Professional Documents

Culture Documents

Danbury 2007

Danbury 2007

Uploaded by

Christophe CaronOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Danbury 2007

Danbury 2007

Uploaded by

Christophe CaronCopyright:

Available Formats

Allenton

TM

Shorewood

TM

Danbury TM

Tahoe TM

Amherst

TM

POCKET BILLIARD TABLE

INSTALLATION MANUAL

www.brunswick-billiards.com

SERVICE DEPARTMENT P.O. BOX 68 BRISTOL, WI 53104

51-904768-003 SEPTEMBER 2006

•ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

NOTE: Please use the instructions in this manual to assemble the tables.

Illustrations may be different depending on the table being assembled.

Also note that careful handling of all components

will assure damage-free assembly.

PAGE 2 BRUNSWICK INSTALLATION MANUAL

LEG AND BASEFRAME ASSEMBLY •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

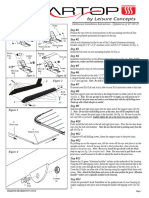

FIGURE ONE A AND B

Step #1: Position the side sills with the inside up on a

flat protected surface. Loosely attach two cross support

brackets to each side sill using 5/16-18 x 3/4” hex head

cap screws and 5/16 washers.

Step #2: With a straight edge or block flat across the

slate attach plate. Slide the bracket up to make contact

and tighten securely. It is critical that the top of the

bracket is flush with the top surface of slate attach plate.

FIGURE ONE

FIGURE TWO

Step #3: Loosely attach the corner brackets to the ends

of the side sills using 5/16-18 x 1-3/4” hex head cap

screws, 5/16 washers and 5/16-18 tab weld nuts.

FIGURE TWO

FIGURE THREE

Step #4: Position the baseframe end sills to the side sills,

and loosely attach the brackets already attached to the

side sills with the same hardware.

FIGURE THREE

BRUNSWICK INSTALLATION MANUAL PAGE 3

LEG AND BASEFRAME ASSEMBLY •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

(CONTINUED)

FIGURE FOUR

Step #5: Loosely attach the leg attach brackets to the

baseframe using 5/16-18 x 3/4” hex head cap screws and

5/16 washers.

FIGURE FOUR

FIGURES FIVE AND SIX

Step #6: With the aide of another person, carefully place

the baseframe on top of the legs and loosely attach using

5/16-18 x 1” hex head cap screws and 5/16” washers.

FIGURE FIVE

FIGURE SIX

PAGE 4 BRUNSWICK INSTALLATION MANUAL

LEG AND BASEFRAME ASSEMBLY •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

(OPTIONAL LEG PLATE)

FIGURE SEVEN (OPTIONAL)

3/4”

Step #7: Install leg plate on top of leg, cavity side down. Metal Leg

Hex Head Cap Screw

Be sure slot is aligned from front to back of corner of leg. Attach Bracket Washer

Step #8: Position leg plate with plate underneath sills.

Step #9: Install 3/4” hex head cap screw (included in leg

plate carton) and washer from hardware kit, through the

slot in the metal leg attach bracket, through the slot in

the leg plate and into the threaded insert in leg. Slot in

plate must align with slot in leg attach bracket. Hand

tighten only at this time.

Leg

Plate

FIGURE SEVEN

FIGURE EIGHT (OPTIONAL)

Step #10: Align leg plate square to sills with Metal Leg

Corner

approximatey 1/8” reveal betweeen corner molding and Molding Attach Bracket

detail shoulder of leg plate.

ll

Si

Step #11: Position leg in center of cavity with approxi-

mately equal gap on all four sides of leg. Fully tighten leg

screw making sure leg does not rotate out of position

during tightening.

