo ratings yet

- Daily Progress ReportDocument1 pageDaily Progress ReportJohn Rheynor MayoNo ratings yet

- Construction MethodsDocument1 pageConstruction MethodsJohn Rheynor MayoNo ratings yet

- Ak 3552Document1 pageAk 3552John Rheynor MayoNo ratings yet

- Ak 3511Document1 pageAk 3511John Rheynor MayoNo ratings yet

- U - Coat Base ResinDocument3 pagesU - Coat Base ResinJohn Rheynor MayoNo ratings yet

- Rebound Hammer - Rosario BridgeDocument2 pagesRebound Hammer - Rosario BridgeJohn Rheynor MayoNo ratings yet

- Construction ScheduleDocument1 pageConstruction ScheduleJohn Rheynor MayoNo ratings yet

- Hammer Test FormDocument1 pageHammer Test FormJohn Rheynor MayoNo ratings yet

- Slwo-0000000490 Alphatec Chemical CorporationDocument6 pagesSlwo-0000000490 Alphatec Chemical CorporationJohn Rheynor MayoNo ratings yet

- Contractors EHS Clearance - RevisedDocument2 pagesContractors EHS Clearance - RevisedJohn Rheynor MayoNo ratings yet

- Contractor's Information Sheet UPDATEDDocument2 pagesContractor's Information Sheet UPDATEDJohn Rheynor MayoNo ratings yet

- Rehabilitation Reconstruction of Roads With Slips, Slope Collapse and Landslide, TertDocument2 pagesRehabilitation Reconstruction of Roads With Slips, Slope Collapse and Landslide, TertJohn Rheynor MayoNo ratings yet

- Sample Detailed Manpower LoadingDocument1 pageSample Detailed Manpower LoadingJohn Rheynor MayoNo ratings yet

- Updated Memorandum For COVID 19 Guidelines and ProtocolDocument2 pagesUpdated Memorandum For COVID 19 Guidelines and ProtocolJohn Rheynor MayoNo ratings yet