Professional Documents

Culture Documents

RSP - Datasheet - Vas Expansiune Incalzire

RSP - Datasheet - Vas Expansiune Incalzire

Uploaded by

Iasmina ClaudiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RSP - Datasheet - Vas Expansiune Incalzire

RSP - Datasheet - Vas Expansiune Incalzire

Uploaded by

Iasmina ClaudiaCopyright:

Available Formats

Page 1 from 11

1. Information

1.1 Heating Project number

Project name

Responsible person

date 2023-05-23

Note

Language English

2. System data of the solution

2.1 System data, general configuration standard DIN EN 12828, VDI 4708

2.2 Futher settings for functional Automatic system monitoring and water make-up yes

requirements accessories

Protection of the system by venting and yes

degassing

Protection of the system by dirt separation yes

Treatment of the filling and make-up water yes

2.3 Temperatures highest setpoint setting of the temperature con- 50 °C

troller (t max)

Expansion coefficient 1.2 %

Maximum Flow Temperature (t v) 50 °C

Return temperature (t r) 30 °C

Safety temperature limiter/monitor (t stb) 55 °C

Antifreeze content 0.0 %

Minimum system temperature (t min) 10 °C

2.4 Pressures Static pressure (p st) 1.0 bar

Safety Valve Actuating Pressure (p sv) 2.5 bar

Final pressure (p e) 2.0 bar

Minimum operating pressure (p 0) 1.2 bar

Minimum inlet pressure for circulating pumps (p z) 1.0 bar

Evaporation pressure (p d) 0.0 bar

Make up from the water supply yes

Potable water supply pressure (p zl) 3.5 bar

2.5 Heating power and system Heat generator

volume

1. Heat generator

Heat generator type Steel boiler / burner blower

Power 18 kW

Volume 59 L

Expansion line <10m//10m <L<30m -

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 2 from 11

2. System data of the solution

Consumer

1. Heating circles

Consumer type Panel radiator

Power 18 kW

Part Load 100.0 %

Volume 353 L

Flow 50 °C

Return 30 °C

Volume 0L

Special pipelines/long pipelines

1. Special lines

Diameter in DN DN 10

Length of the transmission line 0.0 m

Volume 0L

Volume 0L

Total thermal output of the heat generator 18 kW

Calculated system volume 412 L

Expansion line <10m//10m <L<30m DN20//DN20

Expansion volume 5L

Desired minimum water reserve 0.7 %

Water reserve 3L

effective water reserve 1.2 %

effective water reserve 5L

2.6 Approximate values for the Filling pressure at corresponding temperature

system working pressure

50 °C 2.0 bar

40 °C 1.9 bar

30 °C 1.8 bar

20 °C 1.8 bar

10 °C 1.8 bar

This table is only correct if the actual system data correspond to the calculation basis.

2.7 System data, separation Deposition of ferromagnetic particles (magnetite) yes

Flow 0.80 m³/h

Pipe size DN 20 (IG 3/4; 22 mm)

2.8 System data, make-up and Softening according to VDI 2035 yes

water treatment Current water hardness 12.0 °dH

Desired water hardness make-up water 8.4 °dH

Possible refill quantity per cartridge 1667 L

2.9 System data, low loss Flow 0.80 m³/h

headers

2.10 System data, heat exchanger Heat output (Q) 18 kW

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 3 from 11

3. System / Net

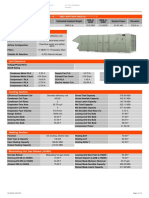

3.1 Membrane expansion vessel

Position Art. No. Quantity Article text

3.1.1 8209300 1 Reflex N 50

Reflex Reflex N 50

Diaphragm expansion tank for sealed heating and cooling water systems. Vessels fit-

ted according to DIN EN 13831. Approval according to Pressure Equipment Directive

2014/68/EC.

