Professional Documents

Culture Documents

Residual Strength of Reinforced Concrete Beams Damaged by Alkali-Silica Reaction-Examination of Rating Index Method

Residual Strength of Reinforced Concrete Beams Damaged by Alkali-Silica Reaction-Examination of Rating Index Method

Uploaded by

Myat NoeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Residual Strength of Reinforced Concrete Beams Damaged by Alkali-Silica Reaction-Examination of Rating Index Method

Residual Strength of Reinforced Concrete Beams Damaged by Alkali-Silica Reaction-Examination of Rating Index Method

Uploaded by

Myat NoeCopyright:

Available Formats

ACI MATERIALS JOURNAL TECHNICAL PAPER

Title no. 99-M6

Residual Strength of Reinforced Concrete Beams

Damaged by Alkali-Silica Reaction—Examination of

Damage Rating Index Method

by L. J. Monette, N. J. Gardner, and P. E. Grattan-Bellew

Estimating the residual strength of structural members affected by tensile stresses in the surrounding aggregate or paste. In

alkali-silica reaction (ASR) is a significant problem. Small-scale, sufficient amounts, the gel can generate enough internal

singly reinforced concrete beams, concrete cylinders, and prisms pressure to crack concrete.1

made with reactive and nonreactive aggregates and high-alkali

cement, were stored submerged in a high-alkali solution at 38 C to Many aspects of ASR have been investigated, ranging

accelerate the ASR. Beams were conditioned either without load, from the reaction mechanism to the effects of ASR on exist-

under sustained load, or under cyclic load. Beam and cylinder ing reinforced concrete structures.1,2 Some papers deal with

expansions were measured. After significant expansion, both sides of the effect of static compressive load (restraint) and concrete

each reactive aggregate beam and one reactive aggregate resonant microcracking on the expansions due to ASR under labora-

frequency prism were polished and examined under a microscope tory conditions.3,4 Few papers, however, deal with the devel-

for features consistent with damage due to ASR. These features were opment and effects of ASR in reinforced concrete flexural

tabulated to determine the damage rating indexes (DRIs) of the vari- members under load.5,6

ous specimens. After measurement of the DRIs, the various reactive

and nonreactive specimens were loaded to failure. The primary object was to determine the usefulness of

Sustained and cyclic flexural load and the longitudinal rein- visually observed damage due to ASR, as quantified by a

forcement had significant restraining effects on ASR expansions. DRI, to predict the residual strength of existing in-service

The DRIs did represent, approximately, the measured expansions. structures damaged by ASR. The methodology was to exam-

Flexural tests to failure showed that neither ASR expansions nor ine the relationship between measured ASR expansions in

load conditioning significantly affected the stiffnesses and load- reinforced concrete beams conditioned without load, under

carrying capacities of the reactive concrete beams. sustained load, or under cyclic load, with the visual evidence

Material tests showed that ASR reduced the compressive stiff- of ASR in the beams, as quantified by the DRI, and the residual

ness, resonant frequency, and flexural strength of the concrete, but strengths and stiffnesses of the beams.

not the compressive strength. The test specimens were conditioned

submerged in a one normal sodium hydroxide solution and not

subject to cycles of wetting and drying as would occur in practice. EXPERIMENTAL PROGRAM

The DRI of the concrete prism correlated with the loss in stiffness, Two sets of specimens were prepared, one using a high-

resonant frequency, and flexural strength. alkali cement and a reactive aggregate (reactive specimens),

and the second using the same cement and mixture propor-

Keywords: alkali-silica reaction; concrete; expansion; reinforced concrete. tions with a nonreactive aggregate (nonreactive specimens).

The reactive concrete specimens were used to determine the

RESEARCH SIGNIFICANCE development of ASR in concrete under load (expansions,

The presence of significant concrete damage due to alkali- DRI, concrete properties, and residual strengths), and the

silica reaction (ASR) expansions in numerous reinforced nonreactive concrete specimens were used for comparison

concrete structures throughout the world has prompted the (expansions, concrete properties, and residual strengths) and

need to predict the residual strength and structural behavior of to determine length changes due to causes other than ASR

such structures. This paper investigates the correlation of (shrinkage, creep) for the same conditioning regimes. Each

measured expansions caused by ASR in reinforced concrete set of specimens included small-scale reinforced concrete

beams conditioned without load, under sustained load, or under beams, cylinders, resonant frequency prisms, and CSA7

cyclic load to the observable damage, quantified as a damage prisms. Table 1 summarizes the test program. Two reactive

rating index (DRI), and the measured residual flexural and one nonreactive reinforced concrete beams were tested

strengths of the beams. to failure at 28 days. From each set of specimens, two rein-

forced concrete beams were conditioned without load, two

INTRODUCTION under sustained load, and two under cyclic load while sub-

merged in a 1N sodium hydroxide solution (NaOH) at 38 C

Increasing evidence of ASR in bridges, parking, and hy-

draulic structures is a concern to engineers and administra- to accelerate the ASR in the reactive beams. Concrete cylin-

ders and resonant frequency prisms were stored without load

tors responsible for such structures. ASR in concrete is the

dissolution of amorphous and poorly crystalline silica min-

eral phases in susceptible aggregates by the hydroxyl ions in ACI Materials Journal, V. 99, No. 1, January-February 2002.

MS No. 01-086 received March, 20, 2001, and reviewed under Institute publication

the pore solution associated with the hydration reactions of policies. Copyright © 2002, American Concrete Institute. All rights reserved, includ-

high-alkali cements. The reaction product is a silica gel that ing the making of copies unless permission is obtained from the copyright proprietors.

Pertinent discussion will be published in the November-December 2002 ACI Materi-

can absorb significant amounts of water and expand, causing als Journal if received by August 1, 2002.

42 ACI Materials Journal/January-February 2002

which were to be correlated with the measured expansions

L. J. Monette is a structural engineer with Harmer Podolak Engineering Consultants

Inc., Ottawa, Ontario, Canada. He received his MASc in civil engineering from the and the beams’ residual strengths. After determination of the

University of Ottawa, Ottawa, Canada. DRI, the beams, cylinders, and prisms were loaded to failure

to determine their residual strengths and stiffnesses.

