Professional Documents

Culture Documents

Terms & Conditions

Terms & Conditions

Uploaded by

Praveen Raj0 ratings0% found this document useful (0 votes)

11 views6 pagesT&C

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentT&C

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

11 views6 pagesTerms & Conditions

Terms & Conditions

Uploaded by

Praveen RajT&C

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

TENDER FOR Supply, Installation and commissioning OF AIR DRYER

at PIYALA LPG PLANT

‘SCOPE OF WORK and SPECIAL TERMS & CONDITIONS

Note: Bidders must read these conditions carefully and comply strictly while submitting

their bids. Rates once quoted shall be firm and final, no revision of rates shall be permitted

1. Since this is e-tender hence it is expected that bidder are well conversant with the GeM-

procurement site before participating in the bidding process. Please quote your lowest rates

{for thejob in e-Tender format only as given in the online e-tender portal. The tender will be

evaluated based on total cash out flow inclusive of all taxes and duties as applicable.

2. The company reserves the right to reject any one of the offers without assigning any reason.

3. Liquidation damages shall be recovered from the contractor in case of delay of

execution, asper general terms & conditions.

4. Every page of tender documents shall be signed and stamped by the tenderer or his

authorized representative.

5. The rates quoted by the tenderer shall be inclusive of all taxes, BPCL will not pay any

amount towards other taxes, levies, fees and the successful tenderer will have to adhere to

all Govt. rules ®ulations ete.

6. No payment will be made in advance. TDS will be deducted as per prevailing rules

®ulations.

7. TECHNICAL SPECIFICATION AND SCOPE OF SUPPLY

‘+ Compressed air entering the air net is always 100% saturated. When it cools, the moisture

will condense, causing damage to your air system and finished products. Removing moisture

from compressed air refrigerant dryers eliminate system failures, production downtime and

costly repairs.

Keeping our Production Running Even in the Harshest Conditions

The temperature in many compressor rooms often rises above 40°C. The air dryer is specially

designed to run optimal in these heavy conditions and can easily cope with higher peaks. This

together with simple and easy controls guarantee the dryer operates in the best way possible.

Easy Installation and Long Maintenance Intervals

Air dryers have a small footprint thanks to the all-in-one design. Delivered ready for use, installation

is straightforward, minimizing costly production downtime. All internal components are easily

accessible to facilitate ergonomic maintenance. All components are defined to the highest standard

of quality to ensure a long lifetime.

Refrigerant circuit

The refrigerant circuit compresses and expands the refrigerant medium in a circular system in

order to efficiently transfer heat from the wet compressed air to the atmosphere. The Air dryer's

refrigerant circuit is designed as a whole and only uses components of high and reliable quality,

supplied by globally recognized manufacturers. ForSPNAQM TECHNOLOGIES INDI PVE LTD

Refrigerant separator

Ensures that only refrigerant gas can enter the compressor, as liquid would cause damage.

Refrigerant compressor

Brings the gaseous refrigerant to a high pressure and a high temperature.

Max. pressure switch

Protects by ensuring that the refrigerant gas never exceeds the maximal pressure.

Fan control pressure switch

‘Saves energy by temporarily turning of the condenser fan when the load on the dryer is low.

Condenser fan

Efficiently provides constant flow of ambient air to the air condenser. (only for air cooled)

Condenser

Cools the refrigerant slightly so that it can change from gas to liquid; refrigerant is more effective in

the liquid state.

Filter

Protects the expansion device from harmful particles.

Expansion valve

Reduces the reftigerant’s pressure, thereby lowering its temperature and increasing its cooling

capacity; the refrigerant is now almost all liquid, with some residual gas. Capillary tubes are

expansion devices that are extremely reliable, and stabilize the dewpoint of the dryer.

Air circuit

Wet compressed air flows directly through the dryer's internal 3-in-1 heat exchanger, wherein the

3 key dryer functions are combined. Firstly the wet compressed air is cooled down to condensate

the moisture, secondly this condensed moisture will be collected and drained out. Finally the dried

‘compressed air is re-heated before it enters the factory's pipework

Hot gas bypass

regulates the amount of refrigerant passing through the air-to-refrigerant heat exchanger, ensuring

a stable pressure dewpoint, and eliminating the chance of the condensate freezing,

Air inlet

Hot saturated air enters the dryer.

