Professional Documents

Culture Documents

Thermiculite Gasket

Thermiculite Gasket

Uploaded by

thanakomCopyright:

Available Formats

You might also like

- Westerman Table 1Document80 pagesWesterman Table 1pawanumarji192% (12)

- Intense Heat. Extreme Cold. Aggressive Chemicals. InnovativeDocument2 pagesIntense Heat. Extreme Cold. Aggressive Chemicals. InnovativeCristian Jhair PerezNo ratings yet

- Lamons Purely High Temperature GasketsDocument6 pagesLamons Purely High Temperature GasketsIjaz AhmedNo ratings yet

- Flexitallic Gasket Criteria DesignDocument59 pagesFlexitallic Gasket Criteria DesignAtif MehmoodNo ratings yet

- FST Agriculture Brochure 2015 A4 - OnlineDocument8 pagesFST Agriculture Brochure 2015 A4 - OnlineriponautosgraphicsNo ratings yet

- Thermiculite 835: Product DatasheetDocument2 pagesThermiculite 835: Product DatasheetBenoit LabreNo ratings yet

- Thermiculite 835 SWGDocument2 pagesThermiculite 835 SWGISEDAC21No ratings yet

- Flexpro Therm 845Document1 pageFlexpro Therm 845Benoit LabreNo ratings yet

- Thermiculite: Intense Heat. Extreme Cold. Aggressive ChemicalsDocument8 pagesThermiculite: Intense Heat. Extreme Cold. Aggressive ChemicalsFilipNo ratings yet

- FL Ange Se Aling Progr Am: Industry Gasket SolutionsDocument8 pagesFL Ange Se Aling Progr Am: Industry Gasket SolutionsjaviervbNo ratings yet

- 12 PAPYEX Flexible Graphite Mersen - 09 PDFDocument14 pages12 PAPYEX Flexible Graphite Mersen - 09 PDFarizagameroNo ratings yet

- Thermiculite BrochureDocument8 pagesThermiculite BrochureXuan TruongNo ratings yet

- Garlock Metallic CatalogueDocument48 pagesGarlock Metallic Catalogueclaudio perez prietoNo ratings yet

- flyMicaTherm PDFDocument2 pagesflyMicaTherm PDFThomasFrenchNo ratings yet

- Aspen Aerogels Pyrogel XT PDFDocument4 pagesAspen Aerogels Pyrogel XT PDFBTconcordNo ratings yet

- Design Criteria PDFDocument58 pagesDesign Criteria PDFsaculNo ratings yet

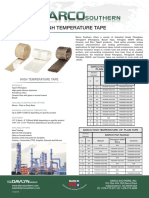

- High Temp Tape Darco 10.16Document1 pageHigh Temp Tape Darco 10.16Jose ArangoitiaNo ratings yet

- Garlock MetalGasket CatalogDocument48 pagesGarlock MetalGasket CatalogG100% (1)

- Klinger Product Catalogue 40 Pages April 2014 Final Doc Trusted - Worldwide PDFDocument40 pagesKlinger Product Catalogue 40 Pages April 2014 Final Doc Trusted - Worldwide PDFStart JaguarNo ratings yet

- GMG 1 1 Metallic Gaskets CatalogDocument48 pagesGMG 1 1 Metallic Gaskets CatalogTecnico GiganteNo ratings yet

- Spectraplan TPE Sales Brochure PDFDocument20 pagesSpectraplan TPE Sales Brochure PDFydrasNo ratings yet

- Thermiculite 894Document2 pagesThermiculite 894Benoit LabreNo ratings yet

- Sealing For Extreme Cold - Best Practices For Statics SealsDocument3 pagesSealing For Extreme Cold - Best Practices For Statics Sealssujith_das_2No ratings yet

- Novaphit Professional Technolgy eDocument8 pagesNovaphit Professional Technolgy eajaysharma_1009No ratings yet

- Insulation ContraThermDocument16 pagesInsulation ContraThermmarcins85No ratings yet

