Professional Documents

Culture Documents

B C D E: Table 1: Model Information

B C D E: Table 1: Model Information

Uploaded by

abu zaidCopyright:

Available Formats

You might also like

- Pce Munich 2022Document5 pagesPce Munich 2022miguel angelNo ratings yet

- Painting and Coating For Fpso (New Construction) : Company Technical StandardDocument83 pagesPainting and Coating For Fpso (New Construction) : Company Technical StandardMohamed GhonaimNo ratings yet

- 1630476984815196Document10 pages1630476984815196John Angelo TuliaoNo ratings yet

- Primer Piso: Cuadro de ColumnasDocument1 pagePrimer Piso: Cuadro de ColumnasJonathan Valenzuela AndiaNo ratings yet

- 1Document1 page1Juan Pablo Arce CarreroNo ratings yet

- Strut Details: S4 Commission On AuditDocument1 pageStrut Details: S4 Commission On AuditajNo ratings yet

- STR 2883Document4 pagesSTR 2883eng.yehia.omara.kbhNo ratings yet

- Sheet Title: Part Plan of Toilet: Working DrawingDocument1 pageSheet Title: Part Plan of Toilet: Working DrawingAditiNo ratings yet

- 11-01-2024 Grill Detail 2Document1 page11-01-2024 Grill Detail 2ABDUL SAMADNo ratings yet

- Sorsogon City Bulk Water Supply As-Built Plan For Water Treatment PlantDocument1 pageSorsogon City Bulk Water Supply As-Built Plan For Water Treatment PlantAlphaMae DitanNo ratings yet

- Estructura Kevin Smith Martos Narvaes - Obra 2021-A0 AligeradoDocument1 pageEstructura Kevin Smith Martos Narvaes - Obra 2021-A0 AligeradoRaul Alfredo Cordova AlvaradoNo ratings yet

- 40.4m 3 Generation Crewboat: Technical SpecificationDocument22 pages40.4m 3 Generation Crewboat: Technical SpecificationokaNo ratings yet

- Estructuras Modulo A E04-0Document1 pageEstructuras Modulo A E04-0Nelly CervantesNo ratings yet

- Summary: C3-ADocument1 pageSummary: C3-ACarl Lou BaclayonNo ratings yet

- TOPOGRAFICO 2021 Actualizado 3 lotes-LOTIZACION 20-21-22Document1 pageTOPOGRAFICO 2021 Actualizado 3 lotes-LOTIZACION 20-21-22Charly Alcantara RodriguezNo ratings yet

- TQ Cisterna y TQ Elevado EstructurasDocument1 pageTQ Cisterna y TQ Elevado EstructurasjhonelNo ratings yet

- Title Water: Engineering & Construction ServicesDocument1 pageTitle Water: Engineering & Construction ServicesMohammed ZughaidNo ratings yet

- Karjan West NetworkDocument1 pageKarjan West Networkdeekarjan11No ratings yet

- GYC C 18 Merged PDF - 230912 - 153556Document6 pagesGYC C 18 Merged PDF - 230912 - 153556krisp14No ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Gabriel PulidoNo ratings yet

- Orca Share Media1673962301261 7021106776030602051Document1 pageOrca Share Media1673962301261 7021106776030602051Von AninonNo ratings yet

- Proposed Single Storey Residential Building: Ar. Rodel S. Falcasantos, MpaDocument1 pageProposed Single Storey Residential Building: Ar. Rodel S. Falcasantos, MpaChy GomezNo ratings yet

- LAAD SECURITY 2024 - Floorplan - 07NOV - 16H00Document1 pageLAAD SECURITY 2024 - Floorplan - 07NOV - 16H00Reinaldo Della RosaNo ratings yet

- Typical Single Slab CulvertDocument1 pageTypical Single Slab CulvertAshok DhakalNo ratings yet

- 172 I1909e 000 46 DW 0109Document2 pages172 I1909e 000 46 DW 0109Jose Carlos Moraga LópezNo ratings yet

- Structural 1Document1 pageStructural 1Ryan LimboNo ratings yet

- SBMT Rwy-12-30 Vac 20210520Document2 pagesSBMT Rwy-12-30 Vac 20210520Nicolas RamosNo ratings yet

- DA42NG Garmin1000 VCDocument1 pageDA42NG Garmin1000 VCLokesh BabuNo ratings yet

- U44-D-2213 - Pipe SupportsDocument4 pagesU44-D-2213 - Pipe SupportsJamil AhmadNo ratings yet

- Oemt Act - Carcamo-CarcamoDocument1 pageOemt Act - Carcamo-CarcamoJesús Abrahan Canul MayNo ratings yet

- Officer South Employment PSP Infrastructure Contributions Plan Draft For Consultation Appendix 3 Part 4Document13 pagesOfficer South Employment PSP Infrastructure Contributions Plan Draft For Consultation Appendix 3 Part 4zihan1chenNo ratings yet

- Section B-BDocument1 pageSection B-BNORTSEN ALBERTNo ratings yet

- Site Plan Kaira ResidenceDocument1 pageSite Plan Kaira ResidenceU RenurNo ratings yet

- Tal Wsa PNG Iso 1CS106901 - 02 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106901 - 02 - A01 - 00landeopauloNo ratings yet

- 27-01-2020) - As built-PLANTA BAIXADocument1 page27-01-2020) - As built-PLANTA BAIXAAndré ZoffoliNo ratings yet

- Panasonic Tnpa5935-1ld km29 Chassis Led-DriverDocument2 pagesPanasonic Tnpa5935-1ld km29 Chassis Led-DriverJonathan Da SilvaNo ratings yet

