Professional Documents

Culture Documents

Fire Alarm Method Statement

Fire Alarm Method Statement

Uploaded by

Nideesh RobertCopyright:

Available Formats

You might also like

- Ward PDFDocument7,410 pagesWard PDFSharanNo ratings yet

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Method Statement For Testing and Commissioning of ACSDocument10 pagesMethod Statement For Testing and Commissioning of ACSRommel Espinosa ParasNo ratings yet

- Method Statement FOR Chiller ReplacementDocument8 pagesMethod Statement FOR Chiller ReplacementSaif ali Khan100% (1)

- Vesdsa System Method StatementDocument39 pagesVesdsa System Method StatementNideesh RobertNo ratings yet

- Hwi Apo CN MSS 0030 02Document119 pagesHwi Apo CN MSS 0030 02Nideesh RobertNo ratings yet

- Testing & Commissioning of Telephone Data SystemDocument1 pageTesting & Commissioning of Telephone Data Systemhaytham65No ratings yet

- Vesda System Method StatementDocument6 pagesVesda System Method Statementsanthilal100% (2)

- Chiller Unit Method Statement PDFDocument5 pagesChiller Unit Method Statement PDFmostafaabdelrazik100% (1)

- Testing and Commissioning Air Handling UnitsDocument32 pagesTesting and Commissioning Air Handling UnitsWin100% (2)

- Method Statement For FA SystemDocument6 pagesMethod Statement For FA SystemsanthilalNo ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument3 pagesTesting & Commissioning of Fan Coil Units FCU'svin ssNo ratings yet

- Method of Statement For Testing & Commissioning of Fire Alarm SystemDocument4 pagesMethod of Statement For Testing & Commissioning of Fire Alarm Systemvin ssNo ratings yet

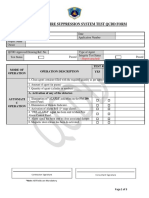

- Clean Agent Fire Suppression System Test QCDD FormDocument3 pagesClean Agent Fire Suppression System Test QCDD FormMahmoud HassanNo ratings yet

- Method Statement For Testing & Commissioning of Disabled Toilet Alarm DTA SystemDocument3 pagesMethod Statement For Testing & Commissioning of Disabled Toilet Alarm DTA Systemvin ssNo ratings yet

- Testing Procedure SprinklerDocument2 pagesTesting Procedure SprinklerBea RullanNo ratings yet

- Method Statement For Installation of BMS M Tower PDFDocument16 pagesMethod Statement For Installation of BMS M Tower PDFAndrew HivNo ratings yet

- Project: My City Centre Masdar, Abu Dhabi, Uae: Method Statement For Installation of Fire Alarm SystemDocument13 pagesProject: My City Centre Masdar, Abu Dhabi, Uae: Method Statement For Installation of Fire Alarm SystemUmair BaBerNo ratings yet

- Fire Alarm System Installation & TestingDocument11 pagesFire Alarm System Installation & TestingMahesh Kumar MNo ratings yet

- MS-E018 Installation of Fire Alarm SystemDocument8 pagesMS-E018 Installation of Fire Alarm Systema wasayNo ratings yet

- Method of Statement For Fire AlarmDocument10 pagesMethod of Statement For Fire AlarmShah MuzzamilNo ratings yet

- Xtralis TrainingDocument315 pagesXtralis TrainingMelina TreminioNo ratings yet

- MST For Fire AlarmDocument22 pagesMST For Fire AlarmVimal K PanickerNo ratings yet

- cOMMISSIONING 1 - WorksheetDocument60 pagescOMMISSIONING 1 - WorksheetPramod Dhir100% (1)

- Fire PUMPS T&C ChecklistDocument6 pagesFire PUMPS T&C ChecklistUmair BaBerNo ratings yet

- Installation Method of Flow SwitchDocument1 pageInstallation Method of Flow SwitchBento Box100% (1)

- Method of Statement (GPON& PABX)Document8 pagesMethod of Statement (GPON& PABX)Muhammad IqbalNo ratings yet

- Checklist For UPS & Accessories InstallationDocument1 pageChecklist For UPS & Accessories InstallationguspriyNo ratings yet

- MS T&C For HumidifierDocument4 pagesMS T&C For Humidifierrommel duranNo ratings yet

- Mos Hvac Ductwork Chilled Water Pipework 1650884167Document56 pagesMos Hvac Ductwork Chilled Water Pipework 1650884167Prabesh ShresthaNo ratings yet

- Method Statement For Installation of Light Fixtures and FittingsDocument6 pagesMethod Statement For Installation of Light Fixtures and Fittingsadeniyi abiolaNo ratings yet

- 5) Method Statement For HVAC Electrical WorkDocument11 pages5) Method Statement For HVAC Electrical WorkIzaaz Ahamed100% (2)

- Electrical & Wiring METHOD STATEMENTDocument4 pagesElectrical & Wiring METHOD STATEMENTAfiq JamalNo ratings yet

- 4) Method Statement For HVAC Copper Piping & Drain PipingDocument16 pages4) Method Statement For HVAC Copper Piping & Drain PipingIzaaz AhamedNo ratings yet

- 0734 Refrigerant Installation ChecklistDocument1 page0734 Refrigerant Installation ChecklistMubashir KhanNo ratings yet

- AV SystemsCommissioningTestsChecklistDocument17 pagesAV SystemsCommissioningTestsChecklistKhaja Muqeem UddinNo ratings yet

- FACP MethodologyDocument6 pagesFACP MethodologyNobita NobiNo ratings yet

- 2nd Floor MDC - CONTINUITY - TEST - FORM - (PRE - AND - POST - ENER) FR-06-EMCD-A-EE-001-rev0Document2 pages2nd Floor MDC - CONTINUITY - TEST - FORM - (PRE - AND - POST - ENER) FR-06-EMCD-A-EE-001-rev0Kris Tolentino100% (2)

- Inspection Checklist For Hvac (DUCT Installation) F01 & F02Document4 pagesInspection Checklist For Hvac (DUCT Installation) F01 & F02Researcher100% (1)

- Method Statement For Testing & Commissioning of Smoke Extract FansDocument3 pagesMethod Statement For Testing & Commissioning of Smoke Extract Fansvin ssNo ratings yet

- Method Statement For Air Balancing in HVAC SystemDocument5 pagesMethod Statement For Air Balancing in HVAC SystemNadeem khan100% (1)

- Installation and Testing of BMS (Building Management System) NSRDocument51 pagesInstallation and Testing of BMS (Building Management System) NSRAnandu Ashokan50% (2)

