Professional Documents

Culture Documents

Astm-D3878 2007 878903303226

Astm-D3878 2007 878903303226

Uploaded by

Malik AzeemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm-D3878 2007 878903303226

Astm-D3878 2007 878903303226

Uploaded by

Malik AzeemCopyright:

Available Formats

https://asrecomposite.

com

Designation: D 3878 – 07

Standard Terminology for

Composite Materials1

This standard is issued under the fixed designation D 3878; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope breather string, n—a string, composed of a material such as

1.1 These definitions cover generic terms, including terms glass, that provides a vacuum path from the laminate to a

of commercial importance, that appear in one or more stan- breather.

dards on composites containing high-modulus (greater than bundle—a general term for a collection of essentially parallel

20-GPa (3 3 106 psi)) fibers. filaments.

1.2 The definitions cover, in most cases, special meanings carbon fiber precursor—a material from which carbon fiber

used in the composites industry. No attempt has been made to is made by pyrolysis. Polyacrylonitrile, rayon, or pitch fibers

include common meanings of the same terms as used outside are commonly used precursors.

the composites industry. catenary:

1.3 Definitions included have, in general, been approved as filament catenary—the difference in length of the filaments

standard. in a specified length of tow, end, or strand as a result of

unequal tension; the tendency of some filaments in a taut

2. Referenced Documents horizontal tow, end, or strand to sag lower than others.

2.1 ASTM Standards: 2 roving catenary—the difference in length of the ends, tows,

D 123 Terminology Relating to Textiles or strands in a specified length of roving as a result of

2.2 Military Standard: unequal tension; the tendency of some ends, tows, or strands

MIL-HDBK-17 3 in a taut horizontal roving to sag lower than others.

caul, n—a flat or contoured tool used to distribute pressure and

3. Terminology to define a surface for the top of the laminate during laminate

3.1 Definitions: consolidation or cure.

co-fabrication, n—in sandwich constructions, a fabrication

645° laminate—a balanced symmetric laminate composed of process where items such as inserts and other structural

only +45° plies and −45° plies. details are bonded into the panel at the same time that the

angleply laminate—any balanced laminate consisting of plus facings are bonded to the core.

and minus theta plies where theta is an acute angle with composite:

respect to a reference direction. composite material—a substance consisting of two or more

balanced laminate—any laminate that contains one ply of materials, insoluble in one another, which are combined to

minus theta orientation with respect to the laminate principal form a useful engineering material possessing certain prop-

axis for every identical ply with a plus theta orientation. erties not possessed by the constituents.

braided fabric—see braided fabric under fabric.

DISCUSSION—a composite material is inherently inhomogeneous on a

microscopic scale but can often be assumed to be homogeneous on a

1

This terminology is under the jurisdiction of ASTM Committee D30 on macroscopic scale for certain engineering applications. The constitu-

Composite Materials and is the direct responsibility of Subcommittee D30.01 on ents of a composite retain their identities: they do not dissolve or

Editorial and Resource Standards. otherwise merge completely into each other, although they act in

Current edition approved May 1, 2007. Published June 2007. Originally concert.

approved in 1981. Last previous edition approved in 2004 as D 3878 – 04a.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or discontinuous fiber-reinforced composite—any composite

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM material consisting of a matrix reinforced by discontinuous

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

fibers. The fibers may be whiskers or chopped fibers.

3

Available from ASTM International as The Composite Materials Handbook— fabric-reinforced composite—any composite material con-

MIL 17. Also available as MIL-HDBK-17 from Standardization Documents Order sisting of a matrix reinforced by fabric (woven, knitted, or

Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111- braided assemblages of fibers).

5094

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

--`,,```,,,,````-`-`,,`,,`,`,,`---

1

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

https://asrecomposite.com

D 3878 – 07

fiber-reinforced composite—any composite material consist- generally is, different than for the same level of tensile load.

ing of a matrix reinforced by continuous or discontinuous Damage resistance is often confused with damage tolerance. Dam-

fibers. age tolerance is directly related only to the size and type of damage

while being only indirectly related to how the damage was created (see

filamentary composite—a composite material reinforced damage resistance). Thus, damage tolerance is distinct from damage

with continuous fibers. resistance.

unidirectional fiber-reinforced composite—any fiber-

reinforced composite with all fibers aligned in a single debond—a deliberate separation of a bonded joint or interface,

direction. usually for repair or rework purposes.

continuous filament yarn, n—two or more continuous fila- debulk, v—to decrease voids between lamina before laminate

ments twisted into a single fiber bundle. consolidation through use of vacuum or by mechanical

crossply laminate—a laminate composed of only 0 and 90° means.

