Professional Documents

Culture Documents

Food Safety Manual - ECCL

Food Safety Manual - ECCL

Uploaded by

SLQC KumaraCopyright:

Available Formats

You might also like

- Ice-Cream-HACCP Guidelines PDFDocument158 pagesIce-Cream-HACCP Guidelines PDFcaya117283% (6)

- 02.SOP of Retention Sample (Raw Material)Document5 pages02.SOP of Retention Sample (Raw Material)Bejoy Karim100% (4)

- Management Review MeetingDocument5 pagesManagement Review Meetingswapon kumar shill67% (3)

- Pas 222Document28 pagesPas 222Aline GrilloNo ratings yet

- Industrial Hygiene Occupational Health StandardDocument36 pagesIndustrial Hygiene Occupational Health Standardlina ekawatiNo ratings yet

- Principles of HACCP Assessment Book TertiaryDocument25 pagesPrinciples of HACCP Assessment Book TertiaryRaha Rajabigamasaei100% (1)

- Haccp - Iso 22000 Food Safety DDocument8 pagesHaccp - Iso 22000 Food Safety DAmr Rifai0% (1)

- 01.collection, Storage and Control of Reserve Samples For Drug ProductsDocument4 pages01.collection, Storage and Control of Reserve Samples For Drug ProductsBejoy KarimNo ratings yet

- SOP QA 010 00 Handling of DeviationDocument17 pagesSOP QA 010 00 Handling of Deviationnetelsrt129875% (4)

- IFS Food V6 HRDocument152 pagesIFS Food V6 HRDarko100% (1)

- Quality Assurance & Quality Control DepartmentDocument29 pagesQuality Assurance & Quality Control Departmentnyumnyum200985% (13)

- ISO - TS 22002-1 (Formerly PAS 220) Certification & Training - LR USADocument4 pagesISO - TS 22002-1 (Formerly PAS 220) Certification & Training - LR USASchrubs0% (1)

- Quality Manual - PGDocument15 pagesQuality Manual - PGjamilvoraNo ratings yet

- Aa Checklist Processing EstablishmentsDocument34 pagesAa Checklist Processing EstablishmentsAkhila MpNo ratings yet

- 4 SOP-Standardization of LDMDocument1 page4 SOP-Standardization of LDMmalatheshgNo ratings yet

- OP-PD-001 Production ProcedureDocument8 pagesOP-PD-001 Production ProcedureShemu PlcNo ratings yet

- Guidance Document Milk 14 03 2019 PDFDocument97 pagesGuidance Document Milk 14 03 2019 PDFSameer DamleNo ratings yet

- Quality Mark Guideline 0Document50 pagesQuality Mark Guideline 0Asma DahaboNo ratings yet

- Chapter 1 (Scope)Document1 pageChapter 1 (Scope)husus “Dusun Tuo” networkNo ratings yet

- Lactonova FSMDocument29 pagesLactonova FSMvictoria3go100% (1)

- QM - ISO 9001 Corrections 1Document5 pagesQM - ISO 9001 Corrections 1Ravichandran BNo ratings yet

- Milk Production Procedure Manual-1Document11 pagesMilk Production Procedure Manual-1ScribdTranslationsNo ratings yet

- Haccp - Plan - Final Vitaset 11 2012Document10 pagesHaccp - Plan - Final Vitaset 11 2012handy de jesusNo ratings yet

- White Paper 10 Problems With Pharma Plant MaintenanceDocument9 pagesWhite Paper 10 Problems With Pharma Plant MaintenanceAlok Kumar SharmaNo ratings yet

- 28-Jul-05 1 of 4Document4 pages28-Jul-05 1 of 4gautamkurtNo ratings yet

- BLD Sustainability Statement 2020Document15 pagesBLD Sustainability Statement 2020Amirul AshrafNo ratings yet

- 15 156Document9 pages15 156AD D100% (1)

- Food & Beverage Overview - 1239972982Document22 pagesFood & Beverage Overview - 1239972982Mixo LogiNo ratings yet

- Ice CreemDocument28 pagesIce CreemVinay MorganNo ratings yet

- QT CL 01 05 en GMP InspectionDocument59 pagesQT CL 01 05 en GMP InspectionAsma DahaboNo ratings yet

- Assignment LAWDocument30 pagesAssignment LAWLahiru ChathurangaNo ratings yet

- HACCP Processed Meats Cop Part 4Document118 pagesHACCP Processed Meats Cop Part 4Arkham KhollyshulNo ratings yet

- Inplant Trainee PDFDocument2 pagesInplant Trainee PDFKalana JayatillakeNo ratings yet

- Ts 3 2 en 20220101Document78 pagesTs 3 2 en 20220101Bpfmix ConsultoriaNo ratings yet

- Quality & Food Safety Manual: Wilverley Trading Estate 813/815 Bath Road Brislington Bristol Bs4 5NlDocument23 pagesQuality & Food Safety Manual: Wilverley Trading Estate 813/815 Bath Road Brislington Bristol Bs4 5NlMohamed100% (1)

- Federal Democratic Republic of Ethiopia Occupational Standard Edible Oil Processing NTQF Level IiDocument121 pagesFederal Democratic Republic of Ethiopia Occupational Standard Edible Oil Processing NTQF Level IiAbera BekeleNo ratings yet

- On Overview Pleasant Food PVT Limited FOR: A Project Report On Study OFDocument11 pagesOn Overview Pleasant Food PVT Limited FOR: A Project Report On Study OFramu rajakannuNo ratings yet

- Mgt+Rev +report+2020Document10 pagesMgt+Rev +report+2020mrawaf balasmehNo ratings yet

- Adindu Nathan Rosemary Siwes Report FullDocument45 pagesAdindu Nathan Rosemary Siwes Report FullPiuskylala PiuskyNo ratings yet

- Quality Audit in Engro FoodsDocument39 pagesQuality Audit in Engro FoodsFerial Afzal0% (1)

- Iso Standards Bee ProductsDocument38 pagesIso Standards Bee Productsdebouck.ludovic01No ratings yet

- Halal Food RegulationDocument13 pagesHalal Food RegulationJameel SmithNo ratings yet

- English Biscuit ManufacturersDocument5 pagesEnglish Biscuit ManufacturersfizaAhaiderNo ratings yet

- Formato de Aplcacion BRCDocument9 pagesFormato de Aplcacion BRCmERCYNo ratings yet

- PT Wni Gresik Sccs Report FinalDocument16 pagesPT Wni Gresik Sccs Report FinalStefanus Satriyo NugrohoNo ratings yet

- EricDocument113 pagesEricThân Hoài NhânNo ratings yet

- Food Safety Pack For Home BakersDocument21 pagesFood Safety Pack For Home BakersCatalina BolcuNo ratings yet

- Process Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDDocument16 pagesProcess Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDsamia khanNo ratings yet

- Iso 22000 Manual +haccpDocument33 pagesIso 22000 Manual +haccpSandhya MishraNo ratings yet

- Food Safety Manual Valley Sport-FS (00000003)Document30 pagesFood Safety Manual Valley Sport-FS (00000003)Balaji Rajaraman100% (2)

- GMP SopDocument5 pagesGMP SopHaider Ali100% (1)

- EFS P 04 Management CommunicationDocument7 pagesEFS P 04 Management Communicationka1onlineNo ratings yet

- HACCP AssignmentDocument14 pagesHACCP AssignmentPushpamali HewawasamNo ratings yet

- EndosulfanDocument3 pagesEndosulfanMayra Sánchez CabanillasNo ratings yet

- JFS-B Standard (Requirements For Organizations) Ver. 2.0Document12 pagesJFS-B Standard (Requirements For Organizations) Ver. 2.0Pongpol MekanuratNo ratings yet