- Gasket RefDocument21 pagesGasket Refjun_bucayuNo ratings yet

- Wound SpiralDocument2 pagesWound SpiralMircea Dan StanciuNo ratings yet

- Aspen Aerogels Industrial InsulationDocument4 pagesAspen Aerogels Industrial InsulationGino De LandtsheerNo ratings yet

- SKF Spectraseal: Sealing Solutions For Extreme Application ChallengesDocument5 pagesSKF Spectraseal: Sealing Solutions For Extreme Application ChallengesmiguelNo ratings yet

- Expansion JointsDocument8 pagesExpansion Jointsterencejustine100% (1)

- PDF.2 74495 157 HighDensBro EDocument16 pagesPDF.2 74495 157 HighDensBro EBojan BjelajacNo ratings yet

- Aislamiento Termico-Broch Cryogel ZDocument2 pagesAislamiento Termico-Broch Cryogel ZJavier Caamaño VillafañeNo ratings yet

- Gasket StandardsDocument40 pagesGasket StandardsSiva Raman Murugesan100% (1)

- Rotary Metallurgical MaterialsDocument4 pagesRotary Metallurgical MaterialsNabeel MohammedNo ratings yet

- E10 HEPA Filter SpecsDocument1 pageE10 HEPA Filter Specsleisurely.dpgNo ratings yet

- Fiberfrax Duraboard Products: Product Information SheetDocument4 pagesFiberfrax Duraboard Products: Product Information SheetShashank MishraNo ratings yet

- FloatingDocument12 pagesFloatingrobson2015No ratings yet

- Tanged Graphite Gasket Material Seals Aggressive Chemicals Under Extreme ConditionsDocument1 pageTanged Graphite Gasket Material Seals Aggressive Chemicals Under Extreme ConditionsPramod DixitNo ratings yet

- Kflex TitanDocument2 pagesKflex TitanShahab Z AhmedNo ratings yet

- JZ-20220423 Siliocne Composite Tape Bochure-ENDocument12 pagesJZ-20220423 Siliocne Composite Tape Bochure-ENLongsun KejiNo ratings yet

- Up Graded Thermal Insulation DCLDocument14 pagesUp Graded Thermal Insulation DCLSubrata NagNo ratings yet

- Flexitallic Products PDFDocument108 pagesFlexitallic Products PDFNguyễn Xuân NamNo ratings yet

- JZ Siliocne Composite Tape Bochure-EN 20230427Document9 pagesJZ Siliocne Composite Tape Bochure-EN 20230427JZ HuangNo ratings yet

- Insulation ReferenceDocument16 pagesInsulation ReferenceSteven SebastianNo ratings yet

- Flexitallic I-Flex 'High Temperature' Flange Insulating SetDocument2 pagesFlexitallic I-Flex 'High Temperature' Flange Insulating SetJandri JacobNo ratings yet

- Ipd Pds Sikalastomer 95 UsDocument2 pagesIpd Pds Sikalastomer 95 Usernest manNo ratings yet

- Thermiculite 815Document1 pageThermiculite 815Aji HatmantoNo ratings yet

- Thermiculite 815Document1 pageThermiculite 815Aji HatmantoNo ratings yet

- Thermiculite 815Document1 pageThermiculite 815Benoit LabreNo ratings yet

- 12 PAPYEX Flexible Graphite Mersen 21Document14 pages12 PAPYEX Flexible Graphite Mersen 21ayushNo ratings yet

- Flexitallic Product ServicesDocument20 pagesFlexitallic Product ServicesFrankie TeoNo ratings yet

- Gasket BrochureDocument26 pagesGasket BrochureAreeb KhanNo ratings yet

- Calcium Silicate Insulation BrochureDocument52 pagesCalcium Silicate Insulation BrochuremukeshsinghtomarNo ratings yet

- Gasket EngineeringDocument28 pagesGasket EngineeringRohit DaveNo ratings yet

- Garlock Metallic Gasket Technical ManualDocument48 pagesGarlock Metallic Gasket Technical ManualMarcio NegraoNo ratings yet