– Durable epoxy resin coating

– Non-replaceable diaphragm according to DIN EN 13831

– 35 litres and above upright

– For antifreeze additive of at least 25 – 50 %

– With threaded connections

– max. permissible system temperature 120 °C

– Max. operating temperature 70 °C

Type N 50

Colour grey

Nominal volume 50 l

Max. useful volume 45 l

Max. permissible system tempera- 120 °C

ture

Max. perm. operating temperature 70 °C

Max. perm. operating pressure 6 bar

Factory provided gas supply pres- 1.5 bar

sure

Connection R 3/4"

Diameter 441 mm

Height 487 mm

High water connection 175 mm

Tilt dimension approx. 657 mm

Weight 9.60 kg

Set gas system pressure 1.2 bar

3.1.2 7613000 1 Reflex Cap valve SU R 3/4" x 3/4"

Reflex cap valve

For diaphragm expansion vessels in sealed heating and cooling systems.With a safe

shut-off to prevent inadvertent closing and a discharge according to DIN EN 12828.

Type SU R 3/4" x 3/4"

Max. perm. operating temperature 120 °C

Max. perm. operating pressure 10 bar

Connection G 3/4"

Weight 0.26 kg

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 4 from 11

3. System / Net

3.2 Degassing

Position Art. No. Quantity Article text

3.2.1 8835800 1 Servitec Mini

Reflex Servitec

Vacuum spray tube degassing for system degassing in sealed heating and chilled

water systems, configured as a fully automatic multi-function unit with auto-stop oper-

ation and automatic hydraulic compensation of the degassing process and monitor-

ing of the make-up request.Suitable for the media water and water/glycol mixtures

up to a mixing ratio of 50/50%.Functional unit comprising hydraulic part designed for

wall mounting and electronic, ergonomically arranged Control Smart controller with

CE marking.Degassing takes place within the hydraulic part using a diaphragm pump

in conjunction with a vertically arranged brass vacuum spray tube. This is equipped

with a vacuum spray nozzle, dipstick-tube degassing unit and pressure monitor-

ing. To protect it against dirt, the unit as a whole is located in a housing made from

expanded polypropylene with an opening maintenance cover.The Control Smart con-

troller is integrated in a robust plastic housing in which both the power and commu-

nication electronics and the control panel with dirt-resistant plastic foil keyboard are

housed. Bluetooth is integrated as standard as a communications interface. The con-

troller has a fully automatic microprocessor controller with time function, differentiat-

ing error and parameter memory, LED display of the operating modes and general

error messaging, visualisation of the control states for system pressure and all rele-

vant operating and fault messages using the Control Smart App via Bluetooth com-

munication.Control Smart enables convenient wireless operation via Bluetooth using

an app for smartphones and tablets running either iOS or Android to provide simple

commissioning as well as visualisation of system operation. The following functions

are available:

– Automatic setting of the time and date

– Setting and adjusting the minimum operating pressure p0

– Switch-on times for permanent and interval degassing can be freely specified and

entered by the operator

– Free configuration of day of the week and time for interval degassing operating

mode including a summer function

– Status, warning and error display relating to facility pressure and operating states

including diagnostic instructions and handling recommendations

– Automatic software updates

Control unit completely assembled and wired ready for connection according to VDE

regulations, mains power cable and mains plug, system connections by means of

integrated shut-off valves.Method of functioning in optimised operation with cycles

for continuous and interval degassing. Actuation takes place via an integrated sys-

tem pressure interpretation unit with automatic interruption and fault messaging upon

exceeding of the running time and/or the number of cycles. Documentation and con-

trol of the entire system in respect of the above mentioned parameters.

Max. electrical rated power 0.06 kW

Type Mini

Max. sound pressure level 55 dB(A)

Max. system volume 1 m³

Max. perm. operating temperature 60 °C

Rated electrical current 0.30 A

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 5 from 11

3. System / Net

3.2 Degassing

Position Art. No. Quantity Article text

Servitec Mini

Pressure side connection G 1/2"

Connection outflow side G 1/2"