- An Organisational Study at Milma Diary Farm Part 3Document14 pagesAn Organisational Study at Milma Diary Farm Part 3Aromal SSNo ratings yet

- HACCP Study JoghurtDocument13 pagesHACCP Study JoghurtAliNo ratings yet

- Manual For Food Safety OfficersDocument352 pagesManual For Food Safety OfficersNeeta PatilNo ratings yet

- 1555409966balaji Investor PDFDocument23 pages1555409966balaji Investor PDFBusiness DevelopmentNo ratings yet

- DAE-ANX-04 CommunicationDocument1 pageDAE-ANX-04 CommunicationRatandeep PandeyNo ratings yet

- Section 3.4 - Implementation and Operation: Resources, Roles, Responsibility, Accountability and AuthorityDocument6 pagesSection 3.4 - Implementation and Operation: Resources, Roles, Responsibility, Accountability and AuthoritySLQC KumaraNo ratings yet

- Section 3.2 - Auditing Against BS OHSAS 18001:2007 Clause 4.2 PolicyDocument2 pagesSection 3.2 - Auditing Against BS OHSAS 18001:2007 Clause 4.2 PolicySLQC KumaraNo ratings yet

- Section 2.1 - What Is A Management System?Document4 pagesSection 2.1 - What Is A Management System?SLQC KumaraNo ratings yet

- Section 1.4 - Audit PlanningDocument7 pagesSection 1.4 - Audit PlanningSLQC KumaraNo ratings yet

- Section 2.2 - Risk Based Approach and Benefits: PART 2 - WHAT IS BS OHSAS18001:2007?Document1 pageSection 2.2 - Risk Based Approach and Benefits: PART 2 - WHAT IS BS OHSAS18001:2007?SLQC KumaraNo ratings yet

- Upasi Tea Research FoundationDocument11 pagesUpasi Tea Research FoundationSLQC KumaraNo ratings yet

- Virgin Coconut Oil 1Document1 pageVirgin Coconut Oil 1SLQC KumaraNo ratings yet

- OPRP MeaningDocument11 pagesOPRP MeaningSLQC KumaraNo ratings yet

- Virgin Coconut Oil 2Document1 pageVirgin Coconut Oil 2SLQC KumaraNo ratings yet

- Virgin 2Document1 pageVirgin 2SLQC KumaraNo ratings yet

- ISO 22000 & HACCP: Hazard Analysis Critical Control PointDocument29 pagesISO 22000 & HACCP: Hazard Analysis Critical Control Pointmazen fakhfakhNo ratings yet

- FrameworkDocument6 pagesFrameworkMani Rathinam RajamaniNo ratings yet

- Mettler Toledo FoodDocument56 pagesMettler Toledo FoodFLed NguyenNo ratings yet

- Iso 22000-1 PDFDocument22 pagesIso 22000-1 PDFFarhan Gohar100% (1)

- New Guideline Document From FSSC 22000 in July 2023Document20 pagesNew Guideline Document From FSSC 22000 in July 2023ahmedNo ratings yet

- Nafood GroupDocument10 pagesNafood GroupPhạm Gia LinhNo ratings yet

- PGDFSQM PG PDFDocument80 pagesPGDFSQM PG PDFm mNo ratings yet

- Pioneer Food Solutions: (A Division of PFS RESEARCH PVT LTD)Document8 pagesPioneer Food Solutions: (A Division of PFS RESEARCH PVT LTD)Phani PrakashNo ratings yet

- Developing Halal Compliance ModelDocument8 pagesDeveloping Halal Compliance ModelrosdiabuNo ratings yet

- ContinueDocument3 pagesContinueValdimiro BelezaNo ratings yet

- Manual Traceability Green CoffeDocument42 pagesManual Traceability Green Coffearta sinatraNo ratings yet

- Food Science Catalog FINAL Low ResDocument29 pagesFood Science Catalog FINAL Low ResJohn Deck TanNo ratings yet

- 300 Food Safety ManualDocument40 pages300 Food Safety Manualพจชรดลยา มัฎศิญากรNo ratings yet

- PGDFSQMDocument2 pagesPGDFSQMSugathan E. KNo ratings yet

- Iso 22000 2005Document35 pagesIso 22000 2005Prasad MgNo ratings yet

- Introduction To ISO22000 101106Document41 pagesIntroduction To ISO22000 101106Asim Masood100% (1)

- Iso 22000 AuditDocument19 pagesIso 22000 AuditBRIGHT DZAH100% (1)

- Iso CertificationsDocument11 pagesIso Certificationsvidyut3No ratings yet

- ISO 22000 Internal AuditDocument1 pageISO 22000 Internal AuditPushpinder Kaur Dhatt0% (1)

- Iso 22000 2018 LacDocument4 pagesIso 22000 2018 LacHaitham Negm0% (1)

- FSSC 22000Document77 pagesFSSC 22000Asep R100% (1)

- Jose Rizal Memorial State University: The Premier University in Zamboanga Del NorteDocument31 pagesJose Rizal Memorial State University: The Premier University in Zamboanga Del NorteJay Calalang ManatadNo ratings yet

- TQM BisleriDocument27 pagesTQM BisleriDishank ShahNo ratings yet

- Food Safety and Quality Policy: M/s Dwaraka Sea Foods Sanitary Standard Operating ProcedureDocument2 pagesFood Safety and Quality Policy: M/s Dwaraka Sea Foods Sanitary Standard Operating ProcedureDevaraj SubrmanayamNo ratings yet

- BRC V6 Zoning PDFDocument5 pagesBRC V6 Zoning PDFolivier_rondouin100% (1)

- HSE & Compliance CV M. HMDocument2 pagesHSE & Compliance CV M. HMrizwan ahmedNo ratings yet

- Iso 22003-1-2022Document34 pagesIso 22003-1-2022sara puentesNo ratings yet

Food Safety Manual - ECCL

Food Safety Manual - ECCL

Uploaded by

SLQC KumaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Food Safety Manual - ECCL

Food Safety Manual - ECCL

Uploaded by

SLQC KumaraCopyright:

Available Formats

Doc. No.

FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Abbreviations

ECCL - Edna Chocolates (Ceylon) Pvt Ltd

FSMS - Food Safety Management System

HACCP - Hazard Analysis and Critical Control Points

PRP - Pre-requisite Programs

GAP - Good Agricultural Practices

GMP - Good Manufacturing Practices

GHP - Good Handling Practices

SOP - Standard Operation Procedure

SSOP -Standard Sanitary Operation Procedure

CCP - Critical Control Point

CL - Control Limit

OPRP - Operational Pre-requisite Program

CAR - Corrective Action Report

MRM - Management Review Meeting

IA - Internal Audits

FSTL - Food Safety Team Leader

FST - Food Safety Team

GM/HOM - General Manager/Head of Manufacturing

PLM - Plant Manager

QAE - Quality Assurance Executive

PM - Production Manager

SE - Stores Executive

MM - Maintenance Manager

PE - Production Executive

QAA - Quality Assurance Assistant

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 1

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

I. Introduction

The Food Safety Management System established at EDNA CHOCOLATE (CEYLON) PVT LTD.

(ECCL) with reference to requirements of ISO 22000:2005 Food Safety Management System is

comprehensively presented in this manual.

II. Distribution Control

The Food Safety Team Leader is responsible for distribution control of this document and distribution

of the controlled copies of this manual will be carried out in accordance with the procedure for

document control (Refer FSP/01- Procedure for Control of Document). Distribution list of controlled

copies is as follows.

.

