Professional Documents

Culture Documents

MDX-3 UserManual

MDX-3 UserManual

Uploaded by

AlejandroJoséUzcangaRodriguézOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MDX-3 UserManual

MDX-3 UserManual

Uploaded by

AlejandroJoséUzcangaRodriguézCopyright:

Available Formats

(MDX-3) Main unit User's Manual

The spindle unit is included with A tool with a width of either 3 mm

Thank you very much for purchasing the MODELA.

a tool-mounting portion having a or 1/8" is included. Check the width

Material for test cuts x 2

• To ensure correct and safe usage with a full understanding of this product's performance, please be sure to read through this manual completely and store it in a safe location. Check the included items diameter of 6 mm or 1/4" value that is inscribed on the tool. 100 x 150 x 15 mm

(3-15/16" x 5-7/8" x 9/16")

• Unauthorized copying or transferral, in whole or in part, of this manual is prohibited. Roland Software Package AC adapter Spindle unit Tool

• The contents of this operation manual and the specifications of this product are subject to change without notice. (with case)

• The operation manual and the product have been prepared and tested as much as possible. If you find any misprint or error, please inform us.

For the USA

Operating Instructions 3 mm or 1/8"

FEDERAL COMMUNICATIONS

KEEP WORK AREA CLEAN. Cluttered areas and benches invites Diameter 6 mm Diameter 1/4"

COMMISSION RADIO FREQUENCY accidents. spindle unit spindle unit

INTERFERENCE STATEMENT DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use

power tools in damp or wet locations, or expose them to rain. Keep Hexagonal wrench Set screw x 2 Double-sided tape MODELA (MDX-3) User's Manual for MODELA PLAYER

This equipment has been tested and found to comply with the work area well lighted.

limits for a Class A digital device, pursuant to Part 15 of the 1.5 mm (1/16") (one spare) Main unit user's MODELA 3D DESIGN/ for Mac OS

DISCONNECT TOOLS before servicing; when changing

FCC Rules. accessories, such as blades, bits, cutters, and like. manual MODELA 3D TEXT/ User's Manual

These limits are designed to provide reasonable protection REDUCE THE RISK OF UNINTENTIONAL STARTING. Make MODELA PLAYER

against harmful interference when the equipment is operated in sure the switch is in off position before plugging in.

a commercial environment. USE RECOMMENDED ACCESSORIES. Consult the owner’s

This equipment generates, uses, and can radiate radio frequency manual for recommended accessories. The use of improper

¢¢

@@

ÀÀ

;;

QQ

energy and, if not installed and used in accordance with the accessories may cause risk of injury to persons.

instruction manual, may cause harmful interference to radio NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

communications. POWER OFF. Don’t leave tool until it comes to a complete stop.

@@

ÀÀ

;;

QQ

¢¢

Operation of this equipment in a residential area is likely to

Switch Panel

cause harmful interference in which case the user will be

For Canada Connect to the computer

required to correct the interference at his own expense. STANDBY Key

@@

ÀÀ

;;

QQ

¢¢

CLASS A NOTICE This is the power switch.

This Class A digital apparatus meets all requirements of the

STANDBY LED

Unauthorized changes or modification to this system can void Never install this unit in any of the following situations, as it could result in damage:

Canadian Interference-Causing Equipment Regulations. This lights up when the

the users authority to operate this equipment.

• Places with excessive electrical noise. STANDBY key is VIEW Key

CLASSE A AVIS • Places with poor ventilation, because the MDX-3 generates considerable heat during pressed, and flashes This is used to pause operation tempo-

The I/O cables between this equipment and the computing Cet appareil numérique de la classe A respecte toutes les operation. when an error has oc- rarily and put the unit in a state where

device must be shielded. exigences du Règlement sur le matériel brouilleur du Canada. • Places with excessive vibration. curred. material or a tool may be loaded, installed,

or removed.

Make sure the power to the computer and the MDX-3 is switched off before attempting to

ROLAND DG CORPORATION connect the cables. DOWN Key

VIEW LED

1-6-4 Shinmiyakoda, Hamamatsu-shi, Shizuoka-ken, JAPAN 431-2103 Securely connect the power cord, computer I/O cable and so on so that they will not be This lowers the blade tip and determines

MODEL NAME : See the MODEL given on the rating plate.

unplugged. Otherwise, faulty operation or breakdown may result. This lights up when the

RELEVANT DIRECTIVE : EC MACHINERY DIRECTIVE (89/392/EEC) the depth-direction reference point for

VIEW key is pressed.

