Professional Documents

Culture Documents

PRDR Cartridges Pressure Control Reducing

PRDR Cartridges Pressure Control Reducing

Uploaded by

Rudi PurnamaCopyright:

Available Formats

You might also like

- Dunham-Bush ACHDX-55 - 245TR-50Hz-ScrewDocument16 pagesDunham-Bush ACHDX-55 - 245TR-50Hz-ScrewEdgar José Silva Rincón0% (1)

- Eric Alexander - Improvising With The Whole Step Triad Combination Scale (2012)Document79 pagesEric Alexander - Improvising With The Whole Step Triad Combination Scale (2012)nikonel100% (25)

- Dhamrai Craft Village, Thesis ArchitectureDocument142 pagesDhamrai Craft Village, Thesis ArchitectureMahbuba Moumi100% (7)

- Relief Valve 5k 6-015-1Document2 pagesRelief Valve 5k 6-015-1francis_15inNo ratings yet

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNo ratings yet

- Axial Piston Variable Pump A2VKDocument12 pagesAxial Piston Variable Pump A2VKAkbarmoradiNo ratings yet

- Danfoss Pressure Switch Type KPDocument9 pagesDanfoss Pressure Switch Type KPMohammed RayanNo ratings yet

- A World of Regulators Valves en 123208Document16 pagesA World of Regulators Valves en 123208rpguidoNo ratings yet

- Regulators - Valves and SystemsDocument16 pagesRegulators - Valves and SystemssalemNo ratings yet

- Model Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPMDocument7 pagesModel Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPManandsubbiahNo ratings yet

- Reducing and Reducing/Relieving Valves: ApplicationsDocument5 pagesReducing and Reducing/Relieving Valves: ApplicationsColinNo ratings yet

- Regulators For Gas With Filter and Safety DiaphragmDocument11 pagesRegulators For Gas With Filter and Safety DiaphragmNhật Quang PhạmNo ratings yet

- 0tf401xyz Re18329-85 PDFDocument4 pages0tf401xyz Re18329-85 PDFInfo MelikNo ratings yet

- Fisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEDocument14 pagesFisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEfiguev2208No ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Model Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckDocument2 pagesModel Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckRajan BediNo ratings yet

- RV56-26 Relief, Pilot-Operated, High PressureDocument2 pagesRV56-26 Relief, Pilot-Operated, High PressurecaiNo ratings yet

- DataSheet NPK018 E305 201708 WebDocument4 pagesDataSheet NPK018 E305 201708 Webzain_zedanNo ratings yet

- API Sellos Mecanicos.Document56 pagesAPI Sellos Mecanicos.Daniel Erasmo Avellaneda SanchezNo ratings yet

- Data Sheet: Duraquench™ C El Deluge Control ValveDocument2 pagesData Sheet: Duraquench™ C El Deluge Control ValveCarlos RodriguezNo ratings yet

- 760 Series ValvesDocument8 pages760 Series ValvesbhekistoNo ratings yet

- G77x - 77xK Valve - CatalogueDocument8 pagesG77x - 77xK Valve - CatalogueEzgi PelitNo ratings yet

- Pipeline Reinjection PumpsDocument2 pagesPipeline Reinjection PumpsManuel GimenezNo ratings yet

- Reducing and Reducing/Relieving Valves: ApplicationsDocument5 pagesReducing and Reducing/Relieving Valves: ApplicationsxxshNo ratings yet

- Catalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Document2 pagesCatalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Joshua Garcia CarrilloNo ratings yet

- Atos Servo Valve TFS330Document10 pagesAtos Servo Valve TFS330back1949No ratings yet

- Electro-Prop ValveDocument2 pagesElectro-Prop Valvemaikel.mNo ratings yet

- 422solenoid DSDocument4 pages422solenoid DSargaNo ratings yet

- Releif Valve 3k 6-010-1Document2 pagesReleif Valve 3k 6-010-1francis_15inNo ratings yet

