Professional Documents

Culture Documents

Book 1

Book 1

Uploaded by

arifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Book 1

Book 1

Uploaded by

arifCopyright:

Available Formats

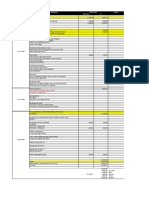

LIFTING LUG CALCULATION - ASME B30.

20 For Below The Hook Lifting Device

INPUT DATA PARAMETER

GENERAL

Lifting Force Per Lug Pu = 15 kN

Design Factor for Yield/Buckling Nd = 2 Design factor for yield or buckling (Nd= 2 for category A)

Value for CR Cr = 0.9 For Dp/DH > 0,9

Minimum Safety Factor

DIMENSION

Lug Width W= 30 mm

Lug Thickness t= 6 mm

Hole Diameter DH = 15 mm

PinDia Meter Dp = 12 mm

Centerline Distance a+Dh/2 = Dc = 32.5 mm

Lug Distance a= DL = 25 mm

Of = 35 mm

LUG MATERIAL PROPERTIES

Ultimate Tensile Strength Fu = 410 Mpa

Ultimate Yield Strength Fy = 240 Mpa

Modulus Elesticity E= 210000 Mpa

TENSILE FAILURE OF THE HEAD CALCULATION

Allowable Tensile Strength Pt = Cr*Fu*At/1,2*Nd

be = (W-Dh)/2 = 7.500 mm

4t = 24.000 mm

be*0,6Fu/Fy*√Dh/be) = 10.872 mm

beff = Min(be, 4t, be*0,6Fu/Fy*√Dh/be) = 7.500 mm

At = 2*t*beff = 90.000 mm2

Pt.u = Cr*Fu*At 33210 N

Pt = 13.84 kN > Pu ==> Ok

SINGEL PLANE FAILURE STRENGTH CALCULATION

Allowable Singel Plane Failure Strength Pb = Cr*Fu/(1,2*Nd)*(1,13*DL+0,92*be/(1+be/DH))*t

Pb = 30304 N

Pb = 30.304 kN > Pu ==> Ok

SINGEL PLANE FAILURE STRENGTH CALCULATION

Allowable Double Plane Shear Strength Pv = 0,7*Fu/(1,2*Nd)*A

Av = 2*DL*t

Av = 300.000 mm2

Pv = 35.9 kN > Pu ==> Ok

CHECK PIN BEARING

Ultimate Pin Bearing Fu = Pu / (2*t*Dp)

Fu = 104 Mpa

Allowable Pin Bearing Stress Fn = 1,2*Fy/Nd

Fn = 144 Mpa > Fu ==> Ok

CHECK LATERAL BENDING

Horizontal Load Fx = 10% x Pu = 1.5 Mpa

Elastic Modulus Sx = 1/6*W*t^2 = 180 mm2

Bending Moment Mx = Fx*of = 53 kN.mm

Ultimate Bending Stress fbs = Mx/Sx 291.7 Mpa <0,65fFy ==> Ok

Load Model Dimension

Concrete iron

L 1

W 1

H/t 0.2

Vol 0.2 2300 460 7850 1570

You might also like

- Friendly Introduction To Number Theory 4th Edition by Silverman ISBN Solution ManualDocument7 pagesFriendly Introduction To Number Theory 4th Edition by Silverman ISBN Solution Manualdaisy94% (34)

- Splice Connection CHSDocument180 pagesSplice Connection CHSRaveendra Babu Cherukuri100% (2)

- Overwatch D&DDocument7 pagesOverwatch D&Dnatni8No ratings yet

- Rigging LoftDocument2 pagesRigging LoftarifNo ratings yet

- Pile Rebar DesignDocument4 pagesPile Rebar Designprakash100% (1)

- Design Calculation of Pile FoundationDocument3 pagesDesign Calculation of Pile Foundationkavitha100% (5)

- Base Plate CircularDocument8 pagesBase Plate Circularmrprabhu16No ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Personal Best A1 Unit 8 Reading TestDocument3 pagesPersonal Best A1 Unit 8 Reading TestLuis Fernando Osorio SanchezNo ratings yet

- M. Ashraf Adeel - Epistemology of The Quran - Elements of A Virtue Approach To Knowledge and Understanding-Springer Internati PDFDocument141 pagesM. Ashraf Adeel - Epistemology of The Quran - Elements of A Virtue Approach To Knowledge and Understanding-Springer Internati PDFimreadingNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkkiran raghukiranNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkkiran raghukiranNo ratings yet

- SPLICEDocument11 pagesSPLICEAgus SholehudinNo ratings yet

- Beam To Column'S Flange Fixed Connection Type Bcff-1: 1-Design DataDocument5 pagesBeam To Column'S Flange Fixed Connection Type Bcff-1: 1-Design DataAchmad RifaiNo ratings yet

- Initial Load Test Pile-Calc (450 MM) Rev0Document2 pagesInitial Load Test Pile-Calc (450 MM) Rev0sathishNo ratings yet