Leg

Si

ll

1/8” Plate

Reveal

FIGURE EIGHT

BRUNSWICK INSTALLATION MANUAL PAGE 5

LEG AND BASEFRAME ASSEMBLY •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

CONTINUED

FIGURE SEVEN

Step #7: Position the cross supports into the brackets

and loosely attach using 3/8-16 x 2” hex head cap

screws, 3/8 washers, and 3/8-16 hex nuts. Assure that

the cross supports are flush with the top to the sills and

tighten securely. If necessary, remove wood from the

bottom of the cross support or place shims in the bottom

of the brackets to obtain a flush fit.

Step #8: Square the table using a carpenter’s square

and assure that the baseframe is sitting flush on the leg

top and securely tighten all corner brackets. Firmly

push downward on the baseframe and securely tighten

the leg attach brackets.

FIGURE SEVEN

FIGURE EIGHT

Step #9: Position the corner post over the baseframe.

While using the two holes in the center of the corner

bracket, pilot drill 1/8” diameter holes into the corner

post. (Be careful not to drill all the way through.) Hold

the corner post firmly in position and attach using #8 x

1-1/4” round head screws and #8 washers.

FIGURE EIGHT

FIGURE NINE

Step #10: At each corner, adjust the legs to the desired

location and securely tighten the center bolt to the leg.

While using the three remaining holes in each leg attach

bracket as a template, pilot drill 1/8” diameter holes into

the legs approximately 1-1/2” deep. Complete the

attachment of the leg bracket using #10 x 1-1/2” hex

washer head self-tapping screws.

Step #11: Position the table in its permanent location.

We recommend a 60” clearance around perimeter of the

table. Proceed with leveling and slate installation.

FIGURE NINE

PAGE 6 BRUNSWICK INSTALLATION MANUAL

•ALLENTON•SHOREWWOOD•DANURY

SLATE ASSEMBLY AND LEVELING •TAHOE •AMHERST

IMPORTANT: Prior to installing the slate, it is

important to level the baseframe.

FIGURE ONE

Step #1: With a carpenter’s level, locate the highest

corner of the baseframe. Level the baseframe by

positioning shims (supplied with the table) underneath

the other three legs as necessary.

Step #2: Be sure that the top surfaces are absolutely

flush. Add shims under the legs as necessary to accom-

plish this.

Step #3: With the baseframe level and carefully

positioned in its permanent location, place the center

section of slate on the table. Be sure that the center

section is precisely square with the frame and an equal

amount of overhang exists on both sides of the table.

FIGURE ONE

FIGURE TWO

Step #4: Position the two end slate sections on the

baseframe. Be sure that the penciled arc forms a radius.

Step #5: Recheck to be sure that the slate has an equal

amount of overhang around the baseframe.

Step #6: Using the twelve (12) countersunk holes in the

slate as a template, pilot drill 5/32" diameter holes into

slate attach plate.

Step #7: Securely fasten the end slate section at both

ends of the table.

FIGURE TWO

BRUNSWICK INSTALLATION MANUAL PAGE 7

SLATE ASSEMBLY AND LEVELING •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

(CONTINUED)

FIGURE THREE

Step #8: With a precision level, level each end slate

section by driving wooden slate wedges (provided)

between the top of the baseframe and bottom of the

slate. Keep the wedges as close to the countersunk holes

as possible. (Loosen and tighten screw as required.)

Step #9: With both end slates perfectly level, continue

fastening the end slates at the joints. Recheck for

levelness and if necessary, back the screws out and

adjust the shim position, then retighten the slate

attaching screws.

Step #10: When satisfied that both end slates are level,

shim the center slate section as required to obtain a

flush fit at both joints, then screw the center slate down.

FIGURE THREE

FIGURE FOUR

Step #11: Slate joints can now be filled with fast setting

rock hard putty, bee’s wax or slate joint wax. Lightly

sand or scrape across joint after grouting.

Step #12: From the end of a bed cloth, cut strips of cloth

approximately 1-1/2" wide by approximately 8" long and

glue the strips to the pocket cutouts (3m Super 77 is

recommended for this step). This is important as this

will provide cushioning from ball impact and the bed

cloth will last much longer.