- Model 252 Servovalves: Typical Applications OperationDocument2 pagesModel 252 Servovalves: Typical Applications OperationAdityo PutrantoNo ratings yet

- PS25 para Altas Variaciones de PresionDocument8 pagesPS25 para Altas Variaciones de PresionHIDRUCOL SASNo ratings yet

- Dosatron 2.5 m3/hDocument2 pagesDosatron 2.5 m3/hFernandoNo ratings yet

- RDDA - Direct-Acting Relief ValveDocument3 pagesRDDA - Direct-Acting Relief ValveD ŠpokauskasNo ratings yet

- High Pressure Full Flow Bi-Directional FilterDocument7 pagesHigh Pressure Full Flow Bi-Directional FilterOscar NavarroNo ratings yet

- Gar 11-37Document2 pagesGar 11-37moisesNo ratings yet

- Regulator Iom EnglishDocument32 pagesRegulator Iom EnglishShaoranNo ratings yet

- SpDesGuide5 02 IXDocument84 pagesSpDesGuide5 02 IXjesus_manrique2753No ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- SCX180 Catalog REV 01-08Document32 pagesSCX180 Catalog REV 01-08Horea CordunianuNo ratings yet

- Series DDocument3 pagesSeries DHugo Martinez LopezNo ratings yet

- PRE G : Subplate Mounting ISO 6264 P Max Bar Max (See Table of Performances)Document16 pagesPRE G : Subplate Mounting ISO 6264 P Max Bar Max (See Table of Performances)Juan AlfredoNo ratings yet

- PFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateDocument8 pagesPFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateOscar NavarroNo ratings yet

- Counterbalance, Standard Guided Poppet Type, Counterclockwise Adjustment SUN Cavity Interchange, T-11ADocument2 pagesCounterbalance, Standard Guided Poppet Type, Counterclockwise Adjustment SUN Cavity Interchange, T-11AFledson Pereira das ChagasNo ratings yet

- VCTDS 01042 enDocument16 pagesVCTDS 01042 enBest Best AmornrattanapongNo ratings yet

- Low Pressure Test Pump Additel 912: Generate 95% Vacuum To 60 Psi (4 Bar) PressureDocument1 pageLow Pressure Test Pump Additel 912: Generate 95% Vacuum To 60 Psi (4 Bar) PressureSiéJustinDembeleNo ratings yet

- Delta Power-P PM HPRDocument11 pagesDelta Power-P PM HPRFlavio ivan HernándezNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- 00 - Valvula Prop - DREB6XDocument12 pages00 - Valvula Prop - DREB6XRonald MonteiroNo ratings yet

- Main Pump PDFDocument36 pagesMain Pump PDFElia MekdadNo ratings yet

- 1229846-EN - Aquamatic - K52-Valve - SpecSheet - Rev D MA2016Document4 pages1229846-EN - Aquamatic - K52-Valve - SpecSheet - Rev D MA2016Singgih KurniawanNo ratings yet

- Data Sheet Avdo Automatic By-Pass Valve: ApplicationDocument4 pagesData Sheet Avdo Automatic By-Pass Valve: ApplicationganaaNo ratings yet

- CDLF 4-14 3PH 50HZ SS-316 3-0KWDocument2 pagesCDLF 4-14 3PH 50HZ SS-316 3-0KWKunal GadeNo ratings yet

- AD.5.I... Cetop 5: Automatic Reciprocating ValvesDocument1 pageAD.5.I... Cetop 5: Automatic Reciprocating ValvesLuka JelovčanNo ratings yet

- Ultrafiltration Process SkidDocument3 pagesUltrafiltration Process SkidDenis AkingbasoNo ratings yet

- Solenoid Valve - Pneumatic: Direct Acting, Pressure RelievedDocument4 pagesSolenoid Valve - Pneumatic: Direct Acting, Pressure RelievedFrancisco Mones RuizNo ratings yet

- New BN TB Cu Aircooled Had .5 6 PDFDocument40 pagesNew BN TB Cu Aircooled Had .5 6 PDFANDERSON G HERRERA DNo ratings yet