- K450 Plus Updated PDFDocument138 pagesK450 Plus Updated PDFCongson JeffNo ratings yet

- Gasket Application and Material Selection GuideDocument10 pagesGasket Application and Material Selection GuideTieu KakaNo ratings yet

- Klingersil Brochure 0605Document20 pagesKlingersil Brochure 0605tsaipeterNo ratings yet

- SISfirepro F-180 Synixtor ENGLISHDocument4 pagesSISfirepro F-180 Synixtor ENGLISHPaloma Carralon FlorezNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Material Selection For Piping Valve and SupportsDocument45 pagesMaterial Selection For Piping Valve and SupportsamlanfacebookNo ratings yet

- Grade Guide A36 SteelDocument3 pagesGrade Guide A36 SteelBayar DiyarNo ratings yet

- History of Fire ExtinguishersDocument8 pagesHistory of Fire ExtinguishersSandeep KumarNo ratings yet

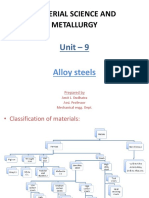

- Material Science and Metallurgy: Unit - 9Document24 pagesMaterial Science and Metallurgy: Unit - 9Vivek BajpaiNo ratings yet

- Iron WorkingDocument2 pagesIron WorkingRedeemerBoyNo ratings yet

- Ellingham Diagram UsesDocument4 pagesEllingham Diagram Usesnanda rizkyNo ratings yet

- Astm A240Document15 pagesAstm A240Luis Fernando Rueda100% (1)

- A532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast IronsDocument4 pagesA532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast Ironsalexander zuritaNo ratings yet

- Cambridge International AS & A Level: CHEMISTRY 9701/23Document20 pagesCambridge International AS & A Level: CHEMISTRY 9701/23nickole.taruc022807No ratings yet

- Tig Welding in AluminiumDocument11 pagesTig Welding in AluminiumMohnishNo ratings yet

- Bronze & Iron CatalogueDocument116 pagesBronze & Iron CatalogueHector Dario Tobon BenjumeaNo ratings yet

- Voltaic Cell and Electrolytic Cell: by 5S3 Jocelyne LewDocument9 pagesVoltaic Cell and Electrolytic Cell: by 5S3 Jocelyne LewJocelyne LewNo ratings yet

- Astm A519 - 2017Document14 pagesAstm A519 - 2017juanvrcicNo ratings yet

- Metal Coupling in Rusting IronDocument20 pagesMetal Coupling in Rusting Ironmr bean animated cartoonsNo ratings yet

- Stmicroelectronics 6.1Document200 pagesStmicroelectronics 6.1domingos aladirNo ratings yet

- f1 c6 Periodic Table NotesDocument13 pagesf1 c6 Periodic Table Notesjasonyeoh333No ratings yet

- BRAZING MATERIALS - Wallchart Eng v10 - 1Document2 pagesBRAZING MATERIALS - Wallchart Eng v10 - 1Jim SmithNo ratings yet

- Metals - Form 4 Chemistry Topical QuestionsDocument13 pagesMetals - Form 4 Chemistry Topical QuestionsEmmanuel KipyegonNo ratings yet

- Training Report - For STUDENTSDocument52 pagesTraining Report - For STUDENTSAbdulziz kurdiNo ratings yet

- D & F Block Elements NCERTDocument18 pagesD & F Block Elements NCERTmehakNo ratings yet

- The Complete Photo Guide To Making Metal JewelryDocument744 pagesThe Complete Photo Guide To Making Metal JewelryAttila Lébényi-Palkovics100% (2)

- Microstructures of Iron-Carbon Alloys: Fine Pearlite 3000XDocument9 pagesMicrostructures of Iron-Carbon Alloys: Fine Pearlite 3000XVaishu 07No ratings yet

- Mini Cut-Off Wheels: Available Wheel Size & Standard Packing QuantityDocument11 pagesMini Cut-Off Wheels: Available Wheel Size & Standard Packing Quantityherysyam1980No ratings yet

