Professional Documents

Culture Documents

WO FLOW - Vendor

WO FLOW - Vendor

Uploaded by

klukluxlandCopyright:

Available Formats

You might also like

- Fine Scale Modeler 2024-01-02Document76 pagesFine Scale Modeler 2024-01-02Khaled BouchouarebNo ratings yet

- Jsa-0002 - CCTV Pipe Inspection RapidDocument8 pagesJsa-0002 - CCTV Pipe Inspection RapidMohamad AfifNo ratings yet

- Practical Guide To SAP Material - Rosana Fonseca PDFDocument209 pagesPractical Guide To SAP Material - Rosana Fonseca PDFidevaldo100% (6)

- BMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationFrom EverandBMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationNo ratings yet

- PTWS Process Flow1Document1 pagePTWS Process Flow1Denis JacutinNo ratings yet

- Mbs Sop-121 Hse PermitsDocument12 pagesMbs Sop-121 Hse Permitsosei kwadwoNo ratings yet

- Contractor Permitting PolicyDocument5 pagesContractor Permitting PolicyMark RusianaNo ratings yet

- LOGISTIC MAINTENANCE PRESENTATION New-1Document4 pagesLOGISTIC MAINTENANCE PRESENTATION New-1Arief ArbiNo ratings yet

- JSA 03 Manual Excavation and TrenchingDocument11 pagesJSA 03 Manual Excavation and TrenchingArt MayoresNo ratings yet

- 008 SWMS General Onsite Activities and RepairsDocument13 pages008 SWMS General Onsite Activities and Repairssiame festusNo ratings yet

- Installation of Fence For Office Lay Dawn Area.Document6 pagesInstallation of Fence For Office Lay Dawn Area.nrphsebarauniNo ratings yet

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- Jsa-0001 - Excavation Cipp RapidDocument11 pagesJsa-0001 - Excavation Cipp RapidMohamad Afif100% (1)

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Document6 pagesSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument14 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- ENCO-JSA-01-Piping - ColdDocument11 pagesENCO-JSA-01-Piping - ColdRobert HaddadNo ratings yet

- Major Findings Major Recommendation Evidence / Action Items RemarksDocument2 pagesMajor Findings Major Recommendation Evidence / Action Items RemarksAsad Maher100% (1)

- MS For Installation of LP System - LatestDocument8 pagesMS For Installation of LP System - Latestمقاول تكييف كهرباء وصحيNo ratings yet

- Management of Contractors ProcedureDocument2 pagesManagement of Contractors ProcedurednmuleNo ratings yet

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument14 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument14 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument15 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Hand Over Check ListDocument3 pagesHand Over Check Listkrvprasad100% (1)

- Work Order ProcedureDocument5 pagesWork Order ProcedureJames Reyes100% (1)

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet

- Subject Area No. 23 Permit To Work: Principle: Level Expectations Targets Suggested Objective Evidence BasicDocument5 pagesSubject Area No. 23 Permit To Work: Principle: Level Expectations Targets Suggested Objective Evidence BasicHarman SandhuNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument16 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Risk Assessment - BLOCK WORKSDocument9 pagesRisk Assessment - BLOCK WORKSShah Muzzamil100% (1)

- Whs 02 Safety Management System ProcedureDocument12 pagesWhs 02 Safety Management System ProcedureIndri WiradhikasariNo ratings yet

- Permit To Work System - LabsDocument17 pagesPermit To Work System - LabsEazy Digital100% (1)

- 10 - Updated - LV Cable Installation and TerminationDocument22 pages10 - Updated - LV Cable Installation and TerminationShah MuzzamilNo ratings yet

- PSSR StandardDocument3 pagesPSSR Standardanjna100% (2)

- Jsa-Rp-005 Concrete WorksDocument19 pagesJsa-Rp-005 Concrete Worksibaig1970No ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument14 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- Plan To Improve Manufcturing and Implement CGMPDocument6 pagesPlan To Improve Manufcturing and Implement CGMPPradeep SNo ratings yet

- Department of Science and Technology: Office/Service/Division/Unit: General Services DivisionDocument5 pagesDepartment of Science and Technology: Office/Service/Division/Unit: General Services Divisionverna cahibaybayanNo ratings yet

- Job Safety Analysis (Jsa)Document49 pagesJob Safety Analysis (Jsa)Azad pravesh khanNo ratings yet

