Professional Documents

Culture Documents

Part ID Process Helpful Hints

Part ID Process Helpful Hints

Uploaded by

MuMoMaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part ID Process Helpful Hints

Part ID Process Helpful Hints

Uploaded by

MuMoMaCopyright:

Available Formats

UNITEC’s Part Identification Process

& Helpful Tips For Ordering

In order for UNITEC to provide its customers with correct parts, in many cases be designated ‘DO’, or the main UP running

an Otis Sales/Machine number is OFTEN not sufficient relay may carry the ‘U’ designation, or the main transformer

enough to obtain and identify the part you are looking for, and might have a TRF1 designation).

must not be the only information you contact UNITEC with, if

Always consult the wiring diagram before leaving the jobsite

at all possible.

to obtain the designation of the Controller component you

It is extremely important that our customers provide a good are looking for. Take photos of parts before leaving jobsite.

description of the part, it’s dimensions, any markings from the

Here are some helpful hints to assist in part identification

part, exactly where the part is installed on the elevator or esca-

for some common elevator/escalator apparatus.

lator, and its function.

Component Vintage Tags are also found on many and varied

If item is from the controller, provide the Designation of this

apparatus for Otis equipment installed after 1988. Do look for

particular component as it is identified on the Otis wiring di-

& photograph/provide the complete information from those

agram. Best practice – Mechanics should call from the field

Vintage tags.

with part in hand. (eg. The relay that opens the doors might

Sales Numbers For Otis Equipment Can Many Times Be Found On:

• Top of Car Crosshead Data Plat • On Machine or MG set Data Tag

• The Controller Data Tag • On a Contract Specific Wiring Diagram

Always mention control system nomenclature/type & tell us:

Escalator, Elevator, Hydro (telescopic, holed, holeless), Geared, Gearless. (eg. 10HOCL, 10UCL, LRV3, 4, 5, 211, 335,

401, 411, Spec 60, etc.)

Always provide an OTIS SALES # & Street Address for inquiries on larger and costly components like:

• SHEAVES • SPIDER/SHEAVE SHAFTS • SHAFTS • SECONDARY EQUIP’T

• SAFETY EQUIPMENT • WIRE ROPE • SHEAVE LINERS • BALUSTRADE GLASS

• MAIN DRIVES • TENSION CARRIAGES • STEP CHAIN • MOTORS

For inquiries on the following components, provide at least the information indicated below.

• BUFFERS: Stroke, Height, • DOOR SYSTEM related: (Size, Type, • HYDRAULIC JACKS: Holed/Holeless –

Contract Speed Hand, Car or Hall side, Hanger Type) Telescopic or not – Piston Diameter

• CONTROLLERS: Otis Sales #, eg. (42” x 84” RH – 2 Speed, Integral • HYDRAULIC MACHINES: ~Year of

Nomenclature (21UCL, LRV, 311), Hanger Car doors) install, Dry or Submersible,

Part designation. [and for ANY PC • ESCALATORS: Type, ~Year of install, Component type

Boards [always provide ASSY # off Step Width, Glass or Solid Balustrade, • MACHINES (GEARED): ~Year of

the PC board (ignore the 610 #] Sales # install, Lower Gearcase 330 Casting

• DOOR LOCKS: ~Year of install, • GOVERNORS: ~Year of install, Sheave #, thrust cover 346 casting #, Sheave

door type & hand, name of Diameter, Rope Diameter, Contract Diameter, Quantity & Size of Ropes

Door Operator Speed, Car/Cwt • MACHINES (GEARLESS): ~Year of

• DOOR OPERATORS: Consult Door • GUIDES: Car or Counterweight – install, Motor Tag info, Sheave

Operator Catalog section. Slide/Roller – Length/Diameter. Diameter, Sales #

Type, hand, size of opening. (For Roller guides – Provide: Roller

• DOOR RESTRICTORS: Consult Door Diameter, Casting # of base, 288

System Catalog Section. casting # off lever arms

Fill out survey form.