FIGURE FOUR

PAGE 8 BRUNSWICK INSTALLATION MANUAL

ATTACHING BED CLOTH •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

Before attaching bed cloth clean slate thoroughly:

FIGURE ONE

Step #1: Lay the bed cloth over the top of the slate, nap

side up. Leave an equal amount of cloth overhang at the

end and sides of the slate.

NOTE: In determining the direction of the nap, run

your hand lightly over the surface of the cloth. If it

meets resistance, it is going against the nap.

Step #2: Adjust cloth to leave only enough cloth

overhang at the head end and left side to permit tacking

into the wood slate frame. Leave the balance of cloth

overhang at the foot end and right side.

NOTE: Do not spread tacks or staples on the bed cloth

because it could cut the cloth. Keep them in a con-

tainer that slides over the cloth.

FIGURE ONE

FIGURE TWO

Step #3: Tack or staple the cloth securely to the wood

frame at location #1 with two tacks or staples approxi-

mately 2" apart.

Step #4: Stretch the cloth across the table and tack or

staple securely at location #2 with two tacks or staples

2" apart.

Step #5: Stretch the cloth from location #1 to location

#3 and tack or staple securely into the wood frame at

the left side of the table.

Step #6: Stretching the cloth across the table from

location #3 and pulling from location #2, tack or staple

the cloth at location #4.

FIGURE TWO

FIGURE THREE

Step #7: On the left side, stretch the cloth tightly from

location #1 toward the side pocket opening and tack or

staple securely at location #5.

Step #8: Repeat Step 5, stretching the cloth from

location #3 and tacking or stapling at location #6.

Step #9: On the right side of the table, grasp the cloth

firmly and stretch across the table from location #5 and

toward the side pocket from location #2 and tack or

staple at location #7.

Step #10: Repeat Step 9, stretching from location #6

and toward the side pocket from location #4 and tack or

staple at location #8. FIGURE THREE

BRUNSWICK INSTALLATION MANUAL PAGE 9

ATTACHING BED CLOTH •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

(CONTINUED)

FIGURE FOUR

Step #11: At location #9, cut a short slit in the cloth at

the edge centered on the side pocket opening. Grasp the

cloth firmly above this slit, pull the cloth into the side

pocket opening and tack or staple to the wood frame.

Complete fastening of the cloth to the side pocket

opening, making sure the cloth is tacked or stapled to the

wood frame.

Step #12: Stretching the cloth tightly across the table

from location #9, repeat Step 11 at location #10.

FIGURE FOUR

FIGURE FIVE

Step #13: At the head end of the table, tack or staple the

cloth at location #11, maintaining uniform overhang.

Step #14: Pull the cloth from location #11 toward

location #12 and tack or staple securely along the wood

frame, keeping the cloth even along the head end.

Step #15: Stretch the cloth firmly from location #11 to

the foot end of the table and tack or staple at location

#13.

Step #16: Stretch the cloth tightly from locations #12

and #13 toward location #14 and tack or staple securely

along the wood slate frame.

FIGURE FIVE

FIGURE SIX

Step #17: Tack or staple all of the left side on 2" centers

keeping the cloth even along the wood frame.

Step #18: Tack or staple the balance of the head end on

2" centers also keeping the cloth even along the wood

frame.

Step #19: Stretch the cloth tightly toward the foot end of

the table, tacking or stapling on 2" centers along the

wood frame at the foot end.

Step #20: Stretch the cloth tightly across the table to

the right side, tacking or stapling on 2" centers all the

way along the wood frame at the right side.

FIGURE SIX

FIGURE SEVEN

Step #21: Stretch the cloth into the corner pocket

openings and tack or staple to the wood slate frame.

Step #22: Trim off excess cloth around the perimeter of

the slate. Locate the eighteen (18) rail attach holes and

cut clearance holes in the cloth with a sharp knife.