- PPP Worksheet - Computer TrainingDocument4 pagesPPP Worksheet - Computer TrainingAngelo SantosNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970100% (1)

- NightDocument2 pagesNightnaalifeshow143No ratings yet

- Generic RA RISK ASS SITE 1072Document24 pagesGeneric RA RISK ASS SITE 1072Daniel LoveNo ratings yet

- BoCEs Recommendations - On - HLTCDocument45 pagesBoCEs Recommendations - On - HLTCRajaNo ratings yet

- 10 - Updated - LV Cable Installation and TerminationDocument22 pages10 - Updated - LV Cable Installation and TerminationShah Muzzamil100% (1)

- Sample Project Closeout TemplateDocument1 pageSample Project Closeout TemplateMikeNo ratings yet

- Business Continuity Plan For NOC Services V 1.4Document7 pagesBusiness Continuity Plan For NOC Services V 1.4Manas Ranjan SahooNo ratings yet

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 pagesJsa-Rp-001 Site Preparation and General Earthworksibaig1970No ratings yet

- Methos of Statement For Startup WorkDocument6 pagesMethos of Statement For Startup WorkMahesh MirajkarNo ratings yet

- DOD-AKG2-MST-ST-002 (REV-0) Repair of Structural SteelsteelDocument5 pagesDOD-AKG2-MST-ST-002 (REV-0) Repair of Structural SteelsteelMohammedNo ratings yet

- MOS Installation of PUBLIC ADDRES SystemsDocument15 pagesMOS Installation of PUBLIC ADDRES SystemsAde FriyundaNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- Job Hazard Analysis of Fabrication WorkDocument7 pagesJob Hazard Analysis of Fabrication WorkBALAL AKRAMNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument17 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Mom 59Document14 pagesMom 59Anonymous kWfNFb100% (1)

- Oil and Natural Gas Corporation LTD: Corporate Materials ManagementDocument40 pagesOil and Natural Gas Corporation LTD: Corporate Materials Managementchahal.manjotNo ratings yet

- 001 - ITP Clearing - Revision 0Document3 pages001 - ITP Clearing - Revision 0randyNo ratings yet

- Press On Permit To Work SystemDocument7 pagesPress On Permit To Work SystemashwaniNo ratings yet

- Concrete ItpDocument5 pagesConcrete ItpMurtada OmerNo ratings yet

- NPTA Evaluation Criteria Handbook May2009Document6 pagesNPTA Evaluation Criteria Handbook May2009Anonymous IeFbdsfCoNo ratings yet

- Sample Complete WODocument6 pagesSample Complete WOklukluxlandNo ratings yet

- Final Report FormatDocument1 pageFinal Report FormatklukluxlandNo ratings yet

- Schedule Ash Pond-R4 - 181218Document2 pagesSchedule Ash Pond-R4 - 181218klukluxlandNo ratings yet

- Agenda 2018Document81 pagesAgenda 2018klukluxlandNo ratings yet

- Additional Exercises Transaction Analaysis Journalizing Posting and Unadjusted TDocument4 pagesAdditional Exercises Transaction Analaysis Journalizing Posting and Unadjusted TRenalyn Ps MewagNo ratings yet

- Answer 1 - Cost of CapitalDocument2 pagesAnswer 1 - Cost of Capitaljeganrajraj100% (1)

- Strategi Peningkatan Kualitas Pelayanan Berbasis Swot Pada Kantor Pelayanan Pajak Pratama Semarang CandisariDocument11 pagesStrategi Peningkatan Kualitas Pelayanan Berbasis Swot Pada Kantor Pelayanan Pajak Pratama Semarang Candisaririza alamsyahNo ratings yet

- 4 Service DesignDocument30 pages4 Service Designhayder nuredinNo ratings yet

- SMM ADocument14 pagesSMM ABereket MinaleNo ratings yet

- Forecast Lecture 1 FinalDocument29 pagesForecast Lecture 1 FinalAB Siddique Rifat100% (1)

- Sample Module-HRM (Credits To Owner)Document8 pagesSample Module-HRM (Credits To Owner)RafNo ratings yet

- Unit-6 SWOT AnalysisDocument12 pagesUnit-6 SWOT Analysisvg_mrtNo ratings yet

- Workshop List: Dubai - DeiraDocument1 pageWorkshop List: Dubai - DeiraMohammed Khalid100% (1)

- Brand Management and Analysis of Bellissimo Premium Ice CreamDocument39 pagesBrand Management and Analysis of Bellissimo Premium Ice CreamSajeed Alam0% (2)