Distribution list

COPY HOLDER’S

CONTROLLED COPY

DESIGNATION

Chairman/CEO Controlled Hard Copy

GM/HOM Controlled Soft Copy & Hard Copy

Food Safety Team Leader Master Soft Copy & Hard Copy

Plant Manager Controlled Hard Copy

Maintenance Manager Controlled Hard Copy

Stores Executive Controlled Hard Copy

Certification body Uncontrolled hard copy

The copies issued to outside parties like certification bodies, customers will become ‘Uncontrolled

Copies’ and such copy shall be issued only on prior approval of the top management.

III. Review and Approval

This Manual is

- Prepared by FSTL/QAE-ECCL

- Reviewed by the Plant Manager(PLM)and Approved by GM/HOM

This manual is a controlled document within the company and when distributed outside it will

become an uncontrolled document

IV. Revision

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 2

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

This Manual will be periodically reviewed for its adequacy, adherences and effectiveness and

revised. Revision will be carried out in accordance with the procedure for document control (Refer

FSP/01- Procedure for Control of Document). Revision shall be finally approved by the General

Manager/HOM prior to application.

V. COMPANY PROFILE

Name of the Organization – EDNA CHOCOLATE (CEYLON) PVT LTD.

Address – Uthuwankanda, Mawanella.

Telephone – 0094 035 224 1660/ 0094 0352241670

Fax – 0352241669

Email – mawanella.tally@edna.lk

Today EDNA group is headed by its present chairman Mr. B.R.S.T Edirisinghe son of late Mr.

Wimaladasa Edirisinghe.

The Edna group is one of the largest diversified conglomerates specializing in many areas. E I&M

(pvt) Ltd is the key subsidiary of Edna Group and is the marketing arm of chocolate, confectionary

and pharmaceuticals which has a work force of over 300.

Today Edna is one of the leading chocolate & confectionary brands in Sri Lanka. It boasts a well

established island-wide distribution network and an extensive product portfolio which includes

chocolates, confectionaries and wafer biscuits. E I&M (pvt) Ltd is also the marketer of world

renowned SMA Nutritional brands of Wyeth Nutritional USA.

Awards and Achievements: Super Brand Award, ISO 22000:2005, GMP

Product Range

ECCL manufacture varies types & flavors of chocolate in vary weight range retail packs & wafer

biscuits under the brand name of “EDNA” and “BUNTY”.

Management

The GM/HO is overall responsible for the total operation and Plant Manager head the whole operation

in the plant with the assistance of the Heads of Production, Maintenance, and Quality Assurance,

Stores and Accounts and their teams of Supervisors/Assistants reporting them.

The organization chart is annexed – Annexure iv

1.0 SCOPE

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 3

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

FSMS is applicable to the entire operation from the point of receiving raw materials, converting those

raw materials into Chocolates, Coated Chocolates, Wafer Biscuits and Chocolate Enrobes and dispatch

of the finished goods complying with statutory and regulatory requirements governed under Sri

Lankan conditions.

2.0 NORMATIVE REFERENCES

ISO 22000:2005 – Food Safety Management System

ISO 9001:2008 – Quality Management System

SLS 143:1999 – General Principles of Food Hygiene

Codex Standard for Chocolate & Chocolate Products(Codex Stan 87-1981,Rev.1-2003)

Food Act No 26 of 1980 Regulation Food(Tea, Coffee, Cocoa & their Products)

3.0 TERMS AND DEFINITIONS

3.1 Food Safety

Concept that food will not cause harm to the consumers when it is prepared and/or eaten according to

its intended use.

3.2 Food Chain

Sequence of the stages and operations involved in the production, processing, distribution, storage and

handling of a food and its ingredients, from primary production to consumption.

3.3 Food Safety Hazard

Biological, chemical or physical agent in food, or condition of food, with the potential to cause an

adverse health effect.

4.0 FOOD SAFETY MANAGEMENT SYSTEM

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 4

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Edna Chocolates Ceylon (pvt) Ltd, has established, documented, implemented and maintain an

effective food safety management system and update it when necessary in accordance with the

requirements ISO 22000:2005 International Standard.

The scope of the food safety management system has covered the reception of raw materials including

packaging, the manufacturing processes, storage & dispatched of the finished products for sales, It also

fulfill all the requirements that are specified in ISO 22000 : 2005 FSMS. Food safety management

system has covered the product and process starting from the supplier, raw materials to finished

products.

4.1 General Requirement

Under this ISO 22000 Food Safety Management System manual has covered all the activities within

ECCL.

EDNA CHOCOLATE CEYLON (Pvt) LTD (ECCL) has been;

a) Ensured that food safety hazards that may be reasonably expected to occur in relation to

product within the scope of the system are identified, evaluated and controlled in such manner that

the product of the organization do not, directly or indirectly, harm the consumer,

b) Communicated appropriate information throughout the food chain regarding safety issues

related to its products,

c) Communicated information concerning development, implementation and updating of the food

safety management system throughout the organization, to the extent necessary to ensure the food

safety required by ISO 22000 International Standard.

d) Evaluated periodically and updated when necessary, the food safety management system to

ensure that the system reflects the organization's activities and incorporates the most recent

information on the food safety hazards subjected to control.

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 5

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

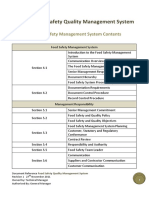

4.2 Documentation Requirements

4.2.1. General Requirements

The food safety management system documentation included:

a) Documented statements of a food safety policy and related objectives

b) Documented procedures and records

c) Documents for the effective development, implementation and updating of the food safety

management system

4.2.2. Control of Documents

ECCL ensures that documents required by the FSMS are controlled and records are kept according to

the requirements specified in 4.2.3 of this Food Safety manual and has established a documented

procedure to define controls that are needed for;

a) Approving documents prior to issue.

b) Reviewing and updating as necessary and to re-approve documents,

c) Ensuring that changes and the current revision status of documents are identified

d) Ensuring that relevant versions of applicable documents are available at points of use

e) Ensuring that documents remain legible and readily identifiable,

f) Ensuring that documents of external origin are identified and their distribution controlled,

and

g) Preventing the unintended use of obsolete documents, and applying suitable identification

to them if they are retained for any purpose.

Reference:

Procedure for Control of Documents (FSP/01)

Master List of Documents (QA/L-01)

4.2.3. Control of Records

ECCL has established and maintains all records to provide evidence of conformity to requirements and

of the effective operation of the FSMS. Records are maintained in a manner that they remain legible,

readily identifiable and retrievable. A documented procedure has been established to define the

controls needed for the identification, storage, protection, retrieval, retention time and disposition of

records. List of Records is maintained to establish the traceability of all records.

Reference Procedure for Control of Records (FSP/02)

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 6

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

List of Records (QA/L-02)

5.0 MANAGEMENT RESPONSIBILITIES

5.1 Management Commitment

Top Management of ECCL shall provide evidence of its commitment to the development and

implementation of the food safety management system and to continually improving its effectiveness

by

a) Showing food safety is supported by business objectives

b) Communicating to the organization the importance of meeting the requirements of this international

standard, any statutory and regulatory requirements, as well as customer requirements relating to

food safety

c) Establishing the food safety policy

d) Conducting management reviews

e) Ensuring the availability of resources

5.2 Food Safety Policy

Edna Chocolates Ceylon (Pvt) Ltd makes every effort to ensure That the Chocolates, Coated

Chocolates, Wafer Biscuits and Chocolate Enrobes Supplied to our customers is Free of all potential

biological, chemical and physical hazards, by manufacturing in an environment where ISO

22000:2005/HACCP principles have been established while complying to all the applicable legal

requirements.

