Professional Documents

Culture Documents

b291-000!02!42-Wsp-0002 Specification For Offshore Pipeline Welding

b291-000!02!42-Wsp-0002 Specification For Offshore Pipeline Welding

Uploaded by

Chris MacMillanCopyright:

Available Formats

You might also like

- ENS0211 - Arc Welding Quality Rev.DDocument58 pagesENS0211 - Arc Welding Quality Rev.Dsophia com vocêsNo ratings yet

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- Quarter4 M 1 SMAW 10 FinalDocument25 pagesQuarter4 M 1 SMAW 10 FinalTitser Ramca100% (1)

- Ens0211 PDFDocument37 pagesEns0211 PDFRosso50% (2)

- Piping Design Criteria Gd-006 - 000pgd006 0 20040909Document28 pagesPiping Design Criteria Gd-006 - 000pgd006 0 20040909Felipe Eduardo Guzmán SilvaNo ratings yet

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidDocument14 pagesRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidThinh NguyenNo ratings yet

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/15/00 EJL TD DJ KM GH Issued For BidDocument13 pagesRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/15/00 EJL TD DJ KM GH Issued For BidThinh NguyenNo ratings yet

- BT Lic 4000007136Document154 pagesBT Lic 4000007136maximilianoclNo ratings yet

- 5.1. 402020-01391-08-PI-SPC-0001 Rev0Document58 pages5.1. 402020-01391-08-PI-SPC-0001 Rev0sumit kumarNo ratings yet

- Annex Ix.3 - Mech'l SpecsDocument202 pagesAnnex Ix.3 - Mech'l SpecsAfsal JhNo ratings yet

- Piping Standard and SpecificationDocument22 pagesPiping Standard and SpecificationMuhamad Firdaus Bin Azizan100% (5)

- KU-TWK-00-PI-SPC-0001 - 0 - General Welding Specification - UpdatedDocument13 pagesKU-TWK-00-PI-SPC-0001 - 0 - General Welding Specification - Updatedbmanojkumar16No ratings yet

- Manual VelanDocument41 pagesManual Velanluiz.superv.valbracNo ratings yet

- S Civ Ohl - 00Document26 pagesS Civ Ohl - 00HARINo ratings yet

- S Civ Drain - 00Document12 pagesS Civ Drain - 00HARINo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- 12-Division 2-Section 02400 Pipeline by NDM-V 2.0Document26 pages12-Division 2-Section 02400 Pipeline by NDM-V 2.0Avaan IvaanNo ratings yet

- 2722-ME-007 - Piping Design, Fabrication & InstallationDocument42 pages2722-ME-007 - Piping Design, Fabrication & InstallationEngr Muhammad AliNo ratings yet

- Technical Specification For Welding Piping Shop and Field FabricationDocument28 pagesTechnical Specification For Welding Piping Shop and Field FabricationالGINIRAL FREE FIRENo ratings yet

- Pdvsa: Engineering Design ManualDocument9 pagesPdvsa: Engineering Design ManualRafael GarciaNo ratings yet

- S-LV-SWG-Outdoor Ds - 00Document51 pagesS-LV-SWG-Outdoor Ds - 00Sachin PrakashNo ratings yet

- Underground Piping Construction Specification: Sociedad Minera Cerro Verde S.A.ADocument16 pagesUnderground Piping Construction Specification: Sociedad Minera Cerro Verde S.A.AYamalokomokieras Punk RockNo ratings yet

- 11Document66 pages11makeencvNo ratings yet

- 10045D-000-PI-SP-005 - Rev 0 - 07sep10Document21 pages10045D-000-PI-SP-005 - Rev 0 - 07sep10RVELEZNo ratings yet

- S Pu MVLV - 00Document22 pagesS Pu MVLV - 00Amr EidNo ratings yet

- 10045D-000-PI-SP-003 - Rev 2 - 16jan12Document20 pages10045D-000-PI-SP-003 - Rev 2 - 16jan12RVELEZNo ratings yet

- SP0793-0000-1M05-005 - Standard Specification For Welding Rev0 Marzo 2022Document19 pagesSP0793-0000-1M05-005 - Standard Specification For Welding Rev0 Marzo 2022Nestor De Jesus Pico TorresNo ratings yet

- 00 Yt - Mip Tre 050 EngDocument54 pages00 Yt - Mip Tre 050 EngJessica RodriguezNo ratings yet

- 4251-FD-00379827 - C - 02 - Piping Layout & DesignDocument22 pages4251-FD-00379827 - C - 02 - Piping Layout & Designsivaguruswamy thangaraj100% (1)

- Koc MS 002Document30 pagesKoc MS 002Ravi MahetoNo ratings yet

- 5 6204193762172731509Document44 pages5 6204193762172731509muhammad sholehNo ratings yet

- Specification For Hdpe (3lpe) Coating of Carbon Steel PipesDocument21 pagesSpecification For Hdpe (3lpe) Coating of Carbon Steel PipesDanish MohammedNo ratings yet

- P Qac Pro 200 38257 DDDDocument64 pagesP Qac Pro 200 38257 DDDBadiNo ratings yet

- 4119-Sa-00315523 - A - 01 - Piping Design PremiseDocument20 pages4119-Sa-00315523 - A - 01 - Piping Design Premisesivaguruswamy thangaraj100% (1)

- Piping Fabrication and Installation Procedure: Doc. No Rev. No DateDocument24 pagesPiping Fabrication and Installation Procedure: Doc. No Rev. No DateMechanical Static WRK100% (1)

- Fabrication and Installation of Piping ES-14-602-01Document26 pagesFabrication and Installation of Piping ES-14-602-01KeremmNo ratings yet

- AlbahaDocument173 pagesAlbahasamNo ratings yet

- Part 2 - Pipeworks English - FinalDocument20 pagesPart 2 - Pipeworks English - FinalDodi SyamsuNo ratings yet

- OQ Spec Concrete ABB-PPF-CIV-SPC-WPO-000-00005-00Document32 pagesOQ Spec Concrete ABB-PPF-CIV-SPC-WPO-000-00005-00MD Francis DuqmNo ratings yet

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 9/15/00 EL TD DJ KM MWJ Issued For BidDocument19 pagesRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 9/15/00 EL TD DJ KM MWJ Issued For BidThinh NguyenNo ratings yet

- E20-E03 - 0 Lighting & Receptacle Circuit Wiring RequirementsDocument6 pagesE20-E03 - 0 Lighting & Receptacle Circuit Wiring RequirementsMuhammad IrfanNo ratings yet

- 101032-0000-46EC-0001 - PB - Design Criteria PipingDocument16 pages101032-0000-46EC-0001 - PB - Design Criteria PipingBudi HahnNo ratings yet

- Appendix 5 - Mechanical Equipment Installation Rev 0Document33 pagesAppendix 5 - Mechanical Equipment Installation Rev 0joalmese3960No ratings yet

- DP-IN-CD-002 Ver 0 Criterio de Diseño EléctricoDocument47 pagesDP-IN-CD-002 Ver 0 Criterio de Diseño Eléctricoheladio huaquiNo ratings yet

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument23 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- Next Generation SDH/SONET: Evolution or Revolution?From EverandNext Generation SDH/SONET: Evolution or Revolution?Rating: 2.5 out of 5 stars2.5/5 (2)

- Advanced Millimeter-wave Technologies: Antennas, Packaging and CircuitsFrom EverandAdvanced Millimeter-wave Technologies: Antennas, Packaging and CircuitsDuixian LiuNo ratings yet

- Vehicular Networking: Automotive Applications and BeyondFrom EverandVehicular Networking: Automotive Applications and BeyondMarc EmmelmannNo ratings yet

- SDH / SONET Explained in Functional Models: Modeling the Optical Transport NetworkFrom EverandSDH / SONET Explained in Functional Models: Modeling the Optical Transport NetworkNo ratings yet

- Triple Play: Building the converged network for IP, VoIP and IPTVFrom EverandTriple Play: Building the converged network for IP, VoIP and IPTVNo ratings yet

- Minimum Requirements IweDocument52 pagesMinimum Requirements IweIonutz TelteuNo ratings yet

