Professional Documents

Culture Documents

Approval Document ASSET DOC LOC 570

Approval Document ASSET DOC LOC 570

Uploaded by

Shibin PoulOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval Document ASSET DOC LOC 570

Approval Document ASSET DOC LOC 570

Uploaded by

Shibin PoulCopyright:

Available Formats

HWD 0268

S IFI

AS

CL

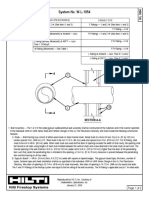

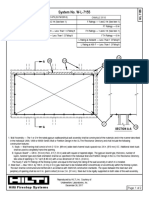

System No. HW-D-0268

ED

C US

Classified by

ANSI/UL2079 CAN/ULC S115

Underwriters Laboratories, Inc.

to UL 2079 and CAN/ULC-S115 Assembly Ratings — 1, 2 and 3 Hr (See Item 3) F Ratings — 1, 2 and 3 Hr (See Item 3)

Nominal Joint Width - 1 In. FT Ratings — 1, 2 and 3 Hr (See Item 3)

Class II or III Movement Capabilities — 12.5% FH Ratings — 1, 2 and 3 Hr (See Item 3)

Compression or Extension

L Rating At Ambient — Less Than 1 CFM/ft FTH Ratings — 1, 2 and 3 Hr (See Item 3)

L Rating At 400 F — Less Than 1 CFM/ft Nominal Joint Width - 25 mm

Class II or III Movement Capabilities — 12.5%

Compression or Extension

L Rating At Ambient — Less Than 1.5 L/s/m

L Rating At 204 C — Less Than 1.5 L/s/m

3A

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

October 09, 2020

Hilti Firestop Systems Page: 1 of 2

HWD 0268

System No. HW-D-0268

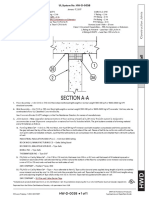

1. Floor Assembly — Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) structural concrete

except that . min thickness of floor is 4-1/2 in. (114 mm) when concrete wall (Item 2) thickness is 4-1/2 in. (114 mm). Floor may also be

constructed of any min 6 in. (152 mm) thick UL Classified hollow-core Precast Concrete Units*.

See Precast Concrete Units (CFTV) category in the Fire Resistance Directory for names of manufacturers.

2. Wall Assembly — Min 8 in. (203 mm) thick steel reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3/) structural concrete.

As an option, for assembly ratings of 1 and 2 hr, the wall may be min 4-1/2 in. (114 mm) thick steel reinforced lightweight or normal weight

(100-150 pcf or 1600-2400 kg/m3) structural concrete. Wall may also be constructed of any UL Classified Concrete Blocks*.

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

3. Joint System — Max separation between bottom of floor assembly and top of concrete wall at time of installation is 1 in. (25 mm). The joint

system is designed to accommodate a max 12.5 percent compression or extension from its installed width. The joint system shall consists of the

following:

A. Fill, Void or Cavity Material* - Sealant — A min 1/4 in. (6 mm) or min 1/2 in. (13 mm) thickness of fill material installed within the joint, flush

with each surface of the wall, as specified in Table below.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP606 Flexible Firestop Sealant

B. Forming Material — (Optional, Not Shown) - Mineral wool insulation or open or closed cell polyethylene or polyurethane foam backer rod.

Forming material to be recessed from both surfaces of the wall as required to accommodate the required thickness of fill material.

Min Sealant (Item

Hourly Rating of Min Floor Thickness Min Wall Thickness Max Nom Joint Forming Material

3A) Thickness In.

Joint In. (mm) In. (mm) Width In. (mm) (Item 3B)

(mm)

1 and 2 4.5 (114) 4.5 (114) 1 (25) 1/4 (6) Optional

3 2.5 (64) 8 (203) 1 (25) 1/2 (13) Optional

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

October 09, 2020

Hilti Firestop Systems Page: 2 of 2

You might also like

- Business Demographic QuestionnaireDocument5 pagesBusiness Demographic QuestionnaireHemanth RatalaNo ratings yet

- Unit 6 Learning Aim A Assessment MatDocument2 pagesUnit 6 Learning Aim A Assessment Mathello'i0% (1)

- 2008 - MIT - Handbook of Antitrust EconomicsDocument711 pages2008 - MIT - Handbook of Antitrust EconomicsbenNo ratings yet

- Dornier 328 Support ServicesDocument22 pagesDornier 328 Support Servicesangelo marraNo ratings yet

- On ProbabilityDocument13 pagesOn ProbabilitySridhar PantNo ratings yet

- System No. HW-D-0931: Hilti Firestop SystemsDocument2 pagesSystem No. HW-D-0931: Hilti Firestop SystemsjlledwinestebanNo ratings yet

- HWD 0930 Sello de Junta Muro - Techo Acceso 1 Solo Lado y Ambos LadosDocument2 pagesHWD 0930 Sello de Junta Muro - Techo Acceso 1 Solo Lado y Ambos Ladoscesar walter salazar garciaNo ratings yet

