Professional Documents

Culture Documents

SMS002R0

SMS002R0

Uploaded by

PRASANTH PRASANTHOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMS002R0

SMS002R0

Uploaded by

PRASANTH PRASANTHCopyright:

Available Formats

Stafford Controls Limited

STAFFORD MATERIAL SPECIFICATIONS : SMS - 002

Material : ASTM A 351 Gr. CF8M Raw Material : Casting

Scope : This material specification confirms to ASTM A 351-1999 and EN 1503-2: 2000

Chemical Composition :

Carbon : C ( max. %) 0.08 (Note 1)

Manganese : Mn (max %) 1.5

Phosphorus : P ( max %) 0.04

Sulphur : S ( max %) 0.04 (Note 1)

Silicon : Si ( max %) 1.5

Chromium : Cr ( % ) 18-21

Molybdenum : Mo (%) 2-3

Nickel : Ni (%) 9-12

Heat Treatment : Solution Annealed.

Mechanical Properties :

Tensile Strength ( Mpa / Psi ) 485 / 70000

Yield Strength ( Mpa / Psi) 205 / 30000

Elongation in 2” or 50 mm ( min. %) 30

Impact Strength (Toughness ) (Note 2) The energy measured on an ISO ‘V’ test-piece should not be

less than 60 J at a temperature not greater than 20 °C.

The reference standards used will be

Property Reference Standard

General requirements ASTM A351/A351M-1999 / ASTM A703/A703M - 1999

Chemical analysis ASTM A351/A351M-1999 / ASTM A751-1996

Tensile test / Yield strength / Elongation /

ASTM A370-1997 / ASTM A703/A703M-1999

Hardness

Note:

1. Castings procured for CE marking as per Pressure Equipment Directive (PED) 97/23/EC–

May 1997 shall have Carbon 0.07% max. & Sulphur 0.03% max.

2. Is mandatory for castings procured for CE marking as per Pressure Equipment Directive (PED) 97/23/EC–

May 1997. Whenever service temperature is below 0°C & is specified by customer, Impact Testing to be

done at that specified temperature and absorbed energy to be 60J minimum. This requirement shall be

specifically highlighted in Purchase Order for casting procurement.

3. Material Test Certificates shall be as per EN 10204-3.1.B.

Prepared and Checked By : SSK Approved By : RKS

Issue Date : 05/ 07/ 2003 Revision No : 00 Revision Date : --

DD-FM-028 / SCL \\Ln2000\DATA3\USERS\SPECS\ISO\SMS\SMS002R0.DOC Page 1 Of 1

You might also like

- Increasing and Decreasing With End BehaviorsDocument2 pagesIncreasing and Decreasing With End BehaviorsMackenzie MurrayNo ratings yet

- Ams4945h 2020Document10 pagesAms4945h 2020BauyrzhanNo ratings yet

- IEC 60079-2-2014 Cor1-2015Document8 pagesIEC 60079-2-2014 Cor1-2015grauNo ratings yet

- 8 CW 5-2Document2 pages8 CW 5-2Kayla IkumaNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Ams4943l 2020Document8 pagesAms4943l 2020BauyrzhanNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5armin heidariNo ratings yet

- SMS005R0Document1 pageSMS005R0PRASANTH PRASANTHNo ratings yet

- SMS001R0Document1 pageSMS001R0PRASANTH PRASANTHNo ratings yet

- SMS015R0Document1 pageSMS015R0PRASANTH PRASANTHNo ratings yet

- SMS013R0Document1 pageSMS013R0PRASANTH PRASANTHNo ratings yet

- SMS008R0Document1 pageSMS008R0PRASANTH PRASANTHNo ratings yet

- SMS009R0Document1 pageSMS009R0PRASANTH PRASANTHNo ratings yet

- SMS007R0Document1 pageSMS007R0PRASANTH PRASANTHNo ratings yet

- SMS019R0Document1 pageSMS019R0PRASANTH PRASANTHNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- Metallic Material Specification: Title: 4140 Mod / 4145 Mod, 125 KSI YS, 285-340 BHNDocument5 pagesMetallic Material Specification: Title: 4140 Mod / 4145 Mod, 125 KSI YS, 285-340 BHNReginaldo SantosNo ratings yet

- A RM 105 19 18 096 SourDocument5 pagesA RM 105 19 18 096 SourGuilherme RochaNo ratings yet

- GRADES of STEELDocument3 pagesGRADES of STEELnpankaj1No ratings yet

- Hyundai Welding Co., LTDDocument4 pagesHyundai Welding Co., LTDGerry Dan ChanliongcoNo ratings yet