Separation level, dissolved gases to 90 %

Max. partial volume flow network 0.050 m³/h

Height 420 mm

Width 295 mm

Depth 220 mm

Weight 5.60 kg

Data of the connected supply system

Water content 412 L

Heat generator safety valve 2.5 bar

Minimum operating pressure 1.2 bar

Final pressure of the pressurisation 2.0 bar

Minimum supply pressure, make-up 1.0 bar

3.3 Water treatment

Position Art. No. Quantity Article text

3.3.1 6811500 1 Fillcontrol Plus Compact

Reflex Fillcontrol Plus Compact

Automatic make-up and filling station for heating and cooling systems with

diaphragm-type expansion tanks (MAG). Enables a controlled and reliable make-up

and system filling in accordance with DIN EN 1717 or DIN 1988 from directly con-

nected mains water grids and implements the recommended function control of the

pressurisation system (MAG) according to DIN EN 12828 and VDI 4807. Comprising

shut-off valve, DVGW tested system isolator (BA) according to DIN EN 12729, dirt

trap, pressure sensor, motorised ball valve, pressure reducer with control manometer

and microprocessor-control unit. All components are integrated in a housing so they

have a minimum footprint and are easily accessible. The controlled, pressure-depen-

dent make-up takes place with automatic interruption and fault messaging upon

exceeding of the running time and/or the number of cycles. First filling of the system

and refilling are possible using the operating mode that can be set for this purpose.

Function control and monitoring of the CE-designated station takes place via a fully

automatic and freely programmable microprocessor control unit with LCD display for

all relevant operating and fault messages and pressure display, as well as a poten-

tial-free output and buzzer alarm for collective fault message.

Type Plus Compact

Max. perm. operating temperature 70 °C

Max. perm. operating pressure 10 bar

Min. flow pressure p 0 + 1,3

Inlet connection R 1/2"

Outlet connection R 1/2"

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 6 from 11

3. System / Net

3.3 Water treatment

Position Art. No. Quantity Article text

Fillcontrol Plus Compact

Electric connection 230V/50Hz

Max. electrical rated power 0.60 kW

Flow rate characteristic value kvs 0.4 m³/h

Height 304 mm

Width 240 mm

Depth 90 mm

Weight 3.00 kg

3.3.2 9112004 1 Reflex Fillsoft FE

Reflex external pressure sensor

Extension kit for functional adaptation of the Fillsoft I or Fillsoft II water softening fit-

ting in conjunction with Reflex Fillcontrol. Comprising in detail:

– Brass T-piece R 1/2"

– Non-return valve

– Fillcontrol-compatible pressure transducer

– Plug-in connection cable

Type FE

Max. perm. operating temperature 70 °C

Max. perm. operating pressure 10 bar

Inlet connection R 1/2"

Height 90 mm

Width 70 mm

Depth 45 mm

Weight 0.30 kg

3.3.3 9127968 1 Reflex Fillsoft Fillguard

Reflex Fillmeter with Fillguard mini-function

Water meter for monitoring softening and desalination systems for heating water

treatment (e.g. Reflex Fillsoft or Reflex Fillsoft Zero) or control of pumps, valves or

systems during filling and draining of containers, etc. The Function Fillmeter is an

electronic water meter for measuring total water volumes and volume flows, as well

as for counting down of a programmable specified water volume with limit value sig-

nalling by means of a pulse output or analogue signal. The Function Fillguard has an

integrated sensor for monitoring the capacity state of desalination cartridges in the

treatment of filling and make-up water for heating systems. Particularly suitable in

conjunction with Reflex Fillsoft Zero for implementation of low-salt running according

to VDI 2035. Fillguard continuously determines the electric conductivity of the desali-

nated water and outputs it via an integrated display; value checking and program-

ming via a plastic foil keyboard. Power supply via supplied fully-wired 1.5 m long con-

nection cable.

Type Fillguard

Max. perm. operating temperature 60 °C

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 7 from 11

3. System / Net

3.3 Water treatment

Position Art. No. Quantity Article text

Reflex Fillsoft Fillguard

Max. perm. operating pressure 10 bar

Connection Rp 1/2"

Height 81 mm

Width 83 mm

Depth 70 mm

Weight 0.40 kg

3.4 Water make-up

Position Art. No. Quantity Article text

3.4.1 9125660 1 Fillsoft FG I

Reflex Fillsoft cartridge housing, compact basic fitting for treatment of filling and

makeup water using an ion-exchanger process for the protection of heat genera-

tors and hot water heating systems according to VDI 2035. Cartridge housing can

be used in combination with the corresponding cartridge inserts (separate products)

optionally for water softening or water desalination.Empty housing is assembly-ready

with wall mounting bracket for optional equipping with one:

– Fillsoft water softening resin cartridge (green) FSP 6000 for the water softeningor

– Fillsoft Zero mixed bed resin cartridge (grey) FZP 3000 for water desalination

Fillsoft I individually comprising:

– a cylindrical propylene housing with brass thread connections for holding one of

the above mentioned water treatment cartridges and optional attachment of a

Reflex Softmix mixing mechanism,

– Flow limiter

– Shut-off ball valve with sampling tap

Components are arranged as a compact fitting for installation in the filling and

makeup water line.