Air-to-refrigerant heat exchanger

Transfers heat from the compressed air to the cold refrigerant, forcing water vapor

compressed air to condense.

the

Air-to-air heat exchanger

Cools down the air inlet whilst re-heating the outlet air.

Water separator

Collects and drains out condensate from the cooled air flow 3-in-1 aluminium heat exchangers

combine above points making them highly efficient and reliable.

Automatic drain ‘For SPIN ADM TECHNOLOGIES INDIA PYT. LID.

Removes the free water collected in the water separator.

4 ,

GNA

Sona

Re-heats the outgoing air to prevent condensation on the factory's pipework

Robust and compact design

Solid base frame with very small footprint

Standard canopy, from smallest to largest size, ensures quiet, clean, and safe operation

High-quality components

Globally recognized manufacturers with highest level of expertise and reliability

Sequence of components designed to operate as one system to optimize performance

Top of the range heat exchanger

1 technology designed dedicated for each size

Low pressure drop by the integration of “air-to air’, “air-to-refrigerant” and *

Compartments,

Suitable for heavy and even subtropical conditions

ater separation”

Delivering quality compressed air in heavy ambient conditions is common practice for the air

dryer due to its design with high reference conditions & high limit conditions (see technical

Even during temporary overload continuous operation is guaranteed

Electronic water drain

Automatically removes free water collected in the water separator

Easy installation and maintenance

The plug and play principle ensures direct air quality

Air dryers save space while making it more simple to reach for easy maintenance

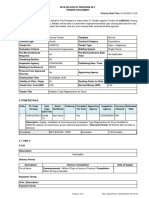

TECHNICAL SPECIFICATIONS.

Outlet pressure dewpoint

Weight

Dimensions(approx.

pepe (prox)

]

Length widty | Height

Ba

bar | psi

|

inch | mm |inch| mm ]inch

|

A | 472 | (000/015 2 | 10 | 145 jatswisis0) 1025

40 | 660 [258 1198 [44-1| 230 [507

|

For SPIN AGM TECHNOLOGIES INDIA PVT LTD.

+ The successful tenderer shall provide the transportation and delivery of the material

to the plant.No additional transportation cost will be charged by the tenderer. The

cost of transportation shallbe included in the rate quoted by tenderer.

+ Any damage during transportation will be borne by the successful tenderer. All

damaged materialwill be replaced by the successful tenderer free of cost within 15

days of receipt of damaged material. Entry of all material should be made in the

material in/out register.

+ Payment will be made after successful completion of job at the site and the

performance is foundsatisfactory.

If the quality of job is found to be unsatisfactory or not according to the specifications, the

whole quantity shall be rejected by BPCL.

Scope of work shall include supply, transportation and delivery at store of Piyala LPG plant.

Please quote your rates accordingly. Rates once quoted shall be firm and final and no

revision in the same will be allowed.

8 Payment Conditions:

Payment against invoices shall be made after successful delivery at store of Piyala LPG plant

or as directed by the officer in charge subjected to submission of following documents along

with your invoices.

‘* Delivery challan / Lorry Receipt duly acknowledged by our:

9. Security Deposit

The successful Tenderer, before commencement of the work, shall have to provide to

company, by way of security deposit, in form of Bank’s Demand Draft amount equivalent to

3% of the total tendered value of the works, subject to a minimum of ‘5,000/- and a maximum

of '1,00,000/- in favour of "Bharat Petroleum Corporation Ltd" payable at New Delhi after

issuance of LO!

10. Other terms and conditions

Material has to be supplied at Plant address as provided below. Unloading of material will

be arranged by supplier as directed by BPCL representative. No additional payment shall be

made in this regard.

Packing & forwarding: the materials should be properly packed so as to withstand all transit

hazards. Road permit shall be issued by BPCL. Loading/Unloading will be in scope of the bidder

and advanced intimation is to be given to the location by the bidder.

Delivery: The lorry receipt date shall be treated as date of dispatch / date of completion of delivery.