- DLL - Wk6 Smaw and IphpDocument3 pagesDLL - Wk6 Smaw and IphpJAKE ANTHONY MAJADILLASNo ratings yet

- TPS 500i ManualDocument252 pagesTPS 500i ManualGeorgi RadnevNo ratings yet

- LNG and Low Temperature Gas StorageDocument32 pagesLNG and Low Temperature Gas StoragemiladiiiNo ratings yet

- STEEL ProblemsDocument21 pagesSTEEL ProblemsFrances Nicole QuitoNo ratings yet

- CSWIP Sample QuestionsDocument31 pagesCSWIP Sample QuestionsNeo80% (5)

- Asme PQRDocument4 pagesAsme PQRHong Dae Yoon100% (2)

- Training Activity Matrix SMAW NC II COMMONDocument9 pagesTraining Activity Matrix SMAW NC II COMMONEugenio Mates Jr.No ratings yet

- Abrasion Resistance of Fe CR C Coating Deposited by FCAW Welding PR - 2021 - WeaDocument12 pagesAbrasion Resistance of Fe CR C Coating Deposited by FCAW Welding PR - 2021 - WeaEdsonNo ratings yet

- Cast Iron Weld RepairDocument1 pageCast Iron Weld RepairssNo ratings yet

- Validated TVL Smaw11 q3 M 6Document11 pagesValidated TVL Smaw11 q3 M 6tibo bursioNo ratings yet

- Cswip 31 Practical PDFDocument4 pagesCswip 31 Practical PDFJigar PrajapatiNo ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- Oerlikon Competence 3 Grade 92 2008Document32 pagesOerlikon Competence 3 Grade 92 2008Claudia MmsNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Smaw 12 Module 1 Grade 12Document39 pagesSmaw 12 Module 1 Grade 12HERNAN JAY BUYOK100% (1)

- CEAW004001 Field Assy ManualDocument329 pagesCEAW004001 Field Assy ManualBiswajit DasNo ratings yet

- Welding Types Procedures ParametersDocument156 pagesWelding Types Procedures ParametersVinodh Kumar YallaNo ratings yet

- Pemilihan Material PipaDocument37 pagesPemilihan Material PipaSeptian FirdausNo ratings yet

- Eletrode List.Document40 pagesEletrode List.kumarmm12340% (1)

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Arc Welding - Calculator ChartDocument3 pagesArc Welding - Calculator ChartDr. Ladeesh V GopinathNo ratings yet

- ADOR Booklet F Web FDocument132 pagesADOR Booklet F Web FbadesharamkNo ratings yet

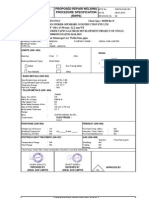

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Section 8 - Arc Equipment and Processes - tcm266-154565Document42 pagesSection 8 - Arc Equipment and Processes - tcm266-154565Maxmore KarumamupiyoNo ratings yet

- 1614416439961ronald Reales OriginalDocument9 pages1614416439961ronald Reales OriginalEstrada Guillan JoyNo ratings yet

- Rig Welder90Document2 pagesRig Welder90Moh AchourNo ratings yet

- AWS A5-5 1996 Low Alloy Steel Electrodes For SMAWDocument55 pagesAWS A5-5 1996 Low Alloy Steel Electrodes For SMAWEmelda JulianNo ratings yet

- 3SS NW00 00007 PDFDocument10 pages3SS NW00 00007 PDFKarthikNo ratings yet

b291-000!02!42-Wsp-0002 Specification For Offshore Pipeline Welding

b291-000!02!42-Wsp-0002 Specification For Offshore Pipeline Welding

Uploaded by

Chris MacMillanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

b291-000!02!42-Wsp-0002 Specification For Offshore Pipeline Welding

b291-000!02!42-Wsp-0002 Specification For Offshore Pipeline Welding

Uploaded by

Chris MacMillanCopyright:

Available Formats

DOCUMENT NO.

SPECIFICATION FOR B291-000-02-42-WSP-0002

OFFSHORE PIPELINE WELDING Rev. 0

Page 1 of 43

SPECIFICATION FOR OFFSHORE PIPELINE WELDING

CLIENT : INDIAN OIL CORPORATION LIMITED

PROJECT:CRUDE HANDLING FACILITIES PROJECT

AT GULF OF KUTCH OFF VADINAR,

GUJARAT

JOB NO. : B291

0 9-06-2020 Issued For Tender S K Mishra P Chowdhary A Roy

Rev.

Date Purpose Prepared by Checked by Approved by

No

Format No. EIL 1641-1924 Rev. 1

Page 1601 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 2 of 45

CONTENTS

1.0 SCOPE ....................................................................................................................................... 3

2.0 CODES, STANDARDS AND SPECIFICATIONS .................................................................... 3

3.0 BASE MATERIAL ..................................................................................................................... 4

4.0 WELDING PROCESSES .............................................................................................................. 4

5.0 WELDING CONSUMABLES................................................................................................... 4

6.0 EQUIPMENT AND ACCESSORIES ....................................................................................... 5

8.0 ALIGNMENT AND SPACING................................................................................................ 6

9.0 WEATHER CONDITIONS ...................................................................................................... 6

10.0 GENERAL WELDING REQUIREMENTS ............................................................................. 7

11.0 HEAT TREATMENT ............................................................................................................. 8

12.0 CLEANING OF THE WELD JOINTS ................................................................................. 9

13.0 INSPECTION AND TESTING .......................................................................................... 10

13.1 General ............................................................................................................................ 10

13.2 WELDING PROCEDURE QUALIFICATION................................................................ 10

13.3 Welder's Qualification ..................................................................................................... 10

14.0 VISUAL INSPECTION ...................................................................................................... 11

15.0 NON-DESTRUCTIVE TESTING ...................................................................................... 11

16.0 REPAIR OF WELDS .......................................................................................................... 12

EXHIBIT – A: ELECTRODE QUALIFICATION TEST RECORD ................................................... 14

EXHIBIT – B: STRESS-RELIEF HEAT TREATMENT PROCEDURE ............................................ 18

EXHIBIT – C: WELDING PROCEDURE APPROVAL TEST RECORD ......................................... 19

EXHIBIT – D: WELDER’S APPROVAL TEST RECORD ................................................................ 22

EXHIBIT – E: WELDER'S IDENTIFICATION CARD ...................................................................... 23

EXHIBIT – F: RADIOGRAPHY PROCEDURE FOR PIPE WELDING ........................................... 24

EXHIBIT – G: AUT PROCEDURE FOR PIPE WELDING ............................................................... 25

ANNEXURE – I: DESTRUCTIVE TESTING OF WELDED JOINT- BUTT WELDS ..................... 26

ANNEXURE – II: RADIOGRAPHY ................................................................................................... 30

ANNEXURE – III: ULTRASONIC TESTING .................................................................................... 35

Format No. EIL 1641-1924 Rev. 1

Page 1602 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 3 of 45

1.0 SCOPE

The requirements stated herein shall be followed for the fabrication of all types of

welded joint of carbon steel piping system connected with the submarine pipeline and

related facilities.

The welded pipe joints shall include the following:

- All line pipe joints of circumferential butt-welded and socket welded types.

- Attachments of castings, forgings, flanges and supports to pipes.

- Welded manifold headers and other sub-assemblies.

- Welded branch connections with or without reinforcing pads.

- Joints in welded / fabricated piping components.

- The attachments of smaller connections for vent, drain drips and other instrument

tapping.

Any approval granted by the COMPANY shall not relieve the CONTRACTOR of his

responsibilities.