N. J. Gardner, FACI, is a professor of civil engineering at the University of Ottawa,

Ottawa, Ontario, Canada. He is a member of ACI Committees 209, Shrinkage and The nonreactive concrete beams were used to determine

Creep; 231, Early-Age Properties of Concrete; 347, Formwork; and 435, Deflection changes in length due to creep and shrinkage. Their residual

of Concrete Building Structures. His research interests include early-age member

behavior, shrinkage, creep, deflection serviceability, and formwork pressures. flexural strengths after conditioning were measured to

provide comparisons with those of the reactive concrete

ACI member P. E. Gratten-Bellew is a senior research officer in the Urban Infra-

structure Directorate at the Institute for Research in Construction of the National

beams. The properties of the nonreactive cylinders and

Research Council of Canada. His main research interest is the durability of concrete, prisms were compared with those of the reactive specimens.

with particular emphasis on alkali-aggregate reactivity. To examine the possibility that part of the reported degra-

dation in the mechanical properties of concrete in ASR

in the same sodium hydroxide solution to monitor expan- experiments is due to the effects of NaOH used to accelerate

sions and to provide material properties. Use of a condition- the reaction, a companion set of nonreactive cylinders was

ing environment of 38 C and NaOH is well documented in stored immersed in a lime water solution at 38 C for the same

other ASR studies and is used in some of the standard Canadian duration as the set stored in NaOH. These were failed in

tests for the determination of ASR reactivity in aggregates compression at the same age as the nonreactive cylinders

(CSA A23.2-14A prism test uses 38 C, CSA A23.2-25A immersed in the NaOH solution.

mortar bar test uses 1N NaOH at 80 C). The presence of large

ASR expansions was taken as evidence of concrete damage Mixture design

due to ASR. The two concrete mixtures were designed according to

Conditioning of the reactive beams was terminated after CSA A23.2-1994, and the proportions are given in Table 2.

significant expansions had been measured. The vertical sides The only differences between the reactive and nonreactive

of the reactive beams were ground and polished and a petro- mixtures were the coarse and fine aggregates. The mixture

graphic examination conducted to determine the DRIs, proportions were chosen so that the concrete could be placed

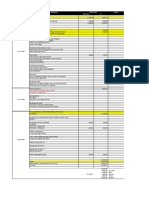

Table 1(a)—Details of specimens tested: reactive concrete specimens

Specimen designation No. of specimens Type of specimen Age at test, days Conditioning regime Measurements

RB-2, RB-5 2 Reinforced concrete beam 28 — Flexural strength

Expansion, flexural strength, damage

RB-1, RB-6 2 Reinforced concrete beam 325* No load, NaOH rating index

Expansion, flexural strength, damage

RB-7, RB-8 2 Reinforced concrete beam 325 Sustained load, NaOH

rating index

RB-3, RB-4 2 Reinforced concrete beam 325 Cyclic load, NaOH Expansion, flexural strength, damage

rating index

RC-1 to 6 6 Concrete cylinder 28 No load, NaOH Compressive strength, stiffness

RC-7 to 10 4 Concrete cylinder 325 No load, NaOH Expansion, compressive strength,

stiffness

RFP-1 to 4 4 Resonant frequency prism 28 No load, NaOH Flexural strength

RFP-6 to 8 3 Resonant frequency prism 325 No load, NaOH Resonant frequency, flexural strength

Resonant frequency, damage rating

RFP-5 1 Resonant frequency prism 325 No load, NaOH

index

RCSA-1 to 4 4 CSA concrete prism 325 100% RH Expansion

*28 days moist curing, 147 days of conditioning, and 150 days in air.

Table 1(b)—Nonreactive concrete specimens

Specimen designation No. of specimens Type of specimen Age at test, days Conditioning regime Measurements

NB-2 1 Reinforced concrete beam 28 — Flexural strength

NB-1, NB-7 2 Reinforced concrete beam 249* No load, NaOH Expansion, flexural strength

NB-4, NB-5 2 Reinforced concrete beam 249 Sustained load, NaOH Expansion, flexural strength

NB-3, NB-6 2 Reinforced concrete beam 249 Cyclic load, NaOH Expansion, flexural strength

NC-1,3,4,

NC-11,13,15 6 Concrete cylinder 28 No load, NaOH Compressive strength, stiffness

NC-2,5, Concrete cylinder stored in Expansion, compressive strength,

4 249 No load, NaOH

NC-12,14 NaOH stiffness

NC-6,8,9,10 4 Concrete cylinder stored in

249 No load, lime water Compressive strength, stiffness

limewater

NFP-1,2,7,8 4 Resonant frequency prism 28 No load, NaOH Flexural strength

Resonant frequency, flexural

NFP-3 to 6 4 Resonant frequency prism 249 No load, NaOH strength

NCSA-1 to 4 4 CSA expansion prism 249 100% RH Expansion

*28 days moist curing, 161 days of conditioning, and 60 days in air.

ACI Materials Journal/January-February 2002 43

Table 2—Concrete mixture proportions plain stirrups at 63.5 mm spacing to ensure flexural failure.

Water-cement ratio 0.61 The ends of the flexural reinforcing bars had 90 degree

Slump 200 mm

hooks. The yield strengths of the reinforcing steels were

measured using standard tension tests. The stirrup spacing

Coarse aggregate dry rodded density 1700 kg/m3 used was less than the maximum spacing permitted by the

Coarse aggregate (10 mm nominal size) 748 kg/m3 Canadian code (CSA A23.3-1994), which is 70% of the

Fine aggregate 1000 kg/m3 effective depth rather than the 50% permitted by ACI 318.

All beams attained full flexural capacity confirming the

Cement (0.9 % Na2O equivalent) 423 kg/m3

adequacy of the shear reinforcement.

Water 258 kg/m3 Steel rods (6 mm diameter) passing through the width of the

NaOH added (0.35 % Na2O equivalent) 1.48 kg/m3 beams were located in the sides of the beam molds before

Total Na2O equivalent 1.25% placement of the concrete. The steel rods had conical holes at

each end to act as targets for the Demec gages. Previous

experience has shown that Demec targets cannot be glued

without using a plasticizer and to provide a compressive

successfully to a concrete specimen in a high-alkaline solu-

strength of at least 25 MPa. All specimens were demolded

tion. The Demec target arrangement was chosen to enable

24 h after casting and cured for 28 days at 20 C in a curing

measurement of longitudinal strains in the constant shear end re-

chamber (approximately 95 to 98% relative humidity) prior

gions, in the constant moment midspan region, over the entire

to conditioning in the NaOH.

length of the beams, and vertically in the end and midspan regions.

The expansiveness of the reactive concrete was determined

Details of the beams, the Demec target layout, and the DRI

using the provisions of CSA A23.2-14A-1994 “Procedure for

areas are shown in Fig. 1.

Length Change due to Alkali-Aggregate Reaction in Concrete

Prisms,”7 identified as the CSA concrete prism test. The

nonexpansiveness of the nonreactive concrete was con- Concrete specimens

firmed using the same test. For both mixtures, four cylinders 100 mm diameter x 200

mm long, and four prisms, 100 x 75 x 400 mm long, were

cast and stored under the same accelerating conditions as the

Aggregates beams. The cylinders were used to monitor concrete expan-

The ASR-susceptible coarse aggregate was obtained from sions and compressive strength. Demec targets, consisting of

the Ministry of Transportation of Ontario stockpiles in Toronto, parallel steel rods (similar to those used for the beams) passing

Ontario, Canada. It is a very reactive, fine-grained, dark gray through the diameter of the cylinders at a gage length of 51 mm,

siliceous limestone originating from Stittsville, Ontario. The were used to monitor expansions. The prisms were used to

nonreactive coarse aggregate was a fine-grained, light gray monitor the resonant frequency and to determine the flexural

limestone of high purity originating from the province of strength of the concrete.

Newfoundland, Canada. The maximum nominal size of the CSA concrete prisms 75 x 75 x 300 mm were made using

coarse aggregate for both reactive and nonreactive mixtures

the same mixture proportions, moist-cured 28 days at 20 to

was 10 mm.

23 C, and then stored in 100% relative humidity at 38 C.

The reactive fine aggregate was crusher fines taken from

the Stittsville, Ontario quarry and mixed with nonreactive

Test program

quartz sand to obtain the required gradation for concrete.