- Aluminium 2014 t6 2014 t651Document3 pagesAluminium 2014 t6 2014 t651Agung Sapto AjiNo ratings yet

- Metallic Material Specification: Title: 2.25 Cr-1 Mo (ASTM A182, Grade F22 Mod), 85 KSI Min Yield Strength - Unified SpecDocument6 pagesMetallic Material Specification: Title: 2.25 Cr-1 Mo (ASTM A182, Grade F22 Mod), 85 KSI Min Yield Strength - Unified SpecReginaldo SantosNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- ESPARRAGO A-193 B7 3l4-10 X 3660Document1 pageESPARRAGO A-193 B7 3l4-10 X 3660Incoservspa cl100% (1)

- Technical Specifications For Boiler Quality Steel Plates For LPGDocument51 pagesTechnical Specifications For Boiler Quality Steel Plates For LPGGerick Eleazar RogadoNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- Spec. of CO2 Gas Shield Flux Cored WireDocument2 pagesSpec. of CO2 Gas Shield Flux Cored WireSTEVENo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- C402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat TreatmentDocument2 pagesC402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat TreatmentRajkumarNo ratings yet

- Astm A 312Document2 pagesAstm A 312Raj KumarNo ratings yet

- Astm A105Document1 pageAstm A105Betto Arriaga100% (1)

- Project ReportDocument4 pagesProject Reportmm21b018No ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- Fio Outershield 71e-HDocument2 pagesFio Outershield 71e-HJose NevesNo ratings yet

- Material Specification: 23dec2015 01sep1961Document2 pagesMaterial Specification: 23dec2015 01sep1961Chuanxiang Weinong (川香味浓)No ratings yet

- Aims03 22 002Document7 pagesAims03 22 002Jorge OrtegaNo ratings yet

- EC 1350-O Product Specification Rev.0Document3 pagesEC 1350-O Product Specification Rev.0serkan temelNo ratings yet

- Aluminum 5052 H38Document2 pagesAluminum 5052 H38Vishal VaishnavNo ratings yet

- Tetra V 309L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra V 309L-G: Technical Data Sheet Cored Welding WireawNo ratings yet

- Material Verification Report: Elongation in 50 MM, Min % (Gauge Length 4D 50 MM)Document2 pagesMaterial Verification Report: Elongation in 50 MM, Min % (Gauge Length 4D 50 MM)shrikant mishraNo ratings yet

- Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesMatmatch Is Trusted by 2 Million+ Engineers and Product Developers Each Yearhardeep SinghNo ratings yet

- SMT 2594Document12 pagesSMT 2594RafaelNo ratings yet

- EN 10025 Grade S355J2C Normalized or Normalized Formed (+N)Document3 pagesEN 10025 Grade S355J2C Normalized or Normalized Formed (+N)melvin ekboteNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Typical Limiting Values of SubStation Equipments.Document10 pagesTypical Limiting Values of SubStation Equipments.Jeya KannanNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- Implant: Stainless SteelDocument2 pagesImplant: Stainless SteelSachin GhalmeNo ratings yet

- TDC Tech Spec For PlateDocument3 pagesTDC Tech Spec For PlateBantoo RajamandiNo ratings yet

- ALTIGDocument5 pagesALTIGbokugairuNo ratings yet

- MTC - 2046Document1 pageMTC - 2046tameem.p2023No ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Cricri CriNo ratings yet

- NST 3.1 PDFDocument1 pageNST 3.1 PDFPankaj RaneNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNo ratings yet

- Minfm33419 en 10028 2 Grade p355gh Normalized or Normalized Formed NDocument4 pagesMinfm33419 en 10028 2 Grade p355gh Normalized or Normalized Formed NMert EmremNo ratings yet

- Filcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

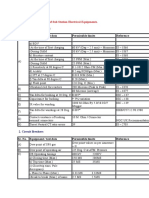

- Typical Limiting Values of Sub Station Electrical EquipmentsDocument6 pagesTypical Limiting Values of Sub Station Electrical EquipmentsPamela BradleyNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- SMS016R0Document1 pageSMS016R0PRASANTH PRASANTHNo ratings yet

- SMS014R0Document1 pageSMS014R0PRASANTH PRASANTHNo ratings yet

- SMS012R0Document1 pageSMS012R0PRASANTH PRASANTHNo ratings yet

- SMS004R0Document1 pageSMS004R0PRASANTH PRASANTHNo ratings yet

- SMS003R0Document1 pageSMS003R0PRASANTH PRASANTHNo ratings yet

- SMS011R0Document1 pageSMS011R0PRASANTH PRASANTHNo ratings yet

- Din Standard From ManufacturerDocument5 pagesDin Standard From ManufacturerPRASANTH PRASANTHNo ratings yet