We believe that the continual improvement of our consumer safety approach is based on the

commitment and contribution of our employees towards food safety and on upgrading their knowledge

and skill on food safety.

This policy has been communicated to all employees by displaying at the premises and reviewed at the

management meeting to ensure compatibility with the company policy, values and objectives to

achieve continual improvement.

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 7

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

5.3 Food Safety Management System Planning

Top management GM/HOM ensures that,

a) Planning and review of the food safety management system is carried out to meet requirements

given in 4.1 as well as the objectives organization that support Food safety Management

system and,

b) The integrity of the FSMS is maintained when changes to the food safety management system

are planned and implemented.

5.4 Responsibility, Authority

Responsibility and authority of each position of the management hierarchy is described throughout

this manual. Managers and supervisors who involve in different stages of the vinegar manufacturing

process should have an adequate knowledge of food hygiene principles and practices to be able to

judge potential risks, take appropriate preventive and corrective action, and ensure that effective

monitoring and supervision takes place.

Reference Organization chart (Annexure - iv)

Food safety team (Annexure - v)

5.5 Food Safety Team Leader

Quality Assurance Executive is the food safety team leader and, Irrespective of other responsibilities,

shall have the responsibility and authority

a) to manage a food safety team and organize its work.

b) To organize relevant training and education programs of Food Safety Team members,

c) to ensure that the food safety management system is established, implemented, maintained and

updated,

d) to report to the organization's top management on the effectiveness and suitability of the food

safety management system and internal audit findings.

Reference Food safety team (Annexure - v)

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 8

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

5.6 Communication

5.6.1. External Communication

The GM/HOM and PLM is overall responsible for ensuring the establishment of an appropriate and

effective communication processes with

a. Suppliers

b. Customer/s

c. Statutory and regulatory authority/s

d. Other organization that have an impact on or will be affected by , the effectiveness or updating

of the FSMS

By the means of enquiries, contracts or order handling including amendments, customer feedback

includes complaints.

5.6.2. Internal Communication

The Plant Manager is responsible for ensuring the establishment of processes for communication with

personnel including Food Safety Team of the organization on issues having an impact on food safety,

by means of meetings with the Food Safety Team, departmental meetings, notices and management

review meetings, electronic and telecommunication means ensuring the effectiveness of the FSMS.

5.7 Emergency Preparedness and Response

The potential emergency situations and accidents that can impact on food safety and which are

relevant to the role of the ECCL are handled according to planned arrangements.

Top management (GM/HOM) has established separate emergency preparedness team and action plan

to manage potential emergency situations and accidents that can impact food safety

Reference Emergency Manual (EM)

5.8 Management Review

5.8.1. General

The food Safety Management System of ECCL, is reviewed by the Management Review Committee

during management review meetings held at an approximate interval of six months, in order to ensure

its continuity, suitability, adequacy and effectiveness and to assess the need and opportunities for

continually improve the FSMS including the Food Safety Policy and objectives.

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 9

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

5.8.2. Review Input

Food safety team reviews included the followings:

a) Follow-up actions from previous Food safety team meeting and way forward,

b) Analysis of results of verification activities and action to be taken,

c) Changing management,

d) Management of Emergency situations, accidents and withdrawals and training.

e) Review of communication activities and customer feed-back including positive comments.

f) Result of external audits or inspections reports and corrective actions to be taken.

g) Required information for Top management review.

5.8.3. Management Review Output

The output from the management reviews included the followings,

a) Assurance of food safety and way forward

b) Improvement of the effectiveness of the food safety management system

c) Resource allocation

d) Revisions of the organization's food safety policy

Reference Procedure for Management Review (FSP/08)

Management Review Meeting Minutes (QA/M/01)

6.0 RESOURCE MANAGEMENT

6.1 Provision of Resources

The Top management of ECCL provides adequate resources for establishment, implement, maintain &

update of the ISO 22000:2005/ FSMS.

6.2 Human Resources

6.2.1 General

Food safety team is assigned and responsibilities defined in the Food Safety management system

should be competent on the basis of appropriate education, training, skills and experience due to all the

personnel activities having an impact on the food safety.

Reference Organizational chart (Annexure - iv)

Food Safety Team (Annexure - v)

6.2.2 Competence, Awareness and Training

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 10

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Competency development and training of ECCL employees are carried out according to planed

arrangements in order to ensure that all the employees are aware of the relevance and importance of

their role within the Food Safety Management System and are competent enough to execute their job.

All personnel involve in the Chocolates, Coated Chocolates, Wafers & Chocolate Enrobes

manufacturing process should have the necessary knowledge and awareness on their role and

responsibility and on caring out the manufacturing process in a hygienic manner protecting

Chocolates, Coated Chocolates, and Wafers & Chocolate Enrobes from contamination and

deterioration.

Reference Food safety Team (Annexure v)

Training Plan (QA/SHL/04)

Training Attendance Record (QA/RE/12)

Training Effectiveness Record (QA/RE/13)

6.3 Infrastructure

The Top Management of ECCL provides the resources for the establishment and maintenance of the

infrastructure needed to implement the FSMS.

6.4 Work Environment

The Top Management of ECCL shall provide the resource for the establishment, management and

maintenance of the work environment needed to implement the requirements of this FSMS.

7. PLANNING AND REALIZATION OF SAFE PRODUCTS

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 11

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

7.1 General

The approach of ECCL, towards planning and manufacturing of Chocolates which is safe for human

consumption by formulating requirements with respect to raw materials and processing, implementing,

monitoring and reviewing effective control systems is comprehensively described in Hazard analysis,

PRP’s and HACCP plan of this manual.

7.2 Prerequisite Programs (PRP’S)

Pre requisite programs are provide basic condition and activities that are necessary to maintain

hygiene environment through the food chain suitable for production handing and provision of safe

product for human consumption.

This basically includes good maintaining previous (GMP) and good hygienic practice (GHP). ECCL

has identified following area when establishing PRP Program.

1. Design and facilities

A) Location and surroundings

The company has considered following criteria in order to avoid threats encountered in chocolates

processing and storage.

Flooding

Surrounding environment pollution

Infestation of Pest

Waste disposal facilities.

The suitability of environment in periodically by Food safety team leader and if required effective

protective measures should be taken.

B) Design and lay out

Design and layout should permit implementation of good hygienic proactive and should prevent cross

contamination during processing of chocolates. The place and the flow of raw material, work in

progress, finished product and equipment identified. Raw and packing material and production area is

adequately segregated from the production area to avoid cross contamination. All operatives enter the

factory by specific entrance to dedicated changing area where showing, hand washing and drying and

toilets facilities area available.

C) Drainage and waste disposal

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 12

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Adequate drainage and wasted disposal system and facilities are provided. Waste materials are not

allowed to accumulate in the food handing food storage, and other area. The solid waste removal

storage /garbage room is located well away from production area in closes area.

Reference: Waste Disposal Records (PR/RE/17)

D) Sitting of equipment

All machinery has positioned to give easy access to all parts of cleaning. Equipments are beat least

50cm from the adjacent walls and set on elevated floor for easy cleaning. Equipments are made of

material with no toxic effect or reaction on the products manufactured. Equipments are movable or

capable of being dissembled to allow for maintenance and cleaning. For every equipment and

machinery, cleaning instruction, schedule with maintenance are available.

E) Condition of floor

Floor is maintaining in good condition and laid using impervious materials with an even, easily

cleaned surface to minimize the accumulation of dust, grease and substance that could become feeding

materials for microorganisms. There is no entry point for insects from drains to floor surfaces. There is

non-slip surface minimizing the risk of accidents.