- W-L-1054 Pipe Through Gyp Board AssemblyDocument2 pagesW-L-1054 Pipe Through Gyp Board AssemblyJason StelleNo ratings yet

- Fire StopDocument48 pagesFire StopRoberto CuevasNo ratings yet

- Ul HWD 0209Document2 pagesUl HWD 0209jlledwinestebanNo ratings yet

- HW-D-0038 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-0038 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- System No. HW-D-0403Document1 pageSystem No. HW-D-0403Daniel Soaloon SibaraniNo ratings yet

- HW D 1104 SilGG JuntaDocument1 pageHW D 1104 SilGG JuntaLibardoNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- MIL DTL 85891B Blast MediaDocument16 pagesMIL DTL 85891B Blast MediaDaniel VillaflorNo ratings yet

- Mil PRF 22750GDocument22 pagesMil PRF 22750GbhorstmannbNo ratings yet

- Source: Http://assist - Dla.mil - Downloaded: 2020-12-23T21:32Z Check The Source To Verify That This Is The Current Version Before UseDocument12 pagesSource: Http://assist - Dla.mil - Downloaded: 2020-12-23T21:32Z Check The Source To Verify That This Is The Current Version Before UsejcNo ratings yet

- ARG1-4-GR-GER-ET-E003 - Technical Specification For Acquisition of Booster Shed - r04Document19 pagesARG1-4-GR-GER-ET-E003 - Technical Specification For Acquisition of Booster Shed - r04David GutierrezNo ratings yet

- MIL-PRF-22750G - Standart - Son KatDocument23 pagesMIL-PRF-22750G - Standart - Son KatCEMRE YAŞLINo ratings yet

- Mil PRF 22750GDocument23 pagesMil PRF 22750Gwei102567No ratings yet

- Mil DTL 53022FDocument22 pagesMil DTL 53022FVictor ParvanNo ratings yet

- Mil-Prf-85285 e (Irr) PDFDocument24 pagesMil-Prf-85285 e (Irr) PDFalfie_nNo ratings yet

- Mil DTL 19834c Amendment 1Document11 pagesMil DTL 19834c Amendment 1Logo SkyNo ratings yet

- Mil PRF 85285eDocument24 pagesMil PRF 85285eAnes HalilovićNo ratings yet

- Sans1783 3Document15 pagesSans1783 3David ShawNo ratings yet

- Firstop DesignDocument2 pagesFirstop DesignAmir IqbalNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- Chapter 10 - Air LouversDocument12 pagesChapter 10 - Air LouversmavenplanningengineerNo ratings yet

- WWD0096Document1 pageWWD0096jlledwinestebanNo ratings yet

- Mil PRF 85285FDocument26 pagesMil PRF 85285Fchampyjm6532No ratings yet

- HW-D-1010 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-1010 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- FS - Muro Cortina - ASSET-DOC-LOC-7765712Document3 pagesFS - Muro Cortina - ASSET-DOC-LOC-7765712S. Priscila Castillo V.No ratings yet

- D 3492 - 02 - Rdm0otitukveDocument16 pagesD 3492 - 02 - Rdm0otitukvePrakash MakadiaNo ratings yet

- Paint - PRF 85285 DDocument21 pagesPaint - PRF 85285 Dsachinjoshi_2006No ratings yet

- A-A-59312 DDocument25 pagesA-A-59312 DHayleyNo ratings yet

- Mil R 1832DDocument12 pagesMil R 1832DvipinNo ratings yet

- Flame StopDocument31 pagesFlame StopaNo ratings yet

- Approval Document ASSET DOC LOC 299Document3 pagesApproval Document ASSET DOC LOC 299Anonymous a3K3WgNo ratings yet

- Mil DTL 24050eDocument15 pagesMil DTL 24050eopie65701No ratings yet

- 7250 Dallas Parkway, Suite 1000 Plano, TX 75024 1-800-879-8000Document5 pages7250 Dallas Parkway, Suite 1000 Plano, TX 75024 1-800-879-8000Thai VoNo ratings yet

- Firestop Application Handbook (Macau) - Part-8 PDFDocument30 pagesFirestop Application Handbook (Macau) - Part-8 PDFSharoon S raoNo ratings yet

- Astm F1043-18 (2022)Document8 pagesAstm F1043-18 (2022)Imane ElkodsiNo ratings yet

- MIL-DTL-53039E - Standart - Son KatDocument26 pagesMIL-DTL-53039E - Standart - Son KatCEMRE YAŞLINo ratings yet

- Mil DTL 15024GDocument15 pagesMil DTL 15024GLogo SkyNo ratings yet

- Mil DTL 53022eDocument21 pagesMil DTL 53022etamil ksNo ratings yet

- TCDS EASA.A.096 Do328 Iss 09Document23 pagesTCDS EASA.A.096 Do328 Iss 09Teofana SuciuNo ratings yet

- XR 625 New ChartekDocument4 pagesXR 625 New ChartekOsama KheadryNo ratings yet

- Mil DTL 53039eDocument26 pagesMil DTL 53039eJustformedia JustformediaNo ratings yet