2.0 CODES, STANDARDS AND SPECIFICATIONS

2.1 All welded work, equipment for welding, heat treatment, other auxiliary functions and

the welding personnel shall meet the requirements of the codes, standards and

specifications listed below with the latest edition (published when this tender is floated

in the market):

a) Det Norske Veritas DNV-OS-F101: Submarine Pipeline Systems

b) API SPEC 1104: Welding Pipelines and Related Facilities

c) ANSI B 31.4: Code for Transportation System for Hydrocarbons, Liquid Petroleum

Gas, Anhydrous Ammonia and Alcohols

d) ASME BPV Section II PART C: Specification for welding electrodes and filler

materials

e) ASNT TC-1A: Non-Destructive Testing (ASNT - American Society of Non

Destructive Testing)

f) BS EN ISO 6892-1: Metallic materials — Tensile testing — Part 1: Method of test

at room temperature

g) ISO 6507-1: Metallic materials – Vickers hardness test – Part 1: Test method

h) ISO 148-1: Metallic materials – Charpy pendulam impact test – Pat 1: Test Method

i) B291-000-02-42-WSC-0002: Welding Specification Charts for Offshore Pipeline

In the event of conflict between this Specification and other specifications, applicable

codes and references, written clarification shall be sought from COMPANY before

proceeding with the Work. CONTRACTOR shall obtain COMPANY’s prior written

approval for any deviation from the requirements of this Specification, the standards

referenced herein, or the contract documents. In case of conflict, the requirements of

this Specification and referenced documents, COMPANY’s decision shall be final

regarding interpretation of requirements. This Specification is not intended to be all-

inclusive and the use of the guideline set forth does not relieve CONTRACTOR of

CONTRACTOR’s responsibility to supply a product capable of performing its intended

service.

Welding Specification Charts specified in this document shall mean document no.

B291-000-02-42-WSC-0002 provided in the tender document.

Format No. EIL 1641-1924 Rev. 1

Page 1603 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 4 of 45

3.0 BASE MATERIAL

3.1 In general, carbon steel is used in the specifications. The details of material

specifications shall be as per the Welding Specification Charts.

3.2 The CONTRACTOR shall provide the manufacturer’s test certificates for every heat of

the materials, supplied by CONTRACTOR.

3.3 “CONTRACTOR shall develop and utilize a full materials traceability program to track

welding materials from VENDOR source to the ultimate use in the product. Full

traceability program shall record every aspect of welding including welded by

information, date, ambient temperature, NDT repairs, etc.

4.0 WELDING PROCESSES

4.1 The welding processes to be employed are given in the Welding Specification Charts.

4.2 CONTRACTOR shall provide details of the automatic welding processes (machines)

along with past references of similar projects where it has been used, to the

COMPANY for approval. The welding procedure adopted and consumables (including

brand) used shall be specifically approved.

4.3 A combination of different welding processes or a combination of electrodes of different

classes or makes other than given in the Welding Specification Charts, could be

employed for a particular joint only after duly qualifying the welding procedures to be

adopted and after obtaining the approval of the COMPANY.

5.0 WELDING CONSUMABLES

5.1 The CONTRACTOR shall provide all the necessary filler materials, shielding gases etc.

required for the execution of the work.

5.2 The welding electrodes/wires supplied by the CONTRACTOR shall conform to the

classification specified in the Welding Specification Charts. The material shall be of the

make approved by the COMPANY.

5.3 The welding electrodes/wires shall be suitable as proved by weld qualification testing

for the welding process recommended and base metal used. Physical properties and

corrosion resistance of the welds produced by an electrode/wire recommended for the

welding of a particular base metal shall not be lower than the minimum values specified

for the base metal in the finally installed condition and chemical composition shall be

with in the limits specified for base metal unless otherwise specified in welding

specification chart. The choice of electrode/filler wire make shall be made after

conducting the required consumable qualification tests and corrosion testing on the

electrode/filler wire as per relevant ASME specification and bid requirements and shall

be the sole prerogative of the COMPANY. These tests shall be witnessed by the

COMPANY.

5.4 Electrode/filler wire qualification tests records should be submitted as per the Exhibit-A

in respect of the electrodes/filler wire tested by the CONTRACTOR and witnessed by

third party authorized by COMPANY viz Lloyds, DNV, ABS, CEIL, EIL, etc. for

obtaining the approval of COMPANY.

5.5 The CONTRACTOR shall submit batch test certificates from the electrodes/filler wire

manufacturers giving details of physical, chemical and corrosion resistance for each

batch of electrodes/filler wires to be used, tests as required by the Project

Specification, carried out by them. The batch test certificates shall be furnished by

them for COMPANY’s review and approval sufficiently in advance prior to the

commencement of work. Definition of batch shall be as per DNV-OS-F101, Appendix

C, clause no. C 400.

Format No. EIL 1641-1924 Rev. 1

Page 1604 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 5 of 45

5.6 All electrodes/wires shall be purchased in sealed containers and stored properly to

prevent deterioration. The electrodes removed from the containers shall be kept in

holding ovens, except cellulose coated electrodes, at a temperature recommended by

the electrodes manufacturer.

Ovens shall be used for low hydrogen electrodes only. Out-of-the oven time of

electrodes before they are consumed shall not exceed the limits recommended by the

electrodes manufacturer. The electrodes shall be handled with care so as to avoid any

damage to the flux covering.

Different grades of electrodes shall be stored separately. Cellulose coated electrodes

shall, however, be stored as per specific recommendations of manufacturer.

5.7 The electrodes used shall be free from rust, oil, grease, earth and other foreign

materials, which affect the quality of welding.

5.8 Shielding Gas

The composition and purity of shielding gas when required by the welding processes

other than shielded metal arc welding and permitted by the COMPANY shall bear the

approval of the COMPANY.

6.0 EQUIPMENT AND ACCESSORIES

6.1 The CONTRACTOR should have the arrangement of sufficient number of welding and

cutting equipment, auxiliaries and accessories of sufficient capacities so as to meet the

target schedules. The welding equipment and specified welding procedure shall be

qualified prior to production welding.

6.2 All the equipment for performing the heat treatment, including transformers,

thermocouples, pyrometers, automatic temperature recorders with suitable calibration

arrangements, etc. shall be provided by the CONTRACTOR, at his own expense and

these should bear the approval of the COMPANY.

6.3 Re-doing of any work necessitated by faculty equipment or operation used by the

CONTRACTOR, shall be done at his own expense.

7.0 BEVEL CLEANING AND INSPECTION

7.1 Before welding, all rust and foreign matter shall be removed from the bevelled ends by

power operated tools. This shall be affected inside and outside and for a minimum

distance of 25 mm from the edge of the weld bevel. The bevel shall be thoroughly

inspected at this stage.

If any of the ends of the pipe joints are damaged to the extent that, in the opinion of

COMPANY, satisfactory weld spacing cannot be obtained and local repair by grinding

can not be successfully done, the damaged ends shall be cut and re-bevelled to the

satisfaction of the COMPANY, with an approved bevelling machine. Manual cutting and

weld repairs of bevels is not allowed. The lamination, split ends or inherent

manufacturing defects in the pipe shall be discovered and the lengths of pipe

containing such defects shall be removed from the line to the satisfaction of

COMPANY.

The pipes that have been cut back, a zone extending 25 mm back from the new field

bevel, shall be ultrasonically tested to the requirement of the line pipe specification to

ensure freedom from lamination, in accordance with the DNV, “Submarine Pipeline

System”. The acceptance limits shall be as per DNV standard and modified by this

specification.

Format No. EIL 1641-1924 Rev. 1

Page 1605 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 6 of 45

8.0 ALIGNMENT AND SPACING

8.1 Immediately prior to line-up the CONTRACTOR shall inspect the pipe ends inside and

outside for damage, dents, lamination, etc. Pipe for welding shall be set up correctly by

giving the space and by allowing for temperature changes during welding.

Incorrect alignment shall in no circumstances be sprung into position. Temporary

attachments of any kind are prohibited from being welded to the pipe. Welds joining the

sections of the pipeline valve installation or similar welds classed as tie-in welds shall

be made in-situ. Otherwise, the alignment and welding shall be made at the non-line

work station of the barge with the pipe supported on skids and pack pads or other

suitable means approved by COMPANY at least 500 mm above the work floor level of

the barge, unless approved by the COMPANY otherwise in specific cases.

8.2 Seam orientation of welded pipe shall be selected to ensure that at the circumferential

welds, the longitudinal welds shall be staggered in the top 900 of the pipeline or 250

mm whichever is the less. A longitudinal joint should pass an appurtenance of a

structural element at a minimum distance of 50 mm. Should a section of the line

containing uncompleted welds fall from the skids, the CONTRACTOR shall

immediately inform COMPANY.