© Unitec Parts Company, 2012

Formerly Page:

You might also like

- Secret Magic Spells of The Romany GypsiesDocument28 pagesSecret Magic Spells of The Romany Gypsiesakenaton4089% (66)

- J-1175 Illustrated Parts CatalogDocument250 pagesJ-1175 Illustrated Parts CatalogIsmael GaldinoNo ratings yet

- Tarex Jaw Crusher Part Manual PDFDocument333 pagesTarex Jaw Crusher Part Manual PDFKAMAL SINGH100% (3)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- I-110RS Illustrated Parts Catalog PDFDocument265 pagesI-110RS Illustrated Parts Catalog PDFGiuro Kralev67% (3)

- Navistar Diagnostic Toolsv 5Document7 pagesNavistar Diagnostic Toolsv 5LESTERMUNGUIA100% (4)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- SMCS Codes User Training ManualDocument38 pagesSMCS Codes User Training ManualJeffersson Gutierrez100% (2)

- 1000 Maxtrak Illustrated Parts CatalogDocument135 pages1000 Maxtrak Illustrated Parts Catalogmarceloaav1100% (5)

- J-1175 Illustrated Parts Catalog - Mastercopy - From Serial No Trx1175jcomd56948Document601 pagesJ-1175 Illustrated Parts Catalog - Mastercopy - From Serial No Trx1175jcomd56948Antonio Castillo81% (26)

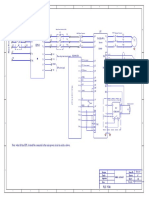

- Electric Drawing-FR2000Document19 pagesElectric Drawing-FR2000MuMoMa100% (1)

- Warrior 1800 Illustrated Parts Catalog Revision 13Document293 pagesWarrior 1800 Illustrated Parts Catalog Revision 13Coordinador Prod y Mtto100% (1)

- Chapter 29 - Test: (60 Minutes)Document3 pagesChapter 29 - Test: (60 Minutes)Minh ThanhNo ratings yet

- 663-653 Illustrated Parts CatalogDocument190 pages663-653 Illustrated Parts CatalogKulthoemNo ratings yet

- Ordering: Carrier Compressor Inspection OfferDocument44 pagesOrdering: Carrier Compressor Inspection OfferIwan HusaeniNo ratings yet

- 710DDocument798 pages710DSegundo Francisco Jauregui Valencia75% (4)

- 693+ Illustrated Parts Catalog Revision 3.1Document483 pages693+ Illustrated Parts Catalog Revision 3.1brianNo ratings yet

- SV Maintenance V1.2 CONE VALEDocument64 pagesSV Maintenance V1.2 CONE VALEVictor Alberto Ramos BarronNo ratings yet

- Gear InspectionDocument6 pagesGear Inspectionbh hbNo ratings yet

- J-1160 Set 01Document183 pagesJ-1160 Set 01Yankonde ChisenseNo ratings yet

- CH1700AL Illustrated Parts Catalog (Hosur) Revision 2 - 0Document297 pagesCH1700AL Illustrated Parts Catalog (Hosur) Revision 2 - 0Alberto LopezNo ratings yet

- Professional Workshop Information SystemDocument6 pagesProfessional Workshop Information Systemsandro ronaldNo ratings yet

- Gear Shift SystemDocument21 pagesGear Shift SystemMihai Cosmin PaunNo ratings yet

- PDF 23503 Audi B8 A4 2.0T Center Resonator Delete Kit InstallationDocument19 pagesPDF 23503 Audi B8 A4 2.0T Center Resonator Delete Kit InstallationBenny NnokoNo ratings yet

- X360L BrochureDocument4 pagesX360L BrochureJean MontescoNo ratings yet

- 161-Point Inspection Checklist: Dealer and Vehicle InformationDocument6 pages161-Point Inspection Checklist: Dealer and Vehicle InformationAnonymous WpMUZCb935No ratings yet

- How To Use The Engine Performance SectionDocument8 pagesHow To Use The Engine Performance SectionjohnNo ratings yet

- 312 Illustrated Parts CatalogDocument121 pages312 Illustrated Parts Catalogpwbotha1No ratings yet

