Professional Documents

Culture Documents

Steelgrid HR PVC System Datasheet AU

Steelgrid HR PVC System Datasheet AU

Uploaded by

Rodrigo Morgado0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

Steelgrid-HR-PVC-System-Datasheet-AU

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views2 pagesSteelgrid HR PVC System Datasheet AU

Steelgrid HR PVC System Datasheet AU

Uploaded by

Rodrigo MorgadoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

TECHNICAL DATA SHEET

Rev. 06, Date 03.06.2014

STEELGRID® HR PVC SYSTEM

HIGH CORROSION PROTECTION GEOCOMPOSITE MESH SYSTEM

The new Steelgrid® HR PVC System is an innovative

complete system for rockfall mitigation and slope

consolidation works. The Steelgrid® HR PVC System

combines a patented high strength steel wire mesh

geocomposite which is used in conjunction with anchor plates,

specific U-bolts and mesh connectors. The Steelgrid® HR

PVC mesh is a composite of double twisted steel wire

hexagonal mesh with high tensile strength steel cables,

woven into the mesh during the manufacturing process.

The high level corrosion protection for the steel wire mesh

and ropes (Class A Zn-Al5% Galvanised and PVC coating),

and for the accessories makes the Steelgrid® HR PVC

System ideal for use in environments ranging from near-

coastal regions and splash zones to high alpine areas.

Innovation in the Maccaferri manufacturing process adapts

Steelgrid® HR PVC System

the traditional twisting process to create a ‘hybrid mesh’; the

mesh features a combination of full and half-hexagonal

shaped mesh apertures. To provide high tensile strength and

punching resistance at low-strain, the steel cables lie

predominantly straight within the hexagonal mesh. As the

mesh offers immediate resistance to loads at minimal strain,

there is no requirement to pre-tension the mesh.

The post-manufacturing alignment of the steel cables within

Steelgrid® HR PVC can vary depending on the rope spacing

and position within the roll. Performance testing is carried out

in compliance with this natural variability. When the mesh is

installed and loaded, the ropes lie straight within the mesh

offering high strength and stiffness (strength at low strain). In

comparison with traditional double twist and single twist

meshes; elongation of Steelgrid® HR PVC is in the range of 5- Figure 2: Punch test performance comparison

9% compared with 16-23% for double twist meshes

depending on mesh / wire combinations. Punch resistance, Steelgrid® HR Punching Ultimate Ultimate

tested in accordance with UNI 11437, shows a greater PVC variant displacement at punching punching

improvement, with average increases of 20-40% compared 50kN punching force displacement

with double twist meshes. force

HR PVC 30 <340 mm 125 kN 430 mm

HR PVC 50 <370 mm 105 kN 450 mm

HR PVC 100 < 420 mm 74 kN 450 mm

Table 2: Punch test performance (UNI 11437)

Figure 1: Production

Steelgrid® HR Nominal longitudinal tensile strength Figure 3: Punching test

PVC variant (Peak value)

HR PVC 30 119 kN/m

HR PVC 50 89 kN/m

HR PVC 100 73 kN/m 13

1301-CPD-0893

Table 1: Longitudinal tensile performance ETA - 13/0524 n° 226/001

Maccaferri reserves the right to amend product specifications without notice and specifiers are

requested to check as to the validity of the specifications they are using.

Steelgrid® HR PVC system is installed in the same general

Table 3 - Standard Production Data

way as conventional double twist mesh. It is easy to handle

and will not require extensive modification of existing method Nominal Roll Nominal Roll

statements and installation techniques. The inclusion of the Steelgrid HR PVC Nominal Roll

width width (by

variant Length

steel ropes greatly enhances the transfer of loads from the (by truck) container)

mesh into the anchorage system thereby increasing safety,

capacity and durability of the mesh as a complete system. HR PVC 30 3.15m 2.85m 25/40m

The accessories supplied by Maccaferri together with the HR PVC 50 3.25m 2.75m 25/40m

Steelgrid® HR PVC system (especially the steel plate to

be combined together with possible anchors) deliver a HR PVC 100 3.10m 2.85m 25/40m

system characterized by high performance and reassurance. All sizes and dimensions are nominal. Confirmation should be sought

from regional office prior to placement of an order. Mesh production

Steel Wire Used for Double Twist Hexagonal Mesh tolerances of ±3% of the length, ±5% of the width, ±8% of

Tensile strength: The wire used for the manufacture of rope spacing shall be permitted.

mesh shall have a tensile strength between 380-550N/ Other roll dim ensions are available on request.

mm2 (EN 10223-3). Wire tolerances (see Table 3) are in Table 4 - Standard Double Twist Mesh & Wire Data

accordance with EN 10218 (Class T1).