- INV43719Document1 pageINV43719usmanNo ratings yet

- Supply and Demand MCQ and ProblemsDocument5 pagesSupply and Demand MCQ and ProblemsNikoleta TrudovNo ratings yet

- Rasel CV.Document3 pagesRasel CV.tkamal_ewuNo ratings yet

- Amount (RS.) Date Script Strike Pr. C/P LOT Level TG-1 TG-2 TG-3 TG-1 TG-2 TG-3 Total Profit or Loss (RS.)Document17 pagesAmount (RS.) Date Script Strike Pr. C/P LOT Level TG-1 TG-2 TG-3 TG-1 TG-2 TG-3 Total Profit or Loss (RS.)Thiya NalluNo ratings yet

- Las LS3 Work SampleDocument9 pagesLas LS3 Work SampleZaibell Jane TareNo ratings yet

- MC 99 NotesDocument3 pagesMC 99 NotesVloudy Mia Serrano PangilinanNo ratings yet

- Emirates DiaryDocument164 pagesEmirates DiarySurendra BhandariNo ratings yet

- Assignment On Business PlanDocument15 pagesAssignment On Business PlanAbdullah Ashik AdnanNo ratings yet

- ANGELINA FRANCISCO Vs NLRCDocument2 pagesANGELINA FRANCISCO Vs NLRCHoreb Felix Villa100% (1)

- Comparsion of RCCM & ASMEDocument2 pagesComparsion of RCCM & ASMEsafeer ahmadNo ratings yet

- Account ShortNotes - CAB2FDocument171 pagesAccount ShortNotes - CAB2Fmopid68742No ratings yet

- Summary Account Payable Statement: JiopayDocument1 pageSummary Account Payable Statement: JiopayhazihappyNo ratings yet

- Creating An Adaptive HR Tech StrategyDocument20 pagesCreating An Adaptive HR Tech StrategyMudassar IqbalNo ratings yet

- IRR Calculation Sheet For Auto LoansDocument8 pagesIRR Calculation Sheet For Auto LoansmskharadeNo ratings yet

- All Risk Policy ScheduleDocument8 pagesAll Risk Policy Schedulejawwad joeNo ratings yet

- Wpffiffi: Indopac (PNG)Document3 pagesWpffiffi: Indopac (PNG)Procopio DoysabasNo ratings yet

- National IPR Policy 2016 An AnalysisDocument7 pagesNational IPR Policy 2016 An AnalysisjptripathyNo ratings yet

- General Purchase Conditions: Material & Contract Deptt-RhqDocument44 pagesGeneral Purchase Conditions: Material & Contract Deptt-RhqTuff qualityNo ratings yet

WO FLOW - Vendor

WO FLOW - Vendor

Uploaded by

klukluxlandOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WO FLOW - Vendor

WO FLOW - Vendor

Uploaded by

klukluxlandCopyright:

Available Formats

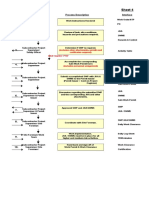

Work Flow Process: Maintenance Work Order for Vendor

Start to Work

TPI VENDOR No Description

1. Create Work Order:

Start to Work

Job Items according to the Contract

between TPI & Vendors

(Reviewed by each section)

2. Approval Work Order & Re-check Item

Work, Etc. on PMS,

Engineering - Engineer/Supervisor Approval

- Section Head Approval

1. Create Work - Manager Approval

Order

-PTW,

PMS, AMP & Receive WO and Submit Schedule for

Special

Contract Permit, JSA,

3. Perform WO as per work scope on

HIRAC, contract/discussion, with prepare permit

LOTO. (SOP Doc.:

Safety)

-PTW, Special Permit, JSA, HIRAC, LOTO.

(SOP Safety)

Perform Job as Work Order Well

MTN Each Vendor Each section engineer must be supervise and

section MTN 4.

3. Receive WO lead the contractor to ensure they are

2. Approval WO comply with TPI safety regulation.

and Scheduling

POMMS Work Scope The operation team will be responsible for

MPMSS all Plant isolation and de-isolation system.

HSE team will be conducted on safety

induction training for the contractor who

had just arrived at the site. It will be

scheduled and well maintain. A list of

Vendor contactor manpower and other workers will

4. Perform Job as be collected and documented.

Work Order HSE team will also hold on safety site survey

Work Scope during the outage period and any

comments, suggestions and results of the

investigation will be sent to outage

coordinators for further assessment and

distribution as needed. For any critical issue

of HSE, it must be discussed on the outage

daily coordination meeting.