Type FG I

Max. perm. operating temperature 40 °C

Max. perm. operating pressure 8 bar

Inlet connection Rp 1/2"

Outlet connection Rp 1/2"

Height 600 mm

Width 260 mm

Weight 1.90 kg

3.4.2 6811800 1 Fillsoft FSP 6000

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 8 from 11

3. System / Net

3.4 Water make-up

Position Art. No. Quantity Article text

Fillsoft FSP 6000

Reflex Fillsoft cartridge

Cation resin cartridge for filling and make-up water softening, fitting in the Fillsoft I or

II cartridge housing. Comprising cylindrical polypropylene cartridge filled with cation

exchanger resin for softening of filling and make-up water according to VDI 2035

and/or manufacturer specifications in hot water based heating systems according to

DIN EN 12828.

Type FSP 6000

Colour green

Max. perm. operating temperature 40 °C

Max. perm. operating pressure 8 bar

Height 513 mm

Weight 1.50 kg

3.4.3 9200276 1 Reflex Fillsoft Tool

Reflex Fillsoft key

Sturdy plastic key for safe undoing and tightening of the Reflex Fillsoft fitting to sim-

plify cartridge replacement.

Type Tool

Colour black

Diameter 143 mm

Height 298 mm

Weight 0.40 kg

3.4.4 9119219 1 Reflex Fillsoft Softmix

Reflex Softmix

Attachment dilution valve for setting a selectable discharge water hardness range for

Reflex Fillsoft I or Fillsoft II water softening valves. Featuring in detail:

– Dilution valve with setting scale

– Bypass pipe

– Fitting set for assembly on above mentioned water softening valves

Type Softmix

Max. perm. operating temperature 70 °C

Max. perm. operating pressure 10 bar

Inlet connection R 1/4"

Outlet connection R 1/4"

Weight 0.20 kg

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 9 from 11

3. System / Net

3.5 Separator Exdirt

Position Art. No. Quantity Article text

3.5.1 9256610 1 Exdirt D 3/4 M

Reflex Exdirt Magnet

Dirt and sludge separator for heating and cooling water systems or closed liquid-filled

plant systems.

Suitable for the media water and water/glycol mixtures up to a mixing ratio of

50/50%.

Integrated high energy permanent magnet easy clip with plug function for a quick

connection without additional assembly effort on the sludge and dirt separator. High

performance magnet comprising an isostatic pressed neodymium washer, that is

inserted in a TPE plug-in washer. Highly efficient separation and fixing of ferro-

magnetic particles from the flow directly in the separator chamber thanks to axi-

ally-aligned magnetic field. Particles are specifically and permanently removed from

the system by simple pulling out of the plug-in magnets from the separator hous-

ing, and subsequent cleaning without any interruption to operation. For maintenance

tasks, the plug-in magnet can be removed from the separator housing by simply

pulling it out.

The cleaning and emptying of the dirt collection chamber is possible via a dedicated

desludging ball valve without any necessity to interrupt operation.

Type D 3/4 M

Housing material brass

Installation variant horizontal

Max. perm. operating temperature 110 °C

Max. perm. operating pressure 10 bar

Connection IG 3/4"

Cleaning connection G 3/4"

Connection variant thread

Max. volume flow 1.3 m³/h

Diameter 63 mm

Height 122 mm

Width 121 mm

Installation length 85 mm

Weight 1.00 kg

3.5.2 9254811 1 Reflex Exiso A/D 22 - 1 1/2

Reflex Exiso

Thermal insulation for Reflex Exvoid micro-bubbles or Exdirt dirt separator. Compris-

ing two shape and temperature-stable, adaptable, form-fitting rigid-foam semi-shells

with a folding closure or clamping strap.