F) Condition of walls, doors and windows

All interior wall are in good condition with no cracks, pores and easy to clean. All wall-wall and wall-

floor junctions are curved for easy cleaning. All external opening doors are kept closed and all doors

to production area is self-closed. All windows are kept closed, where openings are screened with a

small size mesh.

G) Condition of ceiling and lights

Adequate natural and artificial lighting to enable the processing to be carried out in a safe

environment. Lighting fixtures area protected to ensure that the food is not contaminated when

breakage. Throughout production and inspection area, good artificial lighting is provided. Fluorescent

lights (Insecticuters unit) are protected by shatterproof stickers in production area. The lights area

fixed to the ceiling tightly.

H) Ventilation

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 13

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Adequate means of natural or mechanical ventilation is provided to minimize the air born

contamination of food, control ambient temperature, control odours which might affect the quality of

food and control humidity, where necessary to ensure the safety and suitability of food. The

Thermometers & humidity meters are set in production area to monitor the temperature and humidity.

Exhaust fans provided to give adequate ventilation and minimize condensation.

2. Storage facilities

Adequate facilities for the storage of raw, packaging materials and Finished Goods are provided.

Separate facilities to the other cleaning and lubricating chemicals. Storage products are maintained in

first in first out basis and required training are provided for the personnel who working in the stores.

Storage products are clearly labeled and arranged in an order to facilitate the easy accessibility. The

temperature and humidity levels are monitored within the storage area. When necessary, the laboratory

tests are carried out to establish fitness for use. Stocks of raw materials and ingredients are subjected

to effective stock rotation. All materials are stored off the floor on clean pallets to facilitate adequate

cleaning, pest control and product ventilation. Incoming materials and finished products are clearly

identified and stored in separate designated areas of the factory. Loading area is kept cleaned.

Cleaning and pest control system of the storage area are in place.

3. Distribution facility

Prior to loading all Lorries are internally inspected by the Store Keeper to ensure that they are clean,

free from moisture, foreign objects and pests that cause product contamination and damage to the

packages. Delivery of products always in closed vehicles to prevent contamination from external

sources.

Reference: Vehicle cleaning Check List (QA/CL/07)

4. Cleaning and Sanitizing

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 14

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

A well organized cleaning system is established. A cleaning schedule is documented and available for

every section within the factory. It is clear, legible and easy to follow. The cleaning schedule indicates

the place/area/equipment, method of cleaning, frequency, when, and the responsible person.

The cleaning inspection checklist is maintained at each production and storage areas to ensure that the

every single area or equipment used for production process has been appropriately cleaned Cleaning

evaluation audit is done on daily basis by Quality assurance executive in order to maintain consistent

hygienic environment inside the processing area.

Cleaning equipments and chemical are stored in separate area and cleaning operatives are adequately

trained to do their job properly. The entire cleaning process is monitored by quality supervisor. Within

the production area, the food debris levels are maintain in a minimum consistent with the process and

practice “Clean as You Go” principle. Floor debris is removed by designated hygiene operatives rather

than online process workers. All staff facilities including toilets, rest rooms, canteen, lockers are

regularly cleaned throughout the day.

Reference: Outside cleaning check list (QA/CL/01)

Inside cleaning check list (QA/CL/02)

5. Pest Control

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 15

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Access of pest, harborage and infestation should be prevented and potential breeding sites should be

eliminated by

a.Keeping building in good repair condition

b. Keeping factory premises in clean to avoid pest infestation and rubbish bins are totally enclosed

and regularly emptied to prevent over spill.

c.Sealing of drains, holes, other and place where pest are likely to gain access (avoiding of pest entry

point)

d. Installing mesh screens on open windows, doors and ventilators

e.Exclude animal from the premises

f. Potential food sources are stored insect proof containers

g. Ensuring waste materials are stored in covered and located in a manner that prevents breeding

Pest control system is outsourced by an approved and well trained pest control organization and all the

chemicals used are food grade. The pests that covering the pest control is Rats, Ants, Cockroaches

Cocoa moth. They have executed for the regular inspection and treatment of the premises to deter and

destroy infestation by pests. The pest treatments are carried out once a month (last week of the month)

at regular intervals and visited the factory when the requirement is arises.

Quality Assurance Executive has responsible for pest control system and maintained records.

Reference: Pest control check list (QA/CL/05)

6. Personal hygiene

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 16

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

All production and Quality Assurance personnel are fully trained in the principles of Good

Manufacturing Practices and competent the task assigned to them. ‘On the Job’ training is given to

staff to fully understand their responsibilities and the need to follow written instructions and

procedures. Training records are maintaining and effectiveness of training is monitored by Human

Resources Unit.

All operatives enter the factory by a specific entrance, to a dedicated changing area where hand

washing, showering, foot bathing, exchanging of outer garments are available.

Adequate lockers are provided for all operation personnel for safe storage of personnel effects. A

separate rest room and canteen are provided for operatives to take their meals and breaks. Water drink

dispensers are available at production floor as well as canteen. All toilets are adequately lit and

ventilated and separated from production area. Toilet areas are of good hygienic design and the floors,

walls, ceilings and sanitary equipments are clean.

The all employees are provided with suitable uniforms, protective cloth, head coverings, masks and

gloves whenever necessary. To prevent foreign body contamination, the all employees are restricted to

wear jewelry, wrist watch, necklace, rings and bangles. The employees are subjected personnel

hygienic inspection on daily basis prior to entrance of processing area by well fare officer.

A company has provided the services of a fully trained First Aid group and a First Aid room with

adequate equipments for first aid treatment of illness or injury. First aid equipments are kept securely

and issued by a Well Fare Officer. All treatments are fully recorded in the medical record book and

records are maintained by well fare officer. Person suffering from any infectious illness is not be

permitted to work & Food handlers with cuts and wounds should be permitted to work in the food

handling area only after proper covering or dressing of those cuts and wounds. All injuries and

diseases are reported to Well Fare Officer and suitable treatments are done by Well Fare Officer.

Food handles should wash their hands at the starts of food handling activities, immediately after using

toilets, after having meals or after handling any material that can contaminate food items by using

suitable antibacterial hand wash.

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 17

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

All operatives are completed an appropriate medical questionnaire prior to commencing work. Annual

medical inspection is done by The company doctor has assigned for once in two weeks to teat the

employees and all the records are maintained at Human Resources Department by company Safety

Officer.

Reference: Employee Hygiene check list (QA/CL/03)

7. Quality Assurance

The company has sufficient, properly trained Quality Assurance Department to execute the system to

ensure the consistent production of safe, legal product in compliance with the agreed specification.

The quality Assurance personnel are properly trained to maintain agreed quality standards, with

clearly defined responsibilities covering all aspects of the operation. Quality Assurance Department is

operational at all times when production is in progress. Adequate resources and facilities are available

for the Quality Assurance Department to fulfill its tasks.

Chemical, Physical and sensory analysis of raw materials and finished product is inspected at Quality

Assurance Department and accepting of raw materials within the agreed standard and returns the rest.

The laboratory personnel are competently trained to understand the analysis, interpret the results. All

laboratory equipments and instruments used are clean, well maintained, serviced and calibrated at

regular intervals to ensure its accuracy and the information kept on record. The calibration of

laboratory equipments is carried out by either Industrial Technology Institution (ITI) or Sri Lanka

Standards Institute (SLSI).

The results of the calibration is formally documented and signed and the next due calibration date give

to ensure accuracy of all measuring equipments.

The company has a formalized, written complaint procedure, detailing the person responsible.