Elongation: Elongation shall be not lower than 9%, (EN Mesh Type D (mm) ø Wire (mm)

10223-3). 8x10 80 2.70

GalMac® coating: Minimum quantities of GalMac®

shown at Table 2 meet the requirements of EN 10244-2 Mesh wire diameter ø mm 2.70

(Class A). Mesh wire overall diameter ø mm 3.70

Adhesion of GalMac®: The adhesion of the GalMac®

coating to the wire shall be in accordance with EN 10244- Wire diameter tolerance (±) ø mm 0.06

2. ® 2

GalMac minimum quantity gr/m 245

Outwearing accelerated aging test: In a general

condensation of moisture containing sulfur dioxide test (28 PVC coated rope diameter ø mm 8.00

cycles) according to EN ISO 6988 (without showing signs

of red rust).

Outer Polymer coating: Continuous extruded PVC

coating nominal thickness 0.5 mm. The tolerance on the opening of

mesh ‘D’ being the distance

Steel Wire Ropes between the axis of two

Surface Finish of Component Rope Wires: Zinc- consecutive twists, is according

Aluminium alloy (Zn-5%Al) coated to Class A ["A (Zn/Al)"] to EN 10223-3

in accordance with EN 10244-2.

Rope Outer Coating: Continuous extruded PVC

coating of nominal thickness 1 mm

Steel wire Rope Diameter: 6 mm (measured across

the broadest diameter in accordance with the relevant Double Twisted Hexagonal Mesh detail information

standard). Rope overall dia. including PVC coating: 8

mm.

Rope Construction: Diameter 6mm, “6x7WC - WSC”

described in accordance with relevant standards EN

12385-2 2008 and EN 12385-4 2008.

Nominal Grade of Rope: 1770 N/mm 2 defined

according to EN 12385-4 2008.

Minimum Breaking Load (MBL) of Rope: 22.9 kN as

defined in EN 12385-4 2008.

Steel plate (“HR PLATE”)

PVC Coating Used on Wires and Ropes

Material Quality: in accordance with EN 10245-2

Unit Weight: 130 to 135 kg/m3 to ISO 1183

Hardness: 50 to 60 Shore D according to ISO 868 U-bolt wire rope grip

Tensile Strength: ≥ 21 N/mm2 according to ISO 527 (“HR GRIP”)

Elongation at Failure: ≥200% according to ISO 527

UV stabilisation: YES

WARNING: Install all rockfall and mesh products in accordance with National or Local Legal and Security Requirements. If the installation

is performed by working insuspension or using security ropes, personal protective equipment against fall risk must be connected with

anchor points in agreement with EN 795 or other relevant regional equivalanent standards and practices. Mesh connectors (“HR LINK”)

Officine Maccaferri S.p.A.

Via Kennedy, 10 - 40069 Zola Predosa (BO) - Italy Bureau Veritas Certified Quality System Company with

Tel. (+39) 051-6436000 - Fax (+39) 051-6436201 Accredia's and UKAS' s accreditation.

E-mail: comes@maccaferri.com www.officinemaccaferri.com

You might also like

- Plan. SamplingDocument9 pagesPlan. SamplingAstya SeptariniNo ratings yet

- Summary - Changes in Piping ClassesDocument4 pagesSummary - Changes in Piping Classesvelap15504No ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Uk TDS Steelgrid HR-PVCDocument2 pagesUk TDS Steelgrid HR-PVCKenneth KnoxNo ratings yet

- TDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014Document2 pagesTDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014mandeep571No ratings yet

- TDS-PH-Reno Mattress Galfan+PVC 2019Document2 pagesTDS-PH-Reno Mattress Galfan+PVC 2019j.quiminales41No ratings yet

- Stellgrid HR 30Document2 pagesStellgrid HR 30Mario CordovaNo ratings yet

- Western India Wire IndustriesDocument7 pagesWestern India Wire Industriesyns_krisNo ratings yet

- TDS-PH-Gabions Galfan+PVC 2019Document2 pagesTDS-PH-Gabions Galfan+PVC 2019jericquiminalesNo ratings yet

- TDS-PH-Reno Mattress Zinc+PVC 2019Document2 pagesTDS-PH-Reno Mattress Zinc+PVC 2019j.quiminales41No ratings yet