- Method Statement For Installation of VRF SystemDocument8 pagesMethod Statement For Installation of VRF SystemMohammed Abd AlhamedNo ratings yet

- Fire Alarm and Detection System ProcedureDocument7 pagesFire Alarm and Detection System ProcedureProjects aissol100% (1)

- Fire Detection and Alarm System QCDD Form (Record of Completion)Document3 pagesFire Detection and Alarm System QCDD Form (Record of Completion)Ronie PaduaNo ratings yet

- MEP Commissioning ScheduleDocument1 pageMEP Commissioning SchedulePedro PereiraNo ratings yet

- Check List DUCTINGDocument2 pagesCheck List DUCTINGsarmad009100% (1)

- Method Statement FinalDocument11 pagesMethod Statement FinalAbdo okashaNo ratings yet

- Ms For Facade Light InstallationDocument14 pagesMs For Facade Light InstallationAdnan AbdulNo ratings yet

- Copper Pipes InstallationDocument6 pagesCopper Pipes InstallationrkssNo ratings yet

- Method of Statement (Structural Cabling)Document10 pagesMethod of Statement (Structural Cabling)Muhammad Iqbal100% (1)

- Method Statement For Installation of Access Control SystemDocument115 pagesMethod Statement For Installation of Access Control SystemRahul Sharma100% (3)

- Method of Statement For Precommissioning & Commissioning of Chiller Plant ManagerDocument3 pagesMethod of Statement For Precommissioning & Commissioning of Chiller Plant Managervin ssNo ratings yet

- Duct Inspection ChecklistDocument3 pagesDuct Inspection ChecklistHaymanot Baynesagn100% (1)

- MEP - DetailDocument14 pagesMEP - DetailsyedtalhamehmoodNo ratings yet

- Air Balancing Method StatementDocument1 pageAir Balancing Method StatementmpwasaNo ratings yet

- Complete Report On HvacDocument57 pagesComplete Report On HvacJunaid Khan100% (2)

- Property - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-01 - Water Cooled Chiller Installation Checklist FORM - 2pDocument2 pagesProperty - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-01 - Water Cooled Chiller Installation Checklist FORM - 2pHarum100% (1)

- MST Installation of Pressurization UnitDocument10 pagesMST Installation of Pressurization Unitvictor100% (1)

- T & C Procedure For HVAC For Goverment Bldg. 2017Document233 pagesT & C Procedure For HVAC For Goverment Bldg. 2017Yongsak YungyuenNo ratings yet

- Intrusion Detection System Method StatementDocument30 pagesIntrusion Detection System Method StatementNideesh RobertNo ratings yet

- Hydrogen Detection System Method StatementDocument37 pagesHydrogen Detection System Method StatementNideesh RobertNo ratings yet

- QSS2-JEG-CW-00-DR-M-3504-D4.C01 Ground Floor Chilled Water Services Layout Sheet 4 of 8Document1 pageQSS2-JEG-CW-00-DR-M-3504-D4.C01 Ground Floor Chilled Water Services Layout Sheet 4 of 8Nideesh RobertNo ratings yet

- Hwi Apo CN MSS 0040 01Document110 pagesHwi Apo CN MSS 0040 01Nideesh RobertNo ratings yet

- HWI-APO3-ME-DWG-0016-00 (2 of 2)Document1 pageHWI-APO3-ME-DWG-0016-00 (2 of 2)Nideesh RobertNo ratings yet

- HWI-APO3-ME-DWG-0016-00 (1 of 2)Document1 pageHWI-APO3-ME-DWG-0016-00 (1 of 2)Nideesh RobertNo ratings yet

- Intrusion Detection System Method StatementDocument30 pagesIntrusion Detection System Method StatementNideesh RobertNo ratings yet

- Hwi Apo CN MSS 0038 00Document38 pagesHwi Apo CN MSS 0038 00Nideesh RobertNo ratings yet

- Hwi Apo CN MSS 0049 01Document32 pagesHwi Apo CN MSS 0049 01Nideesh RobertNo ratings yet

- Airflow TraverseDocument53 pagesAirflow TraverseNideesh RobertNo ratings yet

- HelperBoard A133 Core BoardDocument9 pagesHelperBoard A133 Core BoardRoberNo ratings yet

- Smart Agriculture Suggestion SystemDocument9 pagesSmart Agriculture Suggestion SystemIJRASETPublicationsNo ratings yet

- 6 Exam Paper - IB HL - DifferentiationDocument35 pages6 Exam Paper - IB HL - DifferentiationDarshana JainNo ratings yet

- Cloud Robotics Using ROS 2014Document5 pagesCloud Robotics Using ROS 2014nathalieNo ratings yet

- Teraco Industry ReportDocument16 pagesTeraco Industry ReportAmon KhosaNo ratings yet

- Powermonitor 5000 Unit: User ManualDocument422 pagesPowermonitor 5000 Unit: User ManualJonathan CerranoNo ratings yet

- Chapter - 5 - v8.0 Part 1-FAZDocument63 pagesChapter - 5 - v8.0 Part 1-FAZMuhammad RafiNo ratings yet

- Proceedings of The 15TH PHD Mini-SymposiumDocument84 pagesProceedings of The 15TH PHD Mini-Symposiumfreshman2No ratings yet

- Unit 2-nnDocument40 pagesUnit 2-nnSujithra saiNo ratings yet

- Muhammad Abdullah CH: Carrier ObjectiveDocument3 pagesMuhammad Abdullah CH: Carrier ObjectiveAbdullah ChaudhryNo ratings yet

- Compare RSLinx Classic and RSLinx Enterprise Software PDFDocument2 pagesCompare RSLinx Classic and RSLinx Enterprise Software PDFlettolimaNo ratings yet

- CATIA V5 - Advance Drafting and CustomDocument128 pagesCATIA V5 - Advance Drafting and Custominvasor86No ratings yet

- NCA 6.5 DemoDocument5 pagesNCA 6.5 Demomahmoudkerdieh1No ratings yet

- 1 100GigE - Report 2023-03-09 R0108950Document17 pages1 100GigE - Report 2023-03-09 R0108950Jan Rey AltivoNo ratings yet

- MemoryDocument6 pagesMemoryHuy VoNo ratings yet

- Research Paper For Computer Science StudentsDocument8 pagesResearch Paper For Computer Science Studentskpqirxund100% (1)

- School of Social Science Assignment of M.B.A. (1 Sem) : Jay BanjaraDocument29 pagesSchool of Social Science Assignment of M.B.A. (1 Sem) : Jay BanjaraHarishpatel BopcheNo ratings yet