- NIIR List of DatabasesDocument61 pagesNIIR List of DatabasesRITESH RATHODNo ratings yet

- Tron C@ 50: Product Data BulletinDocument18 pagesTron C@ 50: Product Data BulletinPrakash SundaramNo ratings yet

- Astm A387 387MDocument3 pagesAstm A387 387MkartsoftNo ratings yet

- N2 Platers' Theory Augsut 2021Document6 pagesN2 Platers' Theory Augsut 2021kgasagodebraNo ratings yet

- Stripping Chrome PlatingsDocument3 pagesStripping Chrome PlatingscondorwayraNo ratings yet

- Department of Education: Learning Activity Worksheets (LAW) General Chemistry 1 Grade 11Document10 pagesDepartment of Education: Learning Activity Worksheets (LAW) General Chemistry 1 Grade 11Ryan Joseph HernoNo ratings yet

Thermiculite Gasket

Thermiculite Gasket

Uploaded by

thanakomOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermiculite Gasket

Thermiculite Gasket

Uploaded by

thanakomCopyright:

Available Formats

INTENSE HEAT.

EXTREME COLD.

AGGRESSIVE CHEMICALS.

Material Technology That Handles It All.

Thermiculite ®

Innovative. Versatile. Complete.

INNOVATIVE. TOTAL FREEDOM

Cutting-Edge Material Technology FROM OXIDATION

Ever since inventing the spiral wound gasket nearly a century ago, Conventional graphite gaskets are susceptible to attack by oxidizing

Flexitallic® has been at the forefront of fluid sealing innovation. agents. This occurs from oxygen flowing through pipes, or simply

In 1999, Flexitallic set new standards for sealing technology with the from oxygen present in the atmosphere surrounding the flange. The

introduction of Thermiculite® Critical Service Grade gasket material rate at which graphite oxidizes depends on the application

available in Tanged Sheet—and later in Spiral Wound Filler and temperature and the concentration of oxygen present. But when it

Flexpro™ (kammprofile) styles. does happen—the end result is seal failure.

Exclusive to Flexitallic, this revolutionary material, comprised of The unique composition of Thermiculite® gasket material ensures that

chemically and thermally exfoliated vermiculite*, simulated the seals maintain their integrity at maximum service temperatures far

structure of exfoliated graphite, with one notable exception—it exceeding that of graphite.

maintained integrity through a wide range of extreme temperatures.

There really is no comparison. When it comes to worry-free sealing,

All Thermiculite Critical Service Grade products were designed and choose Thermiculite® Critical Service Grade or Thermiculite®

engineered for high temperature processes rated for service up to Performance Grade and eliminate the risk of oxidation altogether

980°C (1800°F).

* Vermiculite is a naturally occurring mineral with a plate-like structure demonstrating

an exceptionally broad range of chemical and temperature resistance.

VERSATILE.

A New Level of Performance

Through our continued dedication to research and development,

Flexitallic is now proud to offer our customers a new series of

Thermiculite products.

New Thermiculite Performance Grade gasket material—developed

for use in more moderate temperature applications—maintains the

same broad chemical resistance and freedom from oxidation that has

made Thermiculite® Critical Service Grade such a success.

The Tightness Testing Research Laboratory (TTRL) at École Polytechnique in

Montreal on behalf of the Pressure Vessel Research Council (PVRC) performed

This innovative and versatile material is available in Calendered independent testing to show that the maximum service temperature for graphite in

Sheet and Spiral Wound Filler styles, and is suitable for replacing long-term service is much lower than that quoted in manufacturers' literature. This

aramid fixer, glass fiber, carbon fiber, PTFE and graphite in a wide table summarizes those results.

array of applications.

* Maximum service temperature results based on style 735.

COMPLETE.

The Total Static Sealing Solution

Since its inception, Thermiculite gasket material has proven itself as

an effective long-term sealing solution in over 1000 of the most

demanding industrial sealing applications—the most complete range

since asbestos.