For progress daily monitoring of outage, it

A will be a regularly meetings with contractors

as mandatory and minutes of meeting must

be docummented and recorded.

Agenda of the meeting are to be discussed:

Daily progress and plan

Technical and safety issues

The vendor also submit progress report and

schedule update by daily to TPI

-

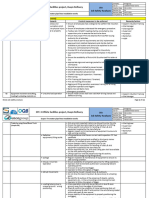

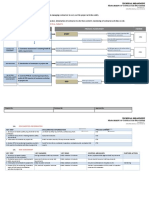

DRAFT_STANDARD OPERATING PROCEDURE (SOP)

WORK ORDER - VENDOR

No. SOP Revised 0.0

Date Page 2 of 2

Work Completion

TPI VENDOR No. Deskripsi/Description

5. Work Order Inspection Result

Check sheet,

A

Attachment Maintenance/inspection result,

With Inspector/leader Approval, etc.

6. TPI Receive report of

MTN Each Section Vendor inspection/maintenance Result as Work

Order and review

5. Work Order

6. WO MTN result

MTN/Inspection

Approval TPI Each section Maintenance

Result 7.

Review/crosscheck result and approve

Approval Approval

7. a. if Yes: the WO result get TPI approval

and continue Enter Maintenance

Result on PMS by TPI and also attach

Vendor

the Maintenance result.

No 7. b. if No: the WO Result included

7. Approve OK? 7 b. Re-work (WO) attachment back to Vendor for Re-

work the un-acceptable item.

Work Scope

Yes After the result inputted on the PMS as per

8. WO number, the superior of each section

MTN Each Section review the result on PMS & Approve as

usual Work Order.

7 a. Enter Maintenance

Result Finish

Closing

MTN Each Section

8. Review WO Result

Closing

Finish

You might also like

- Fine Scale Modeler 2024-01-02Document76 pagesFine Scale Modeler 2024-01-02Khaled BouchouarebNo ratings yet

- Jsa-0002 - CCTV Pipe Inspection RapidDocument8 pagesJsa-0002 - CCTV Pipe Inspection RapidMohamad AfifNo ratings yet

- Practical Guide To SAP Material - Rosana Fonseca PDFDocument209 pagesPractical Guide To SAP Material - Rosana Fonseca PDFidevaldo100% (6)

- BMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationFrom EverandBMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationNo ratings yet

- PTWS Process Flow1Document1 pagePTWS Process Flow1Denis JacutinNo ratings yet

- Mbs Sop-121 Hse PermitsDocument12 pagesMbs Sop-121 Hse Permitsosei kwadwoNo ratings yet

- Contractor Permitting PolicyDocument5 pagesContractor Permitting PolicyMark RusianaNo ratings yet

- LOGISTIC MAINTENANCE PRESENTATION New-1Document4 pagesLOGISTIC MAINTENANCE PRESENTATION New-1Arief ArbiNo ratings yet

- JSA 03 Manual Excavation and TrenchingDocument11 pagesJSA 03 Manual Excavation and TrenchingArt MayoresNo ratings yet

- 008 SWMS General Onsite Activities and RepairsDocument13 pages008 SWMS General Onsite Activities and Repairssiame festusNo ratings yet

- Installation of Fence For Office Lay Dawn Area.Document6 pagesInstallation of Fence For Office Lay Dawn Area.nrphsebarauniNo ratings yet

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- Jsa-0001 - Excavation Cipp RapidDocument11 pagesJsa-0001 - Excavation Cipp RapidMohamad Afif100% (1)

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Document6 pagesSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument14 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- ENCO-JSA-01-Piping - ColdDocument11 pagesENCO-JSA-01-Piping - ColdRobert HaddadNo ratings yet

- Major Findings Major Recommendation Evidence / Action Items RemarksDocument2 pagesMajor Findings Major Recommendation Evidence / Action Items RemarksAsad Maher100% (1)

- MS For Installation of LP System - LatestDocument8 pagesMS For Installation of LP System - Latestمقاول تكييف كهرباء وصحيNo ratings yet

- Management of Contractors ProcedureDocument2 pagesManagement of Contractors ProcedurednmuleNo ratings yet

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument14 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument14 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument15 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Hand Over Check ListDocument3 pagesHand Over Check Listkrvprasad100% (1)