plies. This is not necessarily symmetric. DISCUSSION—Laminae can be debulked at ambient or elevated

dam, n—a solid material (such as silicone rubber, steel, or temperatures.

aluminum), used in processing composites, to contain the

delamination—separation of plies in a laminate. This may be

matrix material within defined boundaries or to prevent

local or may cover a large area in the laminate.

crowning of a processing bag.

denier, n—a direct numbering system for expressing linear

damage, n—in structures and structural mechanics, a struc-

density, equal to the mass in grams per 9000 metres of yarn,

tural anomaly in material or structure created by manufac-

filament, fiber, or other textile strand.

turing or service usage.

disbond—an area within a bonded interface between two

damage resistance, n—in structures and structural mechan-

adherents in which an adhesive or cohesive failure has

ics, a measure of the relationship between the force, energy,

occurred. It may occur at any time during the life of the

or other parameter(s) associated with an event or sequence of

structure and may arise from a wide variety of causes. It is

events and the resulting damage size and type.

--`,,```,,,,````-`-`,,`,,`,`,,`---

sometimes used to describe an area of separation between

DISCUSSION—Damage resistance increases as the force, energy, or two laminae in the finished laminate (the term “delamina-

other parameter increases for a given size or type of damage. Con- tion” is preferred).

versely, damage resistance increases as damage decreases, for a given discontinuous fiber—a polycrystalline or amorphous fiber

applied force, energy, or other parameter. Damage resistance and

damage tolerance are often confused. A material or structure with high

that is discontinuous within the sample or component or that

damage resistance will incur less physical damage from a given event. has one or both ends inside of the stress field under

Materials or structures with high damage tolerance may incur varying consideration. The minimum diameter of a discontinuous

levels of physical damage but will have high amounts of remaining fiber is not limited, but the maximum diameter may not

functionality. A damage-resistant material or structure may, or may not, exceed 0.25 mm (0.010 in.).

be considered damage tolerant. end, n—in fibrous composites, a general term for a continuous,

damage tolerance, n—1) in structures and structure materi- ordered assembly of essentially parallel, collimated fila-

als, a measure of the relationship between damage size and ments, with or without twist.

type and the level of a performance parameter, such as DISCUSSION—This term covers tow, strand, sliver, yarn, and roving.

stiffness or strength, at which the structure or structural The relationship between fiber form terms is shown in Table X1.1.

material can operate for a particular loading condition; 2) in

fabric—a planar textile (Synonym: cdth)

structural systems, a measure of the ability of such systems

braided fabric, n—a cloth constructed by a braiding process.

to function at designated performance parameters (for ex-

knitted fabric, n—a cloth constructed by a knitting process.

ample, magnitude, length of time, and type of loading(s))

nonwoven fabric, n—a cloth constructed by bonding or

without system failure in the presence of a particular or

interlocking, or both (but not interlacing) fiber by any

specified level of damage.

combination of mechanical, chemical, thermal, or solvent

DISCUSSION—Damage tolerance involves, and can be provided by, a means.

number of factors operating at a number of levels: structural material, plied yarn, n—a yarn formed by twisting together two or

structural, and overall system. These factors include 1) basic material

more single yarns in one operation.

ability to operate with damage present (often referred to as the residual

strength aspect), 2) damage growth resistance and containment pro- DISCUSSION—Plying, which is done in the opposite direction from the

vided by material and structural considerations, and 3) system inspec- twist of each of the simple yarns, serves to counter the tendency of

tion and maintenance plans which allow the damage to be detected and simple yarns to untwist.

corrected and which depend upon material, structural, and operational

considerations. woven fabric, n—a cloth constructed by a weaving process.

Damage tolerance increases as the damage size increases for a given fabrication, n—the process of manufacturing, forming, con-

level of a performance parameter. Damage tolerance increases as the structing, or assembling a product or component.

level of the performance parameter increases for a given damage size. fiber, n—one or more filaments in an ordered assemblage.

Damage tolerance depends upon the type of loading which is applied.

For example, the damage tolerance for a compressive load can be, and

Copyright ASTM International 2

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

https://asrecomposite.com

D 3878 – 07

DISCUSSION—There are a number of general and specific terms that knit—a textile process that interlocks, in a specific pattern loop

define specific types of fiber forms. The relationship between fiber form of yarn by means of needles or wires.

terms is shown in Table 1. knitted fabric—See knitted fabric under fabric.

fiber content—the amount of fiber present in a composite lamina—a subunit of a laminate consisting of one or more

expressed either as percent by weight or percent by volume. adjacent plies of the same material with identical orientation.