EC LOW VOLTAGE DIRECTIVE (73/23/EEC) cutting.

Windows® is registered trademark or trademark of Microsoft® Corporation in the United States and/ EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (89/336/EEC)

or other countries.

UP Key

Copyright © 1996-2000 ROLAND DG CORPORATION

This raises the tip of the blade.

Typographic Conventions

This manual uses typographic conventions which are outlined at the right.

To Ensure Safe Use This indicates a point requiring particular care to ensure safe use of the product.

Parallel connector

Use the clips on either side to secure the connector in place.

Do not use with a : Failure to heed this message will result in serious injury or death. Plate mounting screws

Never disassemble or Handle the power cord with care. When pulling the

modify this product. power cord from an damaged AC adapter or : Failure to heed this message may result in serious injury or death.

Do not step on or damage the

electrical socket, be power cord, or with a : Failure to heed this message may result in minor injury.

The AC adpter plugs in here

power cord, or allow heavy Table When connected to the AC adpter, the POWER LED

sure to grip the plug. loose electrical outlet.

objects to be

NOTICE : Indicates important information to prevent machine breakdown or

placed atop it. and VIEW LED flash in alternation, then go dark.

Use with any malfunction and ensure correct use. Workpiece

Failure to heed other power

may result in : Indicates a handy tip or advice regarding use. plate

supply may Plate

electrocution lead to fire or

or fire. electrocution. Spindle mounting

screw

Do not allow liquids, metal Do not install in an Handle the blade Keep hands away Do not use cutting oil Wash hands when Keep hands away from Keep children away

objects or flammables unstable or high location. with care. when a tool longer when performing cutting. finished. the blade during cutting during operation AC Adpter jack

inside the machine. Do not install the machine on

than the spindle unit is

Perform dry cutting with no Wash hands with water to

Fire or breakdown may result. the edge of a table, or it may mounted

cutting oil. Use of cutting oil remove any

fall. may result in fire or machine adhering Dust tray

failure. cutting chips.

In case of emergency,

immediately unplug

When the unit is not in

use for an extended pe-

To Ensure NOTICE About the Labels Affixed to the Unit Do not place any object The cable is available

riod, detach the AC

the AC adpter

adpter from AC outlet. Correct Do not attempt to move the

workpiece plate or spindle-

These label are affixed to the body of this product. The following figure describes the location.

The configuration of the AC adpter varies according to regional differences in voltage. Please

within the area 30 cm separately. Be sure to

unit mounting area by hand (11-13/16") use the correct cable for

Use except when repacking the

note that the descriptions in this manual are for the 117 V adpter. the computer.

unit.

Parallel Cable

How to carry the MDX-3

Connect the unit to

NOTICE NOTICE NOTICE NOTICE the Computer

Do not attempt to cut

Rear view

Do not use an air-gun This product is a precision Do not install in an area

metal objects. when cleaning. instrument and must be subject to dust, high hu-

handled with care. midity or poor ventilation.

Use two hands to securely

grip this area on the left and

Rating label right sides.

Use a rated Parallel connector

Keep hands away from

Model label power supply. Use the clips on either side to secure the connector in place.

the blade during cutting

Power Install a blade and load material Take care not to injury the hands when installing the blade

After Installation and Loading

ON ! Load the material 2 Secure the material to the workpiece plate 3 Secure the workpiece plate to the table

1 Apply double-sided tape to the back

1 Remove the workpiece plate

1 of the material. 1 1

1 Make sure that no double-sided tape OK No Good

Pressing the STANDBY key makes Before Installation Attach the Close the dust tray.

sticks out beyond the material.

the STANDBY LED light up. Loosen the plate workpiece plate

and Loading Use material with a surface that is as

mounting screws.

even as possible.

1 Make sure the top and

2 Workpiece bottom of the workpiece

Press the STANDBY key to

turn off the power. Align with the machining plate 2 plate are oriented cor-

2 reference point (the XY ori-

Workpiece

rectly when installing.

Tighten the plate mount-

Remove the gin point) and secure to the 2

ing screws securely.

workpiece plate workpiece plate. Press the STANDBY

key to turn on the

power.