- P32 Data SheetDocument8 pagesP32 Data Sheetcalidad.monitoxNo ratings yet

- Oil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetDocument4 pagesOil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetJhonNo ratings yet

- Adp 6536 WHDocument16 pagesAdp 6536 WHJarco PetrinNo ratings yet

- 2061-MIX-001 Rev1Document2 pages2061-MIX-001 Rev1Emmanuel Ber SNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- TeSys Deca Contactors - LADT4Document3 pagesTeSys Deca Contactors - LADT4Rudi PurnamaNo ratings yet

- Searchq Paper+Flower+Decoration&Tbm Isch&Ved 2ahUKEwiJ4sn 6ej4AhUwjNgFHbcHBEoQ2 CCegQIABAC&Oq Paper+FlowDocument1 pageSearchq Paper+Flower+Decoration&Tbm Isch&Ved 2ahUKEwiJ4sn 6ej4AhUwjNgFHbcHBEoQ2 CCegQIABAC&Oq Paper+FlowRudi PurnamaNo ratings yet

- Searchq Buzz+Cut+Hairstyle&Rlz 1CDGOYI EnID937ID938&Hl en-US&Prmd Isnv&Sxsrf ALiCzsYYoz Fb1PpvVBlDKzNnTEDocument1 pageSearchq Buzz+Cut+Hairstyle&Rlz 1CDGOYI EnID937ID938&Hl en-US&Prmd Isnv&Sxsrf ALiCzsYYoz Fb1PpvVBlDKzNnTERudi PurnamaNo ratings yet

- Guidebook Pathseeker Business Case Competition 3Document16 pagesGuidebook Pathseeker Business Case Competition 3Rudi PurnamaNo ratings yet

- Marechal DXA1 Zone 1 & Zone 2 Hazardous Area ATEXDocument1 pageMarechal DXA1 Zone 1 & Zone 2 Hazardous Area ATEXRudi PurnamaNo ratings yet

- Demand Letter (Sooho Kim)Document2 pagesDemand Letter (Sooho Kim)kisspecialNo ratings yet

- Cambridge IGCSE: MATHEMATICS 0580/23Document12 pagesCambridge IGCSE: MATHEMATICS 0580/23Anonymous Cr3kV7WNo ratings yet

- S.No Acc No Title of The BookDocument12 pagesS.No Acc No Title of The BookmechhodNo ratings yet

- Goppinti Alludu FilmDocument3 pagesGoppinti Alludu FilmMadhuswamygaddamNo ratings yet

- Book Covers Lesson PlanDocument3 pagesBook Covers Lesson Planapi-545455548No ratings yet

- Test SetupDocument11 pagesTest SetupKarthik PariharNo ratings yet

- Foundations of MathematicsDocument352 pagesFoundations of MathematicsPatrick MorgadoNo ratings yet

- Administration and ManagementDocument28 pagesAdministration and ManagementMonikaNo ratings yet

- Detecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Document5 pagesDetecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Hernan MartNo ratings yet

- Safety Perforation Gun IncidentDocument5 pagesSafety Perforation Gun IncidentB Deyse FernandesNo ratings yet

- Google Classroom Quick Guide For StudentsDocument3 pagesGoogle Classroom Quick Guide For StudentsIlly Zue Zaine GangosoNo ratings yet

- Luxeon 7070Document22 pagesLuxeon 7070guciNo ratings yet

- IB Chem, Topic 10, Organic Quiz 1 ReviewDocument4 pagesIB Chem, Topic 10, Organic Quiz 1 ReviewJulie VuNo ratings yet

- Steel WiseDocument1 pageSteel WisenvnagarajuNo ratings yet

- PercentagesDocument10 pagesPercentagesLisa DiasNo ratings yet

- C IntroDocument17 pagesC IntroamitavjhaNo ratings yet

- Proloquo2go Case Study FinalDocument8 pagesProloquo2go Case Study Finalapi-286531550No ratings yet