Two reactive and two nonreactive reinforced concrete

The nonreactive fine aggregate was crushed Newfound-

beam specimens were conditioned without load, two reactive

land limestone mixed with the nonreactive quartz sand.

and two nonreactive beams under sustained service load, and

two reactive and two nonreactive beams under cyclic load,

Cement from zero to the service load, while immersed in a 1N NaOH

The cement used for the experiment was a CSA Type 10 solution at 38 C. The service load of the beams was calculated

(ASTM Type I) portland cement with an alkali content of to be 52% of the calculated ultimate flexural load. The NaOH

0.9% Na2O equivalent. The alkalinity was increased to solution was used to accelerate the ASR to enable significant

1.25% Na2O equivalent by adding sodium hydroxide to the expansions (up to 0.4%) to be reached within a reasonable

concrete during mixing. time. The effect of NaOH on the strength of concrete was

examined using nonreactive concrete cylinders. Use of a

Beam specimens conditioning environment of 38 C and NaOH is well docu-

Eight reactive and seven nonreactive reinforced concrete mented in other ASR studies and is used in some of the standard

beams 89 x 121 x 902 mm were cast and moist-cured for Canadian tests for the determination of ASR reactivity in

28 days. Two reactive beams and one nonreactive beam aggregates (CSA A23.2-14A prism test uses 38 C, CSA

were loaded to failure in four-point bending at 28 days. A23.2-25A mortar bar test uses 1N NaOH at 80 C).

The remaining three pairs of reactive and nonreactive The beams conditioned under sustained and cyclic loading

beams were conditioned in an ASR accelerating environ- were loaded using four-point loading. Spreader beams with

ment for 147 and 161 days, respectively. The size of the fixed load points were used to provide the two-point loads

beams was sufficient to enable standard behavior equa- while the concrete beams were immersed in the NaOH. Un-

tions to be used, but small enough to permit conditioning fortunately, the fixed load points, without freedom to move

in existing NaOH reservoirs and handling of the beams into longitudinally, caused abrasion of the cyclically loaded

and out of the conditioning apparatus. beams. At their service load, beams conditioned under sus-

Each beam was singly reinforced with two hot-rolled, 8 tained and cyclic loads were cracked in the midspan, posi-

mm diameter deformed bars (yield strength = 530 MPa, steel tive moment, tension face locations. Air pistons, controlled

ratio = 1.1%) and provided with 4.8 mm diameter, hot-rolled by a signal generator, provided the cyclic loading, and a

44 ACI Materials Journal/January-February 2002

Fig. 1—Details of reinforced concrete beam specimens (all measurements

in mm).

combination of a hydraulic jack and a screw jack provided

the sustained loading. The air pistons and the screw jack

were calibrated using a load cell. The cyclic loading frequency

was 0.5 Hz.

The reinforced concrete beams were stored immersed in

the 1N NaOH solution in four stainless steel baths. The

NaOH solution was continuously circulated through the

baths from a reservoir, which contained a heater, to ensure a

constant temperature of 38 C. The conditioning apparatus is

shown in Fig. 2. The cylinders and resonant frequency

prisms were stored without load in the NaOH reservoir.

Beam and cylinder expansions and prism resonant frequen-

cies were measured during the conditioning period. The

reactive and nonreactive specimens were conditioned for

147 and 161 days, respectively. The exposure durations

Fig. 2—Photograph of conditioning apparatus.

were arbitrary; conditioning of the reactive concrete spec-

imens was terminated after ASR induced expansions larger surfaces of the reactive beams were polished to perform

than 0.4% had developed. Conditioning of the nonreactive DRI measurements.

beams was terminated when one of the beams under cyclic The reactive samples were loaded to failure 325 days after

load conditioning failed due to severe abrasion under the casting (28 days moist curing, 147 days of conditioning, and

load points. At the loading frequency of 0.5 Hz, the beams 150 days in air) and the nonreactive samples 249 days after

subjected to cyclic loading underwent approximately 5 and 6 casting (28 days moist curing, 161 days of conditioning, and

million cycles of loading and unloading for the reactive and 60 days in air).

nonreactive beams, respectively. The nonreactive cylinders

in lime water solution were conditioned for 161 days at 38 C. Measurement of expansions

After conditioning, the reactive and nonreactive samples Specimen expansions were measured at intervals ranging

were stored in the laboratory at room temperature. The side from 2 weeks to 1 month. Samples were removed from the

ACI Materials Journal/January-February 2002 45

Table 3—Features associated with ASR ing factor, summed, and normalized for an area of 100 cm2

Feature associated with ASR Weighting factor (standard DRI measurement area) to obtain the final DRI

Coarse aggregate with cracks 0.25 number. This final number is a quantification of concrete

Coarse aggregate debonded from paste 3.0

damage due to ASR, and the concept has previously been ap-

plied to hydroelectric dams. The DRIs were compared with

Reaction rims around aggregate 0.5

the residual structural behavior of the beams to identify any

Cement paste with cracks 2.0

correlation between the DRI and structural residual strength.

Air voids lined with gel 0.5

Flexural capacity of beams and concrete

conditioning environment and allowed to cool overnight in a properties

controlled environment room at 20 C and 50% relative humidity The reactive and nonreactive beams were monotonically

to enable the beams to reach constant temperature. During this loaded to flexural failure at ages of 325 days (28 days moist

time, the specimens were wrapped in plastic to prevent curing, 147 days of conditioning, and 150 days in air) and

excessive loss of moisture from affecting expansion mea- 249 days (28 days moist curing, 161 days of conditioning,

surements. The specimens were re-immersed in the condi- and 60 days in air), respectively. The beams were loaded to

tioning environment after expansion measurements failure in four-point bending, as shown in Fig. 1. Beam midspan

(approximately 24 h after removal from the NaOH). deflections were measured during loading using a dial gage.

Expansion readings were taken with Demec and Huggen- The reactive and nonreactive cylinders were loaded in

burger gages (local horizontal and vertical, and overall hori- compression at the same age as the beams, and their stress-

zontal length measurements, respectively). For local strain curves were compared with those established at 28 days.

horizontal expansion measurements, the gage length was The reactive and nonreactive concrete prisms were loaded

51 mm. Similarly, a 70 mm gage length was used for ver- in three-point bending at 28, 325 (reactive), and 249 days

tical expansions and a 750 mm gage length was used for (nonreactive), respectively. The dynamic modulus of

overall horizontal expansion measurements. The gage length elasticity was determined using the resonant frequency

used for cylinder expansions was 51 mm. measurements of the concrete prisms.

Three well-repeated readings at each Demec gage length

on each side of each beam were taken for each expansion RESULTS AND DISCUSSION

measurement (total of six readings, three on each side of Expansion measurements, DRI, and residual properties are

each beam for each specific gage length). These readings presented, compared, and discussed in the following sections.

were averaged to provide the length change for each gage

location. The concrete cylinder expansions were obtained Expansion results

in a similar manner. A limited set of the expansion results is presented in the

The various reactive beam expansion measurements were following section. The complete set of experimental results

taken to compare the progression of ASR expansions in can be found in Reference 9. Expansion measurements taken

regions of different states of sustained and cyclic stress. from the nonreactive beam specimens and the nonreactive

The expansions of the nonreactive beams were measured to concrete cylinders were negligible and are not presented.

determine length changes due to non-ASR causes such as The vertical expansions of the variously conditioned reactive

creep and shrinkage. beams were similar, indicating that flexural load condition-

ing of the beams had little or no effect on vertical expansions.