2 Install the blade 2 Securely fasten the spindle unit in place

Positional relationship in the depth direction

3

Initialization is performed, and the 1 The flange on the spindle

Loosen the spindle mounting screw Press the VIEW key.

VIEW LED lights up. 1 Install the blade unit fits in here. It is pos-

2 by turning it counterclockwise, and 3

2 move the plate to the left. sible to check whether the

1 Attach a mounting screw on Move the plate

flange is in place by view-

one side only. Material thicker to the right. 4

Pull the dust tray completely Insert the blade shank 40.6 mm ing directly from one side.

out. Either side may be used. (1-9/16") than this value

into the spindle unit. cannot be loaded The spindle unit and workpiece plate

69.5 mm

return to the machining reference point.

Approx. 30 mm (2-11/16")

(1-1/4")

Fixed at 41.7 mm

28.9 mm (1-5/8")

(1-1/8")

2 Fit the spindle unit into place.

Set screw

Workpiece plate 4

3

Spindle unit Tighten the spindle

Use the hexagonal Normally a tool which is longer than this value

wrench to tighten the is installed. If the tool is too short, it may not mounting screw by

cut all the way through the material. turning it clockwise.

screw securely.

Set the reference point for depth (the Z origin point) Perform cutting Be sure the dust tray is closed before starting cutting. Pausing or When cutting is finished

Be sure to do this before sending data from the computer.

Loading is not possible while the VIEW LED is lit up or while cutting is in progress. 1 stopping Press the VIEW key and pull out the dust tray.

Remove the material that has been cut.

One press of the DOWN key: 0.1 mm (0.00393") of movement

Hold down the DOWN key for 0.5 sec. or more to move at 3 mm (1/16") /sec. Use the application software operation To continue with operation, repeat the steps

to create the data. (See the from "2 Install a blade and load material" to "4

1 2 3 4 MODELA User's Manual in- Perform cutting."

The reference point for cluded with the unit.) To end operation, press the STANDBY key,

Press the DOWN The blade rotates When the blade tip When the tip touches

key to lower the as it is lowered the material, release depth has now been set. then switch off the power.

comes close to the ma- Press the VIEW key.

blade the DOWN key. The MDX-3 takes the

terial surface, carefully

position when data is

use the key to lower the

sent from the computer 2 To continue with cutting, press the VIEW

blade a little at a time. If the dust tray becomes

as the depth-direction Send the cutting key again. Cutting is resumed.

reference point for op- more than half full of cuttings

commands. To end cutting, stop the transmission of data

eration. After making while cutting is in progress,

from the computer, then press the UP and DOWN

the setting, do not press press the VIEW key to pause

keys at the same time. The VIEW LED flashes for

the UP or DOWN key. 3 cutting, then pull out and

about two seconds, then the data in the MDX-3 is

empty the dust tray.

Start cutting deleted.

Care and cleaning Do not use an air-gun.

Never lubricate the mechanisms.

What to do if... Specification

- The MDX-3 doesn't operate - Tool movement is different than the data XY table size : X: 170 mm, Y: 110 mm (6-11/16" x 4-5/16") Power consumption : Exclusive AC adpter (DC+12V 1.5A)

Use a vacuum cleaner to clean up cuttings. Use a small amount of water or alcohol for cleaning. Never use solvents such Is the STANDBY key on (with the STANDBY LED lit If an attempt is made to cut more deeply than the range of

Max. cutting area : 152.4 mm (X) x 101.6 mm (Y) x 40.65 mm (Z) Acoustic noise level : Standby mode : under 24 dB (A), Cutting mode (when

as benzene or thinner can smooth out the material so that it sticks securely. up)? movement for the MDX-3 allows, the tool automatically rises

Has operation not been paused by pressing the VIEW key to the uppermost point. (6" (X) x 4" (Y) x 1-9/16" (Z)) not performing cutting) : under 52 dB (A)

(lighting up the VIEW LED)? Check to make sure that depth settings in the cutting data are Feed rate : 0.1 mm/sec. —15 mm/sec. (According to ISO 7779)

Are the cable connected correctly? not too deep, and that the tool extending from the spindle unit (0.00393"/sec.—9/16"/sec.) External dimensions : 350 mm (W) x 380 mm (D) x 310 mm (H)

Are the settings for the computer and software correct? is not too short. Software resolution : 0.025 mm/step (0.000984"/step) (13-13/16" (W) x 15" (D) x 12-1/4" (H))

Option Lists

Name Model No. Specifications

- Speed drops during cutting

When cutting a material of uneven hardness, such as

- Correct cutting is impossible

Are the blade, spindle, and workpiece all installed and loaded

securely? Retighten the setting screw for the blade and the

Mechanical resolution : X, Z-axis : 0.025 mm/step (0.000984"/step)

Spindle motor

Y-axis : 0.05 mm/step (0.00197"/step)

: 5 W (DC motor)

Weight (unit only)

Acceptable tool

Acceptable material

: 7 kg (15.4 lb.)