NOTE: Occasionally cloth will stretch, leaving wrinkles at

the pockets. To retighten, remove apron, one end rail and

one side rail. Pull cloth taut, and retack or restaple along

the open end and side to restore original tightness. FIGURE SEVEN

PAGE 10 BRUNSWICK INSTALLATION MANUAL

RAIL ASSEMBLY •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

FIGURE ONE

Step #1: Position rails upside down on a protected

surface in their respective locations.

FIGURE ONE

FIGURE TWO

Step #2: Insert stud of pocket iron into the end of the

rail as shown. Press in tightly against the end on the rail

while threading a 5/16-18 x 1" hex head bolt with washer

into the threaded hole in the stud. Tighten securely.

Step #3: Repeat above procedure with the remaining

five pockets.

FIGURE TWO

FIGURE THREE

Step #4: Thread a machine stud into the three locations

of each rail as shown.

FIGURE THREE

BRUNSWICK INSTALLATION MANUAL PAGE 11

APRON ASSEMBLY •ALLENTON•SHOREWWOOD•DANURY

•TAHOE •AMHERST

FIGURE ONE

Step #1: With rail assembly remaining upside down,

position the apron brackets into the groove with the

short leg of the bracket facing the back of the rail,

approximately 3 - 4” from each end of the rail. With the

brackets firmly seated, attach them to the back of the rail

core with #6 x 3/4” flat head screws through hole line

”B”.

FIGURE ONE

FIGURE TWO

Step #2: Position the aprons into the grooves so the

ends of apron and rails are even. Apply downward

pressure on the apron and attach the brackets to the

back of the apron with #8 x 1/2” pan head screws

through hole line “A”.

Step #3: Using a partner, carefully turn the rail and

pocket assembly over and lower over the table.

FIGURE TWO

FIGURE THREE

Step #4: Align the eighteen machine studs with the

eighteen clearance through the slate and lower the

assembly onto the slate.

Step #5: Thread the 3/8-16 hex nut and dome washer

onto the machine stud (three places) at the ends of the

table and tighten securely.

Step #6: Making sure that the side rails are in a straight

line as sighted down the length of the table (cushion

side), fasten the side rails securely with remaining nuts

and dome washers.

Step #7: Attach pocket tabs to underside of slate frame

pad with nails, or 1/2” staples.

Step #8: Thoroughly brush the area on which the bed

spots are to be applied. Position the bed spot and firmly

roll a ball over the spot to achieve good adhesion.

NOTE: Bed spots are self adhesive.

FIGURE THREE

PAGE 12 BRUNSWICK INSTALLATION MANUAL

You might also like

- Folding Workbench PlansDocument13 pagesFolding Workbench PlansChris Couch100% (2)

- Woodworking Plans - Workbench - Popular Mechanics - Hard MapleDocument7 pagesWoodworking Plans - Workbench - Popular Mechanics - Hard Maplepandearroz100% (2)

- Woodsmith Shaker Style WorkbenchDocument22 pagesWoodsmith Shaker Style Workbenchricheklund92% (12)

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- Brunswick Metro Pool Table ManualDocument15 pagesBrunswick Metro Pool Table ManualJose Luis GutierrezNo ratings yet

- Ocean Cot-Bed Instructions - Mamas & Papas PDFDocument16 pagesOcean Cot-Bed Instructions - Mamas & Papas PDFJulieNo ratings yet

- Planos Sillon Solarium Reposera MaderaDocument3 pagesPlanos Sillon Solarium Reposera MaderaMarcelo A. NegreiraNo ratings yet

- B&Q 8FT Trampoline PDFDocument22 pagesB&Q 8FT Trampoline PDFpaul_burger_100% (1)

- Airport Literature StudyDocument15 pagesAirport Literature StudySoundar Rajan100% (2)

- What Is RAID Control PDFDocument6 pagesWhat Is RAID Control PDFAhmedNo ratings yet