- Possessive Case / Possessive Pronouns / Question Word: Whose / Clothes, Footwear and AccessoriesDocument2 pagesPossessive Case / Possessive Pronouns / Question Word: Whose / Clothes, Footwear and AccessoriesManuela MarquesNo ratings yet

- Basic C ProgramDocument1 pageBasic C ProgramPallab DattaNo ratings yet

- 14m3 Prefix E9s00342 - NewDocument1,039 pages14m3 Prefix E9s00342 - Newiwan nawiNo ratings yet

- Final Report - CaterpillarDocument17 pagesFinal Report - CaterpillarJainendra SinhaNo ratings yet

- IRS Questions QbankDocument2 pagesIRS Questions Qbanktest1qaz100% (1)

- Power Engineering PM Check ListDocument11 pagesPower Engineering PM Check ListSelvn SubramanianNo ratings yet

- Free IDS V86 Software Download Link For FORD - MAZDA IDS V86Document2 pagesFree IDS V86 Software Download Link For FORD - MAZDA IDS V86Yousef ShishaniNo ratings yet

- 9 9 21 367 PDFDocument7 pages9 9 21 367 PDFaihuutran51No ratings yet

- Marketing Project Report On INDIAN ORGANIZED RETAIL INDUSTRY BIG BAZARDocument78 pagesMarketing Project Report On INDIAN ORGANIZED RETAIL INDUSTRY BIG BAZARSami Zama0% (1)

- CH1104 Chapter 11Document59 pagesCH1104 Chapter 11Chuah Chong YangNo ratings yet

- Circular Flow LessonDocument13 pagesCircular Flow LessonKimball SarmientoNo ratings yet

PRDR Cartridges Pressure Control Reducing

PRDR Cartridges Pressure Control Reducing

Uploaded by

Rudi PurnamaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRDR Cartridges Pressure Control Reducing

PRDR Cartridges Pressure Control Reducing

Uploaded by

Rudi PurnamaCopyright:

Available Formats

ABOUT TECH RESOURCES WHERE TO BUY CONTACT ENGLISH ∨

Model Code or Keyword Entire Site Search

CARTRIDGES MANIFOLDS ELECTRONICS SOLUTIONS ACCESSORIES

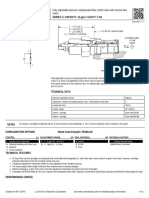

Cartridges » Pressure Control » Reducing » 10 gpm PRDR » Direct-acting, pressure reducing valve U.S. Units Metric Units

CUT SHEET FULL DATA SHEET EMAIL

MODEL reset to default Direct-acting, pressure reducing valve

PRDRLAN

Capacity: 10 gpm | Cavity: T-11A

view all

CONFIGURATION RULES

CONTROL L

Standard Screw Adjustment

ADJUSTMENT RANGE A

500 - 3000 psi (35 - 210 bar),

SEAL MATERIAL N

Buna-N

MATERIAL/COATING (None)

Standard Material/Coating

WHERE TO BUY

Technical Features Technical Data Performance Curves

?

CAD Files FAQs Notes Additional Resources

BUILD AN ASSEMBLY

Expand All

Technical Features [ -]

FIND COMPATIBLE MANIFOLDS

Direct-acting, pressure reducing valves reduce a high primary pressure at

the inlet (port 2) to a constant reduced pressure at port 1. These valves

incorporate a damped construction for stable operation allowing the use of

high reduced pressure.

Note: This valve has no relieving capability. It

should not be used in a dead-headed application.

If the reduced pressure side of the circuit has very

low leakage the pressure may rise significantly.

The pressure rise will vary from valve to valve.

This type of valve, PR*R, is a good replacement

for an LP*C as a normally open, restrictive

compensating element if a higher pressure drop

across an orifice is needed.

Cartridges configured with EPDM seals are for use

in systems with phosphate ester fluids. Exposure

to petroleum based fluids, greases and lubricants

will damage the seals.