8.3 Every effort shall be made to reduce misalignment by the use of the internal clamp and

rotation of the pipes to the best fit. For pipe of same nominal wall thickness the off set

should not exceed 1.6 mm. The off set may be checked from outside using internal

offset checking gauges. Any branch connection sleeve, etc. shall be at least 250 mm

from any other weld. The welds for fittings shall be so located that the toe of the weld

shall not come within 50 mm of any other weld. Cold dressing is permissible only with

prior approval of COMPANY’s representative and only in cases of slight misalignment

and shall only be carried out with a bronze headed hammer. Hot dressing shall not be

permitted. When welding pipes of different wall thickness, the thicker pipe shall be

machined to 1:4 taper.

8.4 The root gap shall be accurately checked and shall conform to the qualified welding

procedure. The use of internal line-up clamps is mandatory. However, in some case

(tie-in welds, flanges, fittings, diameter of pipe below 6" etc.) where it is impossible to

use internal clamps, an external line-up clamp may be used.

8.5 The internal line-up clamps shall not be released before the entire root and first hot

passes have been completed. The pipe/barge also shall not be moved before the first

hot pass is completed.

8.6 When an external line-up clamp is specifically permitted by the COMPANY for risers,

tie-in welds etc., all spaces between bars or at least 600 of the first two passes shall be

welded before the clamp is released. Segments thus welded shall be equally spaced

around the circumference of the pipe. Slag shall be removed and cleaned. The ends of

the segments shall be prepared by grinding to ensure the continuity of the weld bead.

The pipe/barge shall not be moved before the hot pass is 100% completed.

9.0 WEATHER CONDITIONS

9.1 The parts being welded and the welding personnel should be adequately protected

from rain and strong winds. In the absence of such a protection no welding shall be

carried out. The completed welds shall be suitably protected.

9.2 In case of bad weather conditions rendering the sea very rough, welding shall be

suspended till the sea becomes calm.

Format No. EIL 1641-1924 Rev. 1

Page 1606 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 7 of 45

10.0 GENERAL WELDING REQUIREMENTS

10.1 Root Pass

10.1.1 Root pass shall be made with the electrodes/filler wires recommended in the

Welding Specification Charts. The size and type of the electrodes used shall be as

per the approved welding procedures.

10.1.2 Separate welding procedures shall be submitted and qualified for vertical up, vertical

down and roll welding. The vertical up method of welding shall be used for the root

pass as well as hot and filler passes of the tie-ins, special crossings, fittings and

special parts, fillet welds, repairs and bad fit-ups and when an external line up clamp

is used.

10.1.3 The root pass of butt joints should be executed properly so as to achieve full

penetration with complete fusion of the root edges. Weld projection inside the pipe

shall not exceed 1.6 mm wherever not specified by the applicable code.

10.1.4 Any deviation desired from the recommended welding technique and electrodes/filler

wires indicated in the Welding Specification Charts should be adopted only after

obtaining express approval of the COMPANY. Any desired deviation may require a

new welding procedure to be qualified.

10.1.5 Welding shall be continuous and uninterrupted during a pass.

10.1.6 On completion of each run, craters, welding irregularities, slag etc. shall be removed

by grinding or by power wire brushing. When simultaneous segmental beads are

made with multiple welding head automatic equipment, care shall be taken to avoid

lack of fusion or lack of penetration at the start-stop points.

10.1.7 When the welding is in progress, care shall be taken to avoid any kind of movement

of the components, shocks, vibrations and stresses, to prevent the occurrence of the

weld cracks.

10.1.8 Fillet welds shall be made by shielded Metal Are Welding (SMAW) process using

low hydrogen electrodes irrespective of the thickness and class of piping. Electrode

size shall not exceed 3.25 mm diameter for socket joints. Al least two passes shall

be made on socket weld joints.

10.1.9 Peening and chiseling shall not be used.

10.2 JOINT COMPLETION

10.2.1 In case of manual welding, the first pass shall be carried out by a minimum of two

welders working simultaneously and so placed as to cause minimum distortion of the

pipe.

10.2.2 The number of welders and the allowable welding sequences shall be as those laid

down in the qualified Welding Procedure Specification (WPS). Once the deposit of

the first pass has been started, it must be completed as rapidly as possible, reducing

interruptions to the minimum. The welding and wire feed speeds shall be within the

parameters of the welding procedure that was established in the Qualified Welding

Procedure Specification.

10.2.3 The pipe shall always be adequately supported and must not be bumped or shaken

during welding. The clamp shall be removed only as indicated in clause 8.5. Before

starting the second pass, the first pass shall be cleaned and flattened with rotating

grinders.

Format No. EIL 1641-1924 Rev. 1

Page 1607 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 8 of 45

10.2.4 The interruption between completion for the first pass and starting the second pass

shall be as stated in the WPS and shall not exceed four (4) minutes when not

specified.

10.2.5 The welding speed selected shall enable production of a bead that shall be

sufficiently thick without any undercutting.

10.2.6 The time lapse between second and third pass shall be as stated in the WPS and

shall not exceed five (5) minutes when not specified. The temperature of the weld

must at all times be held within the inter-pass temperature range as established

when the approved welding procedure was performed. If welding is stopped for any

reason, the minimum preheat temperature as established in the qualified welding

procedure must be applied and maintained after a restart of welding takes place and

the inter-pass temperature of the qualified welding procedure must be kept within

the ranges of the temperatures in the qualified welding procedure. Cleaning between

the passes shall be done carefully to reduce the possibility of inclusions of slag or

defects within the weld.

10.2.7 Electrode starting and finishing points will be staggered from pass to pass. Arc-

strike or arc-burn on the pipe surface is not permitted. Arc-strike or arc-burn on the

pipe surface that is caused accidentally by the electrical arc between the electrode

and the electrode holder or the welding cable, the affected portion shall be removed

by grinding in accordance with a Qualified Procedure approved by the COMPANY.

The repair shall be checked by ultrasonic test, radiography and magnetic particle or

dye penetrant tests, whichever the COMPANY feels necessary. The pipe wall

thickness after grinding shall not be less than the minimum thickness limit permitted

for the pipe. Repair of arc strikes by welding is prohibited.

10.2.8 The completed joint shall be carefully brushed and cleaned and shall be free from

spatters, scales etc.

These requirements shall apply not only to the completed weld joints but also to the

bare strip at least so wide as to allow full skip examination at both ends of the pipe

by ultrasonic tests, whenever it is required.

11.0 HEAT TREATMENT

11.1 Pre-heating

11.1.1 Pre-heating requirement for the various materials shall be as per the Welding

Specification Charts and/or as established during the Welding Procedure

Qualification. The preheat temperature must be a minimum 40 °C to offset the

coldest conditions at work site.

11.1.2 Pre-heating shall be performed using electrical resistance or induction heating

methods. Pre-heating by gas burners utilizing acetylene or propane gas and oxy-

propane gas can be used with the permission of the COMPANY under careful

supervision.

11.1.3 Pre-heating shall extend uniformly to at least three times the thickness of the joint,

but not less than 50 mm on both sides of the weld.

11.1.4 Pre-heating temperature shall be maintained over the whole length of the joint during

welding. Crayons or any other temperature indicating devices shall be provided by

the CONTRACTOR to check the temperature.

11.2 Post-Weld Heat Treatment (PWHT)

11.2.1 PWHT whenever required for the joint between the pipes and the fitting, the pipe

body and the supports shall be carried out by the CONTRACTOR at his expense as

Format No. EIL 1641-1924 Rev. 1

Page 1608 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 9 of 45

per the relevant specifications and the instructions of the COMPANY to be

applicable for the subject job.

11.2.2 PWHT of the joints shall be carried out as per the requirements laid down in Welding

Specification Charts and/or the requirements of the relevant code.

11.2.3 The CONTRACTOR shall submit the details of the PWHT procedure as per Exhibit

`B' attached for the approval of the COMPANY, before carrying out the actual heat

treatment for the component involved.

11.2.4 PWHT shall be done in a furnace or by using an electric resistance or induction

heating methods.

11.2.5 While carrying out local PWHT, the technique of applying heat shall ensure uniform

temperature attainment at all points of the portion being heated. Care shall be taken

to ensure that the width of the heated band shall attain the specified PWHT

temperature as per the applicable standards/codes.