- Lite-Deck Book WebDocument23 pagesLite-Deck Book WebFlorencio SandovalNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Mil DTL 53039Document26 pagesMil DTL 53039CemalOlgunÇağlayanNo ratings yet

- Mil PRF 81309FDocument36 pagesMil PRF 81309FPDDELUCANo ratings yet

- Preformed Expansion Joint Filler For Concrete (Bituminous Type)Document4 pagesPreformed Expansion Joint Filler For Concrete (Bituminous Type)Shaker QaidiNo ratings yet

- Approval Document ASSET DOC LOC 145Document2 pagesApproval Document ASSET DOC LOC 145Amir IqbalNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- Mıl PRF 32550 Standart - AstarDocument18 pagesMıl PRF 32550 Standart - AstarCEMRE YAŞLINo ratings yet

- Mil PRF 61002BDocument27 pagesMil PRF 61002BAbdullah PalNo ratings yet

- Dell Inspiron 5755, P28E, P28E002, DeLL Regulatory and Environmental DatasheetDocument6 pagesDell Inspiron 5755, P28E, P28E002, DeLL Regulatory and Environmental DatasheetZozoaa ZozoNo ratings yet

- Approval Document ASSET DOC LOC 939Document2 pagesApproval Document ASSET DOC LOC 939andy_ramblaNo ratings yet

- FlatLOK TER 1501 08 0719Document10 pagesFlatLOK TER 1501 08 0719Ryan McKinneyNo ratings yet

- Concept PaperDocument3 pagesConcept PaperJizelle Elaine GumaNo ratings yet

- Ic60 RCBODocument1 pageIc60 RCBOEng.Panelindo masNo ratings yet

- Pyqt 5Document21 pagesPyqt 5MaikOlliverNo ratings yet

- C++ ProgrammingDocument4 pagesC++ ProgrammingMandy SainiNo ratings yet

- Correspondence Option: Society of Cosmetic Chemists South Africa Tel:011 792-4531 Email:bridget@coschem - Co.zaDocument1 pageCorrespondence Option: Society of Cosmetic Chemists South Africa Tel:011 792-4531 Email:bridget@coschem - Co.zanblaksNo ratings yet

- Concrete Placement Inspection ChecklistDocument21 pagesConcrete Placement Inspection ChecklistVasa50% (2)

- Adorama ProPhotoLab Umum Pricelist Feb2011 FinalDocument1 pageAdorama ProPhotoLab Umum Pricelist Feb2011 FinalDidi IDNo ratings yet

- Boiler Design: Heat Recovery Steam GeneratorDocument2 pagesBoiler Design: Heat Recovery Steam Generator郑裕 鸿No ratings yet

- Patriarcal MotherhoodDocument6 pagesPatriarcal Motherhoodj.jaffrin.jNo ratings yet

- American Wheatley Price List 2011Document48 pagesAmerican Wheatley Price List 2011francisb65No ratings yet

- FM DocumentationDocument23 pagesFM DocumentationJohnMatthewBancilNo ratings yet

- Tissues 1.Document2 pagesTissues 1.Adeaga ElizabethNo ratings yet

- GD & T-2Document29 pagesGD & T-221adNo ratings yet

- Maruti 110306013819 Phpapp02Document148 pagesMaruti 110306013819 Phpapp02NishantShah0% (1)

- Principles of Inheritance and Variation Class 12 Notes Biology - myCBSEguideDocument15 pagesPrinciples of Inheritance and Variation Class 12 Notes Biology - myCBSEguideShireen SuhailNo ratings yet

- 1st Shifting Theorem LAPLACE TRANSFORMSDocument42 pages1st Shifting Theorem LAPLACE TRANSFORMSPlaiboiNo ratings yet

- Ionic Bonding G10Document6 pagesIonic Bonding G10Mahmoud AladdasiNo ratings yet

- Carta Al Presidente Javier MileiDocument4 pagesCarta Al Presidente Javier MileiacarraraNo ratings yet

- English FPTDocument6 pagesEnglish FPTDevanarayanan M. JNo ratings yet

- AI in Healthcare - Theory To PracticeDocument6 pagesAI in Healthcare - Theory To PracticensahniNo ratings yet

- Minidis Sony MDS-S39 PDFDocument6 pagesMinidis Sony MDS-S39 PDFMaikel Borges IglesiasNo ratings yet

- Scientific Method BeriberiDocument4 pagesScientific Method BeriberiadelavazNo ratings yet

- Mitsubishi / 304: Oem Number Oem NumberDocument71 pagesMitsubishi / 304: Oem Number Oem NumberBobCavNo ratings yet

- Etiopian Herald April 21 - OptDocument13 pagesEtiopian Herald April 21 - OptgirmabelayNo ratings yet

- XCELL48 v2Document8 pagesXCELL48 v2paulmarlonromme8809No ratings yet

- Earthing and BondingDocument4 pagesEarthing and BondingAbdul QuddusNo ratings yet