Full reverse flow from reduced pressure (port 1) to

inlet (port 2) may cause the main spool to close. If

reverse free flow is required in the circuit, consider

adding a separate check valve to the circuit.

All spring ranges are tested for correct operation

with 5000 psi (350 bar) inlet pressure.

Suitable for accumulator circuits since the absence

of pilot control flow results in reduced secondary

circuit leakage.

Direct operated version offers superior dynamic

response compared to equivalent pilot operated

models.

Pressure at port 3 is directly additive to the valve

setting at a 1:1 ratio and should not exceed 5000

psi (350 bar).

Leakage specified in Technical Data is out of port 3

with a supply pressure of 2000 psi (140 bar) and

the valve set at mid range. This leakage is directly

proportional to pressure differential and inversely

proportional to viscosity expressed in centistokes.

Incorporates the Sun floating style construction to

minimize the possibility of internal parts binding

due to excessive installation torque and/or

cavity/cartridge machining variations.

Back to Top

Technical Data [ -]

Note: Data may vary by configuration. See CONFIGURATION section.

Cavity T-11A

Series 1

Capacity 10 gpm

Factory Pressure Settings Established at 0.25 gpm

Maximum Operating Pressure 5000 psi

Maximum Valve Leakage at 110 SUS (24 cSt) 2 in³/min.

Adjustment - No. of CW Turns from Min. to Max. 5

setting

Valve Hex Size 7/8 in.

Valve Installation Torque 30 - 35 lbf ft

Adjustment Screw Internal Hex Size 5/32 in.

Locknut Hex Size 9/16 in.

Locknut Torque 80 - 90 lbf in.

Model Weight 0.43 lb.

Seal kit - Cartridge Buna: 990011007

Seal kit - Cartridge EPDM: 990011014

Seal kit - Cartridge Polyurethane: 990011002

Seal kit - Cartridge Viton: 990011006

Back to Top

Performance Curves [+]

CAD Files [+]

FAQs [+]

Notes [+]

Additional Resources [+]

Enter your email for our e-newsletter Join

CAREERS SITEMAP CERTIFICATIONS TERMS & CONDITIONS PRIVACY PARTNER LOGIN

SARASOTA, FL USA COVENTRY, UK ERKELENZ, GERMANY INCHEON, KOREA SHANGHAI, CHINA BANGALORE, INDIA NEWCASTLE, AUSTRALIA

Copyright © 2002-2022 Sun Hydraulics LLC, a Company

You might also like

- Dunham-Bush ACHDX-55 - 245TR-50Hz-ScrewDocument16 pagesDunham-Bush ACHDX-55 - 245TR-50Hz-ScrewEdgar José Silva Rincón0% (1)

- Eric Alexander - Improvising With The Whole Step Triad Combination Scale (2012)Document79 pagesEric Alexander - Improvising With The Whole Step Triad Combination Scale (2012)nikonel100% (25)

- Dhamrai Craft Village, Thesis ArchitectureDocument142 pagesDhamrai Craft Village, Thesis ArchitectureMahbuba Moumi100% (7)

- Relief Valve 5k 6-015-1Document2 pagesRelief Valve 5k 6-015-1francis_15inNo ratings yet

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNo ratings yet

- Axial Piston Variable Pump A2VKDocument12 pagesAxial Piston Variable Pump A2VKAkbarmoradiNo ratings yet

- Danfoss Pressure Switch Type KPDocument9 pagesDanfoss Pressure Switch Type KPMohammed RayanNo ratings yet

- A World of Regulators Valves en 123208Document16 pagesA World of Regulators Valves en 123208rpguidoNo ratings yet

- Regulators - Valves and SystemsDocument16 pagesRegulators - Valves and SystemssalemNo ratings yet

- Model Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPMDocument7 pagesModel Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPManandsubbiahNo ratings yet

- Reducing and Reducing/Relieving Valves: ApplicationsDocument5 pagesReducing and Reducing/Relieving Valves: ApplicationsColinNo ratings yet