This is sometimes stated as a fraction, that is, fiber volume lamina orientation—same as ply orientation.

fraction. laminate—any fiber- or fabric-reinforced composite consisting

fiber volume fraction—see fiber content. of laminae (plies) with one or more orientations with respect

filament, n—a fibrous form of matter with an aspect ratio >10 to some reference direction.

and an effective diameter <1 mm. (See also monofilament.) laminate coordinate axes—a set of coordinate axes, usually

right-handed Cartesian, used as reference in describing the

DISCUSSION—Filaments may be essentially continuous (aspect ratio

directional properties and geometrical structure of the lami-

on the order of 105 or larger) or discontinuous. Whiskers are the special

case of single crystal discontinuous filaments. nate. Usually the x-axis and the y-axis lie in the plane of the

laminate and the x-axis is the reference axis from which ply

filament count—number of filaments in the cross section of a angle is measured.

fiber bundle. laminate midplane—the plane that is equidistant from both

fill, n—in a woven fabric, the yarn running from selvage to surfaces of the laminate.

selvage at right angles to the warp. MIL-HDBK-17 laminate principal axis—the laminate coordinate axis that

filler—in composite materials, a primarily inert solid constitu- coincides with the direction of maximum inplane Young’s

ent added to the matrix to modify the composite properties or modulus.

to lower cost. lay-up, n—(1) the stack of plies in specified sequence and

float, n—in woven fabric, the portion of a warp (or fill) yarn orientation before cure or consolidation; (2) the complete

that extends unbound over two ro more fill (or warp) yarns. stack of plies, bagging material, breather material, and so on

D 123 before cure or consolidation; and (3) a description of the

gel time, n—in thermosetting polymers, the period of time component materials, geometry, and so on of a laminate.

from a predetermined starting point to the onset of gelation lay-up, v—to stack plies of material in specified sequence and

as determined by a specific test method. orientation.

hybrid—(for composite materials) containing at least two lay-up code—a designation system for abbreviating the stack-

distinct types of matrix or reinforcement. Each matrix or ing sequence of laminated composites.

reinforcement type can be distinct because of its a) physical mandrel—a form, fixture, or male mold used as the base for

or mechanical properties, or both, b) material form, or c) production of a part in processes such as lay-up or filament

chemical composition. winding.

interlaminar—describing objects (for example, voids), events material form—the contour, arrangement, and structure of an

(for example, fracture), or fields (for example, stress) be- unconsolidated composite material, especially with regard to

tween the laminae of a laminate. the geometry and nature of the reinforcement. Factors

intralaminar—describing objects (for example, voids), events considered part of the material form include, but are not

(for example, fracture), or fields (for example, stress) within limited to: reinforcement diameter, reinforcement length (for

the laminae of a laminate. discontinuous reinforcements), tow size or count, fabric

areal weight, fabric style, reinforcement content, and ply

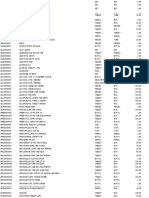

TABLE 1 Fiber Forms thickness.

Continuous Filaments Discontinuous Filaments matrix, n—the continuous constituent of a composite material,

Little

Twist Twisted

Little or

Twisted or No

which surrounds or engulfs embedded filler or reinforce-

No Twist ment.

Twist

A

Tow, *B PC —D — matrix content—the amount of matrix present in a composite

strand,

sliver

expressed either as percent by weight or percent by volume.

Single P * P — For polymer matrix composites this is resin content.

yarn mold, n—the support structure that holds the laminate or

Plied P — P —

yarn

lay-up during the laminate consolidation process.

RovingE * P — — monofilament—a continuous filament strong enough to func-

end (generic term that can be applied to any of the above) tion as a yarn in commercial textile operations or as an entity

Chopped — — — P

fiber

in other operations.

Whisker — — (single crystal) nonwoven fabric—See nonwoven fabric under fabric.

A

Small filament count. off-axis laminate—a laminate whose principal axis is oriented

B

*—Secondary/alternate definition. at an angle theta other than 0 or 90° with respect to a

C

P—primary/preferred definition.

D

—not applicable.

reference direction, usually related to principal load or stress

E

Large filament count. direction.