- TDS-PH-Gabions ZN+PVC 2019Document2 pagesTDS-PH-Gabions ZN+PVC 2019jericquiminalesNo ratings yet

- DYWIDAG Prestressing Systems Using BarsDocument18 pagesDYWIDAG Prestressing Systems Using Barsbignose93gmail.comNo ratings yet

- UK Designers Handbook SteelgridHR Rev2 - 2Document55 pagesUK Designers Handbook SteelgridHR Rev2 - 2Kenneth Knox100% (1)

- TDS PH GabionZinc+PVC May2014Document2 pagesTDS PH GabionZinc+PVC May2014SunderNo ratings yet

- TDS - Galmac PVC Coated Gabions June 10Document2 pagesTDS - Galmac PVC Coated Gabions June 10Chana PalominoNo ratings yet

- TS - Double Twist Wire Mesh Mono Oriented CompositeDocument4 pagesTS - Double Twist Wire Mesh Mono Oriented CompositeSOMNATH JANANo ratings yet

- TDS Jumbo Gabion P8+2.7 PolimacDocument2 pagesTDS Jumbo Gabion P8+2.7 PolimacszemianNo ratings yet

- Product Specification - Triax ® Tx160 GeogridDocument1 pageProduct Specification - Triax ® Tx160 Geogridrodrigobs1988No ratings yet

- Specification Reno Matress Mesh 8Document9 pagesSpecification Reno Matress Mesh 8Najid MohamedNo ratings yet

- Welded Wire MeshDocument23 pagesWelded Wire MeshSushmit Sharma100% (1)

- TDS HEA Panel Galmac C#Document2 pagesTDS HEA Panel Galmac C#szemianNo ratings yet

- Reno MattressDocument2 pagesReno MattressnathychidazNo ratings yet

- PoliMac Coated Gabion Mattress SpecDocument2 pagesPoliMac Coated Gabion Mattress SpecworkatarNo ratings yet

- Specification For Vertical Drains and Surcharge: 1.0 GeneralDocument13 pagesSpecification For Vertical Drains and Surcharge: 1.0 Generaljegatheesan777No ratings yet

- RC Detailing To EuroCode 2Document39 pagesRC Detailing To EuroCode 2ahmadNo ratings yet

- Sikawrap 230C 01012014Document4 pagesSikawrap 230C 01012014rizone83No ratings yet

- Ma Tds Dtnet ZN Rev19Document2 pagesMa Tds Dtnet ZN Rev19sundra0No ratings yet

- TS US Gabion, GalMac Jan19Document8 pagesTS US Gabion, GalMac Jan19johnnee98No ratings yet

- S10-Specification For Gabion Reinforced Earth SystemDocument9 pagesS10-Specification For Gabion Reinforced Earth SystemwongtianhuiNo ratings yet

- TDS Jumbo Gabion P8+2.2 PVC - PubDocument2 pagesTDS Jumbo Gabion P8+2.2 PVC - PubszemianNo ratings yet

- TDS RO GAB GL ENG Rev Jul2014 PDFDocument2 pagesTDS RO GAB GL ENG Rev Jul2014 PDFCatalin GudeiNo ratings yet

- Strengthening of Damaged PSC Bridge Girders With Carbon Fibre Reinforced Polymer "CFRP" SystemDocument40 pagesStrengthening of Damaged PSC Bridge Girders With Carbon Fibre Reinforced Polymer "CFRP" SystemVipin Kumar ParasharNo ratings yet

- N-2409 - Flexible Pipes PDFDocument88 pagesN-2409 - Flexible Pipes PDFIgor BastosNo ratings yet

- VSL Thread Bar Systems BrochureDocument16 pagesVSL Thread Bar Systems BrochureFida GNo ratings yet

- 11 kV-22 kV-33 KV Composite InsulatorsDocument15 pages11 kV-22 kV-33 KV Composite InsulatorsSandip AhireNo ratings yet

- Bushing Connection Animal Cover: Energy DivisionDocument2 pagesBushing Connection Animal Cover: Energy Divisionjorge_moralesmNo ratings yet

- Sikawrap - 600 C WVDocument4 pagesSikawrap - 600 C WVIndra KusumaNo ratings yet

- TriAx TX140 GridDocument2 pagesTriAx TX140 GridDalibor BuriloNo ratings yet

- Grouted Pipe With Double Spirals For Precast Concrete ConnectionsDocument7 pagesGrouted Pipe With Double Spirals For Precast Concrete ConnectionsHafiz SaeedNo ratings yet