- Recording Phone Call On IphoneDocument13 pagesRecording Phone Call On Iphoneapi-523248253No ratings yet

- Introduction To Brute ForceDocument13 pagesIntroduction To Brute ForceprithiksNo ratings yet

- Pitch Deck - IntercomDocument8 pagesPitch Deck - IntercomMiguel Rey RamosNo ratings yet

- Uc5r/uc4q (N91a) Uc5r/uc4q (N91a) : Un C5000qfxza Un C4000pdxza Un C5000qfxza Un C4000pdxzaDocument41 pagesUc5r/uc4q (N91a) Uc5r/uc4q (N91a) : Un C5000qfxza Un C4000pdxza Un C5000qfxza Un C4000pdxzaDaniel De PianoNo ratings yet

- 6.3 ES IVEAdminGuideDocument1,108 pages6.3 ES IVEAdminGuidekripterNo ratings yet

- Partner Playbook: Data Protection PortfolioDocument34 pagesPartner Playbook: Data Protection Portfoliokarlosm84No ratings yet

- Inp314t-4d (3in1) - DB-2P (12-48VDC) QigDocument3 pagesInp314t-4d (3in1) - DB-2P (12-48VDC) QigNatan Genao HdezNo ratings yet

- A Feasibility Study On Establishing Creat3D Printing Business in Batangas City Chapter 2 3Document45 pagesA Feasibility Study On Establishing Creat3D Printing Business in Batangas City Chapter 2 3Tristan John MagrareNo ratings yet

- ACCEED 2104 8 Port Gigabit Fiber EDD: Carrier Ethernet Demarcation DeviceDocument4 pagesACCEED 2104 8 Port Gigabit Fiber EDD: Carrier Ethernet Demarcation DevicePietro CristofoliNo ratings yet

- Heart Disease Prediction Using Machine Learning Techniques: AbstractDocument5 pagesHeart Disease Prediction Using Machine Learning Techniques: Abstractshital shermaleNo ratings yet

- The PyQt4 TutorialDocument69 pagesThe PyQt4 TutorialVictor AlfonsoNo ratings yet

- Netxms Admin PDFDocument468 pagesNetxms Admin PDFDiego Villamar CastroNo ratings yet

Fire Alarm Method Statement

Fire Alarm Method Statement

Uploaded by

Nideesh RobertOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Alarm Method Statement

Fire Alarm Method Statement

Uploaded by

Nideesh RobertCopyright:

Available Formats

METHOD STATEMENT

SUBMITTAL

(MSS)

Project: APOLLO-I

Client / Client Consultant: PIVOT / SUDLOWS

METHOD STATEMENT SUBMITTAL

FOR

TESTING & COMMISSIONING OF FIRE ALARM SYSTEM

Method Statement Submittal No: HWI‐APO‐CN‐MSS‐0037-02

Rev. Prepar Checked Checked

Date Description Approved

No. ed Technical Safety

TESTING & COMMISSIONING OF

02 07/01/2020 Tyco REEF TECH

FIRE ALARM SYSTEM

TESTING & COMMISSIONING OF

01 24/11/2019 Tyco REEF TECH

FIRE ALARM SYSTEM

TESTING & COMMISSIONING OF

00 08/10/2019 Tyco REEF TECH

FIRE ALARM SYSTEM

HWI-APO-CN-MSS-0037-02–Testing & Commissioning of Fire Alarm System Page 1 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

CONTENTS

1.0 Purpose

2.0 Scope

3.0 References

4.0 Definitions

5.0 Responsibilities

6.0 Equipment

7.0 Procedure for Testing & Commissioning

8.0 Health Safety & Environment Requirement.

9.0 Attachments

Appendix A – Inspection & Test Plan (ITP)

Appendix B – Risk Assessments

Appendix C – Check sheets & Test Formats

Appendix D – CxA Preliminary Checklist

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 2 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

1. Purpose

This method statement describes the Testing and Commissioning for Fire alarm system

methodology of the Apollo-I Data Centre Project. It is generated to ensure Testing and

Commissioning for Electrical Works procedures are in place and to provide adequate tools

and equipment to carry out the complete installation in a safe manner.

2. Scope

This method statement covers all processes related to Testing & Commissioning of Fire

Alarm System. This procedure is to be read in conjunction with the relevant ITP, outlining

the responsibility and the quality verification to be performed by various parties.

3. References

3.1 Project Specification

3.2 Approved Shop drawings

3.3 DCD regulation

3.4 NFPA 72 / Test Section

3.5 Local ADDC wiring regulation

3.6 Approved C&E matrix

3.7 As built drawing, electrical schematics, Load Schedule and test sheets

3.8 Main Contractor’s Health, Safety and Environment Plan.

3.9 Manufacturer’s Recommendations.

3.10 Project Quality Plan

3.11 Client Requirements

4. Definitions

4.1 Pivot – Customer/Client

4.2 Huawei – Design and Build Contractor

4.3 Laith Electromechanical – MEP Contractor

4.4 Sudlows – Client Engineer/ Representative

4.5 ITL – Independent Testing Laboratory

5. Responsibilities

Responsibilities for ensuring that the steps in this procedure shall be carried out are

specified at relevant steps in the procedure:

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 3 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

5.1 Project Manager

• Project Manager is the overall responsible for the project in terms of work Testing,

safety, planning & quality. The Project Manager will maintain the planning progress

and coordination of works with the main contractor.

• Specific attention is paid to all safety measures and quality control in coordination

with Safety Engineer and QA/QC Engineer and in line with PSP and PQP.

5.2 Electrical Department Manager

• Coordinating with Engineer, QA/QC Engineer, Supervisor site Team and foremen for

all Testing & Commissioning activities on site.

• Control and check all Test reports before issuing to Consultant approval.

5.3 Site Engineer

• Shall be responsible for the implementation of this method statement as per the

work plan, methodology and resources.

• Compliance with the project specified requirements.

• Notifying the site manager of the works that require testing.

• Ensure the calibration of all equipment in use.

• Schedule all testing and commissioning activities and ensure that all test required are

conducted.

• The constant coordination with the Safety Engineer to ensure that the works are

carried out in safe working atmosphere.

5.3 Third Party Commissioning Specialist

• Shall be responsible for all Pre-Commissioning and Commissioning activities.

• In case of failure in any test, it shall be notified to the Site team and rectified.

• Shall review all Original Test reports.

5.3 Commissioning Engineer

• Ensure that the works are carried out according to the specification and drawings.