: Endmill, Drill

: Wood, Plaster, Resin (modeling wax, styrenefoam)

wood, the MDX-3 may slow down automatically (to a Revolution speed : 4500 rpm (±10%) Operation temperature : 5—40°C (41—104°F)

Shank diameter: 6 mm, mill diameter 3 mm, minimum speed of 0.1 mm (0.00394") /sec.). Once the mounting screws for the spindle.

Tool ZHS-3015 Tool chuck : 6 mm or 1/4" tool chuck included Operation humidity : 35 %—80 % (no condensation)

overall length:50 mm MDX-3 has gone beyond the hard area, cutting contin- - Unusual noise is heard from the spindle Interface : Parallel (in compliance with the specification of Accessories : Roland Software Package, MODELA (MDX-3) Main

MS-3 Tool-mounting portion: 3 mm ues at normal speed.

If an exterior part becomes soiled, wipe gently The spindle unit is a consumable part. Replace with a new Centronics) unit User's Manual, User's Manual for MODELA 3D

MS-6 Tool-mounting portion: 6 mm spindle unit after 700 hours of use. DESIGN/MODELA 3D TEXT/MODELA PLAYER,

with a dry cloth. Spindle unit - The STANDBY LED is flashing slowly (every 0.5 Control keys : STANDBY, VIEW, UP, DOWN, STANDBY

MS-8A Tool-mounting portion: 1/8" MODELA PLAYER for Mac OS User's Manual, AC

sec.) LED, VIEW LED

- The spindle motor does not run adapter, Tool, Spindle unit, Material for test cuts x 2,

MS-4A Tool-mounting portion: 1/4" The material cannot be cut, even when the speed is The spindle motor is a consumable part. Replace with a new Hexagonal wrench, Set screw x 2, Double sided tape

Replacement Exclusively for MDX-3 reduced. Switch the power off and back on.

MM-3 spindle motor after 700 hours of use.

spindle motor unit Switch the power off and back on again. Make sure the Interface Specification

blade being used is appropriate for the hardness of the - Pressing the STANDBY key does not switch off the [ Parallel ]

material in use. Modify the software settings to cut the power Standard : In compliance with the specification of Centronics

material a little at a time. Unplug the AC adapter from the unit. Input signal : STROBE(1BIT), DATA(8BIT)

Output signal : BUSY(1BIT), ACK(1BIT)

- The STANDBY LED is flashing rapidly (every

I/O signal level : TTL level

0.1 sec.)

Switch off the power, and check the cable connections as Transmission method : Asynchronous

well as the settings for the computer and software.

R4-000112

You might also like

- Owner's Manual: Instructions For Installation and Operation / WarningsDocument66 pagesOwner's Manual: Instructions For Installation and Operation / Warningsthisch0% (1)

- RISO MV 7690 C, MZ 770 A, MZ 770 E, MZ 790 U Technical Manual (Service Manual)Document444 pagesRISO MV 7690 C, MZ 770 A, MZ 770 E, MZ 790 U Technical Manual (Service Manual)ali mohebi100% (1)

- B E ECE-SYLLABUS pdf2-07Document87 pagesB E ECE-SYLLABUS pdf2-07SAMIARANTHANGINo ratings yet

- Coll. - Tableting Specification Manual-APhA (2001) PDFDocument136 pagesColl. - Tableting Specification Manual-APhA (2001) PDFMuhammad Aviv Addin80% (5)

- Power Team HNS150 ManualDocument5 pagesPower Team HNS150 ManualTitanplyNo ratings yet

- BMSDocument44 pagesBMSHari Krishna100% (5)

- Incra Mast R Lift II MetricDocument6 pagesIncra Mast R Lift II Metricranafoul42No ratings yet