- Aerodrome Chart SALVADOR / Deputado Lus Eduardo Magalh Es, INTL (SBSV)Document2 pagesAerodrome Chart SALVADOR / Deputado Lus Eduardo Magalh Es, INTL (SBSV)Rêmulo GrangeiroNo ratings yet

- Site PlanDocument1 pageSite PlanErickson MalicsiNo ratings yet

- Pastor A1 SheetDocument1 pagePastor A1 Sheetgbotieno27No ratings yet

- Planos-tramo-Vi Final de EjecucionDocument6 pagesPlanos-tramo-Vi Final de EjecucionDiego RuizNo ratings yet

- Jardineras ModelDocument1 pageJardineras ModelAlberto PalaciosNo ratings yet

- Sitio Y Techos: UbicacionDocument1 pageSitio Y Techos: UbicacionJose Carlos ChuraNo ratings yet

- A 101 Revised Settingout Plan Sheet1606111710104Document1 pageA 101 Revised Settingout Plan Sheet1606111710104Almaali ConsultancyNo ratings yet

- 180w-v SchemeDocument2 pages180w-v SchemeSergeyNo ratings yet

- Auxiliary Room at 30Th FloorDocument1 pageAuxiliary Room at 30Th FloorJohn Michael LimNo ratings yet

- 2Document1 page2MohamedHanyNo ratings yet

- PWM DCDocument2 pagesPWM DCĐỗ Xuân BằngNo ratings yet

- Proyecto Departamentos Mejorado3Document1 pageProyecto Departamentos Mejorado3WilliamYucraNo ratings yet

- MC9.10 220VDocument2 pagesMC9.10 220Vmonozone789No ratings yet

- SF Auditorium Proposal Sht1of2 PDFDocument1 pageSF Auditorium Proposal Sht1of2 PDFHareesh KilaruNo ratings yet

- PLB Alim Ef RDCDocument1 pagePLB Alim Ef RDCRianaNo ratings yet

- Ar00 01 General PlanDocument1 pageAr00 01 General PlanraychristianwijayaNo ratings yet

- Ar00 01 General PlanDocument1 pageAr00 01 General PlanraychristianwijayaNo ratings yet

- Arq. Eusebio EstructurasDocument1 pageArq. Eusebio Estructurasjhon81918156No ratings yet

- Highway Structures 3Document1 pageHighway Structures 3Martin ScottNo ratings yet

- Roof Plan: Foundation Plan Roof Beam Plan Roof Framing PlanDocument1 pageRoof Plan: Foundation Plan Roof Beam Plan Roof Framing PlanAYSON N. DELA CRUZNo ratings yet

- Redes Acueducto Plancha: Rio BogotaDocument1 pageRedes Acueducto Plancha: Rio BogotaJOSE RODRIGO TORRES CORREANo ratings yet

- Foundation Plan Roof Framing Plan Footing DetailDocument1 pageFoundation Plan Roof Framing Plan Footing DetailJohn Aaron HerreraNo ratings yet

- 9205 BP12B MMJV Ifcd Me P1 000 00040 Rev.000Document1 page9205 BP12B MMJV Ifcd Me P1 000 00040 Rev.000Abdulhamit KAYYALINo ratings yet

- Molytherme (Extra) Mod: Codification: AWS/SFA E8018-D3 Use DC+Document1 pageMolytherme (Extra) Mod: Codification: AWS/SFA E8018-D3 Use DC+The TechnicalsNo ratings yet

- EC55B Elec CircuitDocument1 pageEC55B Elec Circuitxiaojun liNo ratings yet

- MW MB Holder Rev 6Document1 pageMW MB Holder Rev 6abu zaidNo ratings yet

- RaDocument1 pageRaabu zaidNo ratings yet

- RaDocument1 pageRaabu zaidNo ratings yet

- Angle CutterDocument1 pageAngle Cutterabu zaidNo ratings yet

- POs Trading Manual v32 29 August 2022 FinalDocument142 pagesPOs Trading Manual v32 29 August 2022 Finalabu zaidNo ratings yet

- 12 Major Causes of Foaming On Copper Plating of The PCB BoardDocument8 pages12 Major Causes of Foaming On Copper Plating of The PCB BoardjackNo ratings yet

- Automotive Differential HousingDocument5 pagesAutomotive Differential Housingfileuse.fNo ratings yet

- Perhitungan Komposting&3R - SIGN Limbah v0.95Document18 pagesPerhitungan Komposting&3R - SIGN Limbah v0.95True SerenityNo ratings yet

- 03 33 00 Architectural ConcreteDocument18 pages03 33 00 Architectural Concreteambar adekaNo ratings yet

- Process Sheet For Furan MouldDocument2 pagesProcess Sheet For Furan Mouldk zNo ratings yet

- Polycrete MCDocument2 pagesPolycrete MCdinescNo ratings yet

- 2 Semu 2712 Chapter 2 - Manufacturing AspectsDocument62 pages2 Semu 2712 Chapter 2 - Manufacturing AspectsShafiq KhaleedNo ratings yet

- Bright Saudia PresentationDocument8 pagesBright Saudia PresentationMohammed SaleemNo ratings yet

- DLyte Technologia 2022 V1 Digital enDocument7 pagesDLyte Technologia 2022 V1 Digital enDamir ZivkusicNo ratings yet

- Wiring Cable StandardDocument6 pagesWiring Cable StandardAli AhmadNo ratings yet

- EXTRUSION DIE DESIGN (Compatibility Mode)Document7 pagesEXTRUSION DIE DESIGN (Compatibility Mode)Śaksham ŔathoreNo ratings yet