• Ensure Testing and Commissioning are carried out as per MS procedure

• Co ordinate with MEP project manager and project engineer for sequence of works at site.

• Co ordinate with consultant during inspection.

• Ensure that all in process test are carried out as per DCD,NFPA & Project specification

requirement

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 4 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

5.4 Foreman

• The carrying-out of work and the proper distribution of all the available resources in

coordination with the Site Engineer on a daily basis.

• Daily reports of the works are achieved and coordinated with the Site Engineer.

• Incorporate all the QA/QC and Safety requirements as requested by the concerned

Engineer.

• Meeting with any type of unforeseen incident or requirement and reporting the same

to the Site Engineer immediately.

5.5 QA/QC Engineer

• Prior to testing, ensure Cable pulling is done as per the drawing.

• Ensure Cable testing is done prior to termination.

• Test reports are being reviewed and approved by the Consultant / Third Party

Commissioning Specialist.

• Coordinate with the site construction team.

5.6 HSE Engineer

• The Safety Officer will be responsible for implementing and maintaining the Project

HSE Plan in full conformance to the safety requirements.

• Conduct regular tool box talks on site.

• He is responsible to ensure all site activities are covered by Safety Inspections and

will initiate and follow up all required corrective actions.

• Compile all safety records as per the Project HSE Plan.

• Ensure that all equipment used on site have valid registration, insurance and test

Certificates.

• Review method statement, material safety data sheets and handle requirements to

enforce compliance of safety aspects.

6. Test and Instruments / Tools Required

Before starting the Commissioning below mentioned tools shall be arranged and necessary

measures will be taken for the safety of the equipment

• Digital Multi-meter

• Smoke Detector & Heat Detector- Aerosol smoke & Heat dispenser

• Portable Hand tools

• Drilling machine

• Standard Tool Box

• Certified mobile scaffoldings (Tower/Podium) / MEWP

• Portable Drilling Machine/ Grinding Machine

• Hammer Drilling Machines

• Mobile Scaffold / Fixed scaffolding & stepladders.

• Spirit Level / Level Threads

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 5 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

• Polyester pipe strings

• Pipe cutter

• Trolleys

➢ Note: All Power tools shall be suitable for use with 110V & 220V power supply.

7. PPE

All workers involved shall be equipped with adequate PPE as stated below:

➢ Uniform

➢ Hard hat

➢ Goggles

➢ Reflective jacket

➢ Steel toed safety shoes

➢ Ear plug

➢ Nose mask

➢ Hand gloves as per the job

8.0 Testing Procedure

8.1 Pre – Commissioning

❖ The installer for this project shall be responsible for the testing of all cabling, with an appropriate

calibrated insulation resistance meter for each complete circuit. The results will be logged on the

cable test sheet and will be available for the commissioning engineer and for inclusion into the

Operation and Maintenance manual. When the insulation tests are complete, the Tyco

representative & the client representative will sign the test certificate.

❖ Upon arrival at site the commissioning engineer will familiarize himself with all aspects of the

system .This will include a visual inspection of the installation, i.e. position of panels, heat

detectors, interface units, Manual call points and notification devices in conjunction with all

approved drawings to ensure that the drawings are true reflection of the installation. If any

changes it will converted as RED Mark Up.

❖ The Commissioning Engineer will also ensure that panel as indicated on the drawings is supplied

with appropriate supply voltage individually fused, labelled accordingly. Make sure all applicable

permits are available for starting the commissioning activity. Ensure a 230 V AC supply is

provided to power the Heat gun that will be used for testing the heat detectors.

❖ When the Commissioning Engineer is satisfied that there are no outstanding works associated

with the detection loops and the interfaces to other equipment, then the commissioning can

commence.

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 6 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

Before the devices are tested the various parts need to be set up and checked individually. Ensure

all equipment’s, devices and panels have been installed as per the approved drawings and identified

correctly.

• Ensure that all cables have been tested for continuity.

• Check approved materials are available for installation.

• Check approved drawings are used for installation.

• Ensure that necessary work permit (if applicable) is obtained prior to commencement

of the work.

• Check work area. It should be clean and safe for work. Check that all correct tools

• Fire Alarm System material shall be in line with the approved material submittal and

approved drawings by authorities rules and standards

• Ensure all equipment’s, devices and panels have been installed as per the approved

drawings and identified correctly.

• Ensure All Loop cable continuity and insulation resistance test to be done and record

before start the commissioning

• Check all devices are labeled as approve labeled

• Check all cable identified as loop tag

• Check all system wiring to verify each circuit is free of grounds and free of any induced

extraneous voltage

• Connect batteries on each panel based on the confirmation on the availability of

permanent power supply

• Ensure all cables are terminated properly.

• Ensure all necessary electrical connections are terminated correctly.

• Verify the absence of unwanted voltage between circuit conductors and ground.

• Verify the control unit is in the normal condition as given in manufacturer’s operation

manual.

• Check the incoming voltage.

• Program the Fire alarm panel per approved drawings.

8.2 Commissioning

• The Fire alarm system shall be commissioned in-line with the functional sequence of

the System which is given below.

8.2.1.Functional Sequence of system in case of Fire condition.

• When a fire condition is detected, the system responds as follows:

❖ The FACP internal buzzer will sound in a continuous tone.

❖ ‘FIRE’ LEDs on the FACP will switch “ON”

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 7 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

❖ FACP configured outputs will be activated.

❖ The FACP LCD will display a custom message programmed for that respective point.

❖ The fire detection notification devices & interfacing modules ( MSFD Dampers, etc)

in the respective area will be activated as per C& E logic

8.2.2. Functional Sequence of System in case of Fault condition

• When a fault condition is detected, the system responds as follows:

❖ The LFACP internal buzzer will sound in a intermittent tone.

❖ ‘FAULT’ LEDs on the LFACP will switch “ON”

❖ The LFACP LCD will display a custom message programmed for that respective point.

Testing of Individual Device

FUNCTION TEST OF DEVICES SHALL BE CARRIED OUT LOOP BY LOOP AS FOLLOWS:

• Function test will annunciate to the FACP, The annunciation includes panel buzzer

and LCD display of location.

• The test will be printed in the printer which is located in main control room.

• Check for cause and effects are functioned according to the approved matrix.

• If the test is successful, moves to the next device and continue the test.

• Check the sounders and flashers are functioning.

• If the test result is successful, move to the next device and continue the test until

all devices are tested in the loop.

• If all devices tested successfully in the one loop, move to the next loop and

continue in same manner.

• If the “Alarm Silence” button is pressed, it will stop all notifications and an

“ALARM SILENCE IN PROGRESS” message will show on the FACP prior to stop the

notification.