With the combination of Thermiculite Critical Service Grade (800

series) and Thermiculite Performance Grade (700 series), a single,

proven material can be used for virtually all of your sealing

requirements. That's why we call Thermiculite® The Total Static

Sealing Solution.

Why Thermiculite Critical Service Series?

● Total freedom from oxidation

● Chemical compatibility exceeds graphite

● Can be used in temperatures from Cryogenics to up

to 1800°F / 982°C

● Fire safe THERMICULITE

835 Spiral

● Proven track record (over 500 applications & Wound Filler

approvals globally)

● Wide range of metals available

Why Thermiculite Performance Series?

● Total freedom from oxidation

● Broad chemical compatibility range

● Fire safe

THERMICULITE

● Genuine opportunity for gasket standardization and 715 Cut

inventory consolidation Gasket

● Wide service capability Available in all

shapes and

sizes.

THERMICULITE THERMICULITE THERMICULITE

815 Tanged Sheet 835 Spiral Wound Filler 845 Flexpro

(kammprofile) Facing

High temperature sheet reinforced High temperature filler

with a 0.004” 316 stainless steel material for spiral wound High temperature facing material

tanged core. Available in gaskets. Wide range of for kammprofile gaskets. Wide

thicknesses of 1/32”, 1/16”, and 1/8” metals available. range of metallic core materials

in meter by meter (standard) and available.

60” x 60” sheet. Cut gaskets also

available in all shapes and sizes.

Effectively manage your

gasket selection process,

simplify inventory

requirements, and receive

proven long-term sealing

with Thermiculite gasket

material – The Total Static

Sealing Solution.

Contact your local authorized

THERMICULITE THERMICULITE

715 Coreless Sheet 735 Spiral Wound Filler distributor today!

High-performance coreless sheet Filler material for spiral wound

material. Replacement of gaskets combined with either

compressed fiber sheet line, SF 304 or 316 alloy steel winding

2401, 2420, 3300, 5000 and tanged wire.

graphite sheet. Available in

thicknesses of 1/32” 1/16”, and 1/8”

in cut gaskets and 60” x 60” sheet.

Flexitallic Sigma offers outstanding chemical resistance while the

unique manufacturing rpoc3ess results in a biaxially fibrillated

structure ensuring high seal integrity in the most demanding

applications.

SIGMA 500 (Blue)

High compression glass microsphere filled

PTFE sheet specially formulated for use on

glass lined, plastic, or ceramic flanges.

INDUSTRIES SERVED:

SIGMA 511 (Fawn)

CHEMICAL PROCESSING Standard compression silica filled PTFE

FOOD AND BEVERAGE sheet for use with concentrated acids and

HYDROCARBON PROCESSING most general aggressive chemicals.

NUCLEAR

ORIGINAL EQUIPMENT MFG’S

PHARMACEUTICAL

POWER GENERATION

PRIMARY METALS SIGMA 533 (Off-White)

PULP AND PAPER Pigment-free barium sulfate filled PTFE

sheet for use with aqueous hydrogen

fluoride, strong caustics, and other general

chemical media.

Flexitallic L.P. Other Sigma styles available.

6915 Highway 225

Deer Park, TX 77536 USA

281.604.2400

Flexitallic Ltd.

PO Box 3

Marsh Works

Dewsbury Road

Cleckheaton, West Yorkshire, UK

BD19 5BT

+44 1274 851273

www.thermiculite.com

www.flexitallic.com

Flexitallic£, Thermiculite£, Flexpro¥, and Sigma¥ are registered trademarks of The Flexitallic Group, Inc.

¤ 2005 The Flexitallic Group, Inc. All rights reserved worldwide.

