Professional Documents

Culture Documents

Hawke Glands

Hawke Glands

Uploaded by

Ion NitaCopyright:

Available Formats

You might also like

- VNX - Su Kangoo 2 BRM PDFDocument626 pagesVNX - Su Kangoo 2 BRM PDFamotimoto100% (1)

- 501/423 Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/423 Cable Gland Type: Flameproof and Increased Safetymadhan rajNo ratings yet

- HAWKE GLAND-type OnlyDocument1 pageHAWKE GLAND-type OnlyJaaffer AliNo ratings yet

- Type 501-453-Universal PDFDocument1 pageType 501-453-Universal PDFwe202No ratings yet

- 501,453 Classified GlandDocument1 page501,453 Classified GlandMuhammad RamzanNo ratings yet

- Hawke Gland CatalogDocument1 pageHawke Gland CatalogIon NitaNo ratings yet

- 501/453/universal Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/453/universal Cable Gland Type: Flameproof and Increased SafetymahdimaziniNo ratings yet

- 501/421 Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/421 Cable Gland Type: Flameproof and Increased Safetywe202No ratings yet

- Unarmored Hawke Gland Datasheet 501-421Document1 pageUnarmored Hawke Gland Datasheet 501-421Sudeep SNo ratings yet

- 121 Cable Gland Type: Industrial General PurposeDocument1 page121 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Hawke 501 - 423 DatasheetDocument2 pagesHawke 501 - 423 DatasheetjaybnovemNo ratings yet

- Hawke - CableGland - 501 - 421 - Compression - Jan 2022Document2 pagesHawke - CableGland - 501 - 421 - Compression - Jan 2022Mohammad Nabil AbdullahNo ratings yet

- 501/453 UNIVERSAL Hazardous Area Cable GlandDocument1 page501/453 UNIVERSAL Hazardous Area Cable Glandhashmin karuvathilNo ratings yet

- HKE 114 Industrial Cable-Gland DatasheetDocument1 pageHKE 114 Industrial Cable-Gland DatasheetSai KamalaNo ratings yet

- Hawke CableGland 501 421Document2 pagesHawke CableGland 501 421rajdavid9655No ratings yet

- Hawke CableGland 501 453 RAC Compression V6Document2 pagesHawke CableGland 501 453 RAC Compression V6Ing ZenerNo ratings yet

- Hawke CableGland 121 Industrial June2019Document1 pageHawke CableGland 121 Industrial June2019Jalal AlbadriNo ratings yet

- Cable Gland 501 Hazardous Type 501 - 421Document1 pageCable Gland 501 Hazardous Type 501 - 421rhomadonaNo ratings yet

- 150 RacDocument1 page150 RacM Umar ChatthaNo ratings yet

- 753 Cable Gland Type: Explosion ProofDocument1 page753 Cable Gland Type: Explosion Proofwe202No ratings yet

- Hawke 501Document1 pageHawke 501Nurdin MubarokNo ratings yet

- GlandDocument2 pagesGlandhtc one x9No ratings yet

- CATALOG 153 GLAND HAWKE - O-0.5in NPTDocument1 pageCATALOG 153 GLAND HAWKE - O-0.5in NPTgalfandraNo ratings yet

- 501-453 Universal Cable GalndsDocument1 page501-453 Universal Cable Galndsmeribout adelNo ratings yet

- Cable Glands: IndustrialDocument1 pageCable Glands: IndustrialM Umar ChatthaNo ratings yet

- 701 Cable Gland Type: Industrial General PurposeDocument1 page701 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Hawke 501 423 Cable Glands SpecificationDocument1 pageHawke 501 423 Cable Glands SpecificationHashmin KaruvathilNo ratings yet

- Hawke 501 421 Cable Gland SpecificationDocument1 pageHawke 501 421 Cable Gland SpecificationIndra GunawanNo ratings yet

- Hawke CableGland 153 UNIV Industrial Jan-2022Document2 pagesHawke CableGland 153 UNIV Industrial Jan-2022RamzzzNo ratings yet

- Hke - 501 453 Univ (Upd260318)Document1 pageHke - 501 453 Univ (Upd260318)pneuma110No ratings yet