• If the “System Reset” button is pressed, “SYSTEM RESET IN PROGRESS” message

will display and reset will take place alarm.

• Will be cleared after a successful reset or the panel will show a massage that

“ALARM PRESENT SYSTEM RESET BOARD”.

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 8 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

8.2.3. Smoke Detection Alarm Condition

• Use the available scaffolding / Ladder to reach the Smoke detector location. Portable

testing tool kit (Aerosol Dispenser) will be used for testing the Smoke Detectors

• Place the testing tool & inject/spray the Aerosol in to Smoke detector.

• The Detector will activate

• Fire led on the panel facia will be “ON”.

• The device details (Loop number, Device number, Panel number etc,) are displayed on

the Fire panel display.

• Device text for the activated device will be displayed.

• Activation of relevant Notification device as per cause and Effect

• FACP configured outputs will be activated

• Move to the next device / Detector

• Repeat the above steps for each Area / System / Building

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 9 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

• Once Tests are completed the respective Fire Alarm panel is reset to bring it to normal

Condition

• All Results will be visually checked verified and recorded in the check sheet.

8.2.4. Heat Detection Alarm Condition

• Use the available scaffolding / Ladder to reach the heat detector location.

• Portable battery Operated testing tool kit will be used for testing the Spot type Heat

detectors indoor and 230 volt Heat gun will be used for Probe type heat detector

• Place the testing tool (Heat Dispenser / Heat Gun) Heat detector till the alarm threshold

is reached. The Detector will activate once the temperature reach to alarm threshold /

ambient temperature

• The detector will activate

• Fire led on the panel facia will be “ON”.

• The device details (Loop number, Device number, Panel number etc,) are displayed on

the Fire panel display.

• Device text for the activated device will be displayed.

• Activation of relevant Notification devices & Interfacing Modules (MSFD Dampers etc)

as per cause and Effect

• FACP configured outputs will be activated

• Move to the next device / Detector

• Repeat the above steps for each Area / System / Building

• Once Tests are completed the respective Fire Alarm panel is reset to bring it to normal

Condition

❖ All Results will be visually checked verified and recorded in the check sheet.

8.2.5. Break Glass Unit / Manual Call Points

• These will be activated individually and manually

• Manual Call point is activated by using the test key.

• Insert the test key into the Test key access to activate the call point

• Fire led on the panel facia will be activated.

• The device details (Loop number, Device number, Panel number etc,) are

displayed on the Fire panel display.

• Device text for the activated device will be displayed.

• Activation of relevant Notification device as per cause and Effect

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 10 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

• FACP configured outputs will be activated

• Repeat for Manual Call Points in each Area / System Building.

• Results to be visually checked verified and recorded in the check sheet.

• Check if the correct message is displayed on the MFACP display with actual

addressed as per approved shop drawings and programming sheet.

• Check if the correct message is displayed on the MFACP display with actual

addressed as per approved shop drawings, PC monitor (Graphic Command

Centre) and printer.

8.2.6 Monitor Modules

• Check before activation the Red indicator LED is flashing (Red Light) on the unit.

• Activate individually using the connected device (FM200, Valve etc.).

• Check after activation the red indicator LED is on (Red Light) on the unit.

• Check if the correct message is displayed on the MFACP display with actual

addressed as per approved shop drawings, PC monitor (Graphic Command

Centre) and printer.

8.2.7 Control modules

• Check before activation the Red indicator LED is flashing (Red Light) on the unit.

• Activate the initiating device associated with the control module and check the

connected device is responding to the fire signal.

• Check after activation the red indicator LED is on (Red Light) on the unit.

8.2.8 Supervisory switch on the control valves

• Operate the valve and receipt of the signal is verified on the FACP.

• Check if the correct message is displayed on the MFACP display with actual

addressed as per approved shop drawings, PC monitor (Graphic Command

Centre) and printer.

8.2.9 Function Test of Interfaces

• Verify all interfaces are functioning in case of activation of corresponding

initiating device Test shall be carried out in the sequence of loop by loop.

Motorized Fire Dampers

Motorized Fire dampers shall be closed upon detection of fire signal and shall be

verified as cause & effect matrix.

Exhaust Fan

Exhaust Fan shall operate to open after holding time of 10 minutes from agent

release and shall be verified as per C & E matrix.

Access Door

All access doors shall operate to open upon fire signal and shall be verified as per

C & E matrix.

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 11 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

NOVEC System

All operations of NOVEC system including operations of solenoid valve shall be

verified as per C & E matrix.

Sprinkler System

Systems operations of alarm check valve and monitoring of all zone control value,

Zone control Flow switches / isolation valves shall be verified as per C & E matrix.

Fire Pumps

Fire pumps operations shall be verified as per C & E matrix.

FAHU

FAHU will turn off during fire at each pod-1 and shall be verified as per C&E Matrix

Cause and Effect Demonstration Procedure.

Testing will be conducted as per approved C & E Matrix to verify the sequence of

operation as per project requirement. Points to be verifying.

• Integration test of Interface with other services

• Public address system

• Motorized dampers

• Pressurization FANS

• Extract FANS

• Access control system

• BMS

• NOVEC System

• Water Spray System

• FAHU

• Fire pump

• It will be tested by activating any detector or break glass in the loop and verify

the following effects are taken place.

• It will be tested by activating one device in the building also, one manual call

point will be operated in each floor. The testing will be done as follows.

8.2.10. Sounders/Sounder Beacon

• Sounders and Sounder Beacon will be tested for operation against the required Cause

& Effect. Results to be visually checked verified and recorded in the check sh eet.

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 12 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

8.2.11 Fire Alarm Indicator Panel

• Switch off the Mains power Supply – Power Fault will be appear on the Panel

• Remove the Backup battery supply - Battery Fault will be appear on the Panel

• Silence Buzzer – Press this key to silence the Buzzer

• Silence Sounder – Press this Key to Silence the Sounders

• Evacuate – Press this key to evacuate the sounders

• Reset – Press this key to reset the Panel

8.2.12 Identification and Labelling

• Samples of Identification labels shall be submitted for Main contractor approval.

• Ensure surface is cleaned prior to fixing of identification labels.

8.2.13 Red Mark Up

• Mark the new routes as per site condition then this information shall be detailed in the

drawings with Red Lines and shall be part of the documents during the inspection.

• After approval of inspection with changes (RED Lines Drawing). This information will be

incorporated in the As Built drawings.

8.2.14 Working requirements:

• Ensure all staff and labour personnel have been inducted.