Type A/D 22 - 1 1/2

Colour black

Insulation material

Insulation strength 15 mm

Max. perm. operating temperature 110 °C

Diameter 125 mm

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 10 from 11

3. System / Net

3.5 Separator Exdirt

Position Art. No. Quantity Article text

Reflex Exiso A/D 22 - 1 1/2

Height 225 mm

Width 100 mm

Depth 108 mm

Weight 0.07 kg

4. Heat generator protection 1

4.1 Separator Exvoid-T

Position Art. No. Quantity Article text

4.1.1 9250000 1 Exvoid T 1/2

Reflex Exvoid T

Automatic quick and large ventilator for heating and chilled water systems or sealed,

liquid-filled system circuits.Suitable for the media water and water/glycol mixtures up

to a mixing ratio of 50/50%.Fitting for the permanent discharge of gas bubbles from

high points or collection points in the hydraulic/piping system that have been pro-

vided for this purpose.

Type T 1/2

Housing material brass

Installation variant vertical

Max. perm. operating temperature 110 °C

Max. perm. operating pressure 10 bar

Connection IG 1/2"

Vent connection G 1/2"

Diameter 63 mm

Height 122 mm

Central flange-jacket 46 mm

Width 78 mm

Weight 0.63 kg

4.2 Safety valve *Third Party Product*

Position Art. No. Quantity Article text

4.2.1 255330 1 Safety valve G 1/2" -external-

Safety valve G 1/2"

Inlet connection G 1/2"

Outlet connection G 3/4"

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

Page 11 from 11

4. Heat generator protection 1

4.2 Safety valve *Third Party Product*

Position Art. No. Quantity Article text

Safety valve G 1/2" -external-

Trigger pressure SV 2.5 bar

4.3 Water level limiter *Third Party Product*

Position Art. No. Quantity Article text

4.3.1 255294 1 Water level limiter -external-

Water level limiter for water level monitoring of heat generators, type-tested accord-

ing to VD-TÜV Data Sheet Water Level 100/2. Alternatively, a minimum pressure lim-

iter, flow limiter or another suitable measure for preventing impermissible heating in

the event of insufficient water can be deployed.This item is a third-party product that

is not part of our company's scope of delivery. These are recommendations for instal-

lation in the complete system.

Modifications, errors and mistakes are subject to change. •

06 – 23 • Reflex Solutions Pro Version 23.05

Reflex Winkelmann GmbH • Gersteinstraße 19 • 59227 Ahlen, Germany +49 2382 7069-9546 • www.reflex.de • info@reflex.de

You might also like

- Cyber Security MIS607 - Assessment 3 Related NotesDocument12 pagesCyber Security MIS607 - Assessment 3 Related NotesShuja ur Rehman100% (1)

- 3D Visualization-Assisted Electromagnetic Theory TeachingDocument10 pages3D Visualization-Assisted Electromagnetic Theory TeachingmumamaduraiNo ratings yet

- Assignment 3 ShazmirDocument10 pagesAssignment 3 ShazmirVedarajan ArmugamNo ratings yet

- RSP - Datasheet - Vas Expansiune Apă CaldăDocument12 pagesRSP - Datasheet - Vas Expansiune Apă CaldăIasmina ClaudiaNo ratings yet

- DAU/O100M: Technical SelectionDocument3 pagesDAU/O100M: Technical SelectionBenny S PutraNo ratings yet

- Technical Datasheeet - R1 - ICL CommentDocument6 pagesTechnical Datasheeet - R1 - ICL CommentAshiq Elahi Design & Application EngineerNo ratings yet

- 20-120 Ton Chiller (CGAM) Product ReportDocument2 pages20-120 Ton Chiller (CGAM) Product ReportMagda Luz Marusich CastroNo ratings yet

- 1137 - Oferta Chiller TraneDocument3 pages1137 - Oferta Chiller TraneGeorge TanasescuNo ratings yet

- 10.3 SAU-SAO 025 Technical Selection R01Document3 pages10.3 SAU-SAO 025 Technical Selection R01Harry CulNo ratings yet

- RTWS - 265kW - Product ReportDocument2 pagesRTWS - 265kW - Product ReportPham Thien TruongNo ratings yet