- Regulators For Gas With Filter and Safety DiaphragmDocument11 pagesRegulators For Gas With Filter and Safety DiaphragmNhật Quang PhạmNo ratings yet

- 0tf401xyz Re18329-85 PDFDocument4 pages0tf401xyz Re18329-85 PDFInfo MelikNo ratings yet

- Fisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEDocument14 pagesFisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEfiguev2208No ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Model Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckDocument2 pagesModel Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckRajan BediNo ratings yet

- RV56-26 Relief, Pilot-Operated, High PressureDocument2 pagesRV56-26 Relief, Pilot-Operated, High PressurecaiNo ratings yet

- DataSheet NPK018 E305 201708 WebDocument4 pagesDataSheet NPK018 E305 201708 Webzain_zedanNo ratings yet

- API Sellos Mecanicos.Document56 pagesAPI Sellos Mecanicos.Daniel Erasmo Avellaneda SanchezNo ratings yet

- Data Sheet: Duraquench™ C El Deluge Control ValveDocument2 pagesData Sheet: Duraquench™ C El Deluge Control ValveCarlos RodriguezNo ratings yet

- 760 Series ValvesDocument8 pages760 Series ValvesbhekistoNo ratings yet

- G77x - 77xK Valve - CatalogueDocument8 pagesG77x - 77xK Valve - CatalogueEzgi PelitNo ratings yet

- Pipeline Reinjection PumpsDocument2 pagesPipeline Reinjection PumpsManuel GimenezNo ratings yet

- Reducing and Reducing/Relieving Valves: ApplicationsDocument5 pagesReducing and Reducing/Relieving Valves: ApplicationsxxshNo ratings yet

- Catalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Document2 pagesCatalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Joshua Garcia CarrilloNo ratings yet

- Atos Servo Valve TFS330Document10 pagesAtos Servo Valve TFS330back1949No ratings yet

- Electro-Prop ValveDocument2 pagesElectro-Prop Valvemaikel.mNo ratings yet

- 422solenoid DSDocument4 pages422solenoid DSargaNo ratings yet

- Releif Valve 3k 6-010-1Document2 pagesReleif Valve 3k 6-010-1francis_15inNo ratings yet

- Model 252 Servovalves: Typical Applications OperationDocument2 pagesModel 252 Servovalves: Typical Applications OperationAdityo PutrantoNo ratings yet

- PS25 para Altas Variaciones de PresionDocument8 pagesPS25 para Altas Variaciones de PresionHIDRUCOL SASNo ratings yet

- Dosatron 2.5 m3/hDocument2 pagesDosatron 2.5 m3/hFernandoNo ratings yet

- RDDA - Direct-Acting Relief ValveDocument3 pagesRDDA - Direct-Acting Relief ValveD ŠpokauskasNo ratings yet

- High Pressure Full Flow Bi-Directional FilterDocument7 pagesHigh Pressure Full Flow Bi-Directional FilterOscar NavarroNo ratings yet

- Gar 11-37Document2 pagesGar 11-37moisesNo ratings yet

- Regulator Iom EnglishDocument32 pagesRegulator Iom EnglishShaoranNo ratings yet

- SpDesGuide5 02 IXDocument84 pagesSpDesGuide5 02 IXjesus_manrique2753No ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- SCX180 Catalog REV 01-08Document32 pagesSCX180 Catalog REV 01-08Horea CordunianuNo ratings yet

- Series DDocument3 pagesSeries DHugo Martinez LopezNo ratings yet

- PRE G : Subplate Mounting ISO 6264 P Max Bar Max (See Table of Performances)Document16 pagesPRE G : Subplate Mounting ISO 6264 P Max Bar Max (See Table of Performances)Juan AlfredoNo ratings yet

- PFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateDocument8 pagesPFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateOscar NavarroNo ratings yet

