Professional Documents

Culture Documents

L1 35148 en BOEHLER Q 71 RC DG 5U0001IT 3405329 EN

L1 35148 en BOEHLER Q 71 RC DG 5U0001IT 3405329 EN

Uploaded by

Roberta RamosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L1 35148 en BOEHLER Q 71 RC DG 5U0001IT 3405329 EN

L1 35148 en BOEHLER Q 71 RC DG 5U0001IT 3405329 EN

Uploaded by

Roberta RamosCopyright:

Available Formats

BÖHLER Q 71 RC DG

Flux-cored wire, mild steel, rutile

Classifications

AWS A5.20 / SFA-5.20 EN ISO 17632-A

E71T-1C T42 0 P C1 1 H10

E71T-1M T46 0 P M21 1 H10

Characteristics and typical fields of application

All position rutile flux-cored wire with fast freezing slag system for single or multipass welding of Carbon, Carbon-Manganese steels and

similar including fine grain steels with Argon-CO2 shielding gas or pure CO2. Excellent mechanical properties, easy slag removal, low

spatter loss, smooth, finely rippled bead surface. The product performs to the highest productivity with significant savings in time and

economical aspects when used for positional welding.

Base materials

Steels up to a yield strength of 460 MPa (67 ksi)

S235JR-S355JR, S235JO-S355JO, S450JO, S235J2-S355J2, S275N-S460N, S275M-S460M, P235GH-P355GH, P275NL1-P460NL1,

P215NL, P265NL, P355N, P285NH-P460NH, P195TR1-P265TR1, P195TR2-P265TR2, P195GH-P265GH, L245NB-L415NB, L450QB,

L245MB-L450MB, GE200-GE240, shipbuilding steels: A, B, D, E, A 32-E 36

ASTM A 106 Gr. A, B, C; A 181 Gr. 60, 70; A 283 Gr. A, C; A 285 Gr. A, B, C; A 350 Gr. LF1; A 414 Gr. A, B, C, D, E, F, G; A 501 Gr. B; A 513 Gr.

1018; A 516 Gr. 55, 60, 65, 70; A 573 Gr. 58, 65, 70; A 588 Gr. A, B; A 633 Gr. C, E; A 662 Gr. B; A 711 Gr. 1013; A 841 Gr. A; API 5 L Gr. B,

X42, X52, X56, X60, X65

Typical analysis

Gas C Si Mn

wt.-% M21 0.05 0.50 1.35

wt.-% C1 0.04 0.45 1.25

Mechanical properties of all-weld metal - typical values (min. values)

Condition Yield strength Rp0.2 Tensile strength Rm Elongation A (L0=5d0) Impact energy ISO-V KV J

MPa MPa % -20°C

u 580 (≥ 460) 640 (550 – 660) 26 (≥ 22) 75 (≥ 27)

u1 520 (≥ 420) 580 (500 – 640) 29 (≥ 22) 70 (≥ 27)

u untreated, as welded – shielding gas M21

u1 untreated, as welded – shielding gas C1

Operating data

Polarity DC+ Dimension mm

Shielding gas M21, C1 1.2

(EN ISO 14175) 1.4

1.6

Welding with standard GMAW-facilities possible

Approvals

ABS, BV, CWB, DNV-GL, FBTS

All information provided is based upon careful investigation and intensive research. 1 / 1 11/2021

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Norsok M-501 Ed. 7 - 2022Document110 pagesNorsok M-501 Ed. 7 - 2022Roberta Ramos94% (17)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jotun - Technical Datasheet - Thinner No.25Document2 pagesJotun - Technical Datasheet - Thinner No.25Roberta RamosNo ratings yet

- Jotun - Technical Datasheet - Marathon 550 Comp ADocument18 pagesJotun - Technical Datasheet - Marathon 550 Comp ARoberta RamosNo ratings yet

- TDS-Barrier Smart Pack-BR-Portuguese-ProtectiveDocument5 pagesTDS-Barrier Smart Pack-BR-Portuguese-ProtectiveRoberta RamosNo ratings yet

- Jotun - Boletim Técnico - Marathon 550 Comp BDocument14 pagesJotun - Boletim Técnico - Marathon 550 Comp BRoberta RamosNo ratings yet

- 1702413860-Certificado Jato28361Document1 page1702413860-Certificado Jato28361Roberta RamosNo ratings yet

- MakSolda Web Sistema de Fabricação e Inspeção de Unidades IndustriaisDocument24 pagesMakSolda Web Sistema de Fabricação e Inspeção de Unidades IndustriaisRoberta RamosNo ratings yet

- TDS Hardtop AX BR Portuguese MarineDocument6 pagesTDS Hardtop AX BR Portuguese MarineRoberta RamosNo ratings yet

- CONSUMIVELDocument1 pageCONSUMIVELRoberta RamosNo ratings yet

- Jotun - Boletim Técnico - Marathon 550Document6 pagesJotun - Boletim Técnico - Marathon 550Roberta RamosNo ratings yet

- TDS Safeguard Universal ES BR Portuguese MarineDocument5 pagesTDS Safeguard Universal ES BR Portuguese MarineRoberta RamosNo ratings yet

- Grécia - GreeceDocument29 pagesGrécia - GreeceRoberta RamosNo ratings yet

- TDS Penguard Primer BR Portuguese MarineDocument5 pagesTDS Penguard Primer BR Portuguese MarineRoberta RamosNo ratings yet

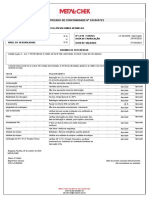

- Certificado de Conformidade #202200650: Produto Metal-Chek E 59 Propelente Hidrocarboneto (Hi) RemovedorDocument1 pageCertificado de Conformidade #202200650: Produto Metal-Chek E 59 Propelente Hidrocarboneto (Hi) RemovedorRoberta RamosNo ratings yet

- TDS Jotacote Universal BR Portuguese MarineDocument6 pagesTDS Jotacote Universal BR Portuguese MarineRoberta RamosNo ratings yet

- N 2683Document14 pagesN 2683Roberta RamosNo ratings yet

- LT-23-0052 104Document1 pageLT-23-0052 104Roberta RamosNo ratings yet

- 467-NR Amd 2023-01Document128 pages467-NR Amd 2023-01Roberta RamosNo ratings yet

- LT 20 0454Document1 pageLT 20 0454Roberta RamosNo ratings yet

- Certificado de Qualidade Bohler Q 71 RC DGDocument1 pageCertificado de Qualidade Bohler Q 71 RC DGRoberta RamosNo ratings yet

- LT 21 0362Document1 pageLT 21 0362Roberta Ramos100% (1)