- TDS-PH-Green Terramesh Galfan+PVC 2019Document2 pagesTDS-PH-Green Terramesh Galfan+PVC 2019jericquiminalesNo ratings yet

- Kingspan Multideck MD60 Datasheet EN UK-1Document6 pagesKingspan Multideck MD60 Datasheet EN UK-1Fabio de PaulaNo ratings yet

- 2005 PSS Road MeshDocument4 pages2005 PSS Road MeshJim Arturo Rivera VidalNo ratings yet

- Cable Tray 27Document37 pagesCable Tray 27Sri Ravindra Yadav PattapogulaNo ratings yet

- 2009 TDS Terramesh Galvanized & PVC AMDocument2 pages2009 TDS Terramesh Galvanized & PVC AMRobert Ibañez MendezNo ratings yet

- Nema Rn1 1998Document1 pageNema Rn1 1998AXEL OMAR SANCHEZNo ratings yet

- CRA 2011 Introductory PresentationDocument34 pagesCRA 2011 Introductory PresentationMasood KhanNo ratings yet

- Specification For Prefabricated Vertical Drain: 1.0 GeneralDocument6 pagesSpecification For Prefabricated Vertical Drain: 1.0 GeneralAbdul HalimNo ratings yet

- Maccaferri - Road Mesh Heavy Duty SpecDocument2 pagesMaccaferri - Road Mesh Heavy Duty SpecNguyen HungNo ratings yet

- Datasheet: 33kV Cold-Shrink Inline Joint With Cold-Shrink Re-Jacketing, Including ConnectorsDocument2 pagesDatasheet: 33kV Cold-Shrink Inline Joint With Cold-Shrink Re-Jacketing, Including ConnectorsMohammed MustafaNo ratings yet

- Coldshrinkable Joints For 3-Core Cable With Heatshrinkable Protection CSJHDocument2 pagesColdshrinkable Joints For 3-Core Cable With Heatshrinkable Protection CSJHSolihin AliNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Gallium Nitride-enabled High Frequency and High Efficiency Power ConversionFrom EverandGallium Nitride-enabled High Frequency and High Efficiency Power ConversionGaudenzio MeneghessoNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Modelling of The Mechanical Interaction Between Anchored Wire Meshes and Granular SoilsDocument17 pagesModelling of The Mechanical Interaction Between Anchored Wire Meshes and Granular SoilsRodrigo MorgadoNo ratings yet

- Dynamic Response of Flexible Rockfall Barriers With Different Block ShapesDocument17 pagesDynamic Response of Flexible Rockfall Barriers With Different Block ShapesRodrigo MorgadoNo ratings yet

- Trustworthiness of Flexible Rockfall Protection Systems - 2021 - Axel Volkwein, Marcel Fulde, Ingvar Krieger HaukssonDocument7 pagesTrustworthiness of Flexible Rockfall Protection Systems - 2021 - Axel Volkwein, Marcel Fulde, Ingvar Krieger HaukssonRodrigo MorgadoNo ratings yet

- Impact of Rock Block Characteristics On Rockfall Hazard and Its ImplicationsDocument22 pagesImpact of Rock Block Characteristics On Rockfall Hazard and Its ImplicationsRodrigo MorgadoNo ratings yet

- Massive Sandstone Falling Analysis and Design BarriersDocument11 pagesMassive Sandstone Falling Analysis and Design BarriersRodrigo MorgadoNo ratings yet

- Geosciences: Landslide Susceptibility Mapping in Brazil: A ReviewDocument15 pagesGeosciences: Landslide Susceptibility Mapping in Brazil: A ReviewRodrigo MorgadoNo ratings yet

- A Comparative Assessment of ASM4 Rockfall Barrier Modelling - R. Boulaud, C. DoutheDocument14 pagesA Comparative Assessment of ASM4 Rockfall Barrier Modelling - R. Boulaud, C. DoutheRodrigo MorgadoNo ratings yet

- L2 - TECCO Techdoc-Summary 2020 screen-ENDocument36 pagesL2 - TECCO Techdoc-Summary 2020 screen-ENRodrigo MorgadoNo ratings yet

- RUVOLUM Product Profile 200131-ENDocument2 pagesRUVOLUM Product Profile 200131-ENRodrigo MorgadoNo ratings yet

- TECCO Slope Stabilization System and RUVOLUM Dimensioning MethodDocument267 pagesTECCO Slope Stabilization System and RUVOLUM Dimensioning MethodMarco ConsortiNo ratings yet