- General Requirements For Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled BarDocument12 pagesGeneral Requirements For Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled BarPRASANTH PRASANTHNo ratings yet

- (K-30) Datasheet - Stafford ValvesDocument2 pages(K-30) Datasheet - Stafford ValvesPRASANTH PRASANTHNo ratings yet

- A 931 - 96 QTKZMS05NGDocument5 pagesA 931 - 96 QTKZMS05NGPRASANTH PRASANTHNo ratings yet

- F 2001 - 00 - RjiwmdetukveDocument12 pagesF 2001 - 00 - RjiwmdetukvePRASANTH PRASANTHNo ratings yet

- Valve Cat-Seats, Offsets Etc..Document12 pagesValve Cat-Seats, Offsets Etc..PRASANTH PRASANTHNo ratings yet

- Tap and Drill SizeDocument2 pagesTap and Drill SizePRASANTH PRASANTHNo ratings yet

- F 1437 - 92 - Rje0mzctotiDocument3 pagesF 1437 - 92 - Rje0mzctotiPRASANTH PRASANTHNo ratings yet

- A 946 - 95 R00 QTK0NGDocument2 pagesA 946 - 95 R00 QTK0NGPRASANTH PRASANTHNo ratings yet

- A 923 - 01 Qtkymy0wmqDocument7 pagesA 923 - 01 Qtkymy0wmqPRASANTH PRASANTHNo ratings yet

- A 564 - A 564M - 01 Qtu2nc0wmqDocument7 pagesA 564 - A 564M - 01 Qtu2nc0wmqPRASANTH PRASANTHNo ratings yet

- B 422 - 99 - Qjqymi05oqDocument3 pagesB 422 - 99 - Qjqymi05oqPRASANTH PRASANTHNo ratings yet

- Rotex EsfDocument3 pagesRotex EsfPRASANTH PRASANTHNo ratings yet

- B 359 - B 359M - 02 - Qjm1os9cmzu5tqDocument11 pagesB 359 - B 359M - 02 - Qjm1os9cmzu5tqPRASANTH PRASANTHNo ratings yet

- Appendix Iii Form of Application For Applying Licence:: M/s Stafford Controls Private Limited: MR SaranganDocument4 pagesAppendix Iii Form of Application For Applying Licence:: M/s Stafford Controls Private Limited: MR SaranganPRASANTH PRASANTHNo ratings yet

- Lead-Coated Copper Sheet and Strip For Building ConstructionDocument5 pagesLead-Coated Copper Sheet and Strip For Building ConstructionPRASANTH PRASANTHNo ratings yet

- B 103 - B 103M - 98 - Qjewmy9cmtaztqDocument6 pagesB 103 - B 103M - 98 - Qjewmy9cmtaztqPRASANTH PRASANTHNo ratings yet

- Chloride in Trichlorotrifluoroethane: Standard Test Method ForDocument2 pagesChloride in Trichlorotrifluoroethane: Standard Test Method ForPRASANTH PRASANTHNo ratings yet

- D 1062 - 96 - RdewnjitukveDocument6 pagesD 1062 - 96 - RdewnjitukvePRASANTH PRASANTHNo ratings yet

- D 3930 - 93a R99 - RDM5MZADocument16 pagesD 3930 - 93a R99 - RDM5MZAPRASANTH PRASANTHNo ratings yet

- D 5632 - 01 - Rdu2mziDocument4 pagesD 5632 - 01 - Rdu2mziPRASANTH PRASANTHNo ratings yet

- D 5616 - 04 - Rdu2mtyDocument2 pagesD 5616 - 04 - Rdu2mtyPRASANTH PRASANTHNo ratings yet

- D 4501 - 01 - Rdq1mdeDocument5 pagesD 4501 - 01 - Rdq1mdePRASANTH PRASANTHNo ratings yet

- Handling, Transportation, and Storage of Halon 1301, Bromotrifluoromethane (CF BR)Document3 pagesHandling, Transportation, and Storage of Halon 1301, Bromotrifluoromethane (CF BR)PRASANTH PRASANTHNo ratings yet

- Strand Century Lighting 2115-2125-2135 3.5-Inch Lekolite Ellipsoidal Spotlight Spec Sheet 6-77Document2 pagesStrand Century Lighting 2115-2125-2135 3.5-Inch Lekolite Ellipsoidal Spotlight Spec Sheet 6-77Alan MastersNo ratings yet