- Labratory TestDocument30 pagesLabratory TestgirumNo ratings yet

- VITALLY PE 0.4 Technical Data PDFDocument2 pagesVITALLY PE 0.4 Technical Data PDFazlen494No ratings yet

- Literature Review Milling MachineDocument6 pagesLiterature Review Milling Machineafmzvadyiaedla100% (1)

- Shubham+Report Abcdpdf PDF To WordDocument46 pagesShubham+Report Abcdpdf PDF To WordGond AbhishekNo ratings yet

- Masterflow 626: Heavy Duty, Epoxy Resin Based GroutDocument2 pagesMasterflow 626: Heavy Duty, Epoxy Resin Based GroutAndri AjaNo ratings yet

- Panduit Heatshrink GuideDocument5 pagesPanduit Heatshrink GuideIndranath MoulickNo ratings yet

- SST Doghouse PlansDocument17 pagesSST Doghouse PlansÁngel PauletteNo ratings yet

- Effect of Molybdenum Addition On Solidification Structure, Mechanical Properties and Wear Resistivity of High Chromium Cast IronsDocument6 pagesEffect of Molybdenum Addition On Solidification Structure, Mechanical Properties and Wear Resistivity of High Chromium Cast IronsMatheus BoligonNo ratings yet

- The Engineering Properties of TantalumDocument121 pagesThe Engineering Properties of TantalumСимеон АрабовNo ratings yet

- Plug Valves RevA 2021Document3 pagesPlug Valves RevA 2021Cap1284No ratings yet

- Dextra PC Headed Bar Brochure 2023 ENDocument4 pagesDextra PC Headed Bar Brochure 2023 ENIbrahim BadhushaNo ratings yet

- Technical Data Sheet Jaz Coilex Pe Primer JP-11002: DescriptionDocument2 pagesTechnical Data Sheet Jaz Coilex Pe Primer JP-11002: DescriptionAhmad BougeisNo ratings yet

- Flexible Manufacturing System.Document11 pagesFlexible Manufacturing System.Yaswanth saiNo ratings yet

- Pi Branorost Chips enDocument2 pagesPi Branorost Chips enJaya RidwantoNo ratings yet

- Brief Installation Guide For Fibrolit UltraDocument2 pagesBrief Installation Guide For Fibrolit UltraK PreitoNo ratings yet

- TDS Byk-A 500 UsDocument2 pagesTDS Byk-A 500 UsGustavo CamposNo ratings yet

- Vanadium and Vanadium CompoundsDocument21 pagesVanadium and Vanadium CompoundsПлейнNo ratings yet

B C D E: Table 1: Model Information

B C D E: Table 1: Model Information

Uploaded by

abu zaidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B C D E: Table 1: Model Information

B C D E: Table 1: Model Information

Uploaded by

abu zaidCopyright:

Available Formats

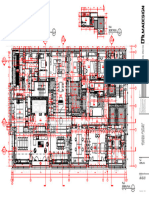

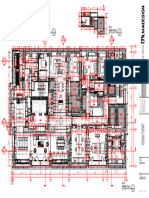

NADCA ALUMINUM CASTING 0.

40

INTERMEDIATE TOLERANCE CHART (mm)

0.30 (2X)

R066309

A

DIMENSION RANGE TOLERANCE

N/A RELEASED FOR PRODUCTION 28 APR 2011

FROM UPTO HM CHIN

0.00 25.40 0.152 PG 1: B4,F3, F4,

C464968

12.05 F7, F9, D7-D9,

25.40

50.80

50.80

76.20

0.178

0.203 0.40

9.80 0.05 (1.19) B H5-G6.

PG 2: D5

MODIFIED SEALING TAB LOCATIONS 28 JUN 2011

PG 3 T. NAVIIN

76.20 101.60 0.229 (0.94)

0.2 PG1: E8-F8, ADDED RECESS C473437

101.60 127.00 0.254

127.00 152.40 0.279 -A- C B3-B4.

PG2: G6,G7. REDUCED BATTERY LATCH RECESS DEPTH 23 AUG 2011

152.40 177.80 0.305 PG3: E8, E10. CHANGED SEALING SURFACES T. NAVIIN

177.80 203.20 0.330 PG1: C12, MODIFIED THE SNAP-IN TABS PROFILE C464348

203.20

228.60

228.60

254.00

0.356

0.381

8.91

D B5, H7 REDUCED Z-STOPPER GAP TO 0.1MM 15 DEC 2011

EXTENDED O-RING SEALING WALL T. NAVIIN

254.00 279.40 0.406

279.40 304.80 0.432 -C- PG1: D8, ADDED 0.1MM RECESS. C490497

(REF: THE TOLERANCES ON THIS TABLE ARE BASED ON E D7-D9, FLEX LOCATOR THICKNESS CHANGED. 14 FEB 2012

NORTH AMERICAN DIE CASTING ASSOCIATION C3-C4 BATTERY CATCH SLIDER MOVED TO BOTTOM. T. NAVIIN

INTERMEDIATE TOLERANCES FOR LINEAR DIMENSIONS.