You might also like

- Westerman Table 1Document80 pagesWesterman Table 1pawanumarji192% (12)

- Intense Heat. Extreme Cold. Aggressive Chemicals. InnovativeDocument2 pagesIntense Heat. Extreme Cold. Aggressive Chemicals. InnovativeCristian Jhair PerezNo ratings yet

- Lamons Purely High Temperature GasketsDocument6 pagesLamons Purely High Temperature GasketsIjaz AhmedNo ratings yet

- Flexitallic Gasket Criteria DesignDocument59 pagesFlexitallic Gasket Criteria DesignAtif MehmoodNo ratings yet

- FST Agriculture Brochure 2015 A4 - OnlineDocument8 pagesFST Agriculture Brochure 2015 A4 - OnlineriponautosgraphicsNo ratings yet

- Thermiculite 835: Product DatasheetDocument2 pagesThermiculite 835: Product DatasheetBenoit LabreNo ratings yet

- Thermiculite 835 SWGDocument2 pagesThermiculite 835 SWGISEDAC21No ratings yet

- Flexpro Therm 845Document1 pageFlexpro Therm 845Benoit LabreNo ratings yet

- Thermiculite: Intense Heat. Extreme Cold. Aggressive ChemicalsDocument8 pagesThermiculite: Intense Heat. Extreme Cold. Aggressive ChemicalsFilipNo ratings yet

- FL Ange Se Aling Progr Am: Industry Gasket SolutionsDocument8 pagesFL Ange Se Aling Progr Am: Industry Gasket SolutionsjaviervbNo ratings yet

- 12 PAPYEX Flexible Graphite Mersen - 09 PDFDocument14 pages12 PAPYEX Flexible Graphite Mersen - 09 PDFarizagameroNo ratings yet

- Thermiculite BrochureDocument8 pagesThermiculite BrochureXuan TruongNo ratings yet

- Garlock Metallic CatalogueDocument48 pagesGarlock Metallic Catalogueclaudio perez prietoNo ratings yet

- flyMicaTherm PDFDocument2 pagesflyMicaTherm PDFThomasFrenchNo ratings yet

- Aspen Aerogels Pyrogel XT PDFDocument4 pagesAspen Aerogels Pyrogel XT PDFBTconcordNo ratings yet

- Design Criteria PDFDocument58 pagesDesign Criteria PDFsaculNo ratings yet

- High Temp Tape Darco 10.16Document1 pageHigh Temp Tape Darco 10.16Jose ArangoitiaNo ratings yet

- Garlock MetalGasket CatalogDocument48 pagesGarlock MetalGasket CatalogG100% (1)

- Klinger Product Catalogue 40 Pages April 2014 Final Doc Trusted - Worldwide PDFDocument40 pagesKlinger Product Catalogue 40 Pages April 2014 Final Doc Trusted - Worldwide PDFStart JaguarNo ratings yet

- GMG 1 1 Metallic Gaskets CatalogDocument48 pagesGMG 1 1 Metallic Gaskets CatalogTecnico GiganteNo ratings yet

- Spectraplan TPE Sales Brochure PDFDocument20 pagesSpectraplan TPE Sales Brochure PDFydrasNo ratings yet

- Thermiculite 894Document2 pagesThermiculite 894Benoit LabreNo ratings yet

- Sealing For Extreme Cold - Best Practices For Statics SealsDocument3 pagesSealing For Extreme Cold - Best Practices For Statics Sealssujith_das_2No ratings yet

- Novaphit Professional Technolgy eDocument8 pagesNovaphit Professional Technolgy eajaysharma_1009No ratings yet

- Insulation ContraThermDocument16 pagesInsulation ContraThermmarcins85No ratings yet

- Gasket RefDocument21 pagesGasket Refjun_bucayuNo ratings yet

- Wound SpiralDocument2 pagesWound SpiralMircea Dan StanciuNo ratings yet

- Aspen Aerogels Industrial InsulationDocument4 pagesAspen Aerogels Industrial InsulationGino De LandtsheerNo ratings yet

- SKF Spectraseal: Sealing Solutions For Extreme Application ChallengesDocument5 pagesSKF Spectraseal: Sealing Solutions For Extreme Application ChallengesmiguelNo ratings yet

- Expansion JointsDocument8 pagesExpansion Jointsterencejustine100% (1)

- PDF.2 74495 157 HighDensBro EDocument16 pagesPDF.2 74495 157 HighDensBro EBojan BjelajacNo ratings yet