- DEL Assembly InstructionsDocument8 pagesDEL Assembly InstructionsKarl Ove BlindheimNo ratings yet

- 501/453/UNIV: Cable Gland Selection TableDocument1 page501/453/UNIV: Cable Gland Selection TableAkmalNo ratings yet

- Application: Flameproof, Increased Safety, Dust Protection Class - Zones - Divisions Certifi Ed Atex / IecexDocument1 pageApplication: Flameproof, Increased Safety, Dust Protection Class - Zones - Divisions Certifi Ed Atex / IecexrhomadonaNo ratings yet

- 501 453 UnivDocument1 page501 453 UnivVishnu LalNo ratings yet

- HKE Cable Glands CatalogueDocument17 pagesHKE Cable Glands Cataloguesogetsu kazamaNo ratings yet

- HAWKE 501-453-RacDocument1 pageHAWKE 501-453-RacJaaffer AliNo ratings yet

- 501 453 RacDocument1 page501 453 RacqaedNo ratings yet

- Single Core Insulated and Sheathed PDFDocument1 pageSingle Core Insulated and Sheathed PDFalamNo ratings yet

- Single Core Insulated and SheathedDocument1 pageSingle Core Insulated and SheathedImthiyasNo ratings yet

- 153/RAC/L: Cable Gland Selection TableDocument2 pages153/RAC/L: Cable Gland Selection TableManikandan ShriNo ratings yet

- DQM IiDocument2 pagesDQM IiLucas MorenoNo ratings yet

- Cable Gland Types E1W, E2W, E1X, E2X, E1U & E2UDocument2 pagesCable Gland Types E1W, E2W, E1X, E2X, E1U & E2UWidhi ImranovichNo ratings yet

- 1mil C 7078 7Document5 pages1mil C 7078 7Agz HrrfNo ratings yet

- Branch v06Document4 pagesBranch v06Kerr AgotNo ratings yet

- Hawke CableGland 153 UNIV Industrial V2Document1 pageHawke CableGland 153 UNIV Industrial V2Saqib JavedNo ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- Sy LSZH Control Flexible CableDocument3 pagesSy LSZH Control Flexible Cableandy175No ratings yet

- Cold Shrink: QSG - AP SerieDocument2 pagesCold Shrink: QSG - AP SerieAVA VANo ratings yet

- Type 501 453 UniversalDocument1 pageType 501 453 Universalrambala123No ratings yet

- Microcell Foam Dielectric: Size 2 1/4" 1 5/8" 1 1/4" 7/8"Document2 pagesMicrocell Foam Dielectric: Size 2 1/4" 1 5/8" 1 1/4" 7/8"Look ManNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument20 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesbalaasenthilNo ratings yet

- Pipes Flexnetflexible Pipes-2020Document12 pagesPipes Flexnetflexible Pipes-2020Bengaluru CommonmanNo ratings yet

- Cable Gland Types E1FW/M, E1FX/M, E1FU/M E1Fw/Mf, E1Fx/Mf, E1Fu/MfDocument2 pagesCable Gland Types E1FW/M, E1FX/M, E1FU/M E1Fw/Mf, E1Fx/Mf, E1Fu/MfRyan Mesina De GuzmanNo ratings yet

- Patch Cord PVCDocument2 pagesPatch Cord PVCRicardo PerezNo ratings yet

- 501/453/UNIV: Cable Gland Selection TableDocument2 pages501/453/UNIV: Cable Gland Selection TableIng ZenerNo ratings yet

- 501/453 UNIVERSAL: Cable Gland Selection TableDocument2 pages501/453 UNIVERSAL: Cable Gland Selection TableManikandan ShriNo ratings yet

- D-SUB Bus Connector - SUBCON-PLUS-M/AX 9 - 2904467: Product DescriptionDocument6 pagesD-SUB Bus Connector - SUBCON-PLUS-M/AX 9 - 2904467: Product Descriptionpietro zugnoniNo ratings yet

- 501 453 Universal ColdFlowDocument2 pages501 453 Universal ColdFlowRavi VarmaNo ratings yet

