Professional Documents

Culture Documents

PWPS 005

PWPS 005

Uploaded by

Mehrdad RezaeiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWPS 005

PWPS 005

Uploaded by

Mehrdad RezaeiCopyright:

Available Formats

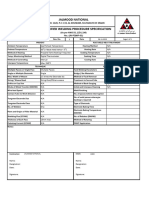

LOGO BASRA STEEL COMPANY LOGO

WELDING PROCEDURE SPECIFICATION

(PLATFORM)

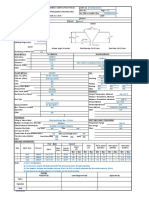

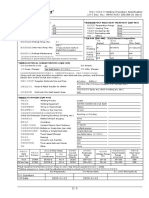

. WPS No. MAJED COMPANY -AWS-005 Rev. 0 JOINTS

Rev. 0 Joints Design Groove

Welding Process SMAW Backing Yes No

Types Manual ■ □

Manual Semi-Automatic/Automatic □n

Semi-Automatic/Automatic Backing Material or Type N.A

BASE METALS

P335GH

Material Spec. C.S

Type or Grade . ? 37.5±2.5°

Thickness Range 6MM<

Thickness Range GROOVE 3 MM TO UNLIMITE

FILLER METALS

F-No. 4 A-No. 1

Spec. No.(SFA) A5.1 3~4 1.6±0.8 mm

AWS No.(Class) E 7018

Size of Filler Metal 2.5 & 3.2 & 4

Deposit Thickness Qualified 6MM<

Trade Name ESAB

Joint Design

POSITION ELECTRICAL CHARACTERISTICS

Position 4G Current AC or DC DC

Welding Progression Up-Hill Polarity, Amps & Volts(Range) As Table Below

Tungsten Electrode Size & Type N.A

PREHEATING & INTERPASS TEMP Transfer Mode N.A

Preheat Temp. Min. 200 Wire Feed Speed N.A

Interpass Temp. Max. 250⁰C

Preheat Maintenance N.A TECHNIQUE

String or Weave Bead Both

POST WELD HEAT TREATMENT Cleaning & Back Gouging Method Grinding & Brushing

Temperature Range ( º C ) N.A Multi or Single Pass Multi Pass

Holding Time N.A Single or Multiple Electrodes N.A

Heating Rate ( º C ) N.A Back Gouging N.A

Cooling Rate ( º C ) N.A

GAS

I PRECENT COMPOSITION GAS MIXTURE FLOWRATE

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

Welding Filler Metal Current Travel Speed

Weld Layers Volt Range(V) Heat Input(Kj/Cm)

Process Class Dia(mm) Type Polar. Amp Range(A) Range(cm/min)

ROOT PASS SMAW E 7018 2.5 & 3.2 DCEP 90-120 21-28 6-12

HOT PASS SMAW E 7018 3.2 DCEP 100-120 23-32 18-32

FILLING PASS SMAW E 7018 3.2 DCEP 100-120 27-35 24-40

COVER PASS SMAW E 7018 3.2 & 4 DCEP 110~200 27-35 18-26

CONTRACTOR QC TPA/COMPANY COMPANY

NAME: NAME: NAME:

SIGN: SIGN: SIGN:

DATE: DATE: DATE:

You might also like

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Analyser Housing: Dep SpecificationDocument37 pagesAnalyser Housing: Dep Specificationeke230% (1)

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Wps Repair WorDocument1 pageWps Repair WorMajdi JerbiNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- 07.4 111 FW ML PF WPS 20mm ENGDocument1 page07.4 111 FW ML PF WPS 20mm ENGViktorNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- Ssangyong Rodius ABSDocument9 pagesSsangyong Rodius ABSMTK2016No ratings yet

- ANSI NEMA MW 1000-2003 Rev.1.2005Document220 pagesANSI NEMA MW 1000-2003 Rev.1.2005carlosantunez111100% (5)

- Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS ClassificationDocument3 pagesProcedure Qualification Record (PQR) : Filler Metals AWS Specification AWS ClassificationRejoy babyNo ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- WPS-CR 01-06-15Document1 pageWPS-CR 01-06-15majdi jerbiNo ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelDocument1 pageWPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelAhmed Gomaa100% (1)

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPS-PTR 01-05-15Document1 pageWPS-PTR 01-05-15majdi jerbiNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- WPS CR 01-08-09Document1 pageWPS CR 01-08-09majdi jerbiNo ratings yet

- WPS TTR 01-08-09Document1 pageWPS TTR 01-08-09majdi jerbiNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Document2 pagesProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- WPS - BilDocument8 pagesWPS - BilShahdeoNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- 焊接工艺指导书 Welding Procedure Specification 文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0Document1 page焊接工艺指导书 Welding Procedure Specification 文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0ANIL PLAMOOTTILNo ratings yet

- Procedure Qualification Record (PQR) Form: JointsDocument12 pagesProcedure Qualification Record (PQR) Form: JointsAl Fatih Darussalam YasfiNo ratings yet

- WPS Astm - A 53Document2 pagesWPS Astm - A 53S. K. M. ShujonNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- Wps API-mwt 2020Document24 pagesWps API-mwt 2020afshohil anamNo ratings yet