11.2.6 Through out the cycle of the PWHT, the portion outside the band shall be suitably

wrapped under insulation to avoid any harmful temperature gradient. At the exposed

surface of the pipe, the temperature shall not be allowed to exceed 316°C.

11.2.7 The temperature during PWHT shall be recorded by means of thermocouple.

Adequate numbers of thermocouples shall be attached to the pipe directly at equally

spaced locations along the periphery of the pipe joint. The minimum number of

thermocouples attached per pipe joint shall be two (2) upto 10" diameter and three

(3) for 12" diameter and above. The COMPANY can increase the minimum number

of thermocouples to be attached if found necessary.

11.2.8 Automatic temperature recorders that have been suitably calibrated shall be

employed. The calibration chart of each recorder shall be submitted to the

COMPANY and the necessary approval shall be obtained prior to the starting the

PWHT operation.

11.2.9 Immediately on completion of the PWHT, the temperature records and charts along

with the hardness test results on the weld joints shall be submitted to COMPANY for

its review and clearance.

11.2.10 Each joint shall bear an identification number that shall be maintained in the piping

sketch to be prepared by the CONTRACTOR. The joint identification number shall

appear on the corresponding PWHT charts. The same identification numbers shall

also be followed for the identification of the corresponding radiography films. The

chart containing identification number and piping sketch shall be submitted to the

COMPANY for its review and clearance.

11.2.11The hardness shall be measured in Vickers or Brinell scale by using a portable

hardness tester on the heat affected zone as well as on the weld metal after PWHT

and shall not exceed the maximum hardness specified in the welding Specification

Charts. The weld joint shall be subjected to re-PWHT, when hardness measured

exceeds the specified limit at the CONTRACTOR's own expense.

11.2.12 The CONTRACTOR shall arrange for the hardness testing and shall maintain the

records of all the joints tested. These records shall be checked by the COMPANY's

inspector.

12.0 CLEANING OF THE WELD JOINTS

12.1 All weld joints shall be free from adherent weld spatter, slag, swarf, dirt or foreign

matter.

Format No. EIL 1641-1924 Rev. 1

Page 1609 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 10 of 45

13.0 INSPECTION AND TESTING

13.1 GENERAL

13.1.1 The COMPANY's representative shall have a free access to all concerned areas,

where the actual work is being performed. The CONTRACTOR shall also afford the

COMPANY's inspector all means and facilities necessary for carrying out inspection.

13.1.2 The COMPANY is entitled to depute its own representative to the shop or field

where prefabrication may be carried out and to the barge where laying of pipelines

are being done with (but not limited to) the following objectives:

i) To check the conformance to relevant standards and suitability of various

welding equipments and the welding performance.

ii) To supervise the welding procedure qualification

iii) To supervise the welders performance qualification

iv) To check whether shop/barge welding being executed is in conformity with the

relevant specifications and codes of practices followed in pipe construction

13.1.3 CONTRACTOR shall notify COMPANY sufficiently in advance of the

commencement of qualification tests, welding works and acceptance tests to enable

the COMPANY's representative present to supervise them.

13.1.4 The CONTRACTOR shall deploy at least two of their quality control personnel per

shift on the barge to supervise, guide, and enforce their quality control activity.

13.2 WELDING PROCEDURE QUALIFICATION

13.2.1 Welding Procedure Qualification shall be carried out in accordance with the

requirements of DNV Rules for Submarine Pipeline System, latest edition or other

applicable codes, by the CONTRACTOR at his expense at the pipelay barge afloat

or at a simulated condition using identical equipment to be used in pipelay welding.

The CONTRACTOR shall submit the Welding Procedure Specification in format as

per Exhibit-C immediately after the receipt of the order. The base pipe to be used

shall conform to the Project Specification.

13.2.2 COMPANY's representative shall review, check and approve the welding procedure

submitted and shall release the procedure for Procedure Qualification Tests (PQT).

The PQT shall be carried out by the CONTRACTOR under field conditions at his

own expense and in presence of COMPANY representative. A complete set of test

results in format as per Exhibit-C shall be submitted to the COMPANY's inspector for

its review and approval immediately after completing the PQT and at least 2 weeks

before the commencement of actual work. All the tests specified in the DNV

standard shall be carried out. In addition to these tests other tests such as corrosion

tests, metallography etc., as specified for the base metal and other tests as per

Project Specifications shall be carried out. It shall be the responsibility of the

CONTRACTOR to carry out all the tests required to the satisfaction of the

COMPANY's representative.

13.3 WELDER'S QUALIFICATION

13.3.1 Welders shall be qualified prior to or at the pipe lay barge at the offshore site in

accordance with the DNV standard by the CONTRACTOR at his expense. The butt

weld test pieces of the qualification test shall meet the radiography requirements or

Automated Ultrasonic testing requirements (as required for welding procedure

qualification) specified in clause no. 15. The COMPANY's representative shall

witness the test and certify the qualification of each welder separately. Only those

welders who have been approved by the COMPANY's inspector shall be employed

Format No. EIL 1641-1924 Rev. 1

Page 1610 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 11 of 45

for actual welding. CONTRACTOR shall submit the welding qualification tests

reports in the standard format as shown in Exhibit C & D and obtain approval before

commencement of the work. It shall be the responsibility of CONTRACTOR to carry

out qualification tests of the Welders.

13.3.2 Pipe material used for Welder's Qualification testing shall conform to Project

specification.

13.3.3 After the Welder’s qualification for each welder, COMPANY can request for a

complete detailed examination of the first weld by each welder to check his ability on

the job. Examination of this test weld shall be carried out in accordance with DNV

standard and as specified in this specification in a laboratory at the expense of the

CONTRACTOR. The CONTRACTOR shall comply with this request.

13.3.4 The welders shall always have in their possession the identification card as shown in

Exhibit-E and shall produce it on demand by the COMPANY's inspector. It shall be

the responsibility of the CONTRACTOR to issue the identity cards after the same is

duly certified by the COMPANY.

13.3.5 No welder shall be permitted to work without the possession of the identify card.

13.3.6 If a welder is found to perform a type of welding or in a position for which he is not

qualified, he shall be stopped from doing any further work. All welds performed by

an unqualified welder shall be cut and re-done by a qualified welder at the expense

of the CONTRACTOR.

14.0 VISUAL INSPECTION

14.1 Inspection of all welds shall be carried out by the COMPANY as per the latest

editions of DNV-OS-F101 before the field coating is applied. All finished welds shall

be visually inspected for parallel and axial alignment of the work, excessive

reinforcement, concavity of welds, shrinkage, cracks, under-cuts, correctness of

dimensions, surface porosity and other surface defects. Undercutting adjacent to the

complete weld shall not exceed the limits specified in the DNV-OS-F101.

15.0 NON-DESTRUCTIVE TESTING

15.1 The non-destructive testing shall mainly consist of examination using AUT inspection

(as per Appendix E of DNV-OS-F101) or X-ray radiography as detailed in Annexure-

II. Contractor to note that narrow bevel weld joints shall be examined by AUT

inspection only.

15.2 100% radiography or AUT for girth welds will be required by the COMPANY. Welds

shall meet the standards of acceptability as set forth in DNV-OS-F101 and as well as

the requirements laid down in subsequent paragraphs of this specification.

15.3 The CONTRACTOR shall make all the arrangements for the NDT (non-destructive

testing) work as required by the specification at his expense.

15.4 The COMPANY shall review all the NDT reports of welds and inform the

CONTRACTOR regarding the unacceptable welds. The decision of the COMPANY

shall be final and binding in this regard.

15.5 All requirements mentioned in the specification shall be arranged and executed by

the CONTRACTOR through his own resources. In addition, the ultrasonic test is

required in the following cases as per Annexure-III of this specification:

15.5.1 When 25 mm or more are cut from the joint as supplied, the ends shall be offered for

ultrasonic testing for an additional length of 25 mm to ensure the absence of

lamination.

Format No. EIL 1641-1924 Rev. 1

Page 1611 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 12 of 45

15.5.2 When welds are repaired. Repair attempts will be limited to one attempt per each

defect. After a repair is made, the repaired weld must be inspected visually and with

NDT as per the welding code acceptance criteria as qualified for the pipeline.