- New Results of Large-Scale Testing (Bucher, 2016)Document12 pagesNew Results of Large-Scale Testing (Bucher, 2016)Rodrigo MorgadoNo ratings yet

- Nickel-Base Superalloys Physical Metallurgy of RecyclingDocument13 pagesNickel-Base Superalloys Physical Metallurgy of Recycling張竣凱No ratings yet

- 61455058924surface Preparation StandardsDocument10 pages61455058924surface Preparation StandardsMULAYAM SINGH YADAVNo ratings yet

- Index MBL22-8 MBL40-6 MBL40-8 enDocument5 pagesIndex MBL22-8 MBL40-6 MBL40-8 enMahir PiricNo ratings yet

- High Speed Milling of Hardened Steel Convex SurfaceDocument12 pagesHigh Speed Milling of Hardened Steel Convex SurfaceZerina ČustovićNo ratings yet

- 04 WIS5 Destructive TestingDocument78 pages04 WIS5 Destructive Testingsaid aminNo ratings yet

- 001.gad Bow String Steel Bridge 200 M SpanDocument1 page001.gad Bow String Steel Bridge 200 M SpanManvendra NigamNo ratings yet

- 0 CR 18 Ni 9Document3 pages0 CR 18 Ni 9m.j.hemmati72No ratings yet

- Trommel Frame 4500 Diax5200 LGDocument3 pagesTrommel Frame 4500 Diax5200 LGFelipe IgnacioNo ratings yet

- How To Install ESD PVC FLOORDocument18 pagesHow To Install ESD PVC FLOORabdulrahman abosteetNo ratings yet

- Effects of Si-Al Ratio On The Structure and Properties of MetakaolinDocument7 pagesEffects of Si-Al Ratio On The Structure and Properties of MetakaolinHoài BãoNo ratings yet

- Cyclone U and PDocument2 pagesCyclone U and PtomaszNo ratings yet

- Zinc Chro Shield Os TDSDocument3 pagesZinc Chro Shield Os TDSErick CruzNo ratings yet

- AlgarobaDocument9 pagesAlgarobaMARIANA GUIMARAES DE SA LOBATO EF9-73MNo ratings yet

- Providing High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForDocument9 pagesProviding High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForAnderson TadeuNo ratings yet

- SF - Architectural ConcreteDocument8 pagesSF - Architectural ConcreteMuwafaq_mibNo ratings yet

- Solid Waste Management of Mnit Campus A Case Study IJERTCONV1IS02029Document6 pagesSolid Waste Management of Mnit Campus A Case Study IJERTCONV1IS02029SREYAS K MNo ratings yet

- Duplex Stainless SteelsDocument24 pagesDuplex Stainless Steelsbhavesh nakumNo ratings yet

- Nippon Steel Carbon Neutral Vision 2050: March 30, 2021Document54 pagesNippon Steel Carbon Neutral Vision 2050: March 30, 2021Kedar BhaveNo ratings yet

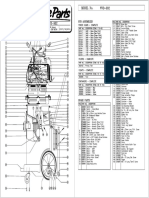

- Mitsubishi Sewing Machine Parts Catalog: Model .. DB130-11 D8130-12 D8130-13 D8130-14 D8130-22Document25 pagesMitsubishi Sewing Machine Parts Catalog: Model .. DB130-11 D8130-12 D8130-13 D8130-14 D8130-22Diego De La FuenteNo ratings yet

- Despiece Aspirador WVD900-2Document7 pagesDespiece Aspirador WVD900-2pmunozNo ratings yet

- 8th India Rubber Expo & Tyre ShowDocument76 pages8th India Rubber Expo & Tyre ShowAshish Angelz ExhibitionsNo ratings yet

- Catalog 2023 FinalDocument55 pagesCatalog 2023 FinalHana VũNo ratings yet

- Uhde Painting SpecificationDocument34 pagesUhde Painting Specificationmohamed elmasryNo ratings yet

- Top Things To Know About PCB Board Thickness ToleranceDocument5 pagesTop Things To Know About PCB Board Thickness TolerancejackNo ratings yet

- MPM ReportDocument6 pagesMPM ReportSiddi Sampath Kumar ReddyNo ratings yet

- Fangsu CatalogDocument13 pagesFangsu Catalog常青树No ratings yet

- RT Relevant DiscontinuitiesDocument70 pagesRT Relevant Discontinuitiesabdo50% (2)

- Belvedere Riverside Waste Bunker 1Document1 pageBelvedere Riverside Waste Bunker 1Sammy ChanNo ratings yet