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International 3

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

https://asrecomposite.com

D 3878 – 07

orthotropic material—a material in which a property of resin content—see matrix content.

interest, at a given point, possesses three mutually perpen- roving, n—in fibrous composites, large filament count tow.

dicular planes of symmetry, which taken together define the (See also tow and filament count.)

principal material coordinate system. satin, adj—description of a weave pattern in which warp yarns

pigment—a substance, generally in the form of fine particles, pass unbound (“float”) over several fill yarns before crossing

that is substantially insoluble in the matrix and is used under a single fill yarn.

because of its color or decorative properties. DISCUSSION—A satin weave is characterized by parallel fibers and no

plied yarn—See plied yarn under yarn. diagonal pattern.

ply—(in laminar composites) the constituent single layer as

used in fabricating, or occurring within a composite struc- selvage, n—the woven edge portion of a fabric parallel to the

ture. warp.

ply coordinate axes—a set of Cartesian coordinates two of single yarn—See single yarn under yarn.

which lie within the plane of the ply, one axis of which is stacking sequence—the arrangement of ply orientations and

--`,,```,,,,````-`-`,,`,,`,`,,`---

parallel to the principal fiber direction and the other axis material components in a laminate specified with respect to

perpendicular to the principal fiber direction (the third axis is some reference direction.

through the ply’s thickness). staple, n—a collection of discontinuous filaments of spinnable

ply count, n—in laminated composite materials, the number of length that are natural, manufactured directly in a short

plies or laminae used to construct the composite. length, or cut from continuous filaments.

ply orientation—the acute angle (theta) including 90° be- strand—in fibrous composites, Synonym for tow.

tween a reference direction and the ply principal axis. The symmetric laminate—a laminate in which the stacking se-

ply orientation is positive if measured counterclockwise quence for the plies located on one side of the geometric

from the reference direction and negative if measured midplane are the mirror image of the stacking sequence on

clockwise. the other side of the midplane.

ply principal axis—the ply coordinate axis that coincides with tab, n—a piece of material used to hold the laminate specimen

the direction of maximum inplane Young’s modulus. For in a grip or fixture for testing so that the laminate is not

balanced weave fabric either warp or fill direction may be damaged and is adequately supported.

chosen. textile, n—a general term applied to fibers and organized

preform, n—a preshaped fibrous reinforcement, normally assemblies of fibers with sufficient integrity to retain the

without matrix, but often containing a binder to facilitate organization.

manufacture, formed by distribution of fibers to the approxi- DISCUSSION—Originally limited to woven fabrics, this term is now

mate contour and thickness of the finished part. also applied to fibers, yarn intermediates, yarns, woven and nonwoven

prepreg—the admixture of fibrous reinforcement and poly- fabrics, braids, knits, and preforms, as illustrated in Fig. 1.

meric matrix used to fabricate composite materials. Its form thermoplastic—a plastic that repeatedly can be softened by

may be sheet, tape, or tow. For thermosetting matrices, it has heating and hardened by cooling through a temperature

been partially cured to a controlled viscosity called “B range characteristic of the plastic, and that in the softened

stage.” state can be shaped by flow into articles by molding or

quasi-isotropic laminate—a balanced and symmetric lami- extrusion.

nate for which a constitutive property of interest, at a given thermoset—a class of polymers that, when cured using heat,

point, displays isotropic behavior in the plane of the lami- chemical, or other means, changes into a substantially

nate. Common quasi-isotropic laminates are (0/660)s and infusible and insoluble material.

(0/645/90)s. tow—in fibrous composites, a continuous, ordered assembly of

DISCUSSION—Usually a quasi-isotropic laminate refers to elastic essentially parallel, collimated filaments, normally without

properties, for which case, the laminate contains equal numbers of twist and of continuous filaments (Synonyms: strand and

identical plies at k orientations such that the angles between the plies silver).

are 180i/k (i = 0, 1 . . . k − 1); k > = 3. Other material properties may

twist, n—in fibrous composites, a measure of the number of

follow different rules. For example, thermal conductivity becomes

quasi-isotropic for k > = 2, while strength properties generally are not turns per unit length a fiber bundle makes around its axis.

capable of true quasi-isotropy, only approximating this behavior. DISCUSSION—Twist is noted as being either ’S’-twist or ’Z’-twist,

where the shape of the letters are used as a mnemonic to describe the

reinforcement, n—in a composite material, the discrete con-

direction of the twist. Following the right-hand rule along the axis of

stituent of a composite material, either fiber or particle, the fiber bundle, ’Z’-twist is a positive twist and ’S’-twist is a negative

which is contained within the matrix, with a purpose of twist. In addition, ’U’ is often used to represent no twist (untwisted) and

increasing the strength, or stiffness, or both. ’N’ no twist (never twisted).

resin—a solid or pseudosolid organic material often of high

void—any pocket of enclosed gas or air within a composite.

molecular weight, which exhibits a tendency to flow when

void content, n—the volume percentage of voids in a com-

subjected to stress, usually has a softening or melting range,

posite.

and usually fractures conchoidally.