- 683 Illustrated Parts Catalog - BellDocument305 pages683 Illustrated Parts Catalog - BellLuan BothaNo ratings yet

- AtlasDocument44 pagesAtlasmpedraza-1No ratings yet

- Inspection Test Record (Itr) - A Jacket Pre-Loadout ST08-ADocument1 pageInspection Test Record (Itr) - A Jacket Pre-Loadout ST08-AMomo ItachiNo ratings yet

- Resolver CatalogDocument85 pagesResolver CatalogAlex StanNo ratings yet

- Monroe Catalogue 2015 PDFDocument244 pagesMonroe Catalogue 2015 PDFSupol100% (2)

- 683 Illustrated Parts CatalogDocument245 pages683 Illustrated Parts CatalogMartín Lescano Paredes100% (2)

- Figueroa Leds de PotenciaDocument92 pagesFigueroa Leds de PotenciaMiguel FigueroaNo ratings yet

- CNC 101Document13 pagesCNC 101Hendi RofiansyahNo ratings yet

- ValveQuoteOrderSpec - Viable Vs Engineered ShortDocument5 pagesValveQuoteOrderSpec - Viable Vs Engineered Shortsnowyjen17No ratings yet

- EuropartMan PDFDocument320 pagesEuropartMan PDFjohnny flahaNo ratings yet

- Industrial TrainingDocument33 pagesIndustrial Trainingpawan0% (1)

- 2015 Training Rev03 080715Document141 pages2015 Training Rev03 080715EDILBERTO MACHORRO MARTINEZNo ratings yet

- X-300M & X-330M: Faith - Vision - WorkDocument4 pagesX-300M & X-330M: Faith - Vision - WorkRobert Ruiz Pertuz0% (1)

- Turbine Supervisory InstrumentsationDocument52 pagesTurbine Supervisory InstrumentsationKarthi Keyan100% (1)

- Turbine Supervisory Instrumentation Selection Guide - RockwellDocument52 pagesTurbine Supervisory Instrumentation Selection Guide - Rockwellhozipek100% (1)

- Carrier 50tc 7 16 SsDocument140 pagesCarrier 50tc 7 16 SsalbertocmarNo ratings yet

- Warrior 1400 Illustrated Parts Catalog Revision 11Document215 pagesWarrior 1400 Illustrated Parts Catalog Revision 11JUAN MANUEL RUIZ BERMEJO100% (1)

- Warrior 1400 Illustrated Parts Catalog Revision 11Document215 pagesWarrior 1400 Illustrated Parts Catalog Revision 11gustavo.lugoNo ratings yet

- Split System Air ConditionersDocument124 pagesSplit System Air ConditionersLubyanka100% (1)

- Socket Screw Catalog 032211 enDocument40 pagesSocket Screw Catalog 032211 enJLLIMPE3116No ratings yet

- Bison RHTDocument60 pagesBison RHTLuis Enrique PeñaNo ratings yet

- TTA-TWE Catálogo (Inglés)Document138 pagesTTA-TWE Catálogo (Inglés)kuraimund100% (1)

- English SL Series Service Manual 2004Document331 pagesEnglish SL Series Service Manual 2004Electronica PolancoNo ratings yet

- 883 MKII Illustrated Parts Catalog Revision 2Document311 pages883 MKII Illustrated Parts Catalog Revision 2Herdre Van Niekerk100% (1)

- Z45 Gehl Miniexcavator PDFDocument268 pagesZ45 Gehl Miniexcavator PDFAndreea BoacaraNo ratings yet

- Tuttnauer Manual Sterilizer Presentation 072016Document45 pagesTuttnauer Manual Sterilizer Presentation 072016Avishay TufikianNo ratings yet

- 2016 Llaves Ilco PDFDocument176 pages2016 Llaves Ilco PDFfrancisco ivan aguilar salmeronNo ratings yet

- 456 - 42000e TESCO Torque Turn ServicesDocument2 pages456 - 42000e TESCO Torque Turn Servicestedongsaleko100% (1)

- Caepipe InfoDocument12 pagesCaepipe Infoxaaabbb_550464353No ratings yet

- Conectores Glandula PDFDocument12 pagesConectores Glandula PDFarturoncNo ratings yet