- Familydatasheet - 536941171 enDocument2 pagesFamilydatasheet - 536941171 enGajanan GaikwadNo ratings yet

- Practical Industrial Data Networks: Design, Installation and TroubleshootingFrom EverandPractical Industrial Data Networks: Design, Installation and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Surge Suppression Diagram Ross HillDocument1 pageSurge Suppression Diagram Ross HillIon Nita100% (1)

- Eaton CE15NN3TDocument2 pagesEaton CE15NN3TIon NitaNo ratings yet

- mb2018cc 9 en Us 5153280Document2 pagesmb2018cc 9 en Us 5153280Ion NitaNo ratings yet

- AmeriMex Blower MotorDocument3 pagesAmeriMex Blower MotorIon NitaNo ratings yet

- Model 780-001 Indoor Explosion-Proof Single Party Handset StationDocument2 pagesModel 780-001 Indoor Explosion-Proof Single Party Handset StationIon NitaNo ratings yet

- B U L L E T I N: Application EngineeringDocument18 pagesB U L L E T I N: Application EngineeringIon NitaNo ratings yet

- Semi-Hermetic Air-Cooled Condensing Units: R22 Discus KW (60Hz)Document4 pagesSemi-Hermetic Air-Cooled Condensing Units: R22 Discus KW (60Hz)Ion NitaNo ratings yet

- #24 Standards and Standards OrganizationsDocument3 pages#24 Standards and Standards OrganizationsnicolasNo ratings yet

- Fiber Rope SlingsDocument8 pagesFiber Rope SlingsLeudys Palma100% (1)

- DMEGC Solar PV Modules Installation Manual V202206Document16 pagesDMEGC Solar PV Modules Installation Manual V202206Yannick CourbonNo ratings yet

- Stepper Vs ServoDocument3 pagesStepper Vs ServoSanan RasheedNo ratings yet

- App Security GuideDocument302 pagesApp Security GuideDuncan NgachaNo ratings yet

- 902, 906 & 908 Compact Wheel L PDFDocument12 pages902, 906 & 908 Compact Wheel L PDFKasidinNo ratings yet

- Assignments - OS and Web Technologies V1 0Document7 pagesAssignments - OS and Web Technologies V1 0api-3710084No ratings yet

- Coalition For Good Governance: 7035 Marching Duck Drive E504 Charlotte, NC 28210 704 552 1618Document18 pagesCoalition For Good Governance: 7035 Marching Duck Drive E504 Charlotte, NC 28210 704 552 1618Coalition for Good GovernanceNo ratings yet

- Nuwe OT 020 - User ManualDocument14 pagesNuwe OT 020 - User Manualchito040570100% (1)

- BWF Envirotec - How To Install A FilterbagDocument17 pagesBWF Envirotec - How To Install A Filterbagalvarikokex100% (2)

- Layer 3 Message in GSMDocument16 pagesLayer 3 Message in GSMFarukh MunirNo ratings yet

- 2013-05-17 RFQ F14 FormsDocument8 pages2013-05-17 RFQ F14 FormsKatneza Katman MohlalaNo ratings yet

- Piping Info - Pipe Support Design GuidelinesDocument4 pagesPiping Info - Pipe Support Design GuidelinesSUSHANTBIJAM100% (1)

- Brochure Liberoassurance Iso Certification Services 2021Document2 pagesBrochure Liberoassurance Iso Certification Services 2021fidanniNo ratings yet

- Fuel Pro Installation Instructions FH230 Series Filter / Separator / WarmerDocument8 pagesFuel Pro Installation Instructions FH230 Series Filter / Separator / WarmerChristian Vásquez Basilio0% (1)

- Rest APIDocument3 pagesRest APIVishnu VardhanNo ratings yet

- Snort - An Network Intrusion Prevention and Detection SystemDocument20 pagesSnort - An Network Intrusion Prevention and Detection SystemChintanNo ratings yet

- PC-lint Plus Factsheet ENDocument2 pagesPC-lint Plus Factsheet ENChaos XiaNo ratings yet

- Hiper Ring Vs RSTP WPDocument37 pagesHiper Ring Vs RSTP WPsybaritzNo ratings yet