Copyright ASTM International 4

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

https://asrecomposite.com

D 3878 – 07

--`,,```,,,,````-`-`,,`,,`,`,,`---

FIG. 1 Illustration of Textile Relationships

warp, n—(1) the yarn running lengthwise in a woven fabric; oriented in two or more directions in a planar textile process.

(2) a group of yarns in long lengths and approximately winding—a process in which continuous material is applied

parallel, put on beams or warp reels for further textile under controlled tension to a form in a predetermined

processing including weaving, knitting, twisting, dyeing, geometric relationship to make a structure. A matrix material

and so forth. D 123 to bind the fibers together may be added before, during or

warp nested, adj—laid up so that warp plies alternate in the after winding. Filament winding is the most common type.

pattern: warp surface up, warp surface down. woven fabric—See woven fabric under fabric.

warp surface, n—the ply surface that shows the larger area of yarn—in fibrous composites, a continuous, ordered assembly

warp tows with respect to fill tows. of essentially parallel, collimated filaments, normally with

twist, and of either discontinuous or continuous filaments.

DISCUSSION—Fabrics in which both surfaces show an equal area of

warp tows with respect to fill tows do not have a warp surface. single yarn, n—an end in which each filament follows the

same twist.

weave, v—interlaces, in a specific pattern, strands or yarns

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 5

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- Astm D883Document16 pagesAstm D883Anonymous nxfFHG32k100% (7)

- Astm D7508 - 2010 - 271493379714Document4 pagesAstm D7508 - 2010 - 271493379714Javad VaziriNo ratings yet

- Astm D-996-04Document12 pagesAstm D-996-04rafael_figueroaNo ratings yet

- (Frater Albertus) The Alchemist's Handbook ManualDocument4 pages(Frater Albertus) The Alchemist's Handbook Manualmelosz0% (1)

- Glass Fiber and Its Products: Standard Terminology Relating ToDocument3 pagesGlass Fiber and Its Products: Standard Terminology Relating Tomohammad yaseenNo ratings yet

- Astm C 557 - 99 - QZU1NY05OQDocument5 pagesAstm C 557 - 99 - QZU1NY05OQSamuel EduardoNo ratings yet

- ASTM C 242 Standard Terminology of Ceramic Whitewares and Related ProductsDocument10 pagesASTM C 242 Standard Terminology of Ceramic Whitewares and Related ProductsRyan Lasaca100% (1)

- D2559Document6 pagesD2559vidal3213100% (1)

- Anti Inflammatory DrugsDocument90 pagesAnti Inflammatory Drugsdrnasim2008817160% (5)

- D 3878 - 02 RDM4NZGTMDMDocument5 pagesD 3878 - 02 RDM4NZGTMDMJuanNo ratings yet

- D 3878 - 02 Rdm4nzgtmdiDocument5 pagesD 3878 - 02 Rdm4nzgtmdiJuanNo ratings yet

- Composite Materials: Standard Terminology ForDocument7 pagesComposite Materials: Standard Terminology ForSullivam PrestesNo ratings yet

- Astm D3878 23Document4 pagesAstm D3878 23Hasan ÜyeNo ratings yet

- ASTM Terminologia de Materiales CompuestosDocument5 pagesASTM Terminologia de Materiales Compuestosanon_102611416No ratings yet

- Astm C 1173Document4 pagesAstm C 1173Andrea Bernal JaraNo ratings yet

- Yarns and Fibers: Standard Terminology Relating ToDocument9 pagesYarns and Fibers: Standard Terminology Relating ToJuanNo ratings yet

- D 5426 - 02 Rdu0mjytmdjbDocument6 pagesD 5426 - 02 Rdu0mjytmdjbJuanNo ratings yet

- ASTM C 168 Standard Terminology Relating To Thermal InsulationDocument6 pagesASTM C 168 Standard Terminology Relating To Thermal InsulationRyan Lasaca100% (1)

- E 631 - 93a (Reapproved 1998) E1 Standard Terminology of Building Constructions1 PDFDocument46 pagesE 631 - 93a (Reapproved 1998) E1 Standard Terminology of Building Constructions1 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Visual Inspection and Grading of Fabrics Used For Inflatable RestraintsDocument6 pagesVisual Inspection and Grading of Fabrics Used For Inflatable RestraintsJuanNo ratings yet

- D1038-11 Standard Terminology Relating To Veneer and PlywoodDocument4 pagesD1038-11 Standard Terminology Relating To Veneer and PlywoodRony YudaNo ratings yet