- Counterbalance, Standard Guided Poppet Type, Counterclockwise Adjustment SUN Cavity Interchange, T-11ADocument2 pagesCounterbalance, Standard Guided Poppet Type, Counterclockwise Adjustment SUN Cavity Interchange, T-11AFledson Pereira das ChagasNo ratings yet

- VCTDS 01042 enDocument16 pagesVCTDS 01042 enBest Best AmornrattanapongNo ratings yet

- Low Pressure Test Pump Additel 912: Generate 95% Vacuum To 60 Psi (4 Bar) PressureDocument1 pageLow Pressure Test Pump Additel 912: Generate 95% Vacuum To 60 Psi (4 Bar) PressureSiéJustinDembeleNo ratings yet

- Delta Power-P PM HPRDocument11 pagesDelta Power-P PM HPRFlavio ivan HernándezNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- 00 - Valvula Prop - DREB6XDocument12 pages00 - Valvula Prop - DREB6XRonald MonteiroNo ratings yet

- Main Pump PDFDocument36 pagesMain Pump PDFElia MekdadNo ratings yet

- 1229846-EN - Aquamatic - K52-Valve - SpecSheet - Rev D MA2016Document4 pages1229846-EN - Aquamatic - K52-Valve - SpecSheet - Rev D MA2016Singgih KurniawanNo ratings yet

- Data Sheet Avdo Automatic By-Pass Valve: ApplicationDocument4 pagesData Sheet Avdo Automatic By-Pass Valve: ApplicationganaaNo ratings yet

- CDLF 4-14 3PH 50HZ SS-316 3-0KWDocument2 pagesCDLF 4-14 3PH 50HZ SS-316 3-0KWKunal GadeNo ratings yet

- AD.5.I... Cetop 5: Automatic Reciprocating ValvesDocument1 pageAD.5.I... Cetop 5: Automatic Reciprocating ValvesLuka JelovčanNo ratings yet

- Ultrafiltration Process SkidDocument3 pagesUltrafiltration Process SkidDenis AkingbasoNo ratings yet

- Solenoid Valve - Pneumatic: Direct Acting, Pressure RelievedDocument4 pagesSolenoid Valve - Pneumatic: Direct Acting, Pressure RelievedFrancisco Mones RuizNo ratings yet

- New BN TB Cu Aircooled Had .5 6 PDFDocument40 pagesNew BN TB Cu Aircooled Had .5 6 PDFANDERSON G HERRERA DNo ratings yet

- P32 Data SheetDocument8 pagesP32 Data Sheetcalidad.monitoxNo ratings yet

- Oil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetDocument4 pagesOil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetJhonNo ratings yet

- Adp 6536 WHDocument16 pagesAdp 6536 WHJarco PetrinNo ratings yet

- 2061-MIX-001 Rev1Document2 pages2061-MIX-001 Rev1Emmanuel Ber SNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- TeSys Deca Contactors - LADT4Document3 pagesTeSys Deca Contactors - LADT4Rudi PurnamaNo ratings yet

- Searchq Paper+Flower+Decoration&Tbm Isch&Ved 2ahUKEwiJ4sn 6ej4AhUwjNgFHbcHBEoQ2 CCegQIABAC&Oq Paper+FlowDocument1 pageSearchq Paper+Flower+Decoration&Tbm Isch&Ved 2ahUKEwiJ4sn 6ej4AhUwjNgFHbcHBEoQ2 CCegQIABAC&Oq Paper+FlowRudi PurnamaNo ratings yet

- Searchq Buzz+Cut+Hairstyle&Rlz 1CDGOYI EnID937ID938&Hl en-US&Prmd Isnv&Sxsrf ALiCzsYYoz Fb1PpvVBlDKzNnTEDocument1 pageSearchq Buzz+Cut+Hairstyle&Rlz 1CDGOYI EnID937ID938&Hl en-US&Prmd Isnv&Sxsrf ALiCzsYYoz Fb1PpvVBlDKzNnTERudi PurnamaNo ratings yet

- Guidebook Pathseeker Business Case Competition 3Document16 pagesGuidebook Pathseeker Business Case Competition 3Rudi PurnamaNo ratings yet