- BROSUR UTT 13012023 PAC NetCol8000-A090D4FD4 PROJEK MPRDocument1 pageBROSUR UTT 13012023 PAC NetCol8000-A090D4FD4 PROJEK MPRyuni4ntoNo ratings yet

- 240x Installation and Servicing InstructionsDocument36 pages240x Installation and Servicing InstructionsRichard DruryNo ratings yet

- RTHD - RTHD AFD 87-99 - Consolidated Customer PackageDocument13 pagesRTHD - RTHD AFD 87-99 - Consolidated Customer Packageimecc ingenieriaNo ratings yet

- Netcol 5000Document2 pagesNetcol 5000febripepNo ratings yet

- Tech DatenDocument5 pagesTech DatenAbdessalam BushwigherNo ratings yet

- CH-03 - Technical Data SheetDocument3 pagesCH-03 - Technical Data SheetsylvanusfimNo ratings yet

- Chiller SE XRAC3612A 17-24Document2 pagesChiller SE XRAC3612A 17-24Mauricio RiscoNo ratings yet

- CCTV - CVHG780-CN123 - Product ReportDocument2 pagesCCTV - CVHG780-CN123 - Product ReportTân NguyễnNo ratings yet

- Chiller SE XRAF3612A 17-24Document2 pagesChiller SE XRAF3612A 17-24Mauricio RiscoNo ratings yet

- Energen 300 Liter Heat PumpDocument10 pagesEnergen 300 Liter Heat PumpVinay TungeNo ratings yet

- ChillerServiceReport 2020-09-23-11-33-44Document7 pagesChillerServiceReport 2020-09-23-11-33-44motlanthoiNo ratings yet

- Pressurization Unit: Vessel AcceptanceDocument11 pagesPressurization Unit: Vessel AcceptancePetre DragomirNo ratings yet

- CGAM - Air-Cooled Chiller, Scroll Compressors - Brazil Product ReportDocument2 pagesCGAM - Air-Cooled Chiller, Scroll Compressors - Brazil Product ReportRafaelDutraNo ratings yet

- Trane Chiller Data Sheet RTHDDocument1 pageTrane Chiller Data Sheet RTHDivyspellNo ratings yet

- 3.0 PEAK Chilled Water Fan Coil - ME Product ReportDocument7 pages3.0 PEAK Chilled Water Fan Coil - ME Product ReportfebousNo ratings yet

- Specifications: WG40 WG75 WG100 WG175 Performance Model NumberDocument1 pageSpecifications: WG40 WG75 WG100 WG175 Performance Model Numberconstantin.iacomi3837No ratings yet

- AC Modular Chiller Performance CompressedDocument3 pagesAC Modular Chiller Performance CompressedGraziella CathleenNo ratings yet

- FCU DATASHEET@MKCH-526-FCU Performance SheetDocument11 pagesFCU DATASHEET@MKCH-526-FCU Performance SheetGopi nathNo ratings yet

- 01 TS Cento 530 MAN NG C LB 50Hz S ENDocument2 pages01 TS Cento 530 MAN NG C LB 50Hz S ENDennis RamsumairNo ratings yet

- Fcu RDocument1 pageFcu RFareethAbdullahNo ratings yet

- Ehc Comet Electric Combi Boiler BrochureDocument4 pagesEhc Comet Electric Combi Boiler BrochureroaltmatNo ratings yet

- 39MN SubmittalDocument14 pages39MN SubmittalAlejandro DuranNo ratings yet

- Schimbator de Caldura 75 KWDocument4 pagesSchimbator de Caldura 75 KWAlin Emil MuresanNo ratings yet

- Technical SelectionDocument8 pagesTechnical SelectionAmNo ratings yet

- Customer: Project Name: Ref. No: Date: Project Details - : Mekar Fcselect V3.610.001Document6 pagesCustomer: Project Name: Ref. No: Date: Project Details - : Mekar Fcselect V3.610.001basheer9No ratings yet

- Technical Characteristics: ProposalDocument3 pagesTechnical Characteristics: ProposalRicardo Ostos LopezNo ratings yet

- DCA25SSIU4F Data SheetDocument4 pagesDCA25SSIU4F Data SheetMatthewNo ratings yet