- BSI - EN 23125 2010 Turning MachinesDocument86 pagesBSI - EN 23125 2010 Turning MachinesEsdrasmec13100% (1)

- Information Security Management SystemDocument3 pagesInformation Security Management SystemShubham SarkarNo ratings yet

- White Paper Bi S For HPV Crp001 MKT 041Document4 pagesWhite Paper Bi S For HPV Crp001 MKT 041vijayns_250355172No ratings yet

- BOOTP - DHCP Option 82, Relay Agent Information PDFDocument3 pagesBOOTP - DHCP Option 82, Relay Agent Information PDFAmari MalikNo ratings yet

- Gas Insulated Switchgear and GIS Substation Essentials1Document4 pagesGas Insulated Switchgear and GIS Substation Essentials1Mishra Sanjib0% (1)

- Description: Data Cable, U/UTP, Category 6, AWG23, Euroclass CDocument2 pagesDescription: Data Cable, U/UTP, Category 6, AWG23, Euroclass Cosmanovic2020No ratings yet

- PR4000 InstructionManualDocument69 pagesPR4000 InstructionManualzelanNo ratings yet

- PROFIBUS Project: Practical Steps For A SuccessfulDocument42 pagesPROFIBUS Project: Practical Steps For A Successfulrajfab100% (1)

- How To Hack WifiDocument10 pagesHow To Hack WifiJakyy100% (1)

- Ali Linux CommandsDocument17 pagesAli Linux CommandsrediNo ratings yet

Hawke Glands

Hawke Glands

Uploaded by

Ion NitaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hawke Glands

Hawke Glands

Uploaded by

Ion NitaCopyright:

Available Formats

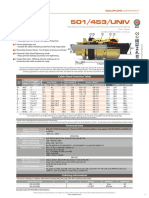

'H' 'G' Approx (Compressed Length) Cable Gland Type

Metric

Entry

501/423

ATEX

Entry Thread

Ø 'B'

Flameproof and Increased Safety

CABLE GLAND SELECTION TABLE Application

Outdoor or Indoor use.

Cable Acceptance Details

Entry Thread Hexagon For use with non-armoured

Size Thread Outer Sheath 'B' elastomer and plastic insulated

Size Dimensions

Length Standard Alternative 'G' cables.

Ref. NPT* 'H' Seal Seal (S) Across Across May be used on cables incorporating

Metric Std./

Option Min. Max. Min. Max. Flats Corners inner and outer cable sheaths.

Os M20 2 ½" See technical section of catalogue for

15.0 3.0 8.0 - - 52.3 24.0

501/423 Cable Gland

27.7

installation rules and regulations.

O M20 2 ½" 15.0 7.5 11.9 - - 52.3 24.0 27.7

A M20 ¾"/½" 15.0 11.0 14.3 8.5 13.4 51.5 30.0 34.6

B M25 1"/¾" 15.0 13.0 20.2 9.5 15.4 54.7 36.0 41.6

C M32 1¼"/1" 15.0 19.0 26.5 15.5 21.2 55.9 46.0 53.1 Features

C2 M40 1½"/1¼" 32.5 22.0 28.0 63.5 Provides a cable retention seal

15.0 25.0 58.1 55.0

D M50 2"/1½" 44.4/42.3 1 27.5 34.8 onto the cables outer sheath at two

15.0 31.5 74.3 65.0 75.1

independent sealing points.

E M63 2½"/2" 15.0 42.5 56.3/54.3 1 39.0 46.5 73.2 80.0 92.4 When used in increased safety

F M75 3"/2½" 15.0 54.5 68.2/65.3 1 48.5 58.3 75 95.0 109.6 applications, this cable gland may be

G M80 3½" 20.0 67.0 73.0 - - 68 106.4 123.0 used with braided cable where the

H M90 3½" 20.0 67.0 77.6 - - 68 115.0 132.8 braid and the cables outer sheath

J M100 4" 20.0 75.0 91.6 - - 68 127.0 146.7 pass into the enclosure.

1 Smaller

The braid must be suitably terminated

value is applicable when selecting reduced NPT entry option.

2 Sizes

inside the enclosure.