ADD THE FOLLOWING TOLERANCES ("PLUS" SIDE ONLY.) -A- 5.88

B

FOR DIMENSIONS ACROSS PARTING LINE OR MADE BY A

MOVING DIE COMPONENT (MDC))

DETAIL

1.94 0.15 2.15 0.15

PROJECTED AREA SCALE 4/1

PARTING LINE MDC 0.99 0.10

OF PART (MM^2)

44.31

UP TO 6.5e3

6.5e3 TO 1.3e4

+0.114

+0.133

+0.178

+0.292

SECTION LF-LF

1.3e4 TO 3.2e4 +0.159 +0.419

3.2e4 TO 6.5e4 +0.254 +0.533

A

B

0.2

6.5e4 TO 1.3e5 +0.381 +0.711

SEE DETAIL 3.00 (2X)

1.3e5 TO 1.9e5 +0.508 +0.889 -D-

-C-

D 5.30 (2X)

2.89 0.10 (2X)

28.00 0.15

1.64 (2X) 1.60

-A-

-A-

11.00 C 6.94 12.50

1.51 (2X)

2.88 (2X)

2.28

5.63 (2X)

3.38 (2X)

4.66 0.10 (2X)

2.60 0.10 13.66

R2.60 2.58

0.30 0.05 (2X)

15.21

30.16

2.60 0.10 7.24 (2X)

81.16 39.05 78.40

67.50 75.26

14.91

11.01 LF 74.06

64.54

20.56 50.41

8.16

121.26 46.48 127.40

2.20 (5X) 41.66

3.60 40.32

32.14 32.96 33.56 M3 X 0.5 THRU

3.86 (3X) 20.80

7.76 (2X)

1.80 0.05 (8X)

RECESSED 0.3MM

POLISHED

0.89 0.10

19.48 4.29

7.18

2.90 0.10 (8X) -B- -B- E 9.43

-B- 7.62

1.71 4.30 (2X)

10.94

B

3.28 0.54 (2X) -F- B

LF 0.87 (2X)

11.00

10.41

4.68 17.96 3.28

22.00

(2X) E 2.78

31.05 38.28 0.17

1.91 BL 14.97 BL

3.10 (2X)

SEE DETAIL A 8.10 D C 24.53 1.63 (2X) 6.20 (2X)

-D- 1.39 0.10 (2X) 30.21 0.15

3.50

SECTION D-D SECTION C-C

33.20 3.39 (2X) -D-

34.09

A SECTION A-A

-G- 1.90

0.90 (2X)

3.10 1.19 (X2)

47.91

45.68 0.10

1.97

9.01

2.54 8.50 (2X)

22.27 0.10 SECTION BL-BL

MOTOROLA PROPRIETARY INFORMATION

SECTION B-B 2011 ARIFF GDTG PENANG

-D- DETAIL A

SCALE 4/1 ARIFF

3.78 (3X)

3.40 (3X)

TEH SIAO HAU CHASSIS

27012010001 BELIZE CHASSIS RELEASED 0871

TOOLING ENGINEER

MOTOROLA P/N DESCRIPTION P/N STATUS PRODUCT ID LAWRENCE WONG

TABLE 1: MODEL INFORMATION SECTION E-E UNITS A1 N/A 27012010001 E

MM 2.000 0871 1 OF 3

format

created

by cmu

41.95 0.10

48.18

SECTION F-F 1. DESCRIPTION AND APPLICATION: DIE CAST CHASSIS FOR USE IN PORTABLE COMMUNICATION EQUIPMENT.

-C- 2. APPLICABLE DOCUMENTS:

46.41 12012000098 SPECIFICATION FOR ELECTROLESS NICKEL COATING ON ALUMINUM METAL PARTS

5.48 12G02897W18 MOTOROLA CONTROLLED AND REPORTABLE MATERIALS

1.20 (2X)

5.10 0.10 (2X) 24.08 12G13933A97 MOTOROLA COSMETIC SPECIFICATION FOR HAND-HELD PRODUCT

12G80967A78 MOTOROLA SUPPLIER MATERIAL QUALITY CONTROL

2.05 0.10 (2X) 12M05022A27 MOTOROLA QUALIFICATION PROCEDURE

-A-

12M05053A70 PRINT REQUIREMENTS FOR PARTS INSPECTED BY CAV

-D- 16.45 12M09195A94 MOTOROLA PPAP REQUIREMENTS FOR PIECE PART AND ASSEMBLY QUALIFICATION

18.82 12S10601A PACKAGING REQUIREMENTS FOR INBOUND SHIPMENTS TO MOTOROLA

4.88

12S11055A MOTOROLA SUPPLIER QUALITY ASSURANCE

12S22968 MOTOROLA MARKING STANDARD

SECTION G-G ASME Y14.5M-1994

ASTM B117

ASME DIMENSIONING AND TOLERANCING STANDARD

STANDARD PRACTICE FOR OPERATING SALT SPRAY (FOG) APPARATUS

10.94 (2X) 3. REQUIREMENTS:

3.1. GENERAL:

DETAIL C 3.1.1. PARTS SHALL BE CLEAN AND FREE OF ALL FOREIGN MATTER.

3.1.2. DIMENSIONING AND TOLERANCING PER ASME Y14.5-1994.

SCALE 2/1 3.1.3. A "REFERENCE" DIMENSION IS USED FOR INFORMATION PURPOSES ONLY, WITH TOLERANCE

EXCLUDED, E.G. (.XXX).

3.1.4. CRITICAL CHARACTERISTICS: PER 12G80967A78.

3.1.4.1. DENOTES PROCESS CONTROL PARAMETER.

6.03

3.1.4.2. DENOTES CRITICAL PARAMETERS THAT REQUIRE FIRST ARTICLE CPK > 1.5

49.80 3.1.4.3. MOTOROLA RESERVES THE RIGHT TO ADD PROCESS CONTROL OR CRITICAL DIMENSIONS

AT ANY TIME.