- Work Order ProcedureDocument5 pagesWork Order ProcedureJames Reyes100% (1)

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet

- Subject Area No. 23 Permit To Work: Principle: Level Expectations Targets Suggested Objective Evidence BasicDocument5 pagesSubject Area No. 23 Permit To Work: Principle: Level Expectations Targets Suggested Objective Evidence BasicHarman SandhuNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument16 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Risk Assessment - BLOCK WORKSDocument9 pagesRisk Assessment - BLOCK WORKSShah Muzzamil100% (1)

- Whs 02 Safety Management System ProcedureDocument12 pagesWhs 02 Safety Management System ProcedureIndri WiradhikasariNo ratings yet

- Permit To Work System - LabsDocument17 pagesPermit To Work System - LabsEazy Digital100% (1)

- 10 - Updated - LV Cable Installation and TerminationDocument22 pages10 - Updated - LV Cable Installation and TerminationShah MuzzamilNo ratings yet

- PSSR StandardDocument3 pagesPSSR Standardanjna100% (2)

- Jsa-Rp-005 Concrete WorksDocument19 pagesJsa-Rp-005 Concrete Worksibaig1970No ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument14 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- Plan To Improve Manufcturing and Implement CGMPDocument6 pagesPlan To Improve Manufcturing and Implement CGMPPradeep SNo ratings yet

- Department of Science and Technology: Office/Service/Division/Unit: General Services DivisionDocument5 pagesDepartment of Science and Technology: Office/Service/Division/Unit: General Services Divisionverna cahibaybayanNo ratings yet

- Job Safety Analysis (Jsa)Document49 pagesJob Safety Analysis (Jsa)Azad pravesh khanNo ratings yet

- PPP Worksheet - Computer TrainingDocument4 pagesPPP Worksheet - Computer TrainingAngelo SantosNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970100% (1)

- NightDocument2 pagesNightnaalifeshow143No ratings yet

- Generic RA RISK ASS SITE 1072Document24 pagesGeneric RA RISK ASS SITE 1072Daniel LoveNo ratings yet

- BoCEs Recommendations - On - HLTCDocument45 pagesBoCEs Recommendations - On - HLTCRajaNo ratings yet

- 10 - Updated - LV Cable Installation and TerminationDocument22 pages10 - Updated - LV Cable Installation and TerminationShah Muzzamil100% (1)

- Sample Project Closeout TemplateDocument1 pageSample Project Closeout TemplateMikeNo ratings yet

- Business Continuity Plan For NOC Services V 1.4Document7 pagesBusiness Continuity Plan For NOC Services V 1.4Manas Ranjan SahooNo ratings yet

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 pagesJsa-Rp-001 Site Preparation and General Earthworksibaig1970No ratings yet

- Methos of Statement For Startup WorkDocument6 pagesMethos of Statement For Startup WorkMahesh MirajkarNo ratings yet

- DOD-AKG2-MST-ST-002 (REV-0) Repair of Structural SteelsteelDocument5 pagesDOD-AKG2-MST-ST-002 (REV-0) Repair of Structural SteelsteelMohammedNo ratings yet

- MOS Installation of PUBLIC ADDRES SystemsDocument15 pagesMOS Installation of PUBLIC ADDRES SystemsAde FriyundaNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- Job Hazard Analysis of Fabrication WorkDocument7 pagesJob Hazard Analysis of Fabrication WorkBALAL AKRAMNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument17 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Mom 59Document14 pagesMom 59Anonymous kWfNFb100% (1)

- Oil and Natural Gas Corporation LTD: Corporate Materials ManagementDocument40 pagesOil and Natural Gas Corporation LTD: Corporate Materials Managementchahal.manjotNo ratings yet

- 001 - ITP Clearing - Revision 0Document3 pages001 - ITP Clearing - Revision 0randyNo ratings yet

- Press On Permit To Work SystemDocument7 pagesPress On Permit To Work SystemashwaniNo ratings yet

- Concrete ItpDocument5 pagesConcrete ItpMurtada OmerNo ratings yet

- NPTA Evaluation Criteria Handbook May2009Document6 pagesNPTA Evaluation Criteria Handbook May2009Anonymous IeFbdsfCoNo ratings yet

- Sample Complete WODocument6 pagesSample Complete WOklukluxlandNo ratings yet

- Final Report FormatDocument1 pageFinal Report FormatklukluxlandNo ratings yet

- Schedule Ash Pond-R4 - 181218Document2 pagesSchedule Ash Pond-R4 - 181218klukluxlandNo ratings yet