Os and O are available with an M16 thread size. For O size with M16

thread, the maximum cable outer sheath diameter is 10.9mm.

Os - F size metric entry threads are 1.5mm pitch as standard. For G size cable glands

and above, a 2mm pitch is supplied as standard (1.5mm pitch with 15mm length of

thread can be supplied) please specifiy when ordering. Technical Data

Flameproof EExd and Increased

General Information Safety EExe. II 2 GD

All dimensions in millimetres (except* where dimensions are in inches). Baseefa Certificate No.

Assembly instruction data sheet No. A.I. 306. For sizes Os to J. BAS 01 ATEX 2071X. For Os - F.

Baseefa Certificate No.

Accessories including locknuts, sealing washers, serrated washers, earth tags,

BAS 01 ATEX 2295X. For G - J.

shrouds, adaptors and reducers available. See pages 44 - 48.

Suitable for use in Zone 1, Zone 2,

Zone 21 and Zone 22.

Suitable for use in Gas Groups

IIA, IIB and IIC.

Materials & Finishes Construction and test standards

The 501/423 cable gland is manufactured as standard in brass, stainless steel EN 50014, EN 50018, EN 50019

and aluminium. and EN 50281-1-1.

NPT entries, nickel plated as standard. Full nickel plating available. IEC 60079-0, IEC 60079-1 and

IEC 60079-7.

IP66, IP67 and IP68 (30 metres for 7 days)

ingress protection to IEC 60529,

Cable Gland Ordering Examples EN 60529 and NEMA 4X.

Cable Gland Type/Size/Thread DTS01 deluge protection certified

by ITS. Additional deluge protection

e.g. 501/423/C/M32 seal also available.

501/423/C/1¼" NPT Operating temperature range

-60°C to +100°C as standard.

Alternative Certification Options Available.

Exd IIC/Exe II.

Cable Gland with Alternative Seal (S)

BR-Exd IIC/Exe II.

e.g. 501/423/C/M32/S AUS-Exd IIC/Exe II.

501/423/C/1¼" NPT/S

To the best of our knowledge the information contained in this leaflet, All copyright reserved-Hubbell Ltd 2004. This document and

is accurate at the time of going to print and the company reserves the all copyright therein is the property of: Hawke International a division

Smarter products right to improve or modify any product illustrated without notification. of Hubbell Ltd (A member of the Hubbell Group of Companies).

Copyright Condition: This document shall be used only for the purpose for which

www.ehawke.com The company is unable to accept liability for any inaccuracies, errors or

omissions that may exist. It is the customer's responsibility to ensure

it is provided and no reproduction or publication of the document may be made International

and no article may be manufactured or assembled in accordance with information

that the product is suitable for their application.

contained in the document without prior written consent of the owner.

HWK21 Feb '04

You might also like

- VNX - Su Kangoo 2 BRM PDFDocument626 pagesVNX - Su Kangoo 2 BRM PDFamotimoto100% (1)

- 501/423 Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/423 Cable Gland Type: Flameproof and Increased Safetymadhan rajNo ratings yet

- HAWKE GLAND-type OnlyDocument1 pageHAWKE GLAND-type OnlyJaaffer AliNo ratings yet

- Type 501-453-Universal PDFDocument1 pageType 501-453-Universal PDFwe202No ratings yet

- 501,453 Classified GlandDocument1 page501,453 Classified GlandMuhammad RamzanNo ratings yet

- Hawke Gland CatalogDocument1 pageHawke Gland CatalogIon NitaNo ratings yet

- 501/453/universal Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/453/universal Cable Gland Type: Flameproof and Increased SafetymahdimaziniNo ratings yet

- 501/421 Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/421 Cable Gland Type: Flameproof and Increased Safetywe202No ratings yet

- Unarmored Hawke Gland Datasheet 501-421Document1 pageUnarmored Hawke Gland Datasheet 501-421Sudeep SNo ratings yet

- 121 Cable Gland Type: Industrial General PurposeDocument1 page121 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Hawke 501 - 423 DatasheetDocument2 pagesHawke 501 - 423 DatasheetjaybnovemNo ratings yet