- VOYAGER3 - TED600B4E - Consolidated Customer PackageDocument14 pagesVOYAGER3 - TED600B4E - Consolidated Customer PackageairemexNo ratings yet

- Technical Data Air Cooled Chiller 105 TRDocument3 pagesTechnical Data Air Cooled Chiller 105 TRHaris Siena100% (1)

- Zxme025e-Tfd R404aDocument5 pagesZxme025e-Tfd R404aMario UrsuNo ratings yet

- Julabo F32 HL 9312632 en UsDocument5 pagesJulabo F32 HL 9312632 en UsEhsan ParsafarNo ratings yet

- ERTAF - ERTAF-2 Maco-2 - Product ReportDocument2 pagesERTAF - ERTAF-2 Maco-2 - Product ReportKaran GnaniNo ratings yet

- KKT Chillers Produktkatalog Nano Line enDocument2 pagesKKT Chillers Produktkatalog Nano Line enDiego Andres Vega RodriguezNo ratings yet

- TRANE - FCU SelectionsDocument16 pagesTRANE - FCU SelectionshanamanNo ratings yet

- Éxito Unicentro Bogota Rev 3 1 Pack Transcr 230 3 60Document4 pagesÉxito Unicentro Bogota Rev 3 1 Pack Transcr 230 3 60Joaquin BusanicheNo ratings yet

- ZR125KCE-TF7 R134a ReportDocument5 pagesZR125KCE-TF7 R134a Report-Tokusatsu Man-No ratings yet

- Schimbator de CalduraDocument4 pagesSchimbator de CalduraAlin Emil MuresanNo ratings yet

- Karcher HDS 1195-4 S Eco EngleskiDocument1 pageKarcher HDS 1195-4 S Eco EngleskivjakovljevicNo ratings yet

- Air Conditioning Unit With Remote Air Cooled Condenser: Unit Power Supply: 400/3ph/50HzDocument2 pagesAir Conditioning Unit With Remote Air Cooled Condenser: Unit Power Supply: 400/3ph/50HzAdy PrasetyoNo ratings yet

- HDCV5100ADocument2 pagesHDCV5100AaugustodiazlaraNo ratings yet

- CGAM - CGAM-1 - Consolidated Customer PackageDocument19 pagesCGAM - CGAM-1 - Consolidated Customer PackageAmeli RNo ratings yet

- Zxme025e-Pfj R404aDocument5 pagesZxme025e-Pfj R404aMario UrsuNo ratings yet

- 3.6 Data Sheet CTE 34 L8 ED Freezer 1Document1 page3.6 Data Sheet CTE 34 L8 ED Freezer 1Le Ngoc AnhNo ratings yet

- Air-Cooled Series R (TM) CRTAG145 Product Report - Rev01aDocument2 pagesAir-Cooled Series R (TM) CRTAG145 Product Report - Rev01aUrsula MottaNo ratings yet

- VAV New Single Duct Product ReportDocument12 pagesVAV New Single Duct Product ReportLuis Miguel Perez PertuzNo ratings yet

- Zr190kre-Tfd R134a ReportDocument5 pagesZr190kre-Tfd R134a ReportLavander ZouzzaNo ratings yet

- Submittal-279873-4 Ton - 5 Ton RTU's 208V - 3Ph + ECONO + CURBDocument13 pagesSubmittal-279873-4 Ton - 5 Ton RTU's 208V - 3Ph + ECONO + CURBMcr KumaraNo ratings yet

- Air Conditioning Unit With Remote Air Cooled Condenser Air Conditioner Model: TDAV1122ADocument2 pagesAir Conditioning Unit With Remote Air Cooled Condenser Air Conditioner Model: TDAV1122AWillybrordus HermawanNo ratings yet

- Máquinas Conductos - 15 Viviendas en La Cala Golf - BasicReportDocument4 pagesMáquinas Conductos - 15 Viviendas en La Cala Golf - BasicReportdaniel castroNo ratings yet

- CH Aly080dDocument2 pagesCH Aly080dEngineer HassanNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Home Studio SeriesDocument8 pagesHome Studio Seriesandrew_ai3100% (3)