All quality complaints are recorded when received, investigated within a given time scale according to

their urgency and a report prepared as the basis for correction action

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 18

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

7.3 Preliminary Steps to Enable Hazard Analysis

7.3.1 General

All relevant information needed to conduct the hazard analysis has been collected, maintained,

updated and documented. Records have been maintained.

7.3.2 Food Safety Team

The food safety team has a combination of multi-disciplinary knowledge and experience in developing

and implementing the food safety management system.

Reference Annexure v-Food Safety Team

7.3.3 Product Characteristics

Chocolate is the generic name for the homogenous products obtained by an adequate manufacturing

process from cocoa materials which may be combined with milk products, sugars and/or sweeteners,

and other additives. Chocolate shall contain, on a dry matter basis, not less than 35% total cocoa

solids, of which not less than 18% shall be cocoa butter and not less than 14% fat-free cocoa solids.

7.3.3.1 Raw Materials, Ingredients And Product Contact Materials

Hazard analysis carried out based on, All Raw materials, Ingredients and Product-contact materials are

described in the document to the extent needed to conduct the hazard analysis including the following,

a. Biological, chemical and physical characteristics

b. Composition of formulated ingredients, including additives and processing aids

c. Origin

d. Method of production

e. Packaging and delivery methods

f. Storage conditions and shelf life

g. Preparation and handling before use or processing

h. Food safety – related acceptance criteria or specifications of purchased materials and

ingredients appropriate to their intended use.

Reference Supplier Specifications

Product Certification/Test reports (MSDS, Food Grade Certifications)

Specification for Raw Material (QA/SPC/01)

Specification for Packing Material (QA/SPC/02)

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 19

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

7.3.3.2 Characteristics Of End Products

The characteristics of end products are described in documents to the extend needed to conduct the

hazard analysis including information on the followings

a) Product name or similar identification

b) Composition

c) Biological , chemical and physical characteristics relevant for food safety

d) Intended shelf life and storage conditions

e) Packaging

f) Labeling related to food safety and / or instructions for handling, preparation and usage

g) Methods of distribution

Reference Specification for Finished Goods (QA/SPC/03)

7.3.4 Intended Use

Chocolates are used as a staple food, snack, luxury gifts, dietary products, etc.

Even though the Chocolates in general is consumed by all age groups including risk groups special

types of Chocolates are tailor made for the consumption of specific risk groups (light/sugar free

chocolates)

Information regarding addition of nut ingredients is mentioned in the ingredient list and therefore any

nut allergy risk group can retrain from eating of those chocolate

7.3.5 Flow Diagrams, Process Steps And Control Measures

7.3.5.1 Flow Diagram

Flow diagrams are prepared for the production process covered by the food safety management system

including the followings

a) The sequence and interaction of all steps in the operation;

b) Any outsourced processes and subcontracted work;

c) Where ingredients and intermediate products enter the flow;

d) The end product.

All these flow diagrams are verified by the food safety team

Reference Process flow Diagram (Annexure i)

7.3.5.2 Description of Process Steps and Control Measures

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 20

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Hazard analysis carried out for the existing control measures, process parameters which they may

influence food safety.

7.4 Hazard Analysis

Hazard Analysis and Determination of Critical Control Points (CCPS)

Identification of all potential biological, chemical and physical hazards encountered together with the

control measures and control points of such identified hazards and

Evaluation and analysis of such hazards to assess the impact of the risk involved the following criteria

is used for the hazard assessment

Severity

5. Can cause fatality

4. Can lead to serious illness/ injury

3. Can cause product recall

2. Can generate customer complaint

1. Non significant

Likelihood of occurrence (LOC)

5. Common occurrence

4. known to occur (has happened at our premises)

3. Could occur (evidence in published material)

2. Not likely to occur

1. Practically impossible to occur

Risk Level = Probability x Severity

When the risk level of hazard is higher than 9 it becomes significant

7.4.1 General

The Food Safety Team conducted a hazard analysis to determine which hazards need to be controlled

and the degree of control required to ensure food safety, and which combination of control measures is

required.

7.4.2 Hazard Identification and Determination of Acceptable Levels

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 21

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

The Hazard Identification Carried Out Based On

a. The preliminary information and data

b. Experience

c. External information including, to the extent possible, epidemiological and other historical data,

Information from the food chain on food safety hazards that may be of relevance for the safety of

the end products, intermediate products and the food at consumption.

When Identifying The Hazards, Consideration Given To

a. The steps preceding

b. The process equipment, utilities/services and surroundings

c. The preceding and following links in the food chain.

Determination Of The Acceptable Level Of The Food Safety Hazard

For each of the food safety hazards identified, the acceptable level of the food safety hazard in the

end product has been determined.

7.4.3 Hazard Assessment

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 22

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

HACCP Plan – Identification and control of hazard – Raw Material and Process steps

Raw Material / Food Control and Hazard Analysis Significant/

Potential Category

Step Contact Material/ Preventive Non

Hazard (B/C/P) Risk

Process Step Measure Probability Severity significant

Level

[1] Receiving raw

materials

Cocoa (Cocoa Presence B Supplier 3 4 12 S

[1a] butter, Cocoa liquor, of guarantee

Cocoa Powder) pathogeni certificate is

c bacteria visually

Presence confirmed

of live

dead RH of the

insects/ store is

debris maintained

Presence C Raw 2 2 4 NS

of material

pesticides Inspection at

receiving

each

Presence P consignment

of dirt, (Moisture 2 2 4 NS

stone %)