- Hawke - CableGland - 501 - 421 - Compression - Jan 2022Document2 pagesHawke - CableGland - 501 - 421 - Compression - Jan 2022Mohammad Nabil AbdullahNo ratings yet

- 501/453 UNIVERSAL Hazardous Area Cable GlandDocument1 page501/453 UNIVERSAL Hazardous Area Cable Glandhashmin karuvathilNo ratings yet

- HKE 114 Industrial Cable-Gland DatasheetDocument1 pageHKE 114 Industrial Cable-Gland DatasheetSai KamalaNo ratings yet

- Hawke CableGland 501 421Document2 pagesHawke CableGland 501 421rajdavid9655No ratings yet

- Hawke CableGland 501 453 RAC Compression V6Document2 pagesHawke CableGland 501 453 RAC Compression V6Ing ZenerNo ratings yet

- Hawke CableGland 121 Industrial June2019Document1 pageHawke CableGland 121 Industrial June2019Jalal AlbadriNo ratings yet

- Cable Gland 501 Hazardous Type 501 - 421Document1 pageCable Gland 501 Hazardous Type 501 - 421rhomadonaNo ratings yet

- 150 RacDocument1 page150 RacM Umar ChatthaNo ratings yet

- 753 Cable Gland Type: Explosion ProofDocument1 page753 Cable Gland Type: Explosion Proofwe202No ratings yet

- Hawke 501Document1 pageHawke 501Nurdin MubarokNo ratings yet

- GlandDocument2 pagesGlandhtc one x9No ratings yet

- CATALOG 153 GLAND HAWKE - O-0.5in NPTDocument1 pageCATALOG 153 GLAND HAWKE - O-0.5in NPTgalfandraNo ratings yet

- 501-453 Universal Cable GalndsDocument1 page501-453 Universal Cable Galndsmeribout adelNo ratings yet

- Cable Glands: IndustrialDocument1 pageCable Glands: IndustrialM Umar ChatthaNo ratings yet

- 701 Cable Gland Type: Industrial General PurposeDocument1 page701 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Hawke 501 423 Cable Glands SpecificationDocument1 pageHawke 501 423 Cable Glands SpecificationHashmin KaruvathilNo ratings yet

- Hawke 501 421 Cable Gland SpecificationDocument1 pageHawke 501 421 Cable Gland SpecificationIndra GunawanNo ratings yet

- Hawke CableGland 153 UNIV Industrial Jan-2022Document2 pagesHawke CableGland 153 UNIV Industrial Jan-2022RamzzzNo ratings yet

- Hke - 501 453 Univ (Upd260318)Document1 pageHke - 501 453 Univ (Upd260318)pneuma110No ratings yet

- DEL Assembly InstructionsDocument8 pagesDEL Assembly InstructionsKarl Ove BlindheimNo ratings yet

- 501/453/UNIV: Cable Gland Selection TableDocument1 page501/453/UNIV: Cable Gland Selection TableAkmalNo ratings yet

- Application: Flameproof, Increased Safety, Dust Protection Class - Zones - Divisions Certifi Ed Atex / IecexDocument1 pageApplication: Flameproof, Increased Safety, Dust Protection Class - Zones - Divisions Certifi Ed Atex / IecexrhomadonaNo ratings yet

- 501 453 UnivDocument1 page501 453 UnivVishnu LalNo ratings yet

- HKE Cable Glands CatalogueDocument17 pagesHKE Cable Glands Cataloguesogetsu kazamaNo ratings yet

- HAWKE 501-453-RacDocument1 pageHAWKE 501-453-RacJaaffer AliNo ratings yet

- 501 453 RacDocument1 page501 453 RacqaedNo ratings yet

- Single Core Insulated and Sheathed PDFDocument1 pageSingle Core Insulated and Sheathed PDFalamNo ratings yet

- Single Core Insulated and SheathedDocument1 pageSingle Core Insulated and SheathedImthiyasNo ratings yet

- 153/RAC/L: Cable Gland Selection TableDocument2 pages153/RAC/L: Cable Gland Selection TableManikandan ShriNo ratings yet