• Ensure all drivers have been inducted

• Ensure all staff and personnel have the required PPE.

• Ensure HSE is present to ensure the requirements of this method statement and

associated risk assessment are adhered to.

• Ensure that competent supervision is present.

• Briefing of this Method statement to all concerned.

• Ensure site is free of any obstruction and is safe to work.

• Ensure availability of power for machines.

• Ensure drawings are of the latest revision and has been approved for installation.

• Ensure material is available on site and has been approved by the employer.

• Secure work permit.

9 Health Safety & Environment Requirement.

Health and Safety procedures by the Main Contractor will be implemented for this

job. The responsible safety officer as per approved HSE plan will conduct a routine

safety inspection in conjunction with the Huawei Product requirements. Tool box

talks will be conducted and documented prior to commencement of works.

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 13 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

9.1 Safety Rules during testing:

⚫ In order to ensure safe conditions during testing the following rules have to be followed.

⚫ Persons engaged with inspection and testing have to be skilled and have received proper

and adequate training related to procedures and test equipment utilized for the particular

testing activity.

⚫ Test instruments and test leads should be maintained in a safe condition and the test

methods not to create danger either for the operator or for other persons or livestock.

⚫ Where tests are required to circuits which are live for amp readings then the tightness of

the cable terminations will be checked without power prior to live amp readings.

⚫ Ensure that all plant drives have been pre-commissioned by the BMS contractor and the

supplier prior to commissioning.

⚫ When readings are being taken for amperage and running speeds a support engineer

will be in attendance for safety reasons.

⚫ Electric safe systems of work will be followed at all times.

⚫ All supporting documentation will be attached to particular permit work/inspect sheet in

Manufactures Pre commissioning inspection test sheets and associated Electrical testing

test sheets.

9.2 Safety Lighting.

⚫ Adequate lighting shall be provided to ensure the good illumination to the working face.

⚫ Site lighting shall be provided by the main Contractor.

9.3 Emergency Arrangement

⚫ General: Site general safety procedures will be followed. In case of emergency the

Safety or the most senior employee present will stop the work, and make the necessary

emergency arrangements and report to the assembly points as described during Site

Induction Course. Fire Precautions: No significant fire risks associated with this activity

but general fire precaution measures will be taken.

⚫ Communication from site areas to Site Office via mobile phones issued to all engineers

in emergency situations the users of handheld 2-way radios to be notified if deemed that

this can speed up notification of relevant personnel and/or the CHt Site Clinic.

Each working on site must be properly trained for the performed tasks. Any installation

work requiring authorization, such as electrical installation or hot work, may only be

performed by persons with relevant permits & clarifications

⚫ First aiders and first aid facilities are available at the site offices / welfare facilities

located at the site office facilities to deal with emergencies on site.

In the event of an emergency call the first aider listed at site office / store / Operative rest

area

Give your name, location and the nature of the accident to the operator. The exact

location will be described on the permit to work.

Fire points are located at all required areas (refer to the site fire and emergency plan)

9.4 Quality

At the start of each activity in each area it should be checked by the foreman that the

latest approved method of statement in hand. All testing arrangement shall be

inspected by QA / QC and once internally approved; the inspection request shall be

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 14 of 15

07/01/2020

METHOD STATEMENT

SUBMITTAL

(MSS)

raised to the Consultant for the witness. All inspections shall be followed as per

attached ITP.

9.5 Monitoring Work

Monitoring of the works for safe working, technical compliance and progress to

programme will be carried out on a continual basis. Site Management will be

directly involved in the day to day management of the activity. Works shall be

supervised at all times by a competent supervisor.

Daily Activity Briefings are to be given by the foremen in charge every morning

prior to the start of works. Operatives are to be encouraged to raise any concerns at

this time and at any time throughout the works.

Should any issues arise which are not covered within the Method Statement, these

are to be notified to the engineers and works in the affected area placed on hold until

such a time as the issue has been resolved.

Operatives are encouraged to carry out hazard identification and report any unsafe

acts or conditions to the safety advisor and foremen.

9.6 Environmental

Any waste generated due to above work shall be segregated and disposed off,

according to the site / and statutory norms and approved EHS plan. For details, refer

Method statement for Construction Environmental Management Plan or Project

Waste Management & Recycling Plan.

10. Attachments

Appendix A – Inspection & Test Plan (ITP)

Appendix B – Risk Assessments

Appendix C – Check sheets & Test Formats

Appendix D – CxA Preliminary Checklist

HWI-APO-CN-MSS-0037-02 Testing & Commissioning of Fire Alarm System Page 15 of 15

07/01/2020

METHOD STATEMENT SUBMITTAL

(MTS)

You might also like

- Ward PDFDocument7,410 pagesWard PDFSharanNo ratings yet

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Method Statement For Testing and Commissioning of ACSDocument10 pagesMethod Statement For Testing and Commissioning of ACSRommel Espinosa ParasNo ratings yet

- Method Statement FOR Chiller ReplacementDocument8 pagesMethod Statement FOR Chiller ReplacementSaif ali Khan100% (1)

- Vesdsa System Method StatementDocument39 pagesVesdsa System Method StatementNideesh RobertNo ratings yet

- Hwi Apo CN MSS 0030 02Document119 pagesHwi Apo CN MSS 0030 02Nideesh RobertNo ratings yet

- Testing & Commissioning of Telephone Data SystemDocument1 pageTesting & Commissioning of Telephone Data Systemhaytham65No ratings yet

- Vesda System Method StatementDocument6 pagesVesda System Method Statementsanthilal100% (2)

- Chiller Unit Method Statement PDFDocument5 pagesChiller Unit Method Statement PDFmostafaabdelrazik100% (1)

- Testing and Commissioning Air Handling UnitsDocument32 pagesTesting and Commissioning Air Handling UnitsWin100% (2)

- Method Statement For FA SystemDocument6 pagesMethod Statement For FA SystemsanthilalNo ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument3 pagesTesting & Commissioning of Fan Coil Units FCU'svin ssNo ratings yet

- Method of Statement For Testing & Commissioning of Fire Alarm SystemDocument4 pagesMethod of Statement For Testing & Commissioning of Fire Alarm Systemvin ssNo ratings yet

- Clean Agent Fire Suppression System Test QCDD FormDocument3 pagesClean Agent Fire Suppression System Test QCDD FormMahmoud HassanNo ratings yet

- Method Statement For Testing & Commissioning of Disabled Toilet Alarm DTA SystemDocument3 pagesMethod Statement For Testing & Commissioning of Disabled Toilet Alarm DTA Systemvin ssNo ratings yet