- Aislamiento Termico-Broch Cryogel ZDocument2 pagesAislamiento Termico-Broch Cryogel ZJavier Caamaño VillafañeNo ratings yet

- Gasket StandardsDocument40 pagesGasket StandardsSiva Raman Murugesan100% (1)

- Rotary Metallurgical MaterialsDocument4 pagesRotary Metallurgical MaterialsNabeel MohammedNo ratings yet

- E10 HEPA Filter SpecsDocument1 pageE10 HEPA Filter Specsleisurely.dpgNo ratings yet

- Fiberfrax Duraboard Products: Product Information SheetDocument4 pagesFiberfrax Duraboard Products: Product Information SheetShashank MishraNo ratings yet

- FloatingDocument12 pagesFloatingrobson2015No ratings yet

- Tanged Graphite Gasket Material Seals Aggressive Chemicals Under Extreme ConditionsDocument1 pageTanged Graphite Gasket Material Seals Aggressive Chemicals Under Extreme ConditionsPramod DixitNo ratings yet

- Kflex TitanDocument2 pagesKflex TitanShahab Z AhmedNo ratings yet

- JZ-20220423 Siliocne Composite Tape Bochure-ENDocument12 pagesJZ-20220423 Siliocne Composite Tape Bochure-ENLongsun KejiNo ratings yet

- Up Graded Thermal Insulation DCLDocument14 pagesUp Graded Thermal Insulation DCLSubrata NagNo ratings yet

- Flexitallic Products PDFDocument108 pagesFlexitallic Products PDFNguyễn Xuân NamNo ratings yet

- JZ Siliocne Composite Tape Bochure-EN 20230427Document9 pagesJZ Siliocne Composite Tape Bochure-EN 20230427JZ HuangNo ratings yet

- Insulation ReferenceDocument16 pagesInsulation ReferenceSteven SebastianNo ratings yet

- Flexitallic I-Flex 'High Temperature' Flange Insulating SetDocument2 pagesFlexitallic I-Flex 'High Temperature' Flange Insulating SetJandri JacobNo ratings yet

- Ipd Pds Sikalastomer 95 UsDocument2 pagesIpd Pds Sikalastomer 95 Usernest manNo ratings yet

- Thermiculite 815Document1 pageThermiculite 815Aji HatmantoNo ratings yet

- Thermiculite 815Document1 pageThermiculite 815Aji HatmantoNo ratings yet

- Thermiculite 815Document1 pageThermiculite 815Benoit LabreNo ratings yet

- 12 PAPYEX Flexible Graphite Mersen 21Document14 pages12 PAPYEX Flexible Graphite Mersen 21ayushNo ratings yet

- Flexitallic Product ServicesDocument20 pagesFlexitallic Product ServicesFrankie TeoNo ratings yet

- Gasket BrochureDocument26 pagesGasket BrochureAreeb KhanNo ratings yet

- Calcium Silicate Insulation BrochureDocument52 pagesCalcium Silicate Insulation BrochuremukeshsinghtomarNo ratings yet

- Gasket EngineeringDocument28 pagesGasket EngineeringRohit DaveNo ratings yet

- Garlock Metallic Gasket Technical ManualDocument48 pagesGarlock Metallic Gasket Technical ManualMarcio NegraoNo ratings yet

- K450 Plus Updated PDFDocument138 pagesK450 Plus Updated PDFCongson JeffNo ratings yet

- Gasket Application and Material Selection GuideDocument10 pagesGasket Application and Material Selection GuideTieu KakaNo ratings yet

- Klingersil Brochure 0605Document20 pagesKlingersil Brochure 0605tsaipeterNo ratings yet

- SISfirepro F-180 Synixtor ENGLISHDocument4 pagesSISfirepro F-180 Synixtor ENGLISHPaloma Carralon FlorezNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Material Selection For Piping Valve and SupportsDocument45 pagesMaterial Selection For Piping Valve and SupportsamlanfacebookNo ratings yet