Damage rating index (DRI) Vertical expansions are not discussed further.

After completion of conditioning, the vertical sides of the The CSA prisms for the reactive concrete mixtures had an

reactive concrete beams and resonant frequency prisms were average expansion of 0.06% after 104 days and 0.33% after

polished for the determination of the concrete DRIs. The 147 days, which is significantly greater than the CSA 1-year

DRI is a petrographic method used to quantify concrete limit of 0.04%. This confirmed the expansiveness of the

damage. 8 Polished concrete sections are examined using reactive concrete mixtures. The CSA prism test is normally

a stereo binocular microscope to visually identify signs used to test the reactivity of either the coarse aggregate or the

associated with various durability problems. Each feature fine aggregate. The CSA prisms for the nonreactive con-

linked to a given durability problem is given a weighting factor crete mixtures showed no appreciable expansion after the

according to its likelihood of having caused the damage. The conditioning period.

ASR features and weighting factors used in determining the The expansions measured during conditioning in the mid-

DRI for the reactive beam specimens are given in Table 3. span, constant moment region (Demec gage locations 7, 8, 9),

Weighting factors less than unity indicate features common of the reactive concrete beams are shown in Fig. 3. Beam

to ASR but which may be due to other causes, such as coarse expansions presented are the combined average of three

aggregate cracks created during the crushing process and measurements taken on each side of two replicate beams for

coarse aggregate rims caused by weathering of the aggregate. each gage location (an average of 12 expansion readings for

Some features, such as air voids with reactive gel, which each data point for each type of load conditioning for each

indicate the presence of ASR, are not given high importance gage location).

factors as they are not features indicating damage due to There is a large difference in expansions at the top gage

the reaction. Weighting factors greater than unity indicate locations for the variously conditioned beams. The top

signs of concrete damage caused by ASR such as coarse gage expansions of the beams conditioned without load are

aggregate and cement paste cracks containing reactive gel. similar to the unrestrained concrete cylinder expansions. The

The 80 cm2 areas used to perform the DRI on each side of beams conditioned under cyclic load displayed smaller

the beams are shown in Fig. 1. For each area, the sums of in- expansions than the beams conditioned without load at the

dividual features were multiplied by their respective weight- top gage location, indicating restraint from the compressive

46 ACI Materials Journal/January-February 2002

a.

(a)

(b)

Fig. 3—Measured expansions of reactive beam specimens.

stresses due to cyclic loading. The top location expansions for (c)

the beams conditioned under sustained load were smaller than

the other two conditioning regimes, indicating greater restraint

to expansion due to continuous flexural compressive stresses. Fig. 4—Surface cracks after conditioning: (a) never loaded

reactive beam (RB-1); (b) statically loaded reactive beam

Expansions were similar for the beams conditioned with-

(RB-7); and (c) dynamically loaded reactive beam (RB-3).

out load and under cyclic load for the midheight, midspan

gage location. The beams conditioned under sustained load

displayed less expansion than the other two conditioning

regimes at this gage location.

For expansions at the reinforcement level, midspan gage

results showed little difference between the beams condi-

tioned without load and under sustained load. The beams

conditioned under cyclic load displayed larger expansions

at the reinforcement level gage locations than the other

two load cases. This may indicate a loss of local reinforc-

ing steel-to-concrete bond due to repeated cycles of load-

ing and unloading in the constant moment area of the

beams, which was where the majority of the load induced

cracking occurred.

Comparing expansions from the variously conditioned

beams, it appears that microcracking in the tension zones, in-

duced by flexural loading, did not increase ASR expansions

in the reinforced concrete beams. The reinforcement in the Fig. 5—Comparison of midspan damage rating indexes.

beams was sufficient to restrain any additional expansion

promoted by mechanically induced microcracking. As the very little cracking due to ASR below their centroidal axes,

test specimens were entirely submerged in a NaOH solution which agrees with the expansion results and confirms restraint

and thus constantly saturated, the additional microcracking to expansion by the flexural reinforcement.

due to load did not increase the level of saturation of the When the polished surfaces of the reactive beams were

beams (entry of additional moisture/water into the concrete) examined under a stereo-binocular microscope, with the exception

as would occur in exterior structures subjected to cycles of of a few air voids, none of the features typical to ASR with

wetting and drying. reactive gel were observed. It was concluded that as the

beams were continuously immersed in the conditioning

DRIs environment, any gel at or near the beam surfaces was leached

After conditioning for 147 days, all the reactive concrete out by the sodium hydroxide solution during conditioning.

beams displayed visible surface cracking above their cent-

The DRIs for the three midspan locations, Zones 2, 5 and

roidal axes. Figure 4(a), (b), and (c) show the surface cracks

after conditioning, but before the vertical faces were ground, 8, corresponding to the three midspan Demec gage locations,

of a never-loaded reactive beam (RB-1), a statically loaded are shown in Fig. 5. The DRIs shown are the averaged values

reactive beam (RB-7), and a dynamically loaded reactive for each side of individual beams that were then averaged for

beam (RB3). The most severe (the beams conditioned with- each pair of beams for each load condition. The top midspan

out load) were homogeneously cracked in this region, which locations displayed more damage in the beams conditioned

was similar to the surface cracking of the concrete prisms. without load than in the beams conditioned under load,

The beams conditioned under load were generally cracked and displayed mechanically induced cracking due to hog-

horizontally in the direction of compressive flexural stresses, ging of the specimens (upward bending of the beams due

indicating restraint to expansion by the flexural compressive to differential expansions between the top fibers and the

stresses above the centroidal axis. All specimens showed level of reinforcement).

ACI Materials Journal/January-February 2002 47

Table 4—Initial stiffnesses of beams loaded to

failure in flexure

Average slope of load-

Conditioning regime deflection curve, kN/mm

Never loaded reactive (325 days) 19

Sustained load reactive (325 days) 23

Cyclic load reactive (325 days) 17

28 day nonreactive 17

Never loaded nonreactive (249 days) 20

Sustained load nonreactive (249 days) 30

Cyclic load nonreactive (249 days) 12

point bending at ages of 325 and 249 days, respectively.

Beam midspan deflections were measured using a dial gage.

The load-deflection curves presented are the average curves

Fig. 6—Load-deflection curves of beam specimens. for two beams for each load condition for reactive and non-

reactive specimens (except for the 28-day nonreactive case,

which only had one specimen due to lack of reinforcing steel,

and one nonreactive beam, conditioned under cyclic load,

that failed during conditioning due to severe concrete

abrasion damage under the loading points).

The load-deflection curves for the reactive and nonreac-

tive beams for the various load conditioning regimes are pre-

sented in Fig. 6. The 28-day reactive beam flexural tests

experienced load cell problems, and the results were discarded.