- Testing Procedure SprinklerDocument2 pagesTesting Procedure SprinklerBea RullanNo ratings yet

- Method Statement For Installation of BMS M Tower PDFDocument16 pagesMethod Statement For Installation of BMS M Tower PDFAndrew HivNo ratings yet

- Project: My City Centre Masdar, Abu Dhabi, Uae: Method Statement For Installation of Fire Alarm SystemDocument13 pagesProject: My City Centre Masdar, Abu Dhabi, Uae: Method Statement For Installation of Fire Alarm SystemUmair BaBerNo ratings yet

- Fire Alarm System Installation & TestingDocument11 pagesFire Alarm System Installation & TestingMahesh Kumar MNo ratings yet

- MS-E018 Installation of Fire Alarm SystemDocument8 pagesMS-E018 Installation of Fire Alarm Systema wasayNo ratings yet

- Method of Statement For Fire AlarmDocument10 pagesMethod of Statement For Fire AlarmShah MuzzamilNo ratings yet

- Xtralis TrainingDocument315 pagesXtralis TrainingMelina TreminioNo ratings yet

- MST For Fire AlarmDocument22 pagesMST For Fire AlarmVimal K PanickerNo ratings yet

- cOMMISSIONING 1 - WorksheetDocument60 pagescOMMISSIONING 1 - WorksheetPramod Dhir100% (1)

- Fire PUMPS T&C ChecklistDocument6 pagesFire PUMPS T&C ChecklistUmair BaBerNo ratings yet

- Installation Method of Flow SwitchDocument1 pageInstallation Method of Flow SwitchBento Box100% (1)

- Method of Statement (GPON& PABX)Document8 pagesMethod of Statement (GPON& PABX)Muhammad IqbalNo ratings yet

- Checklist For UPS & Accessories InstallationDocument1 pageChecklist For UPS & Accessories InstallationguspriyNo ratings yet

- MS T&C For HumidifierDocument4 pagesMS T&C For Humidifierrommel duranNo ratings yet

- Mos Hvac Ductwork Chilled Water Pipework 1650884167Document56 pagesMos Hvac Ductwork Chilled Water Pipework 1650884167Prabesh ShresthaNo ratings yet

- Method Statement For Installation of Light Fixtures and FittingsDocument6 pagesMethod Statement For Installation of Light Fixtures and Fittingsadeniyi abiolaNo ratings yet

- 5) Method Statement For HVAC Electrical WorkDocument11 pages5) Method Statement For HVAC Electrical WorkIzaaz Ahamed100% (2)

- Electrical & Wiring METHOD STATEMENTDocument4 pagesElectrical & Wiring METHOD STATEMENTAfiq JamalNo ratings yet

- 4) Method Statement For HVAC Copper Piping & Drain PipingDocument16 pages4) Method Statement For HVAC Copper Piping & Drain PipingIzaaz AhamedNo ratings yet

- 0734 Refrigerant Installation ChecklistDocument1 page0734 Refrigerant Installation ChecklistMubashir KhanNo ratings yet

- AV SystemsCommissioningTestsChecklistDocument17 pagesAV SystemsCommissioningTestsChecklistKhaja Muqeem UddinNo ratings yet

- FACP MethodologyDocument6 pagesFACP MethodologyNobita NobiNo ratings yet

- 2nd Floor MDC - CONTINUITY - TEST - FORM - (PRE - AND - POST - ENER) FR-06-EMCD-A-EE-001-rev0Document2 pages2nd Floor MDC - CONTINUITY - TEST - FORM - (PRE - AND - POST - ENER) FR-06-EMCD-A-EE-001-rev0Kris Tolentino100% (2)

- Inspection Checklist For Hvac (DUCT Installation) F01 & F02Document4 pagesInspection Checklist For Hvac (DUCT Installation) F01 & F02Researcher100% (1)

- Method Statement For Testing & Commissioning of Smoke Extract FansDocument3 pagesMethod Statement For Testing & Commissioning of Smoke Extract Fansvin ssNo ratings yet

- Method Statement For Air Balancing in HVAC SystemDocument5 pagesMethod Statement For Air Balancing in HVAC SystemNadeem khan100% (1)

- Installation and Testing of BMS (Building Management System) NSRDocument51 pagesInstallation and Testing of BMS (Building Management System) NSRAnandu Ashokan50% (2)

- Method Statement For Installation of VRF SystemDocument8 pagesMethod Statement For Installation of VRF SystemMohammed Abd AlhamedNo ratings yet

- Fire Alarm and Detection System ProcedureDocument7 pagesFire Alarm and Detection System ProcedureProjects aissol100% (1)

- Fire Detection and Alarm System QCDD Form (Record of Completion)Document3 pagesFire Detection and Alarm System QCDD Form (Record of Completion)Ronie PaduaNo ratings yet

- MEP Commissioning ScheduleDocument1 pageMEP Commissioning SchedulePedro PereiraNo ratings yet

- Check List DUCTINGDocument2 pagesCheck List DUCTINGsarmad009100% (1)

- Method Statement FinalDocument11 pagesMethod Statement FinalAbdo okashaNo ratings yet

- Ms For Facade Light InstallationDocument14 pagesMs For Facade Light InstallationAdnan AbdulNo ratings yet

- Copper Pipes InstallationDocument6 pagesCopper Pipes InstallationrkssNo ratings yet

- Method of Statement (Structural Cabling)Document10 pagesMethod of Statement (Structural Cabling)Muhammad Iqbal100% (1)

- Method Statement For Installation of Access Control SystemDocument115 pagesMethod Statement For Installation of Access Control SystemRahul Sharma100% (3)

- Method of Statement For Precommissioning & Commissioning of Chiller Plant ManagerDocument3 pagesMethod of Statement For Precommissioning & Commissioning of Chiller Plant Managervin ssNo ratings yet

- Duct Inspection ChecklistDocument3 pagesDuct Inspection ChecklistHaymanot Baynesagn100% (1)

- MEP - DetailDocument14 pagesMEP - DetailsyedtalhamehmoodNo ratings yet

- Air Balancing Method StatementDocument1 pageAir Balancing Method StatementmpwasaNo ratings yet

- Complete Report On HvacDocument57 pagesComplete Report On HvacJunaid Khan100% (2)

- Property - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-01 - Water Cooled Chiller Installation Checklist FORM - 2pDocument2 pagesProperty - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-01 - Water Cooled Chiller Installation Checklist FORM - 2pHarum100% (1)

- MST Installation of Pressurization UnitDocument10 pagesMST Installation of Pressurization Unitvictor100% (1)