- Beam Design With Deflection CheckDocument6 pagesBeam Design With Deflection CheckKeshav RimalNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection CheckPranshu PalNo ratings yet

- Single Span Fixed Beam Design of Beam As Per Is 456:2000: For SupportDocument7 pagesSingle Span Fixed Beam Design of Beam As Per Is 456:2000: For SupportDipankar NathNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection CheckIndustry Standard Structural DesignNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection CheckAnil kumar RNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection CheckDEVANG VIJAY SHINDENo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection CheckStructural SpreadsheetsNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection CheckDevesh GuptaNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection CheckPranshu PalNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection CheckSitaram PREDCRNo ratings yet

- Samb Expand End PlateDocument5 pagesSamb Expand End PlateArbiNo ratings yet

- BS5950 End Plate DesignDocument4 pagesBS5950 End Plate DesignFodor ZoltanNo ratings yet

- Two Slab DistontinuesDocument4 pagesTwo Slab DistontinuesAnonymous Of0C4dNo ratings yet

- Splice ConnectionDocument18 pagesSplice ConnectionAhmad Pooladi0% (1)

- Steeltek Connection GeneralDocument5 pagesSteeltek Connection GeneralcadsultanNo ratings yet

- Rolled - MomentDocument5 pagesRolled - MomentAdekimi EmmanuelNo ratings yet

- Design of Tie Beam (TB)Document3 pagesDesign of Tie Beam (TB)Khael Angelo Zheus JaclaNo ratings yet

- Column Design2 (Final) PRINTDocument13 pagesColumn Design2 (Final) PRINTAashish MaharjanNo ratings yet

- Cantiver Beam DesignDocument2 pagesCantiver Beam DesignRathinavel VenkateshwaranNo ratings yet

- AISC Connection-2nd Edition (2+2) Bolts Conn Between Tub Col & I-BeamDocument4 pagesAISC Connection-2nd Edition (2+2) Bolts Conn Between Tub Col & I-BeamTuấnThanhNo ratings yet

- Beam Design MenukaDocument3 pagesBeam Design Menukaprakashchalise1993No ratings yet

- Calculation 1Document8 pagesCalculation 1BALANo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkbasanth babuNo ratings yet

- Footing DesignsDocument2 pagesFooting DesignsVishwajith KadriNo ratings yet

- Section Properties: Column Design As Per IS:456-2000 Column No. 3Document4 pagesSection Properties: Column Design As Per IS:456-2000 Column No. 3Eknath TaleleNo ratings yet

- Sa 4Document3 pagesSa 4Khael Angelo Zheus JaclaNo ratings yet

- 4.5 Column Beam Capacity CheckDocument1 page4.5 Column Beam Capacity Checkvijay kumar yadavNo ratings yet

- Rectangular Footing F1Document4 pagesRectangular Footing F1haroon alikhanNo ratings yet

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleNo ratings yet

- A1. SGH CanopyDocument41 pagesA1. SGH CanopyMoustafaNo ratings yet

- Design of Isolated Footing For Security Room: Node No. XDDocument12 pagesDesign of Isolated Footing For Security Room: Node No. XDvenu manikantaNo ratings yet

- Bracing Connection Design PDFDocument3 pagesBracing Connection Design PDFriaz16shaik100% (1)

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Design of Column SpliceDocument2 pagesDesign of Column SpliceAndro Rebuyas100% (1)

- 3.0 Butterfly Valve Chamber Precast Panel DesignDocument2 pages3.0 Butterfly Valve Chamber Precast Panel DesignGaurav BhabadNo ratings yet

- Single Plate Connection - Sheet1 - 2Document3 pagesSingle Plate Connection - Sheet1 - 2AbdullahibnfulanNo ratings yet

- 1Padeye-Design-Cheek-xls SWL WeirDocument1 page1Padeye-Design-Cheek-xls SWL Weircannyengineering.sNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal Vesselmiteshpatel191100% (2)

- Tower Crane Pile Foundation - dc2Document4 pagesTower Crane Pile Foundation - dc2venkatram PadalaNo ratings yet

- Apartment Structural DesignDocument29 pagesApartment Structural DesignpolarisNo ratings yet

- AISC Connection 2nd Edition (4+2) Bolts Knee No UseDocument6 pagesAISC Connection 2nd Edition (4+2) Bolts Knee No UseTuấnThanhNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- Beam Design by SP 16 PDFDocument1 pageBeam Design by SP 16 PDFRafeeq khanNo ratings yet

- Design of T-BeamDocument6 pagesDesign of T-BeamDineshNo ratings yet

- One Side Beam-Beam ConnectionDocument1 pageOne Side Beam-Beam Connectionsamon.itc2019No ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- DrawingDocument3 pagesDrawingarifNo ratings yet

- SIMULASIDocument1 pageSIMULASIarifNo ratings yet

- Report SapDocument42 pagesReport SaparifNo ratings yet

- LIFTING PLAN Tanki Sub Satelit (1-2)Document1 pageLIFTING PLAN Tanki Sub Satelit (1-2)arifNo ratings yet