Thus, there are seven load deflection curves as follows: reactive

without load, reactive under sustained load, reactive under

cyclic load, nonreactive at 28 days, nonreactive without

load, nonreactive under sustained load, and nonreactive

under cyclic load. These curves show that the ultimate behavior

Fig. 7—Flexural failure typical of all reactive aggregate under load of the various beams is generally similar regardless

beams with post steel yield concrete crushing. of either ASR expansions or the type of load conditioning.

The reactive beams conditioned under cyclic load did exhibit

The DRIs at the midheight, midspan locations were simi- a slightly lower ultimate flexural capacity than the other

lar for the beams conditioned without load and under sus- beams. As would be predicted by section analysis, the flex-

tained load. The beams conditioned under cyclic load ural capacities of the beams were limited by yielding of the

displayed more damage than the beams for the other two load flexural reinforcement.

conditions. The greater amount of damage at this location in the The slopes of the linear portions of the load-deflection

beams conditioned under cyclic load may have been caused by

curves are given in Table 4. The initial slopes of the load

an increase in mechanically induced cracking due to the

deflection curves of the reactive and nonreactive beams

repeated cycles of loading and unloading.

are similar, with the beams conditioned under sustained load

The lower midspan locations displayed less damage in the

having the largest stiffness, and the beams conditioned under

beams conditioned without load than those conditioned

cyclic load having the smallest stiffness. The differences

under load. This is due to mechanically induced cracking

observed, however, are not large and are considered to be

in the beam tension zones due to flexural loading. These me-

within the range of experimental error. In addition, the abra-

chanically induced cracks contributed to the DRIs of the

sion damage of the concrete directly under the loading points

loaded beams, even though they were not caused by ASR.

This demonstrates one of the limitations of the DRI, which (which occurred early during conditioning and was repaired) due

does not differentiate between concrete damage due to to cyclic loading may have reduced the initial stiffness of the re-

different causes. active and nonreactive beams conditioned under cyclic load.

The expansions measured at the upper regions of the reac- All reactive beams failed in a flexural mode (even those with

tive beams conditioned without load correspond well with severe abrasion damage to the concrete under the loading points).

the expansions of reactive concrete cylinders. The DRI of the The beams failed by yielding of the reinforcing steel, with large

reactive concrete prism, however, was less than that measured flexural cracks forming in the concrete at the bottom of the

at the top of these beams. This is attributed to mechanical crack- beams, followed by the crushing of the concrete at the top of the

ing due to hogging caused by the differential expansions beams between the loading points. Figure 7 shows a typical reac-

between the top fibers and the reinforcement levels of tive beam loaded to failure.

these beams (approximately 6 mm upward deflection of All nonreactive beams attained full flexural capacity, but the

the beams). post steel yield failure crack patterns of two of these beams, NB4

(Fig. 8), were similar to a shear failure (diagonal cracks from load

Residual mechanical properties points to the supports). The prestressing effect from ASR expan-

Reinforced concrete beams—The reactive and nonreac- sions in the reactive beams may have inhibited diagonal

tive beams were monotonically loaded to failure in four- shear-type crack patterns.

48 ACI Materials Journal/January-February 2002

Fig. 8—Post steel yield shear failure crack pattern of nonre-

active aggregate Beam NB4.

Table 5—Summary of concrete mechanical

properties Fig. 9—Stress-strain curves of concrete cylinders.

Specimen Ec, MPa Ed, MPa f c′ , MPa fr , MPa

28 days

20,000 38,500 26 6

reactive

325 days

6450 35,500 40 4.1

reactive

28 days

nonreactive 20,000 39,000 24 4.8

249 days

nonreactive 26,700 43,000 34 6.3

249 days

26,700 — 37 —

(lime water)

Note: Ec = static modulus of elasticity; Ed = dynamic modulus of elasticity; f c′ = cyl-

inder strength; and fr = modulus of rupture.

Residual mechanical properties of concrete

The reactive and nonreactive cylinders were failed in

compression at the same ages as the beams. The average Fig. 10—Measured resonant frequencies.

stress-strain curves are presented in Fig. 9, and the average

measured strengths and stiffnesses are given in Table 5. The resonant frequency of the reactive prisms (Fig. 10)

The strength of the reactive concrete cylinders at the end of increased during the first 20 days of storage, and subse-

the experiment increased by approximately 30% from the quently dropped for the remainder of the experiment. The

28-day results (26 to 40 MPa). Previous research is incon- resonant frequency of the nonreactive prisms increased

clusive; some research reports strength reductions, while other during the first 60 days and then stabilized or dropped

research reports no appreciable strength reductions with slightly. These results indicate that while the resonant frequency

time.5,10-12 The increase in strength of the reactive aggregate of the reactive aggregate concrete was affected by ASR

concrete with time is much larger than the losses due to ASR. damage, curing in NaOH had an insignificant effect on the

It should be noted that the strength of the test concrete would resonant frequency of the nonreactive concrete.

have been greater than that of field-cured concrete because Table 5 summarizes the various plain concrete properties

of continuous immersion in a warm solution, which accelerated measured from the reactive and nonreactive specimens. The

static modulus of elasticity proved to be very sensitive to the

the hydration process. The stiffness of the reactive concrete

damage in concrete from ASR and decreased by 68% from

cylinders after conditioning was significantly less than the

the 28-day results, while the dynamic modulus only decreased

stiffness of the 28-day reactive concrete and all the nonreac-

by 9% during the same period. This is contrary to what

tive concrete cylinders. A gain in compressive strength with

was expected, and no explanation is suggested. Both the

a loss in static modulus may indicate that the loss in stiffness static and dynamic moduli of elasticity for the nonreactive

of the concrete was due to ASR-induced microcracks that concrete increased or stabilized from 28 days until the end of

closed during compressive loading. The strength of the reac- the experiment.

tive cylinders at the end of the experiment was slightly larger The concrete flexural strength was significantly reduced

than that of the nonreactive cylinders, perhaps due to their by ASR, which indicates that the flexural tensile strength is

slightly greater age (325 against 249 days). a better predictor of ASR damage than the compressive

The nonreactive concrete cylinders stored in lime water strength. This reduction, however, is not significant in prac-

solution at 38 C had a marginally higher compressive tice because reinforcing steel is used in the tension zones of

strength at the end of the experiment than the cylinders reinforced concrete members. This loss in concrete flexural

stored in NaOH at the same temperature. This indicates that strength may affect the cracking load of beams, increasing

storage in NaOH did not have a significant effect on the com- deflections, but would not affect the ultimate load-carrying

pressive strength of the nonreactive concrete specimens and, capacity of under-reinforced concrete beams.

by implication, none on the compressive strength of reactive After this research was completed, Fan and Hanson13

concrete specimens. reported the results of a project on ASR expansion and the

ACI Materials Journal/January-February 2002 49

structural behavior of reinforced concrete beams conditioned significantly reduced the stiffness of the reactive concrete cylin-

in 0.5 N sodium hydroxide cyclically heated to 38 C and ders. In this study, the dynamic modulus of elasticity was less

cooled to 24 C. They concluded that ASR did not affect flex- sensitive to the effects of ASR than the static modulus of elas-

ural strength, but the mechanical properties of the concrete ticity. The flexural strength of concrete was reduced by ASR ex-

decreased after visible ASR cracks were observed. No attempt pansions and proved, as reported previously, to be more

was made to quantify the visually observed damage. sensitive to ASR expansions than the compressive strength.