- PDF 3353 Audi B8 A4 2.0T Valved Exhaust System Installation - Dual Exit r1Document22 pagesPDF 3353 Audi B8 A4 2.0T Valved Exhaust System Installation - Dual Exit r1Benny NnokoNo ratings yet

- DCS PLCDocument21 pagesDCS PLCnetsavy71No ratings yet

- Tritorc - Impact SocketDocument69 pagesTritorc - Impact SocketPhong DuongNo ratings yet

- Alfa Laval Base 11 - enDocument2 pagesAlfa Laval Base 11 - enGerman TchiliNo ratings yet

- 34 6646cyDocument14 pages34 6646cyMuMoMaNo ratings yet

- T02020000740005PDFEDocument13 pagesT02020000740005PDFEMuMoMaNo ratings yet

- Data Sheet Ih5815Document5 pagesData Sheet Ih5815MuMoMaNo ratings yet

- Mpa1954 eDocument8 pagesMpa1954 eMuMoMaNo ratings yet

- MOD6EarthLeakageFAQ FL 001 ENDocument4 pagesMOD6EarthLeakageFAQ FL 001 ENMuMoMaNo ratings yet

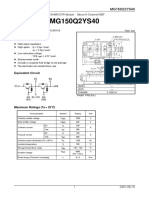

- Datasheet Igbt Mg75j2ys40Document5 pagesDatasheet Igbt Mg75j2ys40MuMoMaNo ratings yet

- pm50rl1b120 eDocument9 pagespm50rl1b120 eMuMoMaNo ratings yet

- WorldDrive 4X Full ManualDocument411 pagesWorldDrive 4X Full ManualMuMoMaNo ratings yet

- I-SIMPA ScriptingGuide enDocument59 pagesI-SIMPA ScriptingGuide enMuMoMaNo ratings yet

- 2169 0111 S1.002 026Document1 page2169 0111 S1.002 026MuMoMaNo ratings yet

- td456 enDocument6 pagestd456 enMuMoMaNo ratings yet

- New Concept For CTO Guidewire Manipulation Importance of Penetration Plane View (PPV)Document27 pagesNew Concept For CTO Guidewire Manipulation Importance of Penetration Plane View (PPV)MuMoMaNo ratings yet

- Dolon BlackSeries Long ExpoDocument7 pagesDolon BlackSeries Long ExpoMuMoMaNo ratings yet

- US7775328Document8 pagesUS7775328MuMoMaNo ratings yet

- Motion 3000ES Rev B9Document81 pagesMotion 3000ES Rev B9MuMoMaNo ratings yet

- Skiip 13Ac12T4V1: Miniskiip 1Document5 pagesSkiip 13Ac12T4V1: Miniskiip 1MuMoMaNo ratings yet

- Escalator Integrated Controller AS330Document2 pagesEscalator Integrated Controller AS330MuMoMaNo ratings yet

- MG150Q2YS40 ToshibaSemiconductorDocument6 pagesMG150Q2YS40 ToshibaSemiconductorMuMoMaNo ratings yet

- Experimental Research of The Application of TurninDocument7 pagesExperimental Research of The Application of TurninMuMoMaNo ratings yet

- CN103159125BDocument9 pagesCN103159125BMuMoMaNo ratings yet

- SEMIX302GB128DSDocument5 pagesSEMIX302GB128DSMuMoMaNo ratings yet

- IgbtprotectDocument9 pagesIgbtprotectMuMoMaNo ratings yet

- BOMBARDIER Learjet 0-Flight Controls and AvionicsDocument88 pagesBOMBARDIER Learjet 0-Flight Controls and AvionicsMuMoMaNo ratings yet

- Chapter 2 Static and Dynamic Characteristics of SignalsDocument18 pagesChapter 2 Static and Dynamic Characteristics of SignalsDiyaa AhmedNo ratings yet

- Stick Cylinder - EspecificationsDocument4 pagesStick Cylinder - EspecificationsFredy Alvarez CespedesNo ratings yet