- DQM IiDocument2 pagesDQM IiLucas MorenoNo ratings yet

- Cable Gland Types E1W, E2W, E1X, E2X, E1U & E2UDocument2 pagesCable Gland Types E1W, E2W, E1X, E2X, E1U & E2UWidhi ImranovichNo ratings yet

- 1mil C 7078 7Document5 pages1mil C 7078 7Agz HrrfNo ratings yet

- Branch v06Document4 pagesBranch v06Kerr AgotNo ratings yet

- Hawke CableGland 153 UNIV Industrial V2Document1 pageHawke CableGland 153 UNIV Industrial V2Saqib JavedNo ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- Sy LSZH Control Flexible CableDocument3 pagesSy LSZH Control Flexible Cableandy175No ratings yet

- Cold Shrink: QSG - AP SerieDocument2 pagesCold Shrink: QSG - AP SerieAVA VANo ratings yet

- Type 501 453 UniversalDocument1 pageType 501 453 Universalrambala123No ratings yet

- Microcell Foam Dielectric: Size 2 1/4" 1 5/8" 1 1/4" 7/8"Document2 pagesMicrocell Foam Dielectric: Size 2 1/4" 1 5/8" 1 1/4" 7/8"Look ManNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument20 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesbalaasenthilNo ratings yet

- Pipes Flexnetflexible Pipes-2020Document12 pagesPipes Flexnetflexible Pipes-2020Bengaluru CommonmanNo ratings yet

- Cable Gland Types E1FW/M, E1FX/M, E1FU/M E1Fw/Mf, E1Fx/Mf, E1Fu/MfDocument2 pagesCable Gland Types E1FW/M, E1FX/M, E1FU/M E1Fw/Mf, E1Fx/Mf, E1Fu/MfRyan Mesina De GuzmanNo ratings yet

- Patch Cord PVCDocument2 pagesPatch Cord PVCRicardo PerezNo ratings yet

- 501/453/UNIV: Cable Gland Selection TableDocument2 pages501/453/UNIV: Cable Gland Selection TableIng ZenerNo ratings yet

- 501/453 UNIVERSAL: Cable Gland Selection TableDocument2 pages501/453 UNIVERSAL: Cable Gland Selection TableManikandan ShriNo ratings yet

- D-SUB Bus Connector - SUBCON-PLUS-M/AX 9 - 2904467: Product DescriptionDocument6 pagesD-SUB Bus Connector - SUBCON-PLUS-M/AX 9 - 2904467: Product Descriptionpietro zugnoniNo ratings yet

- 501 453 Universal ColdFlowDocument2 pages501 453 Universal ColdFlowRavi VarmaNo ratings yet

- Familydatasheet - 536941171 enDocument2 pagesFamilydatasheet - 536941171 enGajanan GaikwadNo ratings yet

- Practical Industrial Data Networks: Design, Installation and TroubleshootingFrom EverandPractical Industrial Data Networks: Design, Installation and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Surge Suppression Diagram Ross HillDocument1 pageSurge Suppression Diagram Ross HillIon Nita100% (1)

- Eaton CE15NN3TDocument2 pagesEaton CE15NN3TIon NitaNo ratings yet

- mb2018cc 9 en Us 5153280Document2 pagesmb2018cc 9 en Us 5153280Ion NitaNo ratings yet

- AmeriMex Blower MotorDocument3 pagesAmeriMex Blower MotorIon NitaNo ratings yet

- Model 780-001 Indoor Explosion-Proof Single Party Handset StationDocument2 pagesModel 780-001 Indoor Explosion-Proof Single Party Handset StationIon NitaNo ratings yet

- B U L L E T I N: Application EngineeringDocument18 pagesB U L L E T I N: Application EngineeringIon NitaNo ratings yet

- Semi-Hermetic Air-Cooled Condensing Units: R22 Discus KW (60Hz)Document4 pagesSemi-Hermetic Air-Cooled Condensing Units: R22 Discus KW (60Hz)Ion NitaNo ratings yet

- #24 Standards and Standards OrganizationsDocument3 pages#24 Standards and Standards OrganizationsnicolasNo ratings yet