- D6477Document4 pagesD6477Luana PalmaNo ratings yet

- ASTM Standard F 1743 Pulled in Place Installation of CIPPDocument7 pagesASTM Standard F 1743 Pulled in Place Installation of CIPPVijay SinghNo ratings yet

- C 274 - 99 Qzi3naDocument2 pagesC 274 - 99 Qzi3namohammad1361No ratings yet

- C 168 - 02 Qze2oc0wmg - PDFDocument6 pagesC 168 - 02 Qze2oc0wmg - PDFGean Paul Bueno FernándezNo ratings yet

- D 6477 - 02 Rdy0nzctmdjbDocument4 pagesD 6477 - 02 Rdy0nzctmdjbJuan GutierrezNo ratings yet

- Plastics: Standard Terminology Relating ToDocument15 pagesPlastics: Standard Terminology Relating ToMuhamed RiskhanNo ratings yet

- Plastics: Standard Terminology Relating ToDocument15 pagesPlastics: Standard Terminology Relating ToHanielNo ratings yet

- C 168 - 00 - Qze2oc0wma - PDFDocument5 pagesC 168 - 00 - Qze2oc0wma - PDFElvis Lionel FLORES ROCANo ratings yet

- Relating To Pile Floor Coverings: Standard TerminologyDocument3 pagesRelating To Pile Floor Coverings: Standard TerminologyJuanNo ratings yet

- D 996 - 02 Rdk5ni0wmg - PDFDocument12 pagesD 996 - 02 Rdk5ni0wmg - PDFomar alvaradoNo ratings yet

- D 5426 - 01 Rdu0mjytmdeDocument6 pagesD 5426 - 01 Rdu0mjytmdeJuanNo ratings yet

- Astm D3518-94Document7 pagesAstm D3518-94Chris KořánNo ratings yet

- Astm D4161 (2001)Document4 pagesAstm D4161 (2001)Thomas C. LaneNo ratings yet

- Packaging and Distribution Environments: Standard Terminology ofDocument13 pagesPackaging and Distribution Environments: Standard Terminology ofShaker QaidiNo ratings yet

- Rigid Wall Relocatable Shelters: Standard Terminology Relating ToDocument7 pagesRigid Wall Relocatable Shelters: Standard Terminology Relating ToAhmad Zubair RasulyNo ratings yet

- D 5426 - 97 Rdu0mjytotcDocument6 pagesD 5426 - 97 Rdu0mjytotcJuanNo ratings yet

- D 5426 - 03 Rdu0mjyDocument6 pagesD 5426 - 03 Rdu0mjyJuanNo ratings yet

- Thermal Insulation: Standard Terminology Relating ToDocument6 pagesThermal Insulation: Standard Terminology Relating ToJohnny HoNo ratings yet

- Topic 5.2 - Composites & Non MetalDocument138 pagesTopic 5.2 - Composites & Non MetalelyanasofeaNo ratings yet

- Astm d2724 1987 PDFDocument9 pagesAstm d2724 1987 PDFHsaam Hsaam0% (1)

- Adhesives For Fastening Gypsum Wallboard To Wood FramingDocument5 pagesAdhesives For Fastening Gypsum Wallboard To Wood FramingEduardo DuranNo ratings yet

- D 996 - 99 Rdk5ni05oq - PDFDocument11 pagesD 996 - 99 Rdk5ni05oq - PDFomar alvaradoNo ratings yet

- Non Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams: Standard Specification ForDocument5 pagesNon Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams: Standard Specification ForLupita RamirezNo ratings yet

- Astm D418Document28 pagesAstm D418SunilNo ratings yet

- Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using A Combination of Polyester and Glass Fiber ReinforcementsDocument3 pagesStyrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using A Combination of Polyester and Glass Fiber Reinforcementsrajivr_ranjan_vermaNo ratings yet

- Astm C 168 2002 PDFDocument6 pagesAstm C 168 2002 PDFjoel estradosoNo ratings yet

- Glass-Fiber Reinforced Polyester Wall and Ceiling Panels: Standard Specification ForDocument4 pagesGlass-Fiber Reinforced Polyester Wall and Ceiling Panels: Standard Specification ForLito EstimosNo ratings yet

- Plastics: Standard Terminology Relating ToDocument15 pagesPlastics: Standard Terminology Relating ToServando LozanoNo ratings yet

- D 3737 - 03 RDM3MZCDocument28 pagesD 3737 - 03 RDM3MZCIsrael Orta SánchezNo ratings yet

- C 1173 Coupling StandardDocument4 pagesC 1173 Coupling StandardFernando GonçalvesNo ratings yet