- Load Information: Hitch Information:: Tensions Are Based On Both Legs Carrying Proper Share of The LoadDocument1 pageLoad Information: Hitch Information:: Tensions Are Based On Both Legs Carrying Proper Share of The LoadarifNo ratings yet

- Logging Truck Noise LevelDocument1 pageLogging Truck Noise LevelarifNo ratings yet

- Roxtec Cable Seals: For Power Transmission and Distribution ApplicationsDocument24 pagesRoxtec Cable Seals: For Power Transmission and Distribution ApplicationsarifNo ratings yet

- Sany 250Document9 pagesSany 250arifNo ratings yet

- Low Pressure Portable Flare Stack: Product Description ApplicationsDocument2 pagesLow Pressure Portable Flare Stack: Product Description ApplicationsarifNo ratings yet

- Tandem Lifting Container SWGDocument1 pageTandem Lifting Container SWGarifNo ratings yet

- Saracrease HG 10Document2 pagesSaracrease HG 10NAGARAJNo ratings yet

- Bridgewave 2x80ghzDocument2 pagesBridgewave 2x80ghzsimog1972No ratings yet

- Toronto TorahDocument4 pagesToronto Torahoutdash2No ratings yet

- All Bodies Are Beautiful: Don't Know Where To Start With Your Assignment?Document1 pageAll Bodies Are Beautiful: Don't Know Where To Start With Your Assignment?Hades RiegoNo ratings yet

- Speech On Independence DayDocument1 pageSpeech On Independence DayMurtazaNo ratings yet

- Mars EssayDocument3 pagesMars EssayAlejandro Cervantes100% (1)

- Shark Tank Episodes: Season 2 Episode ProductsDocument2 pagesShark Tank Episodes: Season 2 Episode ProductsAdelfa Alap-apNo ratings yet

- Date Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)Document1 pageDate Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)PatOcampoNo ratings yet

- HealthcareStudentWorkbook XIIDocument130 pagesHealthcareStudentWorkbook XIIRobin McLarenNo ratings yet

- Lesson Plan For BEEEDocument18 pagesLesson Plan For BEEEdineshanand810100% (1)

- HZ2322 EM250 Series 100mW ZigBee Module (ENG)Document10 pagesHZ2322 EM250 Series 100mW ZigBee Module (ENG)MicroComSolutionsNo ratings yet

- Document Analysis Worksheet: Analyze A PaintingDocument4 pagesDocument Analysis Worksheet: Analyze A PaintingPatrick SanchezNo ratings yet

- Guidelines On Good Research PracticeDocument9 pagesGuidelines On Good Research PracticeAndre SetiawanNo ratings yet

- Navigate A1 WB Answer KeyDocument12 pagesNavigate A1 WB Answer KeyFirenze CalzadosymasNo ratings yet

- Air Is Allowed To Flow From A Large Reservoir ThroDocument3 pagesAir Is Allowed To Flow From A Large Reservoir Throsid202pkNo ratings yet

- Colgate-Palmolive Makes A Total EffortDocument2 pagesColgate-Palmolive Makes A Total EffortNandini NagabhushanNo ratings yet

- Algo Trading BasicsDocument15 pagesAlgo Trading BasicsRajvin DongaNo ratings yet

- In-Depth Interviews & EthnographyDocument29 pagesIn-Depth Interviews & EthnographyJin ZuanNo ratings yet

- TracebackDocument3 pagesTracebackCristi LazărNo ratings yet

- DP 12 2 Practice PDFDocument2 pagesDP 12 2 Practice PDFFlorin CatalinNo ratings yet

- Victor Manuel Chevere v. Jerry Johnson Stephen Kaiser Rick E. Peters Jim Keith Bob Affolter, 38 F.3d 1220, 10th Cir. (1994)Document4 pagesVictor Manuel Chevere v. Jerry Johnson Stephen Kaiser Rick E. Peters Jim Keith Bob Affolter, 38 F.3d 1220, 10th Cir. (1994)Scribd Government DocsNo ratings yet

- MC CSSM JR Correction LSCQ3023 Courier Delivery Executive 16.07.2018Document16 pagesMC CSSM JR Correction LSCQ3023 Courier Delivery Executive 16.07.2018Abhishek ThakurNo ratings yet

- Royal College Grade 11 Tamil Literature Second Term Paper 2022Document9 pagesRoyal College Grade 11 Tamil Literature Second Term Paper 2022naveen naveenan50% (2)

- Bail Application OringiDocument5 pagesBail Application OringiDaniel Dayan SabilaNo ratings yet

- Alfafara V Acebedo Optical CompanyDocument1 pageAlfafara V Acebedo Optical CompanyMaria Cristina MartinezNo ratings yet

- Surgical Technique: Available in Titanium and Stainless SteelDocument53 pagesSurgical Technique: Available in Titanium and Stainless SteelJorge Trinidad de la CruzNo ratings yet