3.1.5. PACKAGING FOR SHIPMENT: PER 12S10601A.

SECTION SH-SH 3.1.5.1. PARTS TO BE PACKED IN INDIVIDUAL CELLS TO PREVENT DAMAGE.

3.2. TOOLING AND MATERIALS:

-C- 3.2.1. MATERIAL: ADC12 OR EQUIVALENT.

C 3.2.2. FINISH: ELECTROLESS NICKEL 5 - 12 MICRON THICK, MID-P.

3.2.3. CAVITY SURFACE SHALL BE TEXTURED WITH MT11020.

0.15 B C 3.2.4. TOOL DESIGN, INCLUDING GATE AND EJECTOR PIN LOCATIONS, MUST BE DISCUSSED

WITH MOTOROLA TOOL ENGINEERING DEPARTMENT BEFORE TOOL DESIGN IS STARTED.

1.71

COMPLETE TOOL DRAWINGS MUST BE SUBMITTED TO MOTOROLA PURCHASING DEPARTMENT

FOR APPROVAL.

SEE DETAIL C 3.2.5. CORES AND CAVITIES MUST BE TOOL STEEL, HARDENED, GROUND AND POLISHED (UNLESS

OTHERWISE SPECIFIED).

3.2.6. NO USE OF MOLD RELEASE ALLOWED.

3.2.7. SAMPLE PARTS (FROM EACH CAVITY) SHALL BE SUBMITTED TO MOTOROLA FOR APPROVAL

BEFORE PROCEEDING WITH PRODUCTION RUN.

SH SH 0.15 B C 3.2.8. CONTROLLED AND REPORTABLE MATERIALS DISCLOSURE - PART MUST COMPLY

12G02897W18, APPENDIX C, SECTION 2 (EU / CHINA) ACCEPTANCE

WITH

CRITERIA.

3.3. MECHANICAL (UNLESS OTHERWISE SPECIFIED):

3.3.1. ALL DIMENSIONS ARE AS SHOWN, PLUS DRAFT.

3.3.2. DRAFT ANGLES SHALL BE 3 MAXIMUM.

0.15 B C 3.3.3. FILLETS AND RADII SHALL BE 0.3 MM UNLESS OTHERWISE SPECIFIED

F F 3.3.4. FLASH ALLOWANCE NOT TO EXCEED 0.05 MM.

3.3.5. PARTING LINE MISMATCH NOT TO EXCEED 0.125 MM.

3.3.6. DENOTES PARTING LINE.

3.3.7. GATES SHALL BE FLUSH TO 0.1 MM BELOW.

G G 3.3.8. MAXIMUM BURR HEIGHT: 0.125 MM. NO LOOSE BURRS PERMITTED.

3.3.9. APPEARANCE: PER 12G13933A97, SURFACE CLASS C.

3.3.10. SEALING SURFACES SHALL NOT HAVE SCRATCHES, FLASHES, SINKS, POROSITES OR PLATING

PART NUMBER

DEFECTS. NO GATING, OVERFLOWS, INSERT LINES, EJECTOR MARKS, TRIM DIE CUTS ARE

MARKING

PERMITTED IN THESE AREAS. SEE SHEET 3 ILLUSTRATING THESE CRITICAL SURFACE AREAS.

3.3.11. MARKING: PER 12S22968.

3.3.11.1. FINISHED MOTOROLA PART NUMBER AND ISSUE LETTER (AND CAVITY NUMBER IF

MULTIPLE) SHALL BE PERMANENTLY CAST IN AREA SHOWN: LAST TWO DIGITS OF

PART NUMBER AND ISSUE LETTER SHALL HAVE INTERCHANGEABLE INSERTS AND

0.15 B C SHALL BE REVISED WITH EACH NEW DRAWING ISSUE.

DATE CODE 3.3.11.2. CHARACTERS SHALL BE 3.00 MM HIGH.

3.3.11.3. DATE CODE MARKING SHALL BE 6.00MM DIAMETER INTERCHANGEABLE CORE PIN,

108.98 0.20 (2X) THE "C" OR MOTOROLA APPROVED EQUIVALENT, TO INDICATE MONTH AND YEAR

0.15 B C OF FABRICATION OF PART. MONTHS TO RUN CLOCKWISE, WITH JANUARY AT

DATUMS F & G

THRU CENTRE OF ONE O'CLOCK, AND LAST DIGIT OF YEAR TO BE IN CENTER AS SHOWN:

THIS FEATURE

EXAMPLE: JANUARY, 2010

0.15 F G

-B- -B-

4. VENDOR QUALITY ASSURANCE PROVISIONS: PER 12G80967A78, 12M05022A27, 12M05053A70 AND 12S11055A.

CAVITY NUMBER 4.1. PART QUALIFICATION - FIRST ARTICLE DATA REQUIREMENTS. VENDOR SHALL PROVIDE:

B B MARKING

-F- 4.1.1. MEASUREMENTS ON THIRTY-FIVE (35) SERIALIZED SAMPLES FROM EACH CAVITY FOR EACH

PARAMETER DENOTED AS OR AS ALONG WITH A PROCESS CAPABILITY STUDY

19.49 H H (CPK > 1.5).

4.1.2. MEASUREMENTS ON FIVE (5) SERIALIZED PARTS, FROM EACH CAVITY, FOR ALL OTHER

PARAMETERS / DIMENSIONS DENOTED ON THE PRINT.

4.1.3. DOCUMENTATION OF CONFORMANCE TO ALL NOTES IN THIS SPECIFICATION AS WELL AS ANY

TESTS SPECIFIED IN THE SUPPORTING DOCUMENTS.