- Chapter 6 Work, Energy and PowerDocument12 pagesChapter 6 Work, Energy and PowerZhu Jiankun100% (1)

- Metro: Installation ManualDocument15 pagesMetro: Installation ManualVinh NguyenNo ratings yet

- 601 Car Frame Installations R1Document16 pages601 Car Frame Installations R1bhupiisterNo ratings yet

- Tail Vise: Installation InstructionsDocument19 pagesTail Vise: Installation InstructionsJohn HarrisonNo ratings yet

- Carrinho FerramentaDocument10 pagesCarrinho Ferramentapaulo75% (4)

- Eagle Eyes Antenna Pan/Tilt Assembly InstructionsDocument12 pagesEagle Eyes Antenna Pan/Tilt Assembly InstructionsdanielNo ratings yet

- Imovr Vigor Installation ManualDocument5 pagesImovr Vigor Installation ManualhollingermikeNo ratings yet

- T8179 Ping Pong TableDocument7 pagesT8179 Ping Pong TableRussel SarachoNo ratings yet

- Maquina para Balancear Un AvionDocument7 pagesMaquina para Balancear Un AvionMarco AlvarezNo ratings yet

- Toxic & Enigma Crossbow Owner'S Guide Theory Recurve Owner'S GuideDocument13 pagesToxic & Enigma Crossbow Owner'S Guide Theory Recurve Owner'S GuidePak Cik FauzyNo ratings yet

- Cleats Shelf Standards.: E. Assemble The CabinetDocument1 pageCleats Shelf Standards.: E. Assemble The CabinetreacharunkNo ratings yet

- Futon Bed Tri - FoldDocument3 pagesFuton Bed Tri - FoldSnezana Stojkovic PavlovicNo ratings yet

- Stand Assembly: Parts CheckDocument16 pagesStand Assembly: Parts CheckGianfranco DyNo ratings yet

- SimplicityDocument232 pagesSimplicityChristian García RubialesNo ratings yet

- LPI101100VA Roof-Top Cargo Basket Installation Instruction 092021 V5Document5 pagesLPI101100VA Roof-Top Cargo Basket Installation Instruction 092021 V5bad.wolffieNo ratings yet

- Rear Sway Bar Installation InstructionsDocument4 pagesRear Sway Bar Installation InstructionsRaduNo ratings yet

- Tail-Vise InstructionsDocument22 pagesTail-Vise InstructionsIulian MihaiNo ratings yet

- Patio CartDocument15 pagesPatio CartAndresRSjrNo ratings yet

- Suffolk Latch Installation: 6159-S316 and 6159-B316Document1 pageSuffolk Latch Installation: 6159-S316 and 6159-B316Anonymous m6A7tNaMgfNo ratings yet

- Wing Installation Section VDocument36 pagesWing Installation Section Vmohamed sidkyNo ratings yet

- Loon 160 Rudder GuideDocument4 pagesLoon 160 Rudder Guidechase simpsonNo ratings yet

- Mech-Tech CCU Interchangeable Stock Instructions: Pg.1 of 5Document5 pagesMech-Tech CCU Interchangeable Stock Instructions: Pg.1 of 5shunkadu2No ratings yet

- Child: Adirondack / Muskoka Chair PlansDocument7 pagesChild: Adirondack / Muskoka Chair PlansVictor M GonzalezNo ratings yet

- Swivel Bench Vise NewDocument31 pagesSwivel Bench Vise NewSudhakarNo ratings yet

- Chair 8Document18 pagesChair 8Naga Raj100% (2)

- O'Brien Neck Joint Routing Jig: Assembly InstructionsDocument16 pagesO'Brien Neck Joint Routing Jig: Assembly InstructionsRamon CoelhoNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Big Block Main Bearing Stud Girdle Kit HUG7380K For "B" & "RB" BlocksDocument6 pagesBig Block Main Bearing Stud Girdle Kit HUG7380K For "B" & "RB" BlocksGabriel ChiavettoNo ratings yet