- h40 500 45 500 50 500 50 600evo en (Ed2) PDFDocument2 pagesh40 500 45 500 50 500 50 600evo en (Ed2) PDFAdmir BašićNo ratings yet

- Bcnp59990791ec PDFDocument1 pageBcnp59990791ec PDFAlex ZXNo ratings yet

- Instructions and Cautions For Safe Use of AC Servos: General-Purpose AC Servo CautionDocument1 pageInstructions and Cautions For Safe Use of AC Servos: General-Purpose AC Servo CautiontadyNo ratings yet

- BCNP 59990794 EcDocument1 pageBCNP 59990794 EcAlex ZXNo ratings yet

- Panasonic Car Stereo System CQ-CP134U PDFDocument16 pagesPanasonic Car Stereo System CQ-CP134U PDFJuan Carlos SoHeNo ratings yet

- Fail Safe FSN Spec SheetDocument4 pagesFail Safe FSN Spec SheetDowneyNo ratings yet

- Signet CR 8860 ManualDocument12 pagesSignet CR 8860 Manualtridata triNo ratings yet

- Endosafe-PTS User's Guide - Charles River Endotoxin & Microbial DetectionDocument36 pagesEndosafe-PTS User's Guide - Charles River Endotoxin & Microbial DetectionMarc HoffmanNo ratings yet

- Installation Instructions: Parts List Cassette Player: P/N 08A53-S5A-100 CD Player: P/N 08A53-S5D-100Document8 pagesInstallation Instructions: Parts List Cassette Player: P/N 08A53-S5A-100 CD Player: P/N 08A53-S5D-100Luis AguirreNo ratings yet

- Dewalt DC845KA ManualDocument7 pagesDewalt DC845KA Manualtestmonger5237No ratings yet

- Radial Arm Drill Press Model 1230: Operating Instructions and Parts ManualDocument32 pagesRadial Arm Drill Press Model 1230: Operating Instructions and Parts ManualCesar VasquesNo ratings yet

- AE270Document16 pagesAE270Fernando MaderasNo ratings yet

- MT 5DX PLUS - Driver Cabinet Operation ManualDocument186 pagesMT 5DX PLUS - Driver Cabinet Operation Manualrzlpratama18No ratings yet

- Minas-A5-2 CTLG e PDFDocument155 pagesMinas-A5-2 CTLG e PDFDefinal ChaniagoNo ratings yet

- ManualDocument32 pagesManualScribdman79No ratings yet

- Industrial Machines PDFDocument36 pagesIndustrial Machines PDFScribdTranslationsNo ratings yet

- Harley-Davidson Softail Breakout / Cvo Breakout Big Radius Installation Instructions PART# 26065Document3 pagesHarley-Davidson Softail Breakout / Cvo Breakout Big Radius Installation Instructions PART# 26065Justin StewartNo ratings yet

- EFL3850 75 Manual ENDocument22 pagesEFL3850 75 Manual ENPaul DanielNo ratings yet

- LDS - Permanent - Magnet - Shakers - Brochure - LR 2Document3 pagesLDS - Permanent - Magnet - Shakers - Brochure - LR 2snowflakefiat121No ratings yet

- Eeam020600 Wa700-3 PDFDocument312 pagesEeam020600 Wa700-3 PDFMilan HájekNo ratings yet

- SOUTH Operation ManualDocument236 pagesSOUTH Operation ManualPrashanth Reddy TummuluriNo ratings yet

- TuffStuff Apollo 7000 High Low Pulley Station (AP-71HL) Owner's ManualDocument19 pagesTuffStuff Apollo 7000 High Low Pulley Station (AP-71HL) Owner's ManualCharlieNo ratings yet

- DR1000 Installation Instruction Rev JDocument4 pagesDR1000 Installation Instruction Rev JLupita ArriagaNo ratings yet

- 6 P8010 P6010 Concise Manual ENDocument2 pages6 P8010 P6010 Concise Manual ENEsteban RamirezNo ratings yet

- Manual Ryobi BDocument18 pagesManual Ryobi BJT AlexanderNo ratings yet

- TBA19Document250 pagesTBA19kykhanhnguyen0302No ratings yet

- 11 SSFC PDFDocument50 pages11 SSFC PDFChaib MaamarNo ratings yet

- Boss fv500h enDocument2 pagesBoss fv500h enGiangregorio SuraceNo ratings yet

- CV-X400/X300 Series: Intuitive Vision SystemDocument20 pagesCV-X400/X300 Series: Intuitive Vision Systemeduardo.juarezNo ratings yet