15.5.3 When in the opinion of the COMPANY, ultrasonic testing is required to conform or

clarify any defects indicated by radiography, the same shall be carried out.

15.5.4 When automatic procedure is used, at least 10 cm on each side of each weld shall

be subject to ultrasonic testing at the CONTRACTOR's expenses.

15.5.5 In addition, the ultrasonic testing shall be required for certain critical welding of the

pipeline (i.e. tie-ins, welding of valves, flanges) randomly selected at COMPANY's

discretion and at CONTRACTOR's expense. All fillet and groove welds, other than

those radiographed, shall be subject to Dye Penetrant (DP) or Magnetic Particle

(MP) testing as per applicable standards. The non-destructive tests used for

inspecting welds shall be approved by the COMPANY.

15.6 Weld quality shall be judged on the basis of the acceptability criteria mentioned

below:

15.6.1 Any weld which as a result of radiographic and/or ultrasonic examination in the

opinion of COMPANY exhibits imperfections greater than the limits stated in DNV

“Submarine Pipeline Systems” and as superseded in this article, shall be considered

defective and shall so be marked with an identification paint marker.

15.6.2 No crater cracks in the root is acceptable. The defects acceptance criteria for

inadequate penetration and incomplete fusion shall be as per DNV-OS-F101 for root

region. However, the maximum length shall not exceed thickness, t of the pipe for

root defects.

In addition to the acceptance criteria given in DNV standard, no amount of linear

shrinkage at the root revealed in the NDT as used is acceptable.

The acceptance criteria for defects other than root shall be as per DNV “Submarine

Pipeline Systems” with the stipulations mentioned therein for each type of defect

weld.

15.6.3 Un-repaired burn through areas are unacceptable.

15.6.4 Suitable records shall be maintained by the CONTRACTOR as desired by the

COMPANY on the day-to-day work done on welding, radiography, ultrasonic testing.

The CONTRACTOR shall present the records to the COMPANY on day-to-day basis

for review and approval.

16.0 REPAIR OF WELDS

16.1 All welds which do not comply with the standards of acceptability shall be repaired or

the joint cut out and re-welded.

16.2 A separate repair Welding Procedure Specification sheet shall be formulated and

qualified by the CONTRACTOR. All the tests carried out for Procedure Welding

Qualifications shall be conducted for repair Welding Procedure Qualification Testing.

16.3 Defective area shall be excavated by air-arc gouging and/or by grinding. For API 5L

grades above X-60 and thickness over 19 mm, pre-heating shall be carried out prior

to gouging. The groove should extent at least 25 mm on either side beyond the

extremities of the defect to ensure that it is completely removed. Excavated area

shall be examined by DP or MP testing prior to welding in order to ensure the

removal of the defects. Pre-heating for repair welding shall be 500C above the

specified pre-heat for the original welds in the respective WPS.

Format No. EIL 1641-1924 Rev. 1

Page 1612 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 13 of 45

Repair of weld cracks will not be accepted. If a weld cracks, a complete cut out of

the subject weld is required prior to re-welding.

16.4 Root sealing or single pass repair deposit shall not be allowed. Internal root defects

shall be ground thoroughly and welded with a minimum of two passes. While

grinding for repair, care shall be taken to ensure that no grinding marks are made on

the pipe surface.

16.5 All repairs shall be subject to minimum requirements such as same testing and

inspection as the original weld. The entire repaired portion, including 50 mm on all

sides of the portion, shall be radiographed. 100% Ultrasonic Testing shall be done at

the repaired area externally including 50 mm all around. Any repaired area that is

wide, irregular or rough shall be rejected and a full cut out shall be done.

16.6 Welds not meeting the specification requirements after one repair may be cut out

depending upon the extent of repair, when decided by COMPANY at

CONTRACTOR’s expense. A report of all repairs shall be maintained by the

CONTRACTOR and submitted every day to the COMPANY for review and approval.

Format No. EIL 1641-1924 Rev. 1

Page 1613 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 14 of 45

EXHIBIT – A: ELECTRODE QUALIFICATION TEST RECORD

A) Tested At (Site Name):___________________________ Date:__________________

Manufacturer's Name:___________________________ Test Period:_____________

Brand Name :___________________________

Batch Number and

Size Tested :___________________________

Classification & Code:___________________________

Intended for Welding

in Position :___________________________

In Combination With :___________________________

(if any)

Code of Reference :___________________________

(Used for Testing)

Special Requirements:___________________________

(if any)

B) All-Weld Tensile Test

Base Material Used :___________________________

Pre-Heat Temp. :___________________________

Post-Weld Heat :___________________________

Treatment Details

Visual Examination :___________________________

Radiography :___________________________

Examination

Tensile Test Results

IDENTIFICATION

S.NO. NO. U.T.S. YIELD POINT ELONGATION REMARKS

1

2

3

4

5

Format No. EIL 1641-1924 Rev. 1

Page 1614 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 15 of 45

C) Impact Test Results

Test Temperature :__________________ Notch In:_________________

Type of Specimens :__________________ Size of Specimens:_________

(CHARPY)

S.NO. SPECIMEN NO. IMPACT VALUE AVERAGE

1

2

3

4

5

D) Chemical Analysis Report

Electrode Size Used:_________

Batch No.:__________________

Other

%C %S %P %Si %Mn %Cr %Ni %Mo Elements

E) Fillet Weld Test Results

Welding Positions :____________________________________________

Base Materials :____________________________________________

Size of Electrode Used :____________________________________________

Visual Inspection : ____________________________________________

____________________________________________

Macrostructure Test Results:_________________________________________

Fracture Test Results :____________________________________________

Remarks :____________________________________________

F) Other Test Results

Transverse Tensile Test:_____________________________________________

In Combination with Base Material Used:________________________________

Position of Welding:_________________________________________________

Pre-HeatTemperature: _______________________________________________

Format No. EIL 1641-1924 Rev. 1

Page 1615 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 16 of 45

Post-Weld HeatTreatment:____________________________________________

Radiography:

IDENTIFICATION NO. U.T.S. FRACTURE IN REMARKS

G) Guided Bend Test

ROOT FACE

POSITION IDENTIFICATION NO. ROOT,

OR SIDEFACE

BEND REMARKS

1.

2.

3.

4.

5.

H) Any other tests

Corrosion Test Remarks

1. ____________________________________

2. ____________________________________

3. ____________________________________

4. ____________________________________

Format No. EIL 1641-1924 Rev. 1

Page 1616 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 17 of 45

Metallography Remarks

1. ____________________________________

2. ___________________________________

3. ____________________________________

4. ____________________________________

CONCLUSIONS:

APPROVED BY:

Format No. EIL 1641-1924 Rev. 1

Page 1617 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 18 of 45

EXHIBIT – B: STRESS-RELIEF HEAT TREATMENT PROCEDURE

Name of the Heat Treater:_________________________________________________

Name of the Project:______________________________________________________

Specification Reference No.:________________________________________________

1. General Details 2. Furnace Details

Name of the Type of Heating: Gas/Oil/Electrical/

Equipment:______________________ Resistance Induction

Applicable type: (Tick

mark)

Name of the

Assembly/Part:____________________ Capacity (Size):_______________

Assembly/Part Maximum Temp (0C):___________

Drawing No.:______________________

Method of temp.

Material:__________________________ Measurement:__________________

Atmosphere Control:______________

3. Heating Treatment Cycle Details

Charging Temp 0C: _______________________________________________

Rate of cooling, 0C/hr:______________________________________________

Soaking Temp., 0C:_________________________________________________

Soaking Time, hrs.:_________________________________________________

Rate of coding, 0C/hr:________________________________________________

Mode of Cooling: ___________________________________________________

4. Number of Thermocouples and Locations on joint:____________________________

5. Other Details, if any: __________________________________________________

______________________________________________________________________

Notes: The following documents shall be furnished along with the specifications:

i) Material test certificates,

ii) Assembly/Part Drawings.