- LAMPIRAN PQRDocument1 pageLAMPIRAN PQRRobby TriNo ratings yet

- WPS PTR 01-08-09Document1 pageWPS PTR 01-08-09majdi jerbiNo ratings yet

- Wps 15Document5 pagesWps 15Avishek GuptaNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- WPS New 2Document1 pageWPS New 2Erica SandersNo ratings yet

- Hfy2 E1890 CPF1WT WLD SPC 0008Document3 pagesHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiNo ratings yet

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- 07.3 111 FW ML PF WPS 20mm EngDocument1 page07.3 111 FW ML PF WPS 20mm EngViktorNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- WPS and PQR of GMAWDocument8 pagesWPS and PQR of GMAW魏利强No ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Prequalified Qualified by TestingDocument5 pagesPrequalified Qualified by Testingcarlosoliveros1967No ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- PQR001Document1 pagePQR001Susmita SahaNo ratings yet

- محاسبه مساحت متریالDocument14 pagesمحاسبه مساحت متریالMehrdad RezaeiNo ratings yet

- محاسبه وزن الکترود و فیلرDocument14 pagesمحاسبه وزن الکترود و فیلرMehrdad RezaeiNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- UntitledDocument19 pagesUntitledMehrdad RezaeiNo ratings yet

- Friction ExperimentDocument7 pagesFriction ExperimentSyamil RahmanNo ratings yet

- PU-SE-2003 & 2008 Course-QP-OCT-2012Document799 pagesPU-SE-2003 & 2008 Course-QP-OCT-2012rbc1230% (1)

- Magnetic Water TreatmentDocument66 pagesMagnetic Water Treatmentmdkadry100% (2)

- Why Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuresDocument5 pagesWhy Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuressitaracommercialcomplexNo ratings yet

- Lab Report 4Document17 pagesLab Report 4Lee Yann LynnNo ratings yet

- Mixers MixerGrindersDocument21 pagesMixers MixerGrindersKumar PranavNo ratings yet

- Chemistry Markscheme (All in One)Document728 pagesChemistry Markscheme (All in One)AliMushtaq50% (2)

- Porosity and Pore Size Distribution in Recycled ConcreteDocument9 pagesPorosity and Pore Size Distribution in Recycled ConcreteBagus Rizqi KurniawanNo ratings yet

- UG-40 Dial and Lever Governors: Installation and Operation ManualDocument62 pagesUG-40 Dial and Lever Governors: Installation and Operation Manualoscar monroyNo ratings yet

- Instruction Manual: Izml Electromagnetic FlowmeterDocument60 pagesInstruction Manual: Izml Electromagnetic FlowmeterelenanomgmmNo ratings yet

- Chemical Reactions and Quantities: Types of Reactions Oxidation-Reduction ReactionsDocument21 pagesChemical Reactions and Quantities: Types of Reactions Oxidation-Reduction ReactionsHakakNo ratings yet

- SeparationsDocument8 pagesSeparationsHidayat KesumaNo ratings yet

- Dokumen - Tips - Method Statement For Steel Balustrade and Railing InstallationDocument6 pagesDokumen - Tips - Method Statement For Steel Balustrade and Railing InstallationKhaing Zin WaikonicNo ratings yet

- WTP Drawings PDFDocument3 pagesWTP Drawings PDFpastorgeeNo ratings yet

- Reg - Institutewise - CLOUSER 2021Document17 pagesReg - Institutewise - CLOUSER 2021opNo ratings yet

- Stellgrid HR 30 - GeofabricsDocument2 pagesStellgrid HR 30 - GeofabricsMario CordovaNo ratings yet

- NuaireHousebuilderCatalogue MVHRDocument85 pagesNuaireHousebuilderCatalogue MVHRreplicaderNo ratings yet

- Application of LDR System As Automatic SwitchDocument24 pagesApplication of LDR System As Automatic Switchfitrhrotul nahdiyyahNo ratings yet

- Electrical ClassificationDocument14 pagesElectrical ClassificationguhadebasisNo ratings yet

- ADMIX - RotosolverDocument2 pagesADMIX - RotosolverRaul DiazNo ratings yet

- Alumi Frame FormworkDocument12 pagesAlumi Frame FormworkSullam SyamsunNo ratings yet

- For All Three Reactors Move SG After The Valve.: Bauxite Conveyor (Bc-115)Document1 pageFor All Three Reactors Move SG After The Valve.: Bauxite Conveyor (Bc-115)Anonymous 7I5qQ0eAxgNo ratings yet

- Instruction Manual For Installation, Operation and MaintenanceDocument32 pagesInstruction Manual For Installation, Operation and MaintenanceRobinson GuerreroNo ratings yet

- Eddy Current Testing ApplicationsDocument21 pagesEddy Current Testing ApplicationsvibinkumarsNo ratings yet

- Nitoproof 230 PDFDocument2 pagesNitoproof 230 PDFmilanbrasinaNo ratings yet

- CNHT'2022Document4 pagesCNHT'2022Talhi Mama0% (1)

- Lecture 18-19Document25 pagesLecture 18-19Ahmed SFNo ratings yet