- GPSMAP 7x2-9x2 Install EN-USDocument8 pagesGPSMAP 7x2-9x2 Install EN-USVarun K.JNo ratings yet

- 99MAD014M4 Digimatic CaliperDocument2 pages99MAD014M4 Digimatic CaliperermankurNo ratings yet

- TuffStuff Apollo 7000 Multi Press (AP-71MP) Owner's ManualDocument23 pagesTuffStuff Apollo 7000 Multi Press (AP-71MP) Owner's ManualCharlieNo ratings yet

- CSW-7000 Manual Ed11Document2 pagesCSW-7000 Manual Ed11scribdNo ratings yet

- Panasonic MotorDocument155 pagesPanasonic MotorEnrique MarquezNo ratings yet

- Craftsman Router Lathe ManualDocument29 pagesCraftsman Router Lathe Manualcs2swNo ratings yet

- ManualDocument4 pagesManualJose Van de KruisNo ratings yet

- Sinobaler Automatic Horizontal Baler PDFDocument1 pageSinobaler Automatic Horizontal Baler PDFliu zhao liu zhaoNo ratings yet

- CNC 104 Rim Vent: DatasheetDocument1 pageCNC 104 Rim Vent: DatasheetAs'adNo ratings yet

- Apollo 7000 Leg Extension / Curl Station (AP-71LE) Owner's ManualDocument19 pagesApollo 7000 Leg Extension / Curl Station (AP-71LE) Owner's ManualCharlieNo ratings yet

- Sin Nombre - Especificación 3Document1 pageSin Nombre - Especificación 3Jesus Miguel CallupeNo ratings yet

- GENUINE Parking Sensor: Installation InstructionsDocument30 pagesGENUINE Parking Sensor: Installation InstructionsRonNo ratings yet

- Mimaki JV3-160 SP PDFDocument136 pagesMimaki JV3-160 SP PDFAlisson BrighentiNo ratings yet

- MT9083 Series: ACCESS MasterDocument34 pagesMT9083 Series: ACCESS Masteroscarleon77No ratings yet

- Modenas Service Manual An 110 EditedDocument183 pagesModenas Service Manual An 110 EditedploffyNo ratings yet

- MR-JE - Safety Installation Manual IB (NA) 0300194E-D (08.13)Document1 pageMR-JE - Safety Installation Manual IB (NA) 0300194E-D (08.13)Puji AntoroNo ratings yet

- Downhole Tool Dressing Brochure 2022Document7 pagesDownhole Tool Dressing Brochure 2022Ricky VelascoNo ratings yet

- Protaper Universal Endo System DFUDocument7 pagesProtaper Universal Endo System DFUMaya SafitriNo ratings yet

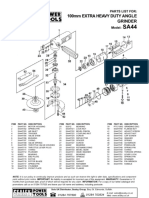

- SA44 SA44: 100Mm Extra Heavy Duty Angle Grinder 100Mm Extra Heavy Duty Angle GrinderDocument1 pageSA44 SA44: 100Mm Extra Heavy Duty Angle Grinder 100Mm Extra Heavy Duty Angle GrinderVeronica CastroNo ratings yet

- 3000 Air Tool ManualDocument16 pages3000 Air Tool Manualabdallah.hammodNo ratings yet

- 3.2mRollShaftUnit D203048-V10Document12 pages3.2mRollShaftUnit D203048-V10Mulya WijayaNo ratings yet

- Boss FV-500H - OMDocument1 pageBoss FV-500H - OMbaggy trousersNo ratings yet

- T B S G I M: IE AR Train AGE Nstruction AnualDocument22 pagesT B S G I M: IE AR Train AGE Nstruction AnualJansirani SelvamNo ratings yet

- T B S G I M: IE AR Train AGE Nstruction AnualDocument22 pagesT B S G I M: IE AR Train AGE Nstruction AnualSelvamNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterRating: 4 out of 5 stars4/5 (3)

- Non Linear EqualizationDocument20 pagesNon Linear EqualizationThota DeepNo ratings yet

- Control Products CatalogDocument50 pagesControl Products Catalogmk saravananNo ratings yet