- D 6477 - 02 Rdy0nzctmdiDocument3 pagesD 6477 - 02 Rdy0nzctmdiJuan GutierrezNo ratings yet

- C 475 - C 475M - 02 - QZQ3NS9DNDC1TQDocument2 pagesC 475 - C 475M - 02 - QZQ3NS9DNDC1TQMalak HindiNo ratings yet

- Leo Chelsea Portfolio CheckpointDocument23 pagesLeo Chelsea Portfolio CheckpointLeo SpurginNo ratings yet

- Astm A1023m - 09Document40 pagesAstm A1023m - 09Joanne WaiNo ratings yet

- D 6798 - 02 Rdy3otgDocument2 pagesD 6798 - 02 Rdy3otgJuan GutierrezNo ratings yet

- E192 PDFDocument3 pagesE192 PDFMohamedNo ratings yet

- BOnd Strength ASTM-F904-98Document1 pageBOnd Strength ASTM-F904-98akash.biradarNo ratings yet

- Astm D3681Document8 pagesAstm D3681Viswanath100% (1)

- Determining The Integrity of Factory Seams Used in Joining Manufactured Flexible Sheet GeomembranesDocument3 pagesDetermining The Integrity of Factory Seams Used in Joining Manufactured Flexible Sheet GeomembranesEdmundo Jaita CuellarNo ratings yet

- Core Shear Properties of Sandwich Constructions by Beam FlexureDocument8 pagesCore Shear Properties of Sandwich Constructions by Beam FlexureBarang TeknikNo ratings yet

- Executive Summary: H QLDDDLDocument3 pagesExecutive Summary: H QLDDDLMalik AzeemNo ratings yet

- Astm-D3914 2002R-2008 933696652097Document6 pagesAstm-D3914 2002R-2008 933696652097Malik AzeemNo ratings yet

- IEEE Recommended Practices For Safety in High-Voltage and High-Power TestingDocument24 pagesIEEE Recommended Practices For Safety in High-Voltage and High-Power TestingMalik AzeemNo ratings yet

- Martin 1992Document21 pagesMartin 1992Malik AzeemNo ratings yet

- Paper: Sophie Cavallero, Diane Riccobono, Michel Drouet, and Sabine FrançoisDocument16 pagesPaper: Sophie Cavallero, Diane Riccobono, Michel Drouet, and Sabine FrançoisMalik AzeemNo ratings yet

- 2 ICRP Publication 103 Protection Quantities and ICRU Report 39/51 Operational QuantitiesDocument4 pages2 ICRP Publication 103 Protection Quantities and ICRU Report 39/51 Operational QuantitiesMalik AzeemNo ratings yet

- Ieee 484 - 2019Document29 pagesIeee 484 - 2019Malik AzeemNo ratings yet

- Bunge 1994Document15 pagesBunge 1994Malik AzeemNo ratings yet

- Paper "Living in Contaminated Areas"-Consideration of Different PerspectivesDocument10 pagesPaper "Living in Contaminated Areas"-Consideration of Different PerspectivesMalik AzeemNo ratings yet

- Reed 2009Document4 pagesReed 2009Malik AzeemNo ratings yet

- Paper: Volodymyr A. Vinnikov and Oleg BelyakovDocument12 pagesPaper: Volodymyr A. Vinnikov and Oleg BelyakovMalik AzeemNo ratings yet

- Paper: Matthäus Majewski, Marco Rozgic, Patrick Ostheim, Matthias Port, and Michael AbendDocument8 pagesPaper: Matthäus Majewski, Marco Rozgic, Patrick Ostheim, Matthias Port, and Michael AbendMalik AzeemNo ratings yet

- 118Document10 pages118Malik AzeemNo ratings yet

- Paper: Harold M. Swartz, Ann Barry Flood, Vijay K. Singh, and Steven G. SwartsDocument11 pagesPaper: Harold M. Swartz, Ann Barry Flood, Vijay K. Singh, and Steven G. SwartsMalik AzeemNo ratings yet

- Paper: Nicoleta Simona Bicheru, Cerasela Haidoiu, Octavian C Ălborean, Adrian Popa, Ioana Porosnicu, and Radu HertzogDocument8 pagesPaper: Nicoleta Simona Bicheru, Cerasela Haidoiu, Octavian C Ălborean, Adrian Popa, Ioana Porosnicu, and Radu HertzogMalik AzeemNo ratings yet

- 109Document9 pages109Malik AzeemNo ratings yet

- Paper: C. Norman ColemanDocument5 pagesPaper: C. Norman ColemanMalik AzeemNo ratings yet