- Limit Exceeded For Recovery Files - DB - Recovery - File - Dest - Size and Archiver Error Oracle DBA - A Lifelong Learning ExperienceDocument5 pagesLimit Exceeded For Recovery Files - DB - Recovery - File - Dest - Size and Archiver Error Oracle DBA - A Lifelong Learning ExperienceAlberto Hernandez HernandezNo ratings yet

- GC Buffer BusyDocument19 pagesGC Buffer BusySaeed MeethalNo ratings yet

- App Module 2,3,4 NotesDocument38 pagesApp Module 2,3,4 NotesNikhil SekharanNo ratings yet

- 1Document134 pages1hemasrikNo ratings yet

- AN9003 - A Users Guide To Intrinsic Safety: Reasons For Selecting The Intrinsically Safe ConceptDocument20 pagesAN9003 - A Users Guide To Intrinsic Safety: Reasons For Selecting The Intrinsically Safe ConceptIC013 Rakshit JethwaNo ratings yet

- agSupIndexArist - rose.Bonitz..Berolin - Didot.paris.1870.1874. TextDocument899 pagesagSupIndexArist - rose.Bonitz..Berolin - Didot.paris.1870.1874. TextZhuang8zhouNo ratings yet

- Pertemuan 8: Dasar Query Basis Data Dengan SqliteDocument22 pagesPertemuan 8: Dasar Query Basis Data Dengan SqliteIrma Permata SariNo ratings yet

- Introduction To Research and Title ProposalDocument34 pagesIntroduction To Research and Title ProposalDave Matthew Campillos (Vilgacs)No ratings yet

- IDOCs DDocument7 pagesIDOCs DamitNo ratings yet

- Trends and Challenges in Soc Design v3Document32 pagesTrends and Challenges in Soc Design v3Nitheesh Kumar100% (1)

- Oop 3140705 Ce&itDocument87 pagesOop 3140705 Ce&itPatel SarthakNo ratings yet

- 50 PC 55 ZBDocument53 pages50 PC 55 ZBVali IgnatNo ratings yet

- Tutorial 0 - Part B Modelling Groundwater Flow Using FreewatDocument50 pagesTutorial 0 - Part B Modelling Groundwater Flow Using FreewatУрошМилићNo ratings yet

- Apxvbll26ex 43-C-I20 PreDocument4 pagesApxvbll26ex 43-C-I20 Precmsd01No ratings yet

- Sensorless Control of 5 Phase BLCD MotorDocument6 pagesSensorless Control of 5 Phase BLCD Motorschlemihl69No ratings yet

- New Principal Guide HCMDocument34 pagesNew Principal Guide HCMapi-299456193No ratings yet

- Albrt931002 SpecDocument148 pagesAlbrt931002 SpecArturo Treviño MedinaNo ratings yet

- Citation 28 - On-The-Combination-Of-Naive-Bayes-And-Decision-Trees-For-IntrusiDocument6 pagesCitation 28 - On-The-Combination-Of-Naive-Bayes-And-Decision-Trees-For-IntrusiZahedi AzamNo ratings yet

- Regular Expression HOWTO: Guido Van Rossum and The Python Development TeamDocument18 pagesRegular Expression HOWTO: Guido Van Rossum and The Python Development TeamRanu GamesNo ratings yet

- GCSE - A6 - NetworksDocument7 pagesGCSE - A6 - NetworksWisdon NaniNo ratings yet

- Renovar Licença SAP RouterDocument8 pagesRenovar Licença SAP RouterJose Carlos Dantas SilvaNo ratings yet

- Library Management System PDFDocument1 pageLibrary Management System PDFahilaNo ratings yet

- A Few Things You Need To Know About The New Site Coefficients inDocument7 pagesA Few Things You Need To Know About The New Site Coefficients inAdriel ElezarNo ratings yet

- Unit 1 - A Brief History of ComputersDocument9 pagesUnit 1 - A Brief History of ComputersMarian MladinoviciNo ratings yet

- Int Is - Gis - Kms NotesDocument16 pagesInt Is - Gis - Kms NotesMulumudi PrabhakarNo ratings yet

- Power Electronics Question Model 1Document5 pagesPower Electronics Question Model 1sagarNo ratings yet

- Lifebooke 733Document86 pagesLifebooke 733KlausNo ratings yet