- Backlash ErrorDocument15 pagesBacklash ErrorarunNo ratings yet

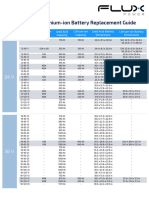

- Lead Acid Model Lithium-Ion Battery Replacement GuideDocument2 pagesLead Acid Model Lithium-Ion Battery Replacement GuideRaymundo MartinezNo ratings yet

- Pv6Uslp PV6UE-05 PV6U-O Compression of Series 6 ConnectorsDocument2 pagesPv6Uslp PV6UE-05 PV6U-O Compression of Series 6 ConnectorsDiego CapezioNo ratings yet

- Transformer Protection: Power Transformers and Power AutotransformersDocument29 pagesTransformer Protection: Power Transformers and Power Autotransformersmoham akhNo ratings yet

- Perseus A500 Quick GuideDocument24 pagesPerseus A500 Quick GuideRemusNo ratings yet

- Most Important Interview Questions For Electronics Communication EngineeringDocument11 pagesMost Important Interview Questions For Electronics Communication EngineeringPavan Kumar ThopaNo ratings yet

- 13 - ECE 3125 ECE 3242 - Nov 21 2012 - Baseband Demodulation and DetectionDocument18 pages13 - ECE 3125 ECE 3242 - Nov 21 2012 - Baseband Demodulation and DetectionEng-Ahmed ShabellNo ratings yet

- A Survey On FEC Codes For 100G and BeyonDocument15 pagesA Survey On FEC Codes For 100G and BeyonnghtlghtNo ratings yet

- RCDs Operating TimeDocument2 pagesRCDs Operating Timehossimo33No ratings yet

- Lab 3 ReportDocument5 pagesLab 3 Reportwilliam1230No ratings yet

- DS HG2427GDocument2 pagesDS HG2427GLema GustavoNo ratings yet

- Isdn Bri Back UpDocument47 pagesIsdn Bri Back UpSandeep KumarNo ratings yet

- Outdoor Directional Tri-Band Antenna: ODV-065R17EKK-GDocument1 pageOutdoor Directional Tri-Band Antenna: ODV-065R17EKK-GNatalya DrugakovaNo ratings yet

- Moses Kavi ThesisDocument238 pagesMoses Kavi Thesisamir AlmodaferNo ratings yet

- Jumper: Source Connector Signal Pin - Pin Signal Connector DestinationDocument142 pagesJumper: Source Connector Signal Pin - Pin Signal Connector DestinationFrank OforiNo ratings yet

- Usw E48pDocument3 pagesUsw E48pMohamed Shaffaf Ali RasheedNo ratings yet

- Wmex 678Document18 pagesWmex 678zolexoNo ratings yet

- Machine Lab CombineDocument38 pagesMachine Lab Combinelakha ramNo ratings yet

- MPK203x 200A MicroOhmmeterDocument2 pagesMPK203x 200A MicroOhmmeterJoab NgNo ratings yet

- TT TubemapDocument7 pagesTT TubemapGio GioNo ratings yet

- Efficient Utilisastion of Hybrid Power Plant Using MPPT Technique and Reducing The Voltage Intrupption by Using DstatcomDocument17 pagesEfficient Utilisastion of Hybrid Power Plant Using MPPT Technique and Reducing The Voltage Intrupption by Using DstatcomAnuj TripathiNo ratings yet

- Massive MIMO EIRP and EMF For VFUKDocument15 pagesMassive MIMO EIRP and EMF For VFUKUmer AftabNo ratings yet

- Cerabar S PMC71, PMP71, PMP75: Technical InformationDocument92 pagesCerabar S PMC71, PMP71, PMP75: Technical InformationSardar PerdawoodNo ratings yet

- Lecture 31: Filter Implementation: 1 ELEC4630, Shu Yang, HKUSTDocument18 pagesLecture 31: Filter Implementation: 1 ELEC4630, Shu Yang, HKUSTAlejandro GudiñoNo ratings yet

- Lab 01 P-N DiodeDocument5 pagesLab 01 P-N DiodeyayayehNo ratings yet

- 01 - Equipment Cabinet ICC330-H7-C1 Datasheet 01 - (20170613)Document2 pages01 - Equipment Cabinet ICC330-H7-C1 Datasheet 01 - (20170613)alexdaniel666100% (1)