- 48 Inch Az El Instructions 01242020 New RibsDocument20 pages48 Inch Az El Instructions 01242020 New RibsCarlosAgustoPinedaSanchezNo ratings yet

- Shorelandr ManualDocument8 pagesShorelandr ManualWaaboooo wañangoNo ratings yet

- PergolaInstallGuide v2Document8 pagesPergolaInstallGuide v2آلاء محمد عبدالعزيزNo ratings yet

- AARBK48 User-ManualDocument8 pagesAARBK48 User-ManualChris HeNo ratings yet

- Plans Dovetail Jig StandDocument6 pagesPlans Dovetail Jig Standhmam_88100% (1)

- Build Instructions: See What You Can Grow .....Document16 pagesBuild Instructions: See What You Can Grow .....RuiNo ratings yet

- Assemly Instructions FDocument18 pagesAssemly Instructions FDimitris AtsalasNo ratings yet

- Smartop Upright Deckmount Installation Instructions 7-30-19Document4 pagesSmartop Upright Deckmount Installation Instructions 7-30-19kimba worthNo ratings yet

- Installation Instructions Overhead Volleyball System by DraperDocument2 pagesInstallation Instructions Overhead Volleyball System by DraperAmr GadNo ratings yet

- Criss-Cross: Installation and Assembly Guide July 2006Document8 pagesCriss-Cross: Installation and Assembly Guide July 2006Eddie TarpleyNo ratings yet

- Install Manual SL-LB 2020Document12 pagesInstall Manual SL-LB 2020Ronald SiraitNo ratings yet

- Medieval Folding Stool - Popular WoodworkingDocument32 pagesMedieval Folding Stool - Popular WoodworkingplaytesteurNo ratings yet

- Kid-Powered "Squaris" WheelDocument6 pagesKid-Powered "Squaris" WheelzebrazeroNo ratings yet

- Tail Section IvDocument7 pagesTail Section Ivmohamed sidkyNo ratings yet

- Dovetail Key JoineryDocument3 pagesDovetail Key Joineryricheklund100% (4)

- Table Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!Document8 pagesTable Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!LinNo ratings yet

- Trebuchet in T RuctionsDocument6 pagesTrebuchet in T RuctionsJonatan PerezNo ratings yet

- Westbury C10, C20 InstalltionDocument2 pagesWestbury C10, C20 InstalltionKristen AlfredNo ratings yet

- Plan Bed Heirloom Arts and CraftsDocument13 pagesPlan Bed Heirloom Arts and Craftspoimandres0% (1)

- PakCanoe Assembly 2016Document6 pagesPakCanoe Assembly 2016macbeni1969No ratings yet

- Before You Get Started: Safety Notice!Document5 pagesBefore You Get Started: Safety Notice!pc Express30No ratings yet

- Rolling InstallnstructionsDocument8 pagesRolling InstallnstructionsANDINo ratings yet

- Directions For The T-REX PRO SLOTTER - Final 2019Document1 pageDirections For The T-REX PRO SLOTTER - Final 2019Danny DanNo ratings yet

- Antena Bibanda, OSJ146440Document3 pagesAntena Bibanda, OSJ146440CarlosAgustoPinedaSanchezNo ratings yet

- BridgeportDocument16 pagesBridgeportChristophe CaronNo ratings yet

- MiG 29ADocument1 pageMiG 29AChristophe CaronNo ratings yet

- Wooden-Ships-Iron-Men Manual DOS ENDocument53 pagesWooden-Ships-Iron-Men Manual DOS ENChristophe CaronNo ratings yet

- F 14A TomcatDocument1 pageF 14A TomcatChristophe CaronNo ratings yet

- Us Navy Target Kites ManualDocument52 pagesUs Navy Target Kites ManualChristophe CaronNo ratings yet