- T & C Procedure For HVAC For Goverment Bldg. 2017Document233 pagesT & C Procedure For HVAC For Goverment Bldg. 2017Yongsak YungyuenNo ratings yet

- Intrusion Detection System Method StatementDocument30 pagesIntrusion Detection System Method StatementNideesh RobertNo ratings yet

- Hydrogen Detection System Method StatementDocument37 pagesHydrogen Detection System Method StatementNideesh RobertNo ratings yet

- QSS2-JEG-CW-00-DR-M-3504-D4.C01 Ground Floor Chilled Water Services Layout Sheet 4 of 8Document1 pageQSS2-JEG-CW-00-DR-M-3504-D4.C01 Ground Floor Chilled Water Services Layout Sheet 4 of 8Nideesh RobertNo ratings yet

- Hwi Apo CN MSS 0040 01Document110 pagesHwi Apo CN MSS 0040 01Nideesh RobertNo ratings yet

- HWI-APO3-ME-DWG-0016-00 (2 of 2)Document1 pageHWI-APO3-ME-DWG-0016-00 (2 of 2)Nideesh RobertNo ratings yet

- HWI-APO3-ME-DWG-0016-00 (1 of 2)Document1 pageHWI-APO3-ME-DWG-0016-00 (1 of 2)Nideesh RobertNo ratings yet

- Intrusion Detection System Method StatementDocument30 pagesIntrusion Detection System Method StatementNideesh RobertNo ratings yet

- Hwi Apo CN MSS 0038 00Document38 pagesHwi Apo CN MSS 0038 00Nideesh RobertNo ratings yet

- Hwi Apo CN MSS 0049 01Document32 pagesHwi Apo CN MSS 0049 01Nideesh RobertNo ratings yet

- Airflow TraverseDocument53 pagesAirflow TraverseNideesh RobertNo ratings yet

- HelperBoard A133 Core BoardDocument9 pagesHelperBoard A133 Core BoardRoberNo ratings yet

- Smart Agriculture Suggestion SystemDocument9 pagesSmart Agriculture Suggestion SystemIJRASETPublicationsNo ratings yet

- 6 Exam Paper - IB HL - DifferentiationDocument35 pages6 Exam Paper - IB HL - DifferentiationDarshana JainNo ratings yet

- Cloud Robotics Using ROS 2014Document5 pagesCloud Robotics Using ROS 2014nathalieNo ratings yet

- Teraco Industry ReportDocument16 pagesTeraco Industry ReportAmon KhosaNo ratings yet

- Powermonitor 5000 Unit: User ManualDocument422 pagesPowermonitor 5000 Unit: User ManualJonathan CerranoNo ratings yet

- Chapter - 5 - v8.0 Part 1-FAZDocument63 pagesChapter - 5 - v8.0 Part 1-FAZMuhammad RafiNo ratings yet

- Proceedings of The 15TH PHD Mini-SymposiumDocument84 pagesProceedings of The 15TH PHD Mini-Symposiumfreshman2No ratings yet

- Unit 2-nnDocument40 pagesUnit 2-nnSujithra saiNo ratings yet

- Muhammad Abdullah CH: Carrier ObjectiveDocument3 pagesMuhammad Abdullah CH: Carrier ObjectiveAbdullah ChaudhryNo ratings yet

- Compare RSLinx Classic and RSLinx Enterprise Software PDFDocument2 pagesCompare RSLinx Classic and RSLinx Enterprise Software PDFlettolimaNo ratings yet

- CATIA V5 - Advance Drafting and CustomDocument128 pagesCATIA V5 - Advance Drafting and Custominvasor86No ratings yet

- NCA 6.5 DemoDocument5 pagesNCA 6.5 Demomahmoudkerdieh1No ratings yet

- 1 100GigE - Report 2023-03-09 R0108950Document17 pages1 100GigE - Report 2023-03-09 R0108950Jan Rey AltivoNo ratings yet

- MemoryDocument6 pagesMemoryHuy VoNo ratings yet

- Research Paper For Computer Science StudentsDocument8 pagesResearch Paper For Computer Science Studentskpqirxund100% (1)

- School of Social Science Assignment of M.B.A. (1 Sem) : Jay BanjaraDocument29 pagesSchool of Social Science Assignment of M.B.A. (1 Sem) : Jay BanjaraHarishpatel BopcheNo ratings yet

- Recording Phone Call On IphoneDocument13 pagesRecording Phone Call On Iphoneapi-523248253No ratings yet

- Introduction To Brute ForceDocument13 pagesIntroduction To Brute ForceprithiksNo ratings yet

- Pitch Deck - IntercomDocument8 pagesPitch Deck - IntercomMiguel Rey RamosNo ratings yet

- Uc5r/uc4q (N91a) Uc5r/uc4q (N91a) : Un C5000qfxza Un C4000pdxza Un C5000qfxza Un C4000pdxzaDocument41 pagesUc5r/uc4q (N91a) Uc5r/uc4q (N91a) : Un C5000qfxza Un C4000pdxza Un C5000qfxza Un C4000pdxzaDaniel De PianoNo ratings yet

- 6.3 ES IVEAdminGuideDocument1,108 pages6.3 ES IVEAdminGuidekripterNo ratings yet

- Partner Playbook: Data Protection PortfolioDocument34 pagesPartner Playbook: Data Protection Portfoliokarlosm84No ratings yet

- Inp314t-4d (3in1) - DB-2P (12-48VDC) QigDocument3 pagesInp314t-4d (3in1) - DB-2P (12-48VDC) QigNatan Genao HdezNo ratings yet

- A Feasibility Study On Establishing Creat3D Printing Business in Batangas City Chapter 2 3Document45 pagesA Feasibility Study On Establishing Creat3D Printing Business in Batangas City Chapter 2 3Tristan John MagrareNo ratings yet

- ACCEED 2104 8 Port Gigabit Fiber EDD: Carrier Ethernet Demarcation DeviceDocument4 pagesACCEED 2104 8 Port Gigabit Fiber EDD: Carrier Ethernet Demarcation DevicePietro CristofoliNo ratings yet

- Heart Disease Prediction Using Machine Learning Techniques: AbstractDocument5 pagesHeart Disease Prediction Using Machine Learning Techniques: Abstractshital shermaleNo ratings yet

- The PyQt4 TutorialDocument69 pagesThe PyQt4 TutorialVictor AlfonsoNo ratings yet

- Netxms Admin PDFDocument468 pagesNetxms Admin PDFDiego Villamar CastroNo ratings yet