4.2. ON-GOING PRODUCTION LOTS - FOR EACH PARAMETER DENOTED AS PROCESS CONTROL .

0.15 F G 0.15 F G VENDOR SHALL:

4.2.1. TAKE MEASUREMENTS ON THIRTY-FIVE (35) SERIALIZED SAMPLES RANDOMLY SPACED THRU-OUT

RUN, FROM EACH CAVITY.

REVISION MARKING 4.2.2. PERFORM CAPABILITY STUDY (SHOWING CONFORMANCE TO CPK > 1.5).

4.2.3. DATA MUST KEPT ON FILE AT THE VENDOR AND AVAILABLE TO MOTOROLA UPON REQUEST.

4.3 SALT FOG TEST REQUIREMENTS (PIECE PART LEVEL): PER ASTM B117.

4.3.1. PART SHALL MEET 8 HOURS SALT FOG TEST. PER 12012000098.

4.3.2. PASS / FAIL CRITERION: PER (TBD SPEC)

C -G-

5. EXCEPTIONS:

5.1. NO CHANGE SHALL BE ALLOWED ON PRODUCTION MATERIAL, REGARDLESS OF WHETHER SUCH

SECTION C-C 46.99

CHANGE AFFECTS REQUIREMENTS SPECIFIED, WITHOUT PRIOR EXPLICIT WRITTEN

MOTOROLA DEVELOPMENT ENGINEERING AND PURCHASING DEPARTMENTS.

APPROVAL BY

5.2. THE PART DEPICTED ON THIS DRAWING IS REPRESENTED IN GRAPHIC DETAIL TO SHOW ALL OF

41.95 0.10

ITS FEATURES FOR THE PURPOSE OF ENGINEERING DOCUMENTATION. ONLY THOSE DIMENSIONS

WHICH AFFECT THE FIT AND FUNCTION OF THE OVERALL PRODUCT ASSEMBLY HAVE BEEN

INCLUDED FOR THE PURPOSE OF INSPECTION. ALL REMAINING FEATURES NOT SPECIFICALLY

DIMENSIONED MUST STILL BE APPROVED BY MOTOROLA MECHANICAL ENGINEERING PRIOR TO

QUALICATION OF THE TOOL. MOTOROLA RESERVES THE RIGHT TO REJECT QUALIFICATION FOR

PARTS WITH MISSING OR INCOMPLETE FEATURES.

SECTION B-B

5.10 1.00 (2X)

2.05 0.10 (2X)

-D-

MOTOROLA CONFIDENTIAL PROPRIETARY

2.10 0.08

A1 N/A 27012010001 E

SECTION H-H 2.000 0871 2 OF 3

GATE ON THIS SIDE

ALONG THE SURFACE

PARTING LINE AWAY FROM

O-RING SEATING SURFACE

SURFACE TEXTURE

SEE NOTE 3.2.3.

TOOL NEED POLISHING ON SEALING SURFACES AS INDICATED.

MOTOROLA CONFIDENTIAL PROPRIETARY

A1 N/A 27012010001 E

2.000 0871 3 OF 3

You might also like

- Pce Munich 2022Document5 pagesPce Munich 2022miguel angelNo ratings yet

- Painting and Coating For Fpso (New Construction) : Company Technical StandardDocument83 pagesPainting and Coating For Fpso (New Construction) : Company Technical StandardMohamed GhonaimNo ratings yet

- 1630476984815196Document10 pages1630476984815196John Angelo TuliaoNo ratings yet

- Primer Piso: Cuadro de ColumnasDocument1 pagePrimer Piso: Cuadro de ColumnasJonathan Valenzuela AndiaNo ratings yet

- 1Document1 page1Juan Pablo Arce CarreroNo ratings yet

- Strut Details: S4 Commission On AuditDocument1 pageStrut Details: S4 Commission On AuditajNo ratings yet

- STR 2883Document4 pagesSTR 2883eng.yehia.omara.kbhNo ratings yet

- Sheet Title: Part Plan of Toilet: Working DrawingDocument1 pageSheet Title: Part Plan of Toilet: Working DrawingAditiNo ratings yet

- 11-01-2024 Grill Detail 2Document1 page11-01-2024 Grill Detail 2ABDUL SAMADNo ratings yet

- Sorsogon City Bulk Water Supply As-Built Plan For Water Treatment PlantDocument1 pageSorsogon City Bulk Water Supply As-Built Plan For Water Treatment PlantAlphaMae DitanNo ratings yet

- Estructura Kevin Smith Martos Narvaes - Obra 2021-A0 AligeradoDocument1 pageEstructura Kevin Smith Martos Narvaes - Obra 2021-A0 AligeradoRaul Alfredo Cordova AlvaradoNo ratings yet

- 40.4m 3 Generation Crewboat: Technical SpecificationDocument22 pages40.4m 3 Generation Crewboat: Technical SpecificationokaNo ratings yet

- Estructuras Modulo A E04-0Document1 pageEstructuras Modulo A E04-0Nelly CervantesNo ratings yet

- Summary: C3-ADocument1 pageSummary: C3-ACarl Lou BaclayonNo ratings yet

- TOPOGRAFICO 2021 Actualizado 3 lotes-LOTIZACION 20-21-22Document1 pageTOPOGRAFICO 2021 Actualizado 3 lotes-LOTIZACION 20-21-22Charly Alcantara RodriguezNo ratings yet

- TQ Cisterna y TQ Elevado EstructurasDocument1 pageTQ Cisterna y TQ Elevado EstructurasjhonelNo ratings yet