particles,

iron FIFO at

particles, issue

polythene,

human

hair

[1b] Sugar Presence B Purchase 2 2 4 NS

of live from a

dead guaranty

insects/ supplier

debris

Raw Material / Food Potential Category Control and Hazard Analysis Significant/

Step Non

Contact Material/ Hazard (B/C/P) Preventive Probability Severity Risk

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 23

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Level

significant

Process Step Measure

[1b] Sugar Presence C Raw 2 1 2 NS

of material

Lubricants Inspection at

/chemical receiving

additives each

consignment

Presence P 5 1 5 NS

of iron

particles, Passing

sand, through a

polythene, sieve

human

hair Installing

metal traps

in the

process

[1c] Milk powder Presence B Supplier 2 4 8 NS

of guarantee

pathogeni certificate is

c bacteria visually

Presence confirmed

of live

dead Raw

insects/ material

debris Inspection at

receiving

each

Presence C consignment 2 4 8 NS

of

Melamine RH of the

store is

Presence P maintained 2 4 8 NS

of iron

particles, Adhere to

polythene, GMP

human

hair FIFO at

issue

Step Raw Material / Food Potential Category Control and Significant/

Hazard Analysis

Contact Material/ Hazard (B/C/P) Preventive Non

Process Step Measure Probability Severity Risk significant

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 24

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Level

[1d] Vegetable fat Presence B Supplier 2 4 8 NS

of live guarantee

dead certificate is

insects/ visually

debris confirmed

Presence C Raw 2 3 6 NS

of material

Lubricants Inspection at

/chemical receiving

additives each

consignment

Presence P 2 3 6 NS

of stones RH of the

wooden store is

particles, maintained

polythene,

human Adhere to

hair GMP

[1e] Fillers (cashew nuts, Presence B Supplier 3 2 6 NS

pea nuts, sultana, & of moulds guarantee

rice crispy) and fungi certificate is

Presence visually

of live confirmed

dead

insects/ Raw

debris material

Inspection at

Presence C receiving 2 4 8 NS

of each

aflatoxin consignment

Roasting

Presence P pea nut up 3 2 6 NS

of stones, to 1500C for

polythene, 30mins

human

hair

Manual

Sorting

Hazard Analysis Significant/

Raw Material / Food Control and

Potential Category Non

Step Contact Material/ Preventive

Hazard (B/C/P) Probability Severity

Risk significant

Process Step Measure Level

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 25

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

[1f] Chemical additives Presence B Supplier 2 4 8 NS

(Lecithin, Flavours of live guarantee

(Vanilla-Powder & dead certificate is

flavour, strawberry, insects/ visually

orange & rum ), debris confirmed

Antioxidants

,salt, malt extract, Presence C Raw 2 3 6 NS

sodium carbonate) of material

Lubricants Inspection at

/chemical receiving

additives each

consignment

Presence P 2 3 6 NS

of stones RH of the

wooden store is

particles, maintained

polythene,

human Adhere to

hair GMP

[1g] Packing materials Presence B Supplier 2 4 8 NS

of live guarantee

dead certificate is

insects/ visually

debris confirmed

Presence C Raw

of material

Lubricants Inspection at 2 3 6 NS

/chemical receiving

additives each

consignment

Presence

of stones P 2 3 6 NS

wooden

particles, RH of the

polythene, store is

human maintained

hair

Adhere to

GMP

Hazard Analysis Significant/

Raw Material / Food Control and

Potential Category Non

Step Contact Material/ Preventive

Hazard (B/C/P) Probability Severity

Risk significant

Process Step Measure Level

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 26

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

[1h] Wheat flour Presence B Supplier 2 4 8 NS

of guarantee

pathogeni certificate is

c bacteria visually

Presence confirmed

of live

dead

insects/ FIFO at 2 4 8 NS

debris C issue

Presence

of

chemical P 2 4 8 NS

residue Flour

sieving

Presence trough a

of iron mesh

particles,

woods,

polythene

head

treads

[1i] Tapioca flour/ corn Presence B Supplier 2 4 8 NS

starch of guarantee

pathogeni certificate is

c bacteria visually

Presence confirmed

of live

dead

insects/

debris P Flour 2 4 8 NS

sieving

Presence trough a

of iron mesh

particles,

woods,

polythene

head

treads

Hazard Analysis Significant/

Raw Material / Food Control and

Potential Category Non

Step Contact Material/ Preventive

Hazard (B/C/P) Probability Severity

Risk significant

Process Step Measure Level

[1j] Portable water Presence B Adhere to 2 4 8 NS

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 27

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

of GMP daily

pathogeni

c bacteria Detail

Presence microbiologi

of live cal analysis

dead at every 3

insects/ months

debris

Filtering

before

addition

[3] Storing (RM and Growth of B Maintain the 2 4 8 NS

Packaging materials) vegetative temperature

pathogens sufficiently

low to

minimize

the growth

of

pathogens.

Clean the

storage

areas at

frequencies

Adhere to

GMP and

GHP at

stores

[4] Issuing (RM and Introducin P Adhere to 2 2 4 NS

PM) g dust, GMP

soil, sand

or

polythene

due to

poor GMP

Significant/

Raw Material / Food Control and Hazard Analysis

Potential Category Non

Step Contact Material/ Preventive

Hazard (B/C/P) Risk significant

Process Step Measure Probability Severity

Level

[5] Fat Melting Introducin P Filtering 3 2 6 NS

g after melting

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 28

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

polythene

pieces

[6] Sugar grinding Introducin P Magnetic 5 2 10 S

g dust, screen to

iron remove

particles metal

foreign particles

materials

Or human

hair

Equipments

[7] Cocoa liquor Introducin B used for 2 4 8 NS

treating g addition is

pathogeni constructed

c bacteria to minimize

P product or 2 2 4 NS

Introducin ingredient

g exposure

impurities, Self

foreign inspection

particles of

from neutralizing

neutralizin agents.

g agents

Adhere to

[8] Manual sorting Introducin B GHP 2 4 8 NS

(cashew nuts, g (sanitizing

peanuts, sultana) pathogeni hands with

c IPA)

microbes

P Sorting area 4 3 12 S

is controlled

Introducin in hygiene

g conditions.

extraneous Adhere to

matters GHP

Hazard Analysis Significant/

Raw Material / Food Control and

Potential Category Non

Step Contact Material/ Preventive Risk

Hazard (B/C/P) Probability Severity significant

Process Step Measure Level

[9] Weighing and Introducin B Pest 3 3 9 NS

mixing (chemical g controlling

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 29

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

additives) live dead in the plant

insects/

debris

Contamin C Adhere to 2 1 2 NS

ation with GMP (using

lubricants food grade

chemicals)

Introducin

g extra C Recipe 3 4 12 S

amount of weight

additives controlling

Calibration

of scales

Introducin

g dust, P Adhere to 2 2 4 NS

foreign GMP -

materials Preventive

maintenance

[10] Refining Introducin B Adhere to 2 4 8 NS

g GMP

pathogeni

c bacteria

Use food

Introducin B grade 2 2 4 NS

g live / chemicals

dead

insects C Adhere to 2 1 2 NS

GMP

Introducin

g Pest

lubricants P controlling 2 2 4 NS

Introducin in the plant

g sand

Step Raw Material / Food Potential Category Control and Hazard Analysis Significant/

Contact Material/ Hazard (B/C/P) Preventive Non

Risk

Process Step Measure Probability Severity

Level

significant

[11] Transferring Introducin B Adhere to 3 2 6 NS

(refined powder) g GMP and

pathogeni GHP

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 30

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

c bacteria

due to

manual

handling

B 2 2 4 NS

Introducin Pest

g dead controlling

live in the plant

insects or

debris

P 3 2 6 NS

Adhere to

Introducin GMP

g sand,

dust or

foreign

maters

[12] Conching Contamin B Using 2 4 8 NS

ate with equipments

vegetative meeting

pathogens sanitary

design

guidelines

Contamin C 3 1 3 NS

ation with Adhere to

lubricants GMP

Use food

grade

Introducin P chemicals 3 2 6 NS

g foreign

materials Preventive

maintenance

Filtering

Step Raw Material / Food Potential Category Control and Hazard Analysis Significant/

Contact Material/ Hazard (B/C/P) Preventive Risk Non

Process Step Measure Probability Severity significant

Level

[14] Tempering ( cocoa Introducin B WIP 2 4 8 NS

butter chocolates) g Inspection

pathogeni temperature

c (batch wise)

microbes

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 31

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Adhere to

Contamin C GMP/ using 2 2 4 NS

ation with food grade

lubricants lubricants.

Introducin P Adhere to 3 2 6 NS

g foreign GMP

materials

Introducin Minimize 2 4 8 NS

[15] Filtering g B product

vegetative exposure to

microbes air

Frequent

Contamin P inspection to 4 3 12 S

ation with ensure free

physical of

impurities contaminati

on.