- Linear Accelerator Acceptance Testing and CommissioningDocument17 pagesLinear Accelerator Acceptance Testing and CommissioningSaamyNo ratings yet

- Laboratorio Hofarm - 0001Document2 pagesLaboratorio Hofarm - 0001نيلسون هيريراNo ratings yet

- Schneider - Medidor de Energía Ion Catálogo-Pm2000 - Plsed310053en - WebDocument53 pagesSchneider - Medidor de Energía Ion Catálogo-Pm2000 - Plsed310053en - WebpeterNo ratings yet

- Leonardo 5.000 W Instruction Manual: Standard EN-60598-2-17 Class 1Document4 pagesLeonardo 5.000 W Instruction Manual: Standard EN-60598-2-17 Class 1JohnNo ratings yet

- C9 Engines For Motor Graders CaterpillarDocument7 pagesC9 Engines For Motor Graders Caterpillarspelz 1No ratings yet

- F. Trigonometric Leveling1Document6 pagesF. Trigonometric Leveling1Russell AyaquilNo ratings yet

- Angular Momentum: Reading: Chapter 11 (11-7 To 11-12)Document11 pagesAngular Momentum: Reading: Chapter 11 (11-7 To 11-12)Arafat AnikNo ratings yet

- 425ºC AHT: Ower EATDocument2 pages425ºC AHT: Ower EATSivagurunathan SpNo ratings yet

- 2770 1 PDFDocument12 pages2770 1 PDFAbhinav KumarNo ratings yet

- Types of AgitatorsDocument2 pagesTypes of Agitatorsjeamnard balitaanNo ratings yet

- JEE Main 2022 (June 25 Morning Shift) Question Paper With Solutions (PDF)Document24 pagesJEE Main 2022 (June 25 Morning Shift) Question Paper With Solutions (PDF)avaneesh khadyeNo ratings yet

- Straalsund JHE 2018Document22 pagesStraalsund JHE 2018alvin bautistaNo ratings yet

- Linear Motion Power Transmission Design Guide 02Document274 pagesLinear Motion Power Transmission Design Guide 02Ravindra KirangeNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument21 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAllan PaoloNo ratings yet

- 24-Flow Meters and Flow SensorsDocument4 pages24-Flow Meters and Flow SensorsSigfrido Bader GNo ratings yet

- Flora Dale Senior Sec. School SYLLABUS (2020 - 21) Term - 1 (May - October) Class - XiDocument5 pagesFlora Dale Senior Sec. School SYLLABUS (2020 - 21) Term - 1 (May - October) Class - Xis KUMARNo ratings yet

- Prestressed Concrete With Internal or External Tendons Behaviour and AnalysisDocument294 pagesPrestressed Concrete With Internal or External Tendons Behaviour and AnalysisLuis Pablo Ramirez ZavalaNo ratings yet

- SR CHEM - VSAQ'S - FINALDocument4 pagesSR CHEM - VSAQ'S - FINALArvind GoudNo ratings yet

- Physical Geodesy100Document23 pagesPhysical Geodesy100EfrenNo ratings yet

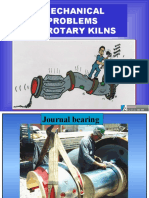

- Kiln Mechanical ProblemsDocument40 pagesKiln Mechanical ProblemsIrshad Hussain83% (6)

- 05 - ARISTONCAVI - Mining Tunneling CablesDocument55 pages05 - ARISTONCAVI - Mining Tunneling CablesJuan AdrianzenNo ratings yet

- Process DesignDocument6 pagesProcess DesignDaniel Andres Canro CalderónNo ratings yet

- tp2 Systc3a8mes Asservis Numc3a9riquesDocument1 pagetp2 Systc3a8mes Asservis Numc3a9riquesomarNo ratings yet

- García-Lodeiro, I., Maltseva, O., Palomo, A., & Fernández-Jiménez, A. (Enero de 2012)Document7 pagesGarcía-Lodeiro, I., Maltseva, O., Palomo, A., & Fernández-Jiménez, A. (Enero de 2012)Jorge GonzalezNo ratings yet

- KSOU Distance Diploma in Mechanical Engineering SyllabusDocument64 pagesKSOU Distance Diploma in Mechanical Engineering SyllabusSunil JhaNo ratings yet

- WR Pump 2-1 & 2-2Document1 pageWR Pump 2-1 & 2-2Bhuneshwar ChelakNo ratings yet