CONCLUSION ACKNOWLEDGMENTS

The major conclusion derived from this research is that the The authors thank the following people for their help or advice: G. Mould,

T. Hoogeveen, and G. Chan of the National Research Council, B. Kotter and

expansions and concrete damage due to the ASR did not reduce M. Grira of the University of Ottawa, and T. Law of Carleton University.

the flexural capacity of simply supported, under-reinforced

concrete beams conditioned under sustained, or cyclic, service

REFERENCES

loads. The type of load conditioning may affect the precracking 1. Swamy, R. N., The Alkali-Silica Reaction in Concrete, Blackie and

stiffness and cracking loads of the beams to a minor extent. Son Ltd., Glasgow, 1992, 333 pp.

There is some evidence that ASR may increase the shear 2. Blight, G. E.; Alexander, M. G.; Ralph, T. K.; and Lewis, B. A.,

capacity of beams due to a prestressing effect from expan- “Effect of Alkali-Silica Reaction on the Performance of a Reinforced

sions. This agrees with previously published results. These Concrete Structure over a Six Year Period,” Magazine of Concrete

Research, V. 41, No. 147, 1989, pp. 69-77.

conclusions agree with what would be predicted from section 3. Jones, A. E. K., and Clark L. K., “The Effects of Restraint on ASR

analysis using the measured concrete properties. Sustained and Expansion of Reinforced Concrete,” Magazine of Concrete Research,

cyclic flexural load, as well as the longitudinal reinforcement, V. 48, No. 174, 1996, pp. 1-13.

had significant restraining effects on ASR expansions. 4. Guédon, J. S., and Le Roux, A., “Influence of Microcracking on the Onset

and Development of the Alkali Silica Reaction,” Durability of Concrete,

The DRIs did approximate the measured expansions. The lack SP-145, V. M. Malhotra, ed., American Concrete Institute, Farmington

of surface features typical of ASR with reactive gel was attribut- Hills, Mich., 1993, pp. 713-723.

ed to the surface gel being leached out by conditioning speci- 5. Inoue, S.; Fujii, M.; Kobayashi, K.; and Nakano, K., “Structural

mens in warm sodium hydroxide solution. Expansion Behavior of Reinforced Concrete Beams Affected by Alkali-Silica Reac-

measurements were more sensitive in indicating the magnitude tion,” Proceedings of the 8th International Conference on Alkali-Aggregate

Reaction, The Society for Materials Science, Japan, 1989, pp. 727-732.

of ASR expansions than the DRI measurements due to the inabil- 6. Swamy, R. N., and Al-Asali, M. M., “Effect of Alkali-Silica Reaction

ity of the DRI to differentiate between ASR cracks and mechan- on the Structural Behavior of Reinforced Concrete Beams,” ACI Structural

ical cracks. In the future, effort should be made to eliminate Journal, V. 84, No. 4, 1989, pp. 451-459.

damage other than that from ASR from the DRI. The DRI 7. Canadian Standards Association, CSA A23.2-14A-1994, “Potential

and measured expansions correlated well with the reduction Expansivety of Aggregates (Procedure for Length Change Due to Alkali-

Aggregate Reaction in Concrete Prisms),” Concrete Materials and Meth-

in the static modulus of plain concrete, but neither was a ods of Concrete Construction, Methods of Testing for Concrete, CSA,

good indicator of residual beam or concrete strength. Rexdale, Ontario, 1994, pp. 204-214.

Conclusions related to the mechanical properties of concrete 8. Grattan-Bellew, P. E., “Laboratory Evaluation of Alkali-Silica

are limited in that the test specimens were entirely submerged in Reaction in Concrete from Saunders Generating Station,” ACI Materials

Journal, V. 92, No. 2, Mar.-Apr. 1995, pp. 126-134.

a NaOH solution and not subjected to cycles of wetting and 9. Monette, L. J., “Effects of the Alkali-Silica Reaction on Unloaded,

drying that would occur in exterior structures and reduce fur- Statically Loaded and Dynamically Loaded Reinforced Concrete Beams,”

ther hydration. The compressive strength of the reactive cylinders Master’s thesis, University of Ottawa, Ottawa, Ontario, Canada, 1997.

at 325 days (28 days moist curing, 147 days of conditioning, and 10. Clayton, N., “Structural Performance of ASR Affected Concrete,”

150 days in air) was slightly higher than that of the nonreactive Proceedings of the 8th International Conference on Alkali-Aggregate Reac-

tion, The Society for Materials Science, Japan, 1989, pp. 671-675.

cylinders’ 249 days (28 days moist curing, 161 days of condi- 11. Thorsen, T., and Stockund Larsen, E., “Alkali-Silica Reactions in

tioning, and 60 days in air), but similar to nonreactive cylinders Damaged Concrete, Static and Dynamic Tests, Material Investigations,”

stored in lime water. Expansions from the ASR did not prevent Proceedings, 10th International Conference on Alkali-Aggregate Reaction,

the increase of reactive concrete compressive strength with CSIRO, Melbourne, 1996, pp.402-409.

time. The compressive strength of the nonreactive concrete in 12. Swamy, R. N., The Alkali-Silica Reaction in Concrete, Blackie and

Son, Ltd., Glasgow, 1992, 333 pp.

NaOH was slightly lower than that of the concrete stored in lime 13. Shengfu, F., and Hanson, J. M., “Effect of Alkali Silica Reaction

water, indicating a possible marginal effect from immersion in Expansion and Cracking on Structural Behavior of Reinforced Concrete

warm NaOH. Concrete cracking caused by ASR expansions Beams,” ACI Structural Journal, V. 95, No. 5, Sept.-Oct. 1998, pp. 498-505.

50 ACI Materials Journal/January-February 2002

You might also like

- Fatigue Evaluation For Reinforced Concrete Box CulvertsDocument8 pagesFatigue Evaluation For Reinforced Concrete Box CulvertsProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- AGoT2 Illustrated Cheat SheetDocument2 pagesAGoT2 Illustrated Cheat SheetIgor Silva100% (1)

- Macr1300282 OffprintDocument11 pagesMacr1300282 OffprintASMAMAW GEDEFAWNo ratings yet

- Moment Capacity, Cracking Behaviour and Ductile Properties of Reinforced Concrete Beams Using Steel Slag As A Coarse AggregateDocument7 pagesMoment Capacity, Cracking Behaviour and Ductile Properties of Reinforced Concrete Beams Using Steel Slag As A Coarse AggregatePiyushNo ratings yet

- Zhang 2021Document16 pagesZhang 2021Jacob Nicolas Muñoz AriasNo ratings yet

- BashaDocument13 pagesBashaTariqul IslamNo ratings yet

- Engineering Structures: Yu-Ye Zhang, Kent A. Harries, Wan-Cheng YuanDocument11 pagesEngineering Structures: Yu-Ye Zhang, Kent A. Harries, Wan-Cheng YuanstevanylydiaNo ratings yet

- Modelling The Cyclic Response and Development of The Backbone Curve of Corroded RC Bridge PiersDocument10 pagesModelling The Cyclic Response and Development of The Backbone Curve of Corroded RC Bridge PierskamatchiNo ratings yet