The delivery is to be completed as mention in LO!

Specifications: The dimensionsimakes/models are mentioned within the item texts. In case any

Clarification is required or for the items for which dimensions are not mentioned bidder may contact

the BPCL. Valid Test certificate of the material used is to be submitted before dispatching the material

to BPCL. All the items will be accepted only if they mest t jonal specifications as per the

BPCL officer in-charge. . " : ec RADE Te CH 3S IMDIA PVT. ETD,

Sick.

Documents: all documents listed below (in triplicate) whichever is applicable should be submitted

for payments:

‘A) Invoice

8) Challan

©) Lorry receiptiGR

) Inspection release note along with the material test certificates,

E) Original money receipt for octroi charges

F) Guarantee certificate

G) Excise gate pass & other relevant documents.

Warranties: Material should be guaranteed for all material, subassemblies, workmanship free from

manufacturing and operation defects. In case of any defects/rejections during the guarantee period

the same should be replaced by you free of cost.

k purchase clause: We reserve the right to curtail or cancel the order either in full or part thereof

if you fail to comply with delivery schedule and other terms and conditions of the order. BPCL also

reserves the right to procure same or similar materials / equipment through other sources at your

entire risk, cost and consequences.

You should warrant that the use BPCL of materials specified by you will not subject BPCL to charges

of infringement of any patent & further agree to hold BPCL harmless & indemnified against any & all

costs, charges & expenses resulting there from.

Rejected materials lying in BPCL premises must be replaced within 30 days from the date of

intimation to you.

Delivery Address and contact person details:

ADDRESS: B PCL “PIYALA LPG BOTTLING PLANT,

VILL- Piyala , P.O: Asaoti, Tesil: Baalbgarh,

Faridabad, Haryana -121102

For SPIN AQM TECHNOLOGIES iNDkx PVE, Lv

Ms

y Sy

bh >

fo at,

11. Delivery of material: Delivery to be done within 05 days from Purchase order. Vendor

would be responsible for the safe loading, unloading and transportation of the material

throughout. The payment for transportation shall be done by successful bidder BEFORE THE

DISPATCH, hence bids should be submitted inclusive of the transportation cost from

manufacturing site to the above mentioned address.

12, The contractor and his men shall abide by all security / safety rules / regulations in force at

the plant location.

13. No change in specifications/counter conditions on tender terms & conditions shall be

allowed.

14. In the event of any defect in the material, the vendor

BPCL's concerned loc:

replace / repair the material at

n at vendor's risk and cost on due notice.

15. All supporting documents are to be self-certified and uploaded on BPCL’s e procurement

site,

CERTIFICATE: I/We have fully understood all above terms and conditions and I/ We accept the

same fully.

NAME OF VENDOR: Mls SplpQQM Tgrhatogles Incia Private Lit

HES IND PTT,

SIGNATURE WITH SEAL:

DATE: 05/06/2023 4, =

'Signttory

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Self CertificationDocument1 pageSelf CertificationPraveen RajNo ratings yet

- Indian Railways: South Western RailwayDocument89 pagesIndian Railways: South Western RailwayPraveen RajNo ratings yet

- Government of India Government of India Government of India Government of IndiaDocument47 pagesGovernment of India Government of India Government of India Government of IndiaPraveen RajNo ratings yet

- Final Specs - 2023 01 30 15 40 10Document3 pagesFinal Specs - 2023 01 30 15 40 10Praveen RajNo ratings yet

- viewNitPdf 4133031Document4 pagesviewNitPdf 4133031Praveen RajNo ratings yet

- DocScanner01 Feb 202309 51Document1 pageDocScanner01 Feb 202309 51Praveen RajNo ratings yet

- Trident BHRD ManualDocument11 pagesTrident BHRD ManualPraveen RajNo ratings yet

- Sahara Regenerative Air Dryers 03 2020Document32 pagesSahara Regenerative Air Dryers 03 2020Praveen RajNo ratings yet

- ACCUMULATOR CatalogueDocument2 pagesACCUMULATOR CataloguePraveen RajNo ratings yet

- Copper Alloy C13600Document2 pagesCopper Alloy C13600Praveen RajNo ratings yet