- Title Water: Engineering & Construction ServicesDocument1 pageTitle Water: Engineering & Construction ServicesMohammed ZughaidNo ratings yet

- Karjan West NetworkDocument1 pageKarjan West Networkdeekarjan11No ratings yet

- GYC C 18 Merged PDF - 230912 - 153556Document6 pagesGYC C 18 Merged PDF - 230912 - 153556krisp14No ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Gabriel PulidoNo ratings yet

- Orca Share Media1673962301261 7021106776030602051Document1 pageOrca Share Media1673962301261 7021106776030602051Von AninonNo ratings yet

- Proposed Single Storey Residential Building: Ar. Rodel S. Falcasantos, MpaDocument1 pageProposed Single Storey Residential Building: Ar. Rodel S. Falcasantos, MpaChy GomezNo ratings yet

- LAAD SECURITY 2024 - Floorplan - 07NOV - 16H00Document1 pageLAAD SECURITY 2024 - Floorplan - 07NOV - 16H00Reinaldo Della RosaNo ratings yet

- Typical Single Slab CulvertDocument1 pageTypical Single Slab CulvertAshok DhakalNo ratings yet

- 172 I1909e 000 46 DW 0109Document2 pages172 I1909e 000 46 DW 0109Jose Carlos Moraga LópezNo ratings yet

- Structural 1Document1 pageStructural 1Ryan LimboNo ratings yet

- SBMT Rwy-12-30 Vac 20210520Document2 pagesSBMT Rwy-12-30 Vac 20210520Nicolas RamosNo ratings yet

- DA42NG Garmin1000 VCDocument1 pageDA42NG Garmin1000 VCLokesh BabuNo ratings yet

- U44-D-2213 - Pipe SupportsDocument4 pagesU44-D-2213 - Pipe SupportsJamil AhmadNo ratings yet

- Oemt Act - Carcamo-CarcamoDocument1 pageOemt Act - Carcamo-CarcamoJesús Abrahan Canul MayNo ratings yet

- Officer South Employment PSP Infrastructure Contributions Plan Draft For Consultation Appendix 3 Part 4Document13 pagesOfficer South Employment PSP Infrastructure Contributions Plan Draft For Consultation Appendix 3 Part 4zihan1chenNo ratings yet

- Section B-BDocument1 pageSection B-BNORTSEN ALBERTNo ratings yet

- Site Plan Kaira ResidenceDocument1 pageSite Plan Kaira ResidenceU RenurNo ratings yet

- Tal Wsa PNG Iso 1CS106901 - 02 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106901 - 02 - A01 - 00landeopauloNo ratings yet

- 27-01-2020) - As built-PLANTA BAIXADocument1 page27-01-2020) - As built-PLANTA BAIXAAndré ZoffoliNo ratings yet

- Panasonic Tnpa5935-1ld km29 Chassis Led-DriverDocument2 pagesPanasonic Tnpa5935-1ld km29 Chassis Led-DriverJonathan Da SilvaNo ratings yet

- Aerodrome Chart SALVADOR / Deputado Lus Eduardo Magalh Es, INTL (SBSV)Document2 pagesAerodrome Chart SALVADOR / Deputado Lus Eduardo Magalh Es, INTL (SBSV)Rêmulo GrangeiroNo ratings yet

- Site PlanDocument1 pageSite PlanErickson MalicsiNo ratings yet

- Pastor A1 SheetDocument1 pagePastor A1 Sheetgbotieno27No ratings yet

- Planos-tramo-Vi Final de EjecucionDocument6 pagesPlanos-tramo-Vi Final de EjecucionDiego RuizNo ratings yet

- Jardineras ModelDocument1 pageJardineras ModelAlberto PalaciosNo ratings yet

- Sitio Y Techos: UbicacionDocument1 pageSitio Y Techos: UbicacionJose Carlos ChuraNo ratings yet

- A 101 Revised Settingout Plan Sheet1606111710104Document1 pageA 101 Revised Settingout Plan Sheet1606111710104Almaali ConsultancyNo ratings yet

- 180w-v SchemeDocument2 pages180w-v SchemeSergeyNo ratings yet

- Auxiliary Room at 30Th FloorDocument1 pageAuxiliary Room at 30Th FloorJohn Michael LimNo ratings yet

- 2Document1 page2MohamedHanyNo ratings yet

- PWM DCDocument2 pagesPWM DCĐỗ Xuân BằngNo ratings yet

- Proyecto Departamentos Mejorado3Document1 pageProyecto Departamentos Mejorado3WilliamYucraNo ratings yet

- MC9.10 220VDocument2 pagesMC9.10 220Vmonozone789No ratings yet

- SF Auditorium Proposal Sht1of2 PDFDocument1 pageSF Auditorium Proposal Sht1of2 PDFHareesh KilaruNo ratings yet

- PLB Alim Ef RDCDocument1 pagePLB Alim Ef RDCRianaNo ratings yet

- Ar00 01 General PlanDocument1 pageAr00 01 General PlanraychristianwijayaNo ratings yet

- Ar00 01 General PlanDocument1 pageAr00 01 General PlanraychristianwijayaNo ratings yet

- Arq. Eusebio EstructurasDocument1 pageArq. Eusebio Estructurasjhon81918156No ratings yet

- Highway Structures 3Document1 pageHighway Structures 3Martin ScottNo ratings yet

- Roof Plan: Foundation Plan Roof Beam Plan Roof Framing PlanDocument1 pageRoof Plan: Foundation Plan Roof Beam Plan Roof Framing PlanAYSON N. DELA CRUZNo ratings yet