- 095Document6 pages095Malik AzeemNo ratings yet

- Defining Economics and Islamic EconomicsDocument31 pagesDefining Economics and Islamic EconomicsMalik AzeemNo ratings yet

- Islamic Economics As A Social Science: Some Methodological IssuesDocument10 pagesIslamic Economics As A Social Science: Some Methodological IssuesMalik AzeemNo ratings yet

- Chinese Strategic Decision-MakingDocument168 pagesChinese Strategic Decision-MakingMalik AzeemNo ratings yet

- Paper: André BouvilleDocument22 pagesPaper: André BouvilleMalik AzeemNo ratings yet

- An Analysis of Islamic Economic ModelDocument17 pagesAn Analysis of Islamic Economic ModelMalik AzeemNo ratings yet

- 2018al BassamAZMHPhDDocument224 pages2018al BassamAZMHPhDFloren Ardila AlvaradoNo ratings yet

- 300-Foundations & Equipment Mounting PDFDocument32 pages300-Foundations & Equipment Mounting PDFStephen KokoNo ratings yet

- ResearchDocument4 pagesResearchhvivaldemoroNo ratings yet

- Mixing TechnologyDocument1 pageMixing TechnologymasimnNo ratings yet

- FS1248ENDocument2 pagesFS1248ENAamir AlmanNo ratings yet

- BS en 1514 1 1997Document22 pagesBS en 1514 1 1997Phaneendra Tirumani100% (2)

- Sikaswell s-2Document4 pagesSikaswell s-2Eko PriambudiNo ratings yet

- Ashish Kumar Patel (Assistant Professor) Mechanical Engineering Department Lovely Professional UniversityDocument16 pagesAshish Kumar Patel (Assistant Professor) Mechanical Engineering Department Lovely Professional UniversitySachin KumarNo ratings yet

- AKZO-3126 Oilfield Brochure 2014-8 5x11-Ind Pages-FINAL Lo Def PDFDocument36 pagesAKZO-3126 Oilfield Brochure 2014-8 5x11-Ind Pages-FINAL Lo Def PDFgerardo sifuentesNo ratings yet

- Development of Mixed Starter Culture For The Fermentation of Ethiopian Honey Wine, TejDocument15 pagesDevelopment of Mixed Starter Culture For The Fermentation of Ethiopian Honey Wine, TejEskindir GetachewNo ratings yet

- Gas Turbine Power PlantDocument20 pagesGas Turbine Power Plantumar100% (1)

- Co2 Water Content ThermoDocument19 pagesCo2 Water Content ThermoAnushka GNo ratings yet

- Tyco DatasheetDocument4 pagesTyco DatasheetPCNo ratings yet

- ACTIVITY 2 - OrbitalsDocument2 pagesACTIVITY 2 - OrbitalsSylvs EnongNo ratings yet

- Full Report With Cover Page PDFDocument91 pagesFull Report With Cover Page PDFFareez AizatNo ratings yet

- Membrane Filtration Method, Types, Advantages, Disadvantages, Applications.Document27 pagesMembrane Filtration Method, Types, Advantages, Disadvantages, Applications.Muhammed SabdatNo ratings yet

- NCI - LV Cables CatalogueDocument55 pagesNCI - LV Cables Catalogues50% (2)

- Sinochem ReportDocument46 pagesSinochem Reportabhishek singh100% (1)

- Shell Gadus S2 A320 From Rhodina EPLFDocument2 pagesShell Gadus S2 A320 From Rhodina EPLFAnonymous oAbjbl4HNo ratings yet

- EcosystemDocument36 pagesEcosystemR. JhansiraniNo ratings yet

- Astm A53 Grade B Pipe ManufacturersDocument4 pagesAstm A53 Grade B Pipe ManufacturersRajendra FittingsNo ratings yet

- Ch19 Wade ChemistryDocument58 pagesCh19 Wade ChemistrySunnyd1013No ratings yet

- Dispensing, Incompatibilities and Adverse Drug Reactions Answer Key - RED PADocument17 pagesDispensing, Incompatibilities and Adverse Drug Reactions Answer Key - RED PAArk Olfato ParojinogNo ratings yet

- Painting HintDocument19 pagesPainting HintSenthil KumaranNo ratings yet

- Gas LawsDocument4 pagesGas LawsPrincess Joy Dilim KimayongNo ratings yet

- Inertaire ABBDocument20 pagesInertaire ABBRaul GalvanNo ratings yet

- Rotary Lobe Pump Mechanical Seal SelectionDocument2 pagesRotary Lobe Pump Mechanical Seal SelectionSachin HolkarNo ratings yet

- Satuan KecilDocument144 pagesSatuan KecilWahyuNo ratings yet