- United States Army Field Manuals FM 55-17 Army CargoDocument440 pagesUnited States Army Field Manuals FM 55-17 Army CargoChristophe CaronNo ratings yet

- Bata Shoe Company (Bangladesh) Ltd.Document6 pagesBata Shoe Company (Bangladesh) Ltd.Vurdalack666No ratings yet

- Inverse of A FunctionDocument10 pagesInverse of A Functionnitin30100% (2)

- Manual Epson L555Document92 pagesManual Epson L555Asesorias Académicas En CaliNo ratings yet

- TPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™Document57 pagesTPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™sbrhomeNo ratings yet

- James Coleman (October Files) by George BakerDocument226 pagesJames Coleman (October Files) by George Bakersaknjdasdjlk100% (1)

- Intensifying AdjectivesDocument2 pagesIntensifying AdjectivesReena JimmyNo ratings yet

- Premium HC: 120 Halfcell Monocrystalline High Performance Solar ModuleDocument2 pagesPremium HC: 120 Halfcell Monocrystalline High Performance Solar ModuleMujahed Al-HamatiNo ratings yet

- Surveillance, Torture and Contr - Rosanne Marie SchneiderDocument135 pagesSurveillance, Torture and Contr - Rosanne Marie SchneiderMagic MikeNo ratings yet

- Case Study of WapdaDocument34 pagesCase Study of WapdaImran Chaudhry100% (1)

- Nepra ManualDocument60 pagesNepra Manualabdulwasay_bzuNo ratings yet

- TSB-1139 8SC Wiring DiagramDocument2 pagesTSB-1139 8SC Wiring Diagramxavier marsNo ratings yet

- HDR10+ System Whitepaper: September 4, 2019 HDR10+ Technologies, LLCDocument14 pagesHDR10+ System Whitepaper: September 4, 2019 HDR10+ Technologies, LLCDragomir ConstantinNo ratings yet

- English3 Q2 Mod2 TensesOfTheVerb V3Document33 pagesEnglish3 Q2 Mod2 TensesOfTheVerb V3Johanna Zandra MariaNo ratings yet

- TDS 0033 FlexoTop 202003Document3 pagesTDS 0033 FlexoTop 202003Mearg NgusseNo ratings yet

- (2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Document367 pages(2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Erol BicerNo ratings yet

- Combustion Engineering, Heat Transfer, Refrigeration Engineering, & Air ConditioningDocument17 pagesCombustion Engineering, Heat Transfer, Refrigeration Engineering, & Air ConditioningNicole Mae AllosadaNo ratings yet

- Earth Quake DesignDocument13 pagesEarth Quake DesignRanie boy CabanillaNo ratings yet

- ASTM GradesDocument4 pagesASTM GradesSaurabh MundheNo ratings yet

- هاشم عدي حاتم سيارات ثاني التجربة الثانيهDocument6 pagesهاشم عدي حاتم سيارات ثاني التجربة الثانيههاشم عديNo ratings yet

- Rotorcraft Aerodynamics: Muhammad Abdullah Tahir 180101034 Aero 17 (A)Document15 pagesRotorcraft Aerodynamics: Muhammad Abdullah Tahir 180101034 Aero 17 (A)Abdullah CheemaNo ratings yet

- Plant Hormones PDFDocument5 pagesPlant Hormones PDFYASHNo ratings yet

- Schiavi Enc Met Page015Document1 pageSchiavi Enc Met Page015Adel AdelNo ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- EuropeDocument5 pagesEuropeAmicus CuriaeNo ratings yet

- BEL PE Question Papers For ECE With Answers - 6 Knowledge AddaDocument14 pagesBEL PE Question Papers For ECE With Answers - 6 Knowledge AddaVishwanand ThombareNo ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- Perdev Module 3Document13 pagesPerdev Module 3Renelyn JacoNo ratings yet