- CIE 525 Group 1 Final ReportDocument10 pagesCIE 525 Group 1 Final ReportChris BuckNo ratings yet

- Materials Today: Proceedings: Rajib Kumar Biswas, Mistuyasu Iwanami, Nobuhiro Chijiwa, Kazuhide NakayamaDocument6 pagesMaterials Today: Proceedings: Rajib Kumar Biswas, Mistuyasu Iwanami, Nobuhiro Chijiwa, Kazuhide NakayamaEng mohammadNo ratings yet

- Life-Cycle Seismic Performance Assessment of Aging RC Bridges Considering Multi-Failure Modes of Bridge ColumnsDocument18 pagesLife-Cycle Seismic Performance Assessment of Aging RC Bridges Considering Multi-Failure Modes of Bridge ColumnsThea Sofia Newton-JohnNo ratings yet

- Corrosion Science: Mohammad M. Kashani, Adam J. Crewe, Nicholas A. AlexanderDocument14 pagesCorrosion Science: Mohammad M. Kashani, Adam J. Crewe, Nicholas A. AlexanderOdlinNo ratings yet

- Effect of Corrosion in Reinforced Concrete Frame Components On Pushover Behavior and Ductility of FrameDocument23 pagesEffect of Corrosion in Reinforced Concrete Frame Components On Pushover Behavior and Ductility of Framef puglieseNo ratings yet

- CMD 03 00012 v2Document11 pagesCMD 03 00012 v2johnalfred051801No ratings yet

- IMP Paper-1Document13 pagesIMP Paper-1Prasanth SekarNo ratings yet

- Finite Element Analysis of Reinforced Concrete BeaDocument15 pagesFinite Element Analysis of Reinforced Concrete BeaZainab FarooqNo ratings yet

- 2007, Comparison of Two Accelerated Corrosion Techniques For Concrete StructuresDocument4 pages2007, Comparison of Two Accelerated Corrosion Techniques For Concrete StructuresSairam KatikalaNo ratings yet

- 104 s37 PDFDocument9 pages104 s37 PDFRajKumarNo ratings yet

- EIJCSE6005Document19 pagesEIJCSE6005Faizan TariqNo ratings yet

- EIJCSE6005Document19 pagesEIJCSE6005Faizan TariqNo ratings yet

- Construction and Building Materials: Junzu Sun, Qiao Huang, Yuan RenDocument12 pagesConstruction and Building Materials: Junzu Sun, Qiao Huang, Yuan RenrehanmaazNo ratings yet

- Effectof Cyclic Loadingsonthe Shear StrengthandDocument14 pagesEffectof Cyclic Loadingsonthe Shear StrengthandAbel MulugetaNo ratings yet

- Research PaperDocument8 pagesResearch PaperMuhammad JunaidNo ratings yet

- Effect of Corrosion in Reinforced Concrete Frame Components On Pushover Behavior and Ductility of FrameDocument24 pagesEffect of Corrosion in Reinforced Concrete Frame Components On Pushover Behavior and Ductility of Framef puglieseNo ratings yet

- Comparative Performance of RC Shear Walls Designed by Different StandardsDocument22 pagesComparative Performance of RC Shear Walls Designed by Different StandardsSlavoljub IlicNo ratings yet

- ICEAS13 DashtiandDhakal Wallscomparison PDFDocument22 pagesICEAS13 DashtiandDhakal Wallscomparison PDFSlavoljub IlicNo ratings yet

- 26 Year Old SpecimenDocument12 pages26 Year Old Specimendebabrata duttaNo ratings yet

- Seismic Behaviour of Double Skin Composite Shear Walls With Overlapped Headed StudsDocument19 pagesSeismic Behaviour of Double Skin Composite Shear Walls With Overlapped Headed StudsAnonymous cKV7P2magXNo ratings yet

- Bo Da Study On Shear Behavior of Reinforced CoralDocument11 pagesBo Da Study On Shear Behavior of Reinforced CoralKamishka SandaruwanNo ratings yet

- Experimental Evaluation and Modeling of Corroded Reinforced Concrete ColumnsDocument16 pagesExperimental Evaluation and Modeling of Corroded Reinforced Concrete ColumnsCristhian PardoNo ratings yet

- 1 s2.0 S0143974X22002760 MainDocument17 pages1 s2.0 S0143974X22002760 MainwflowerNo ratings yet

- Comparison of Two Accelerated Corrosion TechniquesDocument1 pageComparison of Two Accelerated Corrosion TechniquesFaraz TariqNo ratings yet

- Seismic Behavior of Nonseismically Detailed Interior Beam-Wide Column Joints-Part I: Experimental Results and Observed BehaviorDocument12 pagesSeismic Behavior of Nonseismically Detailed Interior Beam-Wide Column Joints-Part I: Experimental Results and Observed BehaviorpaulkohanNo ratings yet

- Disarno 2020Document47 pagesDisarno 2020Eng mohammadNo ratings yet

- Service Life Prediction of CorrosionDocument26 pagesService Life Prediction of CorrosionRicardoNo ratings yet

- Materials Today: ProceedingsDocument6 pagesMaterials Today: ProceedingsSREEJITH S NAIRNo ratings yet

- Engineering Docs3Document11 pagesEngineering Docs3rosekavalierhcNo ratings yet

- Environment-Assisted Corrosion Damage of Steel Bridges - A Conceptual Framework For Structural IntegrityDocument18 pagesEnvironment-Assisted Corrosion Damage of Steel Bridges - A Conceptual Framework For Structural IntegrityEduardo Elí Garcia JimenezNo ratings yet

- Metals: Corrosion Effects On Durability of RC StructuresDocument2 pagesMetals: Corrosion Effects On Durability of RC StructuresAvinash PrajapatiNo ratings yet

- Deep Underground Science and Engineering - 2023 - Chen - Triaxial Creep Damage Characteristics of Sandstone Under HighDocument12 pagesDeep Underground Science and Engineering - 2023 - Chen - Triaxial Creep Damage Characteristics of Sandstone Under Highyanli.gao.0No ratings yet

- Ductility Characteristics of Concrete Frames ReinfDocument12 pagesDuctility Characteristics of Concrete Frames ReinfDoua AbdouNo ratings yet

- Engineering Structures: SciencedirectDocument13 pagesEngineering Structures: SciencedirectJHON WILMAR CARDENAS PULIDONo ratings yet

- Behavior of Interior Beam-to-Column Connections UnderDocument7 pagesBehavior of Interior Beam-to-Column Connections UnderMarimuthu KaliyamoorthyNo ratings yet

- 1 s2.0 S0029801822018443 MainDocument13 pages1 s2.0 S0029801822018443 MainAlvin ReynaldiNo ratings yet

- TAREA No 05Document27 pagesTAREA No 05Bautista TañinNo ratings yet

- 2014 OudahandEl Hacha SeismicevaluationofRCmoment Resistingframeswithmasonryinfillwalls PDFDocument9 pages2014 OudahandEl Hacha SeismicevaluationofRCmoment Resistingframeswithmasonryinfillwalls PDFamikcorNo ratings yet