- Fiber Rope SlingsDocument8 pagesFiber Rope SlingsLeudys Palma100% (1)

- DMEGC Solar PV Modules Installation Manual V202206Document16 pagesDMEGC Solar PV Modules Installation Manual V202206Yannick CourbonNo ratings yet

- Stepper Vs ServoDocument3 pagesStepper Vs ServoSanan RasheedNo ratings yet

- App Security GuideDocument302 pagesApp Security GuideDuncan NgachaNo ratings yet

- 902, 906 & 908 Compact Wheel L PDFDocument12 pages902, 906 & 908 Compact Wheel L PDFKasidinNo ratings yet

- Assignments - OS and Web Technologies V1 0Document7 pagesAssignments - OS and Web Technologies V1 0api-3710084No ratings yet

- Coalition For Good Governance: 7035 Marching Duck Drive E504 Charlotte, NC 28210 704 552 1618Document18 pagesCoalition For Good Governance: 7035 Marching Duck Drive E504 Charlotte, NC 28210 704 552 1618Coalition for Good GovernanceNo ratings yet

- Nuwe OT 020 - User ManualDocument14 pagesNuwe OT 020 - User Manualchito040570100% (1)

- BWF Envirotec - How To Install A FilterbagDocument17 pagesBWF Envirotec - How To Install A Filterbagalvarikokex100% (2)

- Layer 3 Message in GSMDocument16 pagesLayer 3 Message in GSMFarukh MunirNo ratings yet

- 2013-05-17 RFQ F14 FormsDocument8 pages2013-05-17 RFQ F14 FormsKatneza Katman MohlalaNo ratings yet

- Piping Info - Pipe Support Design GuidelinesDocument4 pagesPiping Info - Pipe Support Design GuidelinesSUSHANTBIJAM100% (1)

- Brochure Liberoassurance Iso Certification Services 2021Document2 pagesBrochure Liberoassurance Iso Certification Services 2021fidanniNo ratings yet

- Fuel Pro Installation Instructions FH230 Series Filter / Separator / WarmerDocument8 pagesFuel Pro Installation Instructions FH230 Series Filter / Separator / WarmerChristian Vásquez Basilio0% (1)

- Rest APIDocument3 pagesRest APIVishnu VardhanNo ratings yet

- Snort - An Network Intrusion Prevention and Detection SystemDocument20 pagesSnort - An Network Intrusion Prevention and Detection SystemChintanNo ratings yet

- PC-lint Plus Factsheet ENDocument2 pagesPC-lint Plus Factsheet ENChaos XiaNo ratings yet

- Hiper Ring Vs RSTP WPDocument37 pagesHiper Ring Vs RSTP WPsybaritzNo ratings yet

- BSI - EN 23125 2010 Turning MachinesDocument86 pagesBSI - EN 23125 2010 Turning MachinesEsdrasmec13100% (1)

- Information Security Management SystemDocument3 pagesInformation Security Management SystemShubham SarkarNo ratings yet

- White Paper Bi S For HPV Crp001 MKT 041Document4 pagesWhite Paper Bi S For HPV Crp001 MKT 041vijayns_250355172No ratings yet

- BOOTP - DHCP Option 82, Relay Agent Information PDFDocument3 pagesBOOTP - DHCP Option 82, Relay Agent Information PDFAmari MalikNo ratings yet

- Gas Insulated Switchgear and GIS Substation Essentials1Document4 pagesGas Insulated Switchgear and GIS Substation Essentials1Mishra Sanjib0% (1)

- Description: Data Cable, U/UTP, Category 6, AWG23, Euroclass CDocument2 pagesDescription: Data Cable, U/UTP, Category 6, AWG23, Euroclass Cosmanovic2020No ratings yet

- PR4000 InstructionManualDocument69 pagesPR4000 InstructionManualzelanNo ratings yet

- PROFIBUS Project: Practical Steps For A SuccessfulDocument42 pagesPROFIBUS Project: Practical Steps For A Successfulrajfab100% (1)

- How To Hack WifiDocument10 pagesHow To Hack WifiJakyy100% (1)

- Ali Linux CommandsDocument17 pagesAli Linux CommandsrediNo ratings yet