- Redes Acueducto Plancha: Rio BogotaDocument1 pageRedes Acueducto Plancha: Rio BogotaJOSE RODRIGO TORRES CORREANo ratings yet

- Foundation Plan Roof Framing Plan Footing DetailDocument1 pageFoundation Plan Roof Framing Plan Footing DetailJohn Aaron HerreraNo ratings yet

- 9205 BP12B MMJV Ifcd Me P1 000 00040 Rev.000Document1 page9205 BP12B MMJV Ifcd Me P1 000 00040 Rev.000Abdulhamit KAYYALINo ratings yet

- Molytherme (Extra) Mod: Codification: AWS/SFA E8018-D3 Use DC+Document1 pageMolytherme (Extra) Mod: Codification: AWS/SFA E8018-D3 Use DC+The TechnicalsNo ratings yet

- EC55B Elec CircuitDocument1 pageEC55B Elec Circuitxiaojun liNo ratings yet

- MW MB Holder Rev 6Document1 pageMW MB Holder Rev 6abu zaidNo ratings yet

- RaDocument1 pageRaabu zaidNo ratings yet

- RaDocument1 pageRaabu zaidNo ratings yet

- Angle CutterDocument1 pageAngle Cutterabu zaidNo ratings yet

- POs Trading Manual v32 29 August 2022 FinalDocument142 pagesPOs Trading Manual v32 29 August 2022 Finalabu zaidNo ratings yet

- 12 Major Causes of Foaming On Copper Plating of The PCB BoardDocument8 pages12 Major Causes of Foaming On Copper Plating of The PCB BoardjackNo ratings yet

- Automotive Differential HousingDocument5 pagesAutomotive Differential Housingfileuse.fNo ratings yet

- Perhitungan Komposting&3R - SIGN Limbah v0.95Document18 pagesPerhitungan Komposting&3R - SIGN Limbah v0.95True SerenityNo ratings yet

- 03 33 00 Architectural ConcreteDocument18 pages03 33 00 Architectural Concreteambar adekaNo ratings yet

- Process Sheet For Furan MouldDocument2 pagesProcess Sheet For Furan Mouldk zNo ratings yet

- Polycrete MCDocument2 pagesPolycrete MCdinescNo ratings yet

- 2 Semu 2712 Chapter 2 - Manufacturing AspectsDocument62 pages2 Semu 2712 Chapter 2 - Manufacturing AspectsShafiq KhaleedNo ratings yet

- Bright Saudia PresentationDocument8 pagesBright Saudia PresentationMohammed SaleemNo ratings yet

- DLyte Technologia 2022 V1 Digital enDocument7 pagesDLyte Technologia 2022 V1 Digital enDamir ZivkusicNo ratings yet

- Wiring Cable StandardDocument6 pagesWiring Cable StandardAli AhmadNo ratings yet

- EXTRUSION DIE DESIGN (Compatibility Mode)Document7 pagesEXTRUSION DIE DESIGN (Compatibility Mode)Śaksham ŔathoreNo ratings yet

- Labratory TestDocument30 pagesLabratory TestgirumNo ratings yet

- VITALLY PE 0.4 Technical Data PDFDocument2 pagesVITALLY PE 0.4 Technical Data PDFazlen494No ratings yet

- Literature Review Milling MachineDocument6 pagesLiterature Review Milling Machineafmzvadyiaedla100% (1)

- Shubham+Report Abcdpdf PDF To WordDocument46 pagesShubham+Report Abcdpdf PDF To WordGond AbhishekNo ratings yet

- Masterflow 626: Heavy Duty, Epoxy Resin Based GroutDocument2 pagesMasterflow 626: Heavy Duty, Epoxy Resin Based GroutAndri AjaNo ratings yet

- Panduit Heatshrink GuideDocument5 pagesPanduit Heatshrink GuideIndranath MoulickNo ratings yet

- SST Doghouse PlansDocument17 pagesSST Doghouse PlansÁngel PauletteNo ratings yet

- Effect of Molybdenum Addition On Solidification Structure, Mechanical Properties and Wear Resistivity of High Chromium Cast IronsDocument6 pagesEffect of Molybdenum Addition On Solidification Structure, Mechanical Properties and Wear Resistivity of High Chromium Cast IronsMatheus BoligonNo ratings yet

- The Engineering Properties of TantalumDocument121 pagesThe Engineering Properties of TantalumСимеон АрабовNo ratings yet

- Plug Valves RevA 2021Document3 pagesPlug Valves RevA 2021Cap1284No ratings yet

- Dextra PC Headed Bar Brochure 2023 ENDocument4 pagesDextra PC Headed Bar Brochure 2023 ENIbrahim BadhushaNo ratings yet

- Technical Data Sheet Jaz Coilex Pe Primer JP-11002: DescriptionDocument2 pagesTechnical Data Sheet Jaz Coilex Pe Primer JP-11002: DescriptionAhmad BougeisNo ratings yet

- Flexible Manufacturing System.Document11 pagesFlexible Manufacturing System.Yaswanth saiNo ratings yet

- Pi Branorost Chips enDocument2 pagesPi Branorost Chips enJaya RidwantoNo ratings yet

- Brief Installation Guide For Fibrolit UltraDocument2 pagesBrief Installation Guide For Fibrolit UltraK PreitoNo ratings yet

- TDS Byk-A 500 UsDocument2 pagesTDS Byk-A 500 UsGustavo CamposNo ratings yet

- Vanadium and Vanadium CompoundsDocument21 pagesVanadium and Vanadium CompoundsПлейнNo ratings yet