- Research On The Degradation of Steel Structures For The Needs of Structural Life-Cycle Design and Time-Dependent Reliability in Corrosive EnvironmentDocument3 pagesResearch On The Degradation of Steel Structures For The Needs of Structural Life-Cycle Design and Time-Dependent Reliability in Corrosive EnvironmentRaees MazharNo ratings yet

- Mechanical Properties of Reinforcing Steel Bars Corroded at Different LevelsDocument13 pagesMechanical Properties of Reinforcing Steel Bars Corroded at Different LevelsJorge BlancoNo ratings yet

- Nuclear Engineering and Design: Xuhui Zhang, Lei Wang, Jianren Zhang, Yafei Ma, Yongming LiuDocument11 pagesNuclear Engineering and Design: Xuhui Zhang, Lei Wang, Jianren Zhang, Yafei Ma, Yongming LiuJos PereNo ratings yet

- 30-An Experimental Study of Flexural Cracking in ReinDocument49 pages30-An Experimental Study of Flexural Cracking in ReinJan Van MiddendorpNo ratings yet

- Structural Behaviour of Composite Members With Recycled Aggregate Concrete - An OverviewDocument21 pagesStructural Behaviour of Composite Members With Recycled Aggregate Concrete - An OverviewMoisés Ocampo FernándezNo ratings yet

- Abaqus AnalysisDocument12 pagesAbaqus AnalysisMohan BhalmeNo ratings yet

- Shayan Far 2016Document11 pagesShayan Far 2016sdsdNo ratings yet

- Seismic Behavior of Reinforced Engineered Cementitious Composite Members and Reinforced Concrete/engineered Cementitious Composite Members: A ReviewDocument21 pagesSeismic Behavior of Reinforced Engineered Cementitious Composite Members and Reinforced Concrete/engineered Cementitious Composite Members: A Reviewoscar cardenasNo ratings yet

- Nepal 2015 J. Phys.: Conf. Ser. 628 012050Document9 pagesNepal 2015 J. Phys.: Conf. Ser. 628 012050shakyrNo ratings yet

- 4.evaluation of Structures Affected by Alkali-Silica Reaction (ASR) UsingDocument14 pages4.evaluation of Structures Affected by Alkali-Silica Reaction (ASR) UsingchileanNo ratings yet

- Experiments On Ductile and Non Ductile R PDFDocument13 pagesExperiments On Ductile and Non Ductile R PDFbiniamNo ratings yet

- 1 s2.0 S0141029618324465 MainDocument12 pages1 s2.0 S0141029618324465 MainAnirudh SabooNo ratings yet

- Corrosion Propagation of Steel Rebar Embedded in MarineDocument8 pagesCorrosion Propagation of Steel Rebar Embedded in MarineAlmas XamiNo ratings yet

- "Effect of Corrosion On RC Building": "Tanhavi Gajbhiye"Document28 pages"Effect of Corrosion On RC Building": "Tanhavi Gajbhiye"TanviNo ratings yet

- E&p Business Process Reference ModelDocument83 pagesE&p Business Process Reference ModelArie Wibowo SutiarsoNo ratings yet

- (Extra) Questões - Phrasal VerbsDocument6 pages(Extra) Questões - Phrasal VerbsRafael GomesNo ratings yet

- Top Law Firm in Dubai, UAE - RAALCDocument20 pagesTop Law Firm in Dubai, UAE - RAALCraalc uaeNo ratings yet

- 3i's Rubrics ACTIVITY 1Document2 pages3i's Rubrics ACTIVITY 1Jaeneth SimondoNo ratings yet

- Air Is Allowed To Flow From A Large Reservoir ThroDocument3 pagesAir Is Allowed To Flow From A Large Reservoir Throsid202pkNo ratings yet

- Spoken Cues To DeceptionDocument32 pagesSpoken Cues To DeceptionSruthy KrishnaNo ratings yet

- MyDigital ID Brochure 2024Document6 pagesMyDigital ID Brochure 2024ariff29132776No ratings yet

- Overtime in NursingDocument5 pagesOvertime in NursingallisonNo ratings yet

- How Is Paper MadeDocument9 pagesHow Is Paper MadeDeo WarrenNo ratings yet

- FIN201 CF T3 2021 BBUS Unit Guide V2 07092021Document11 pagesFIN201 CF T3 2021 BBUS Unit Guide V2 07092021Nguyen Quynh AnhNo ratings yet

- VDSL POTS Splitter Whitepaper PDFDocument12 pagesVDSL POTS Splitter Whitepaper PDFEzZamNo ratings yet

- HZ2322 EM250 Series 100mW ZigBee Module (ENG)Document10 pagesHZ2322 EM250 Series 100mW ZigBee Module (ENG)MicroComSolutionsNo ratings yet

- Your Contacts From TelephoneDocument73 pagesYour Contacts From TelephoneEly IEJINo ratings yet

- TracebackDocument3 pagesTracebackCristi LazărNo ratings yet

- Separation of Ceftibuten Stereo Isomers With 100% Aqueous MoDocument2 pagesSeparation of Ceftibuten Stereo Isomers With 100% Aqueous Moducngoctrinh100% (1)

- Algo Trading BasicsDocument15 pagesAlgo Trading BasicsRajvin DongaNo ratings yet

- Holiday Assignment - GR12 EnglishDocument3 pagesHoliday Assignment - GR12 Englishabhishektatu2007No ratings yet

- English 2-3 Class 10Document2 pagesEnglish 2-3 Class 10Binode SarkarNo ratings yet

- Reasons For Decision-Appeal Judgment-Mandaya Thomas-V - The QueenDocument4 pagesReasons For Decision-Appeal Judgment-Mandaya Thomas-V - The QueenBernewsAdminNo ratings yet

- Scotia Bank WorkDocument3 pagesScotia Bank WorkVaidant SunejaNo ratings yet

- Resultados de Búsqueda: Artículos Académicos para Vocal Function Exercises Stemple PDFDocument3 pagesResultados de Búsqueda: Artículos Académicos para Vocal Function Exercises Stemple PDFleandro__scribdNo ratings yet

- 904B Compact Wheel LoaderDocument40 pages904B Compact Wheel LoaderSaid TouhamiNo ratings yet

- Ieep 104Document7 pagesIeep 104Praveen KumarpillaiNo ratings yet

- China Pakistan Economic Corridor CPEC IsDocument12 pagesChina Pakistan Economic Corridor CPEC IsNasir HussainNo ratings yet

- Letter of Inquiry About Internship Opportunities - HardDocument1 pageLetter of Inquiry About Internship Opportunities - Hardapi-370641050% (2)

- Date Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)Document1 pageDate Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)PatOcampoNo ratings yet

- Sample Diary Curriculum Map SUBJECT: Mathematics QUARTER: Second Grade Level: 10 TOPIC: CircleDocument3 pagesSample Diary Curriculum Map SUBJECT: Mathematics QUARTER: Second Grade Level: 10 TOPIC: CircleRichimon LicerioNo ratings yet

- Assignment - Research Methods For ManagementDocument19 pagesAssignment - Research Methods For Managementnatashashaikh93No ratings yet

- Hasil SKD Publish (Ok) 3Document60 pagesHasil SKD Publish (Ok) 3SolahudinNo ratings yet