- Marechal DXA1 Zone 1 & Zone 2 Hazardous Area ATEXDocument1 pageMarechal DXA1 Zone 1 & Zone 2 Hazardous Area ATEXRudi PurnamaNo ratings yet

- Demand Letter (Sooho Kim)Document2 pagesDemand Letter (Sooho Kim)kisspecialNo ratings yet

- Cambridge IGCSE: MATHEMATICS 0580/23Document12 pagesCambridge IGCSE: MATHEMATICS 0580/23Anonymous Cr3kV7WNo ratings yet

- S.No Acc No Title of The BookDocument12 pagesS.No Acc No Title of The BookmechhodNo ratings yet

- Goppinti Alludu FilmDocument3 pagesGoppinti Alludu FilmMadhuswamygaddamNo ratings yet

- Book Covers Lesson PlanDocument3 pagesBook Covers Lesson Planapi-545455548No ratings yet

- Test SetupDocument11 pagesTest SetupKarthik PariharNo ratings yet

- Foundations of MathematicsDocument352 pagesFoundations of MathematicsPatrick MorgadoNo ratings yet

- Administration and ManagementDocument28 pagesAdministration and ManagementMonikaNo ratings yet

- Detecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Document5 pagesDetecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Hernan MartNo ratings yet

- Safety Perforation Gun IncidentDocument5 pagesSafety Perforation Gun IncidentB Deyse FernandesNo ratings yet

- Google Classroom Quick Guide For StudentsDocument3 pagesGoogle Classroom Quick Guide For StudentsIlly Zue Zaine GangosoNo ratings yet

- Luxeon 7070Document22 pagesLuxeon 7070guciNo ratings yet

- IB Chem, Topic 10, Organic Quiz 1 ReviewDocument4 pagesIB Chem, Topic 10, Organic Quiz 1 ReviewJulie VuNo ratings yet

- Steel WiseDocument1 pageSteel WisenvnagarajuNo ratings yet

- PercentagesDocument10 pagesPercentagesLisa DiasNo ratings yet

- C IntroDocument17 pagesC IntroamitavjhaNo ratings yet

- Proloquo2go Case Study FinalDocument8 pagesProloquo2go Case Study Finalapi-286531550No ratings yet

- Possessive Case / Possessive Pronouns / Question Word: Whose / Clothes, Footwear and AccessoriesDocument2 pagesPossessive Case / Possessive Pronouns / Question Word: Whose / Clothes, Footwear and AccessoriesManuela MarquesNo ratings yet

- Basic C ProgramDocument1 pageBasic C ProgramPallab DattaNo ratings yet

- 14m3 Prefix E9s00342 - NewDocument1,039 pages14m3 Prefix E9s00342 - Newiwan nawiNo ratings yet

- Final Report - CaterpillarDocument17 pagesFinal Report - CaterpillarJainendra SinhaNo ratings yet

- IRS Questions QbankDocument2 pagesIRS Questions Qbanktest1qaz100% (1)

- Power Engineering PM Check ListDocument11 pagesPower Engineering PM Check ListSelvn SubramanianNo ratings yet

- Free IDS V86 Software Download Link For FORD - MAZDA IDS V86Document2 pagesFree IDS V86 Software Download Link For FORD - MAZDA IDS V86Yousef ShishaniNo ratings yet

- 9 9 21 367 PDFDocument7 pages9 9 21 367 PDFaihuutran51No ratings yet

- Marketing Project Report On INDIAN ORGANIZED RETAIL INDUSTRY BIG BAZARDocument78 pagesMarketing Project Report On INDIAN ORGANIZED RETAIL INDUSTRY BIG BAZARSami Zama0% (1)

- CH1104 Chapter 11Document59 pagesCH1104 Chapter 11Chuah Chong YangNo ratings yet

- Circular Flow LessonDocument13 pagesCircular Flow LessonKimball SarmientoNo ratings yet