Signature of the Heat Treater Approved By

Format No. EIL 1641-1924 Rev. 1

Page 1618 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 19 of 45

EXHIBIT – C: WELDING PROCEDURE APPROVAL TEST RECORD

Project/Contrac CONTRACTOR

t

Pipe and fitting material

Process

Outside

diameter

Pipe thickness

Joint design (Sketch attached)

Make and type Diameter Current Voltage

of filler metal

Root

Second run

Other runs

Other electrical characteristics ac/dc Electrode negative/positive

Shielding gas

Type of mixture

Flow

Shielding flux

Position

Direction of welding:

Root: Vertical up*/ Vertical down

Second run: Vertical up*/ Vertical down

Other runs: Vertical up*/ Vertical down

Number of welders:

Root:

Format No. EIL 1641-1924 Rev. 1

Page 1619 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 20 of 45

Second run:

Other runs:

Time lapse between commencement of second

run and commencement of other runs:

Minimum number of runs before joint allowed

to cool:

Maximum time between commencement and

Completion of weld:

Type of line-up clamp:

Removal of clamp after run:

Lowering off after run:

Cleaning:

Pre-heating:

Minimum temperature:_____0C Ambient temperature:____ 0C

Type of heater to be used:

Interpass temperature:

Minimum temperature:_____0C Maximum temperature:____ 0C

Post weld heat treatment:

Speed of travel:

Test results:

State acceptable:___________ non-acceptable (with reasons):________________ or

give numerical results________________

Non-destructive tests:

Visual:

Radiography:

Format No. EIL 1641-1924 Rev. 1

Page 1620 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 21 of 45

Destructive tests: 1 2 3 4

Transverse tensile:

Tensile strength:

Fracture location:

Test temperature:

Macro-examination:

Fillet-weld fracture:

Hardness survey:

Type:_____________ Load:_______

Location of hardness measurements: (Sketch)

Hardness range:_____________

Parent metal________________

Heat affected zone:___________

Weld:______________________

Charpy V-notch impact tests:

Specimen location and size:__________________

Notch location:_____________________________

Test temperature:___________________________

Energy values:______________________________

Additional tests and results

Chemical analysis:______________________________

Microstructural examination:_______________________(attach photographs)

CTOD tests:_____________________________________

Bend tests:_______________________________________

The statements in this record are correct. The test joints were prepared, welded and tested in

accordance with the requirements of this specification.

CONTRACTOR: Inspector:

Position: Witnessed by:

Date: Date:

Format No. EIL 1641-1924 Rev. 1

Page 1621 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 22 of 45

EXHIBIT – D: WELDER’S APPROVAL TEST RECORD

Welder test certificate: Test no.:

Project/Contract: Date:

CONTRACTOR: Inspector:

Welder’s name:

Address:

Pipe material:

Pipe thickness:

Pipe outside diameter:

Welding process: Root: Fill and Cap:

Electrode/wire:

Root: Current: Voltage:

Second run: Current: Voltage:

Full and Cap: Current: Voltage:

Direction of travel Root: Vertical up*/ Fill and Cap: Vertical up*/

Vertical down Vertical down

Reason for failure:

Visual:

Non-destructive testing:

Butt joint:

Fillet weld:

Number of attempts:

Comments:

Signature of CONTRACTOR Signed by Inspector

Date: Date:

Time: Time:

* Delete as necessary

Format No. EIL 1641-1924 Rev. 1

Page 1622 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 23 of 45

EXHIBIT – E: WELDER'S IDENTIFICATION CARD

Name :__________________________________________

Identification :__________________________________________

Photograph :

Date of Testing :___________________________________________

Valid unit :___________________________________________

Approval of Welding :___________________________________________

Welding Process :___________________________________________

Welding Position :___________________________________________

Material :___________________________________________

Diameter :____________________________________________

Wall thickness :____________________________________________

Type of welding Consumable :_____________________________________________

Code of compliance :_____________________________________________

Welding procedure reference :______________________________________________

Remarks :______________________________________________

Approved by: Employer's Signature with seal

Format No. EIL 1641-1924 Rev. 1

Page 1623 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 24 of 45

EXHIBIT – F: RADIOGRAPHY PROCEDURE FOR PIPE WELDING

1. Location:

2. Date of Testing:

3. Name of Supervised CONTRACTOR:

4. Material:

5. Diameter and Thickness:

6. Type of weld joint:

7. Radiation Source (X-ray/Iridium-192):

8. Radiation Intensity:

9. Type of equipment (External/internal):

10. Intensifying screens and material:

11. Filter type and placement mask, Diaphragm lead screen etc. adjacent to radiation

source or specimen):

12. Radiography technique:

13. Geometric relationship (Source Local spot size., Max. and min. source strength, object

to film distance, radiation angle with respect to weld and film):

14. Limit of film coverage:

15. Film type and make:

16. Exposure Time:

17. Processing (Time temperature for development, Stop bath or rinse, fixation, washing,

drying etc.):

18. Density:

19. Sensitivity:

20. Type of Penetrameter:

Approval of the COMPANY Signature of CONTRACTOR with Seal

Format No. EIL 1641-1924 Rev. 1

Page 1624 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 25 of 45

EXHIBIT – G: AUT PROCEDURE FOR PIPE WELDING

1. Location:

2. Date of Testing:

3. Name of Supervised CONTRACTOR:

4. Material:

5. Diameter and Thickness:

6. Type of weld joint with sketch:

7. Instrument manufacturer and model:

8. Search unit(s) detail:

9. Surface preparation:

10. Couplant:

11. Focal range(s):

12. Virtual aperture size(s):

13. Scan plan:

14. Calibration blocks:

15. Frequency of calibration:

16. Recording/Evaluation criteria:

17. Data presentation:

18. Acceptance criteria:

Approval of the COMPANY Signature of CONTRACTOR with Seal

Format No. EIL 1641-1924 Rev. 1

Page 1625 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 26 of 45

ANNEXURE – I: DESTRUCTIVE TESTING OF WELDED JOINT- BUTT WELDS

1.0 DESTRUCTIVE TESTING OF WELDED JOINT- BUTT WELDS

1.1 Preparation

1.1.1 After the completion of satisfactory visual and non-destructive testing, the test weld

shall be subject to mechanical test.

After satisfactory completion of all visual and non-destructive testing, no further work

on the test weld and no cutting of test specimens from the weld for qualification tests

shall be performed until a period of at least 24 hours has expired since preparation

of test welds.

1.1.2 Weld specimens, shall be taken from the positions indicated in Fig. 1 and 1A of this

specification, from areas as free from defects as possible. For this reason it is

necessary to take the previous non-destructive tests into account. The minimum

number of tests to be carried out is given in Table 1 of this Annexure.

1.1.3 The test shall be carried out at laboratories approved by the COMPANY. The

specimens shall be prepared in accordance with the figures given in the paragraphs

which refer to the individual test.

1.2 Tensile strength

1.2.1 Specimen

1.2.1.1 Specimen shall be taken form the position indicated in Fig.1 and 1A of this

specification.

Table 1

Type and Number of Tests for Procedure Qualification and Production Weld Joints

CHAR CORROSIO

PY N TESTS

TRAN V- MAC

S- NOTC RO+

WALL OUTSI VERS H HARD

THICK DE E ROO SAMP -

- DIA- WELD T NICK LE (3) NESS MICR

NESS METER TENSI BEN FACE SIDE BREA (4) (5) (200X O SSC

(MM) (MM) LE D BEND BEND K (2) & (6) ) (25X) HIC C

12.5 300 2 2 2 0 2 4 2 2 2 2

12.5 300 4 4 0 4 (1) 4 4 2 2 2 2

12.5 300 2 0 0 4 2 4 2 2 2 2

12.5 >300 4 0 0 8 4 4 2 2 2 2

Notes:

1. Root and face bend tests may be used instead of side bends.

2. Nick break test may be omitted for manual metal arc welding to be performed above

water.

Format No. EIL 1641-1924 Rev. 1

Page 1626 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 27 of 45

3.

4. Each Charpy `V' notch sample consists of 3 specimens.

5. Impact testing is to be carried out with the `V' notch positioned in the weld metal, on the

fusion line, 2 mm from the fusion line and 5 mm from the fusion line.

6. When more than one welding processes or welding consumables are used, impact

testing shall be carried out in the corresponding welding regions, if the region tested

can not be considered representative for the complete weld.