- Agenda 2018Document81 pagesAgenda 2018klukluxlandNo ratings yet

- Additional Exercises Transaction Analaysis Journalizing Posting and Unadjusted TDocument4 pagesAdditional Exercises Transaction Analaysis Journalizing Posting and Unadjusted TRenalyn Ps MewagNo ratings yet

- Answer 1 - Cost of CapitalDocument2 pagesAnswer 1 - Cost of Capitaljeganrajraj100% (1)

- Strategi Peningkatan Kualitas Pelayanan Berbasis Swot Pada Kantor Pelayanan Pajak Pratama Semarang CandisariDocument11 pagesStrategi Peningkatan Kualitas Pelayanan Berbasis Swot Pada Kantor Pelayanan Pajak Pratama Semarang Candisaririza alamsyahNo ratings yet

- 4 Service DesignDocument30 pages4 Service Designhayder nuredinNo ratings yet

- SMM ADocument14 pagesSMM ABereket MinaleNo ratings yet

- Forecast Lecture 1 FinalDocument29 pagesForecast Lecture 1 FinalAB Siddique Rifat100% (1)

- Sample Module-HRM (Credits To Owner)Document8 pagesSample Module-HRM (Credits To Owner)RafNo ratings yet

- Unit-6 SWOT AnalysisDocument12 pagesUnit-6 SWOT Analysisvg_mrtNo ratings yet

- Workshop List: Dubai - DeiraDocument1 pageWorkshop List: Dubai - DeiraMohammed Khalid100% (1)

- Brand Management and Analysis of Bellissimo Premium Ice CreamDocument39 pagesBrand Management and Analysis of Bellissimo Premium Ice CreamSajeed Alam0% (2)

- INV43719Document1 pageINV43719usmanNo ratings yet

- Supply and Demand MCQ and ProblemsDocument5 pagesSupply and Demand MCQ and ProblemsNikoleta TrudovNo ratings yet

- Rasel CV.Document3 pagesRasel CV.tkamal_ewuNo ratings yet

- Amount (RS.) Date Script Strike Pr. C/P LOT Level TG-1 TG-2 TG-3 TG-1 TG-2 TG-3 Total Profit or Loss (RS.)Document17 pagesAmount (RS.) Date Script Strike Pr. C/P LOT Level TG-1 TG-2 TG-3 TG-1 TG-2 TG-3 Total Profit or Loss (RS.)Thiya NalluNo ratings yet

- Las LS3 Work SampleDocument9 pagesLas LS3 Work SampleZaibell Jane TareNo ratings yet

- MC 99 NotesDocument3 pagesMC 99 NotesVloudy Mia Serrano PangilinanNo ratings yet

- Emirates DiaryDocument164 pagesEmirates DiarySurendra BhandariNo ratings yet

- Assignment On Business PlanDocument15 pagesAssignment On Business PlanAbdullah Ashik AdnanNo ratings yet

- ANGELINA FRANCISCO Vs NLRCDocument2 pagesANGELINA FRANCISCO Vs NLRCHoreb Felix Villa100% (1)

- Comparsion of RCCM & ASMEDocument2 pagesComparsion of RCCM & ASMEsafeer ahmadNo ratings yet

- Account ShortNotes - CAB2FDocument171 pagesAccount ShortNotes - CAB2Fmopid68742No ratings yet

- Summary Account Payable Statement: JiopayDocument1 pageSummary Account Payable Statement: JiopayhazihappyNo ratings yet

- Creating An Adaptive HR Tech StrategyDocument20 pagesCreating An Adaptive HR Tech StrategyMudassar IqbalNo ratings yet

- IRR Calculation Sheet For Auto LoansDocument8 pagesIRR Calculation Sheet For Auto LoansmskharadeNo ratings yet

- All Risk Policy ScheduleDocument8 pagesAll Risk Policy Schedulejawwad joeNo ratings yet

- Wpffiffi: Indopac (PNG)Document3 pagesWpffiffi: Indopac (PNG)Procopio DoysabasNo ratings yet

- National IPR Policy 2016 An AnalysisDocument7 pagesNational IPR Policy 2016 An AnalysisjptripathyNo ratings yet

- General Purchase Conditions: Material & Contract Deptt-RhqDocument44 pagesGeneral Purchase Conditions: Material & Contract Deptt-RhqTuff qualityNo ratings yet