- EoE Programme AgendaDocument9 pagesEoE Programme AgendathegpcgroupNo ratings yet

- Fdpc8016S: Powertrench Power Clip 25V Asymmetric Dual N-Channel MosfetDocument12 pagesFdpc8016S: Powertrench Power Clip 25V Asymmetric Dual N-Channel MosfetRDNo ratings yet

- Onkyo H500MDocument2 pagesOnkyo H500Mmttw010No ratings yet

- Piping Info - Carbon Steel & Stainless Steel Guide SpacingDocument2 pagesPiping Info - Carbon Steel & Stainless Steel Guide SpacingpalluraviNo ratings yet

- Basic Water Chemistry For Power PlantDocument6 pagesBasic Water Chemistry For Power PlantSanjay BhariyaNo ratings yet

- Silage Pile Sizing Documentation 5 12 2016 3Document9 pagesSilage Pile Sizing Documentation 5 12 2016 3Zaqueu Ferreira RodriguesNo ratings yet

- Fighter Archetypes & Fighting StylesDocument17 pagesFighter Archetypes & Fighting StylesKristopher GarrettNo ratings yet

- Crossword 1Document4 pagesCrossword 1GodyNo ratings yet

- Chapter 1Document9 pagesChapter 1Dary OngNo ratings yet

- Barang 3Document12 pagesBarang 3Sujoko SkinzNo ratings yet

- Framework For Local Government To Implement Integrated Water Resource Management Linked To Water Service DeliveryDocument12 pagesFramework For Local Government To Implement Integrated Water Resource Management Linked To Water Service DeliveryChanel el hifnawyNo ratings yet

- Dell Service ManualDocument220 pagesDell Service ManualYeik ThaNo ratings yet

- MC-WHY DO PEOPLE SNORE - PFC In-Class Language Practice MaterialDocument1 pageMC-WHY DO PEOPLE SNORE - PFC In-Class Language Practice MaterialKutay KılıçtekNo ratings yet

- Released FOR Manufacturing: 2509 ANTAMINA PERU SMC 100/14400 Truck Bridge Assembly Truck Bridge Steel Structure - RightDocument1 pageReleased FOR Manufacturing: 2509 ANTAMINA PERU SMC 100/14400 Truck Bridge Assembly Truck Bridge Steel Structure - RightCarlos ParedesNo ratings yet

- Little House in The Big WoodsDocument14 pagesLittle House in The Big Woodsgaragebandtutorials2021No ratings yet

- Grover WasherDocument51 pagesGrover WasherFourHorsemenNo ratings yet

- Signals and Systems DE-40 EE - Semester 4 Spring 2020: Lab Report # 06Document21 pagesSignals and Systems DE-40 EE - Semester 4 Spring 2020: Lab Report # 06Muhammad YousafNo ratings yet

- Applied Mathematics OneDocument251 pagesApplied Mathematics OneSetegn YeshawNo ratings yet

- Housekeeping: Hotel Management Hospitality ServicesDocument41 pagesHousekeeping: Hotel Management Hospitality ServicesDASARATHI_PRAVEENNo ratings yet

- Tokyo Martis User Manual (En)Document32 pagesTokyo Martis User Manual (En)kyaw zin tun TunNo ratings yet

- Journal Ranking - AnthropologyDocument3 pagesJournal Ranking - AnthropologyDavide CarnevaleNo ratings yet

- General Chemistry 1: Quarter 2 - Module 4 Polymers & BiomoleculesDocument22 pagesGeneral Chemistry 1: Quarter 2 - Module 4 Polymers & BiomoleculesKaren de los ReyesNo ratings yet

- AV Control Receiver: Operating InstructionsDocument32 pagesAV Control Receiver: Operating InstructionsCuthbert Marshall100% (1)

- Environmental, Social, and Economic Costs of Recycled Plastic BiocompositesDocument21 pagesEnvironmental, Social, and Economic Costs of Recycled Plastic BiocompositesPasan SubasingheNo ratings yet

- 11 2019 Product BrochureDocument2 pages11 2019 Product BrochureTapes AndreiNo ratings yet