7. In case the pipe dimensions are such that the use of sub-sized specimens become

necessary, the Charpy V-notch impact values specified in the Welding Specification

Chart shall be modified as below:

Specimen Size (mm) Energy Reduction Factor

10 x 7.5 5/6

10 x 5 2/3

The number of tests indicated herein is for welding procedure qualification only.

Production test shall be carried out as per DNV Rules for Submarine Pipeline System.

1.2.2 Method

1.2.2.1 The test shall be carried out in accordance with BS EN ISO 6892-1.

1.3.0 Nick-break Test

1.3.1 Preparation

1.3.3.1 Specimens for nick-break test with notches thus worked can break in the base

metal, instead of in the fusion zone. Therefore, an alternative test piece must be

used after authorization by the COMPANY with a notch cut in the reinforcement of

cut side weld bead to a maximum depth of 1.5 mm, measured from the surface of

the weld bead. The acceptance criteria shall be as per API 1104.

1.4.0 Macroscopic Inspection

1.4.1 Preparation

1.4.1.1 Specimens shall be taken from the positions indicated in Fig. 1 of this specification

and shall be prepared in accordance with ASTM E3-11.

1.4.1.2 The width of the macro-section has to be at least three times the width of the weld.

The section is to be prepared by grinding and polishing and etched to clearly reveal

the weld metal and heat affected zone.

1.4.2 Method

1.4.2.1 Specimens shall be carefully examined under the microscope, with a magnification

of at least 25x. The COMPANY may ask for microphotographs with 5x

magnification, for documentation purpose.

1.4.3 Requirements

1.4.3.1 Under microscope examination, the welded joints shall show good penetration and

fusion, without any defect exceeding the limits stated in DNV-OS-F101.

1.5.0 Hardness Test

1.5.1 Preparation

Format No. EIL 1641-1924 Rev. 1

Page 1627 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 28 of 45

1.5.1.1 The prepared macro-section is to be used for hardness testing using the Vickers

method as per ASTM E92 with 10 kg load. Indentations are to be made along

traverses each approximately 1 mm below the surface at both side of the weld.

In the weld metal a minimum of 6 indentations equally spaced along the traverses

are to be made. The HAZ indentations are to be made along the transverses for

approximately 0.5 mm each into unaffected material and starting as close to the

fusion line as possible.

1.5.1.2 One indentation at each side of the weld along each traverse has to be made on

parent metal. Reference is made to Fig. 3 of this specification. The indentations

are to be made in the adjacent region as well as on the opposite side of the macro-

section along the specified traverses.

1.6.2 Method

1.5.2.1 The test shall be carried out in accordance with ASTM E 92, Vickers hardness,

using a laboratory type machine with a load of 10 kg.

1.5.3 Requirements

1.5.3.1 Hardness value shall not exceed the value given in Welding Specification Chart

(250 HV10) in case of a single reading slightly (+10 HV10) higher than the specified

limit, further indentations should be made to check if the high value is on isolated

case.

1.6.0 Charpy V-Notch Impact Test

1.6.1 Specimen

1.6.1.1 Specimens shall be taken from the position indicated in Fig.1 of this specification.

The test specimens shall be prepared in accordance with BS EN ISO 148-1. Charpy

V-notch specimens shall have dimensions as given in Fig.4 of this specification.

1.6.1.2 Three (3) test specimens shall be taken from each sample and they shall be out and

worked so that their length is transverse and perpendicular to the weld bead with the

notch position as shown perpendicular to the roller direction wherever applicable the

test specimen width shall depend upon the pipe wall nominal thickness as follows:

Wall nominal thickness (mm) Test specimen width (mm)

Over 12 10

Over 9.5 and upto 12 7.5

From 7 upto 9.5 5

Less than 7 2.5

1.6.2 Test Method

1.6.2.1 The test shall be carried out in accordance with BS EN ISO 148-1 or ASTM A 370.

1.6.2.2 Test pieces shall be immersed in a thermostatic bath and maintained at the test

temperature for at least 15 minutes. They shall then be placed in the testing

machine and broken within 5 seconds of their removal from the batch. The test

temperature shall be as specified in the Welding Specification Chart.

1.6.3 Requirements

1.6.3.1 The impact energy shall meet the requirements laid down in APPENDIX C of DNV-

OS-F101, Rules for Submarine Pipeline Systems, unless otherwise specifically

modified by this specification or mentioned in the Welding Specification Chart,

B291-000-02-42-WSC-0002.

Format No. EIL 1641-1924 Rev. 1

Page 1628 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 29 of 45

1.7 Bend Test Requirements

1.7.1 The Bend test specimens shall be made and tested as per the requirements of

APPENDIX B of DNV-OS-F101, Rules for submarine pipelines except that the

dimensions of the Jig for guided bend test shall be modified as follows:

Radius of the Plunger `A' : 2t (t = thickness of specimen)

Radius of the dia. `B' : 3t + 1.5 mm

Radius of the dia. `C' : 50.8 mm

1.7.2 The acceptance criterion shall be as per Clause No. F.306 of APPENDIX C of DNV-

OS-F101, Rules for Submarine Pipeline Systems.

1.8 Corrosion Tests

Corrosion tests shall be done on the weld procedure tests when specified regarding

the specification chart as per the following requirements and as specified in the bid

documents to determine the suitability of the weld procedure for the application.

1.8.1 Hydrogen Induced Cracking Test

Method of Testing - The method of testing shall be as per test procedure mentioned

in NACE TM0284.

A) Procedure for Extraction

The specimen shall be as per NACE TM0284.

B) Frequency and number of specimens

Three (3) specimens shall be tested for each weld procedure. Three (3)

specimens shall be taken 1200 apart around the circumference.

C) Acceptance Criteria

The acceptance criteria for Crack Sensitivity Ratio (CSR) shall be 0.00%

(Max.). If one (1) specimen fails to meet the criteria, three (3) more specimens

shall be taken from the same pipe for retests and all the specimens shall meet

the requirements otherwise the weld procedure shall be rejected.

1.8.3 Four Point-bend Test (Sulphide Stress Corrosion Cracking Test)

Bend test shall be carried out on the test made for each weld procedure. One set of

three (3) specimens shall be machined for four point bending tests. The specimen

thickness shall be minimum 5 millimeters and shall be machined from pipe wall

thickness. The location and selection of the specimens shall be decided by the

COMPANY. The test specimen shall be as per NACE TM0177. The specimens shall

be bent to reach a stress level of 72% SMYS, as per ASTM G 39, and then

immersed in NACE solution as per NACE TM0177 for a period of 96 hours with

inner surface in tension. There shall be no Sulphide Stress Corrosion (SSC) Cracks.

If one (1) specimen fails to meet the Criteria, three (3) more specimens shall be

taken from the same pipe for retests and all the specimens shall meet the

requirement otherwise the weld procedure shall be rejected.

Format No. EIL 1641-1924 Rev. 1

Page 1629 of 2324

SPECIFICATION FOR DOCUMENT NO.

OFFSHORE PIPELINE B291-000-02-42-WSP-0002

WELDING Rev. 0

Page 30 of 45

ANNEXURE – II: RADIOGRAPHY

1.0 SCOPE

This annexure covers the radiographic inspection of all types of welded joints of the

main pipeline.

The welded joints shall include the following:

i) DNV Standard “Submarine Pipeline Systems”, OS-F101

ii) ASTM E94 - 04(2010) Standard Guide for Radiographic Examination

iii) The American Society for Nondestructive Testing. Recommended Practice

No. SNT-TC-1A Supplement A.

iv) Project Specification

3.0 PROCEDURE

3.1 The radiography procedure to be adopted shall be submitted by the CONTRACTOR

as per Exhibit F.

3.2 The procedure of radiography shall be qualified to the entire satisfaction of

COMPANY prior to use as per the requirements of DNV. It shall include but not be

limited to the following requirements:

i) Only automatic film processing shall be used.

ii) Lead foil intensifying screens, at both sides of the film shall be used for all

exposures

iii) Only type 2 & 3 films as per ASTM E-94 shall be used.

iv) A densitometer shall be used to determine film density. The transmitted film

density shall be 1.8 - 2.5 throughout the weld. The unexposed base density of

the film shall exceed 0.30.

v) Radiography identification system and documentation for radiography

interpretation reports and their recording system.