- Grade Guide A36 SteelDocument3 pagesGrade Guide A36 SteelBayar DiyarNo ratings yet

- History of Fire ExtinguishersDocument8 pagesHistory of Fire ExtinguishersSandeep KumarNo ratings yet

- Material Science and Metallurgy: Unit - 9Document24 pagesMaterial Science and Metallurgy: Unit - 9Vivek BajpaiNo ratings yet

- Iron WorkingDocument2 pagesIron WorkingRedeemerBoyNo ratings yet

- Ellingham Diagram UsesDocument4 pagesEllingham Diagram Usesnanda rizkyNo ratings yet

- Astm A240Document15 pagesAstm A240Luis Fernando Rueda100% (1)

- A532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast IronsDocument4 pagesA532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast Ironsalexander zuritaNo ratings yet

- Cambridge International AS & A Level: CHEMISTRY 9701/23Document20 pagesCambridge International AS & A Level: CHEMISTRY 9701/23nickole.taruc022807No ratings yet

- Tig Welding in AluminiumDocument11 pagesTig Welding in AluminiumMohnishNo ratings yet

- Bronze & Iron CatalogueDocument116 pagesBronze & Iron CatalogueHector Dario Tobon BenjumeaNo ratings yet

- Voltaic Cell and Electrolytic Cell: by 5S3 Jocelyne LewDocument9 pagesVoltaic Cell and Electrolytic Cell: by 5S3 Jocelyne LewJocelyne LewNo ratings yet

- Astm A519 - 2017Document14 pagesAstm A519 - 2017juanvrcicNo ratings yet

- Metal Coupling in Rusting IronDocument20 pagesMetal Coupling in Rusting Ironmr bean animated cartoonsNo ratings yet

- Stmicroelectronics 6.1Document200 pagesStmicroelectronics 6.1domingos aladirNo ratings yet

- f1 c6 Periodic Table NotesDocument13 pagesf1 c6 Periodic Table Notesjasonyeoh333No ratings yet

- BRAZING MATERIALS - Wallchart Eng v10 - 1Document2 pagesBRAZING MATERIALS - Wallchart Eng v10 - 1Jim SmithNo ratings yet

- Metals - Form 4 Chemistry Topical QuestionsDocument13 pagesMetals - Form 4 Chemistry Topical QuestionsEmmanuel KipyegonNo ratings yet

- Training Report - For STUDENTSDocument52 pagesTraining Report - For STUDENTSAbdulziz kurdiNo ratings yet

- D & F Block Elements NCERTDocument18 pagesD & F Block Elements NCERTmehakNo ratings yet

- The Complete Photo Guide To Making Metal JewelryDocument744 pagesThe Complete Photo Guide To Making Metal JewelryAttila Lébényi-Palkovics100% (2)

- Microstructures of Iron-Carbon Alloys: Fine Pearlite 3000XDocument9 pagesMicrostructures of Iron-Carbon Alloys: Fine Pearlite 3000XVaishu 07No ratings yet

- Mini Cut-Off Wheels: Available Wheel Size & Standard Packing QuantityDocument11 pagesMini Cut-Off Wheels: Available Wheel Size & Standard Packing Quantityherysyam1980No ratings yet

- NIIR List of DatabasesDocument61 pagesNIIR List of DatabasesRITESH RATHODNo ratings yet

- Tron C@ 50: Product Data BulletinDocument18 pagesTron C@ 50: Product Data BulletinPrakash SundaramNo ratings yet

- Astm A387 387MDocument3 pagesAstm A387 387MkartsoftNo ratings yet

- N2 Platers' Theory Augsut 2021Document6 pagesN2 Platers' Theory Augsut 2021kgasagodebraNo ratings yet

- Stripping Chrome PlatingsDocument3 pagesStripping Chrome PlatingscondorwayraNo ratings yet

- Department of Education: Learning Activity Worksheets (LAW) General Chemistry 1 Grade 11Document10 pagesDepartment of Education: Learning Activity Worksheets (LAW) General Chemistry 1 Grade 11Ryan Joseph HernoNo ratings yet