Contamin B WIP 3 4 12 S

[16] Roasting (cashew ation with inspection

nuts and pea nuts, pathogeni Roasting

rice crispy) c time

microbes /temperature 3 2 6 NS

Introducin P

g Adhere to

extraneous GMP and

matters GHP

[17] Oven Drying of Introducin B Heat up to 3 4 8 S

Sultana g relevant

pathogeni temperature

c

microbes

Contamin P Adhere to 2 2 4 NS

ation with GHP and

foreign GHP

matters

Step Raw Material / Food Potential Category Control and Hazard Analysis Significant/

Contact Material/ Hazard (B/C/P) Preventive Risk Non

Probability Severity

Process Step Measure Level significant

[18] Cooling Introducin P Adhere to 3 2 6 NS

g foreign GMP

maters Passing

human through a

hair, metal metal

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 32

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

particles detector

Contamin C 2 2 4 NS

ate with Using food

lubricants grade

lubricants

[19] De-moulding Contamin Adhere to 1 4 4 NS

ation with B GHP and

pathogeni GMP

c bacteria

Contamin C 2 2 4 NS

ation with Using food

lubricants grade

lubricants

Introducin P 3 2 6 NS

g foreign Adhere to

matters GMP and

GHP

[20] Contamin B Adhere to 3 2 6 NS

Melting of chocolate ation with GMP

(rework) pathogeni

c bacteria

and yeast

& mould

Introducin P Adhere to 3 2 6 NS

g foreign GMP

maters Passing

human through a

hair, metal metal

particles detector

Raw Material / Food Control and Hazard Analysis Significant/

Potential Category

Step Contact Material/ Preventive Risk Non

Hazard (B/C/P) Probability Severity

Process Step Measure Level significant

[22] Butter wash of fillers Introducin P Adhere to 3 2 6 NS

(rework) g foreign GMP

maters

Growth of B Reduce the 3 3 9 NS

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 33

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

yeast and time of

mould keeping

after rework

[23] Metal detector Contamin P Well 3 2 6 NS

ation with cleaning of

foreign detector

materials surface

Passing P 2 4 8 NS

metals Calibrating

without detector

detecting with a 1mm

dummy

metal

practical

[24] Primary Packing Contamin B Packaging 2 4 8 NS

(Filling & sealing or ation with environment

Aluminum foil vegetative to be

wrapping & sealing) pathogens controlled

Introducin P 2 2 4 NS

g foreign Adhere to

materials GHP and

GMP

Introducin

[25] Secondary g foreign P Adhere to 1 2 2 NS

Packaging materials GMP

[26] Coding (printing of No

product information) Possible - - - - - -

hazards

[27] Chocolate FG stores Contamin P Adhere to 1 2 2 NS

ation with GMP

Foreign

Maters

Raw Material / Food Control and Hazard Analysis Significant/

Potential Category

Step Contact Material/ Preventive Risk Non

Hazard (B/C/P) Probability Severity

Process Step Measure Level significant

Sugar syrup boiling Implementin

Introducin B g an insect- 4 2 8 NS

[29] g insects o-cutor

Contamin B Temperature 3 4 12 S

ation with and time

vegetative controlling

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 34

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

pathogens

P

Introducin Filtering 3 2 6 NS

g foreign after

materials preparation

Introducin B Minimize 2 4 8 NS

g product

vegetative exposure to

microbes air

P 3 2 6 NS

[30] Syrup filtering Contamin Frequent

ation with inspection to

physical ensure free

impurities of

contaminati

on.

Introducin

g B Adhere to 2 3 6 NS

pathogeni GMP

c bacteria

due to

manual

handling P Frequent 3 2 6 NS

[31] Syrup transferring

inspection to

Introducin ensure free

g sand, of

dust or contaminati

foreign on

maters

Contamin P Adhere to 2 2 4 NS

[32] ation with GMP

Adding colours

physical

impurities

Raw Material / Food Control and Hazard Analysis Significant/

Potential Category

Step Contact Material/ Preventive Risk Non

Hazard (B/C/P) Probability Severity

Process Step Measure Level significant

Chocolate coating

[33] Introducin B Adhere to 3 2 6 NS

g GMP and

pathogeni GHP

c bacteria

due to

manual

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 35

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

handling

Contamin B Preventive 3 2 6 NS

ated with maintenance

Microbes – Filter

presence cleaning of

[34] Cooling with blow in Air compressors

air

Contamin P 3 2 6 NS

ation with

physical

impurities

Contamin P Filtering 3 2 6 NS

ation with Sugar syrup

[35] Sugar coating physical prior to use

impurities

Contamin P Filtering 3 2 6 NS

ation with Sugar syrup

[36] Colour coating physical prior to use

impurities

Contamin

Polishing ation with

[37] physical P Adhere to 3 2 6 NS

impurities GMP/ GHP

Raw Material / Food Control and Hazard Analysis Significant/

Potential Category

Step Contact Material/ Preventive Risk Non

Hazard (B/C/P) Probability Severity

Process Step Measure Level significant

[38] Weighing and Introducin B Pest 3 3 9 NS

mixing (batter and g live controlling

cream) dead in the plant

insects/

debris C Adhere to 2 1 2 NS

GMP (using

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 36

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Contamin food grade

ation with chemicals)

lubricants

Recipe

C weight 3 4 12 S

Introducin controlling

g extra

amount of Calibration

additives of scales

Introducin Adhere to 2 2 4 NS

g dust, P GMP -

foreign Preventive

materials maintenance

[39] Introducin B Minimize 2 4 8 NS

g product

vegetative exposure to

microbes air

P 4 3 12 S

Filtering Batter Contamin Frequent

ation with inspection to

physical ensure free

impurities of

contaminati

on.

[40] Introducin B Maintain 3 4 12 S

g time

vegetative temperature

Wafer Biscuit microbes combination

accurately

Baking

Raw Material / Food Control and Hazard Analysis Significant/

Potential Category

Step Contact Material/ Preventive Risk Non

Hazard (B/C/P) Probability Severity

Process Step Measure Level significant

[40] Wafer Biscuit Contamin P Frequent 2 2 4 NS

Baking ation with inspection to

physical ensure free

impurities of

contaminati

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 37

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

on

[41] Cooling Wafer Contamin C Adhere to 2 4 8 NS

Biscuit ation with GMP

lubricants

Introducin P Adhere to 3 2 6 NS

g dust, GMP

foreign Preventive

materials maintenance

[42] Cream transferring Contamin P Frequent 2 2 4 NS

ation with inspection to

physical ensure free

impurities of

contaminati

on

[43] Cream deposition Introducin P Adhere to 2 2 4 NS

g dust, GMP

foreign

materials

[44] Pressing of cream Introducin P Adhere to 2 2 4 NS

g dust, GMP

foreign

materials

Introducin

[45] Cooling g live B Frequent 3 2 6 NS

dead inspection to

insects/ ensure free

debris of

Introducin contaminati

g dust, on 2 2 4 NS

foreign

P Adhere to

materials

GMP

Raw Material / Food Control and Hazard Analysis Significant/

Potential Category

Step Contact Material/ Preventive Risk Non

Hazard (B/C/P) Probability Severity

Process Step Measure Level significant

[46] Wire cutting Introducin P Adhere to 2 2 4 NS

g dust, GMP and

foreign GHP

materials

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 38

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

Introducin

g B Adhere to

pathogeni GMP and

c bacteria GHP

due to

manual Frequent

handling inspection to

ensure free

of

contaminati

on

[47] Biscuit WIP Storing Introducin P 2 2 4 NS

g dust,

foreign Adhere to

materials GMP and

GHP

Introducin

g B 3 2 6 NS

pathogeni

c bacteria

due to

storage

[48] Biscuit Feeding Introducin B Adhere to 3 2 6 NS

g GMP and

pathogeni GHP

c bacteria

due to

manual

handling

[49 Chocolate Enrobing Introducin P Adhere to 3 2 6 NS

& and Cooling g dust, GMP and

50] foreign GHP

materials

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 39

Doc. No. FSM

EDNA CHOCOLATES CEYLON (PVT) LTD Issue No. 05

Issue Date 2015.06.23

Food Safety Manual

No. 00

7.4.4 Selection and Assessment of Control Measures

Based on the hazard assessment an appropriate combination of control measures has been selected

which is capable of preventing, eliminating or reducing these food safety hazards to defined acceptable

levels.

The selection and categorization carried out using a logical approach that includes assessments with,

a. Feasibility for monitoring

Prepared by Reviewed by: Approved by:

Quality Assurance Plant

Executive Manager GM/HOM

Page | 40