Professional Documents

Culture Documents

WSS M4D924 B11.

WSS M4D924 B11.

Uploaded by

JOSEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WSS M4D924 B11.

WSS M4D924 B11.

Uploaded by

JOSECopyright:

Available Formats

ENGINEERING MATERIAL SPECIFICATION

POLYCARBONATE/ACRYLONITRILE BUTADIENE WSS-M4D924-B1

STYRENE BLEND (PC+ABS) MEDIUM IMPACT

MOLDING COMPOUND, INTERIOR

1. SCOPE

The material defined by this specification is a thermoplastic UV stabilized, medium impact molding

compound based on a blend of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) for mold-

in-color interior applications.

2. APPLICATION

This specification was released originally for material used in interior instrument panel applications for

small bezels in non-head impact and medium UV exposure (977.6kJ/m2) areas.

2.1 LIMITATIONS

The use of HALS (Hindered Amine Light Stabilizers) is prohibited in PC+ABS materials.

3. REQUIREMENTS

3.1 STANDARD REQUIREMENTS FOR PRODUCTION MATERIALS

Material suppliers and part producers must conform to the Company's Standard Requirements

for Production Materials (WSS-M99P1111-A).

3.1.1 Many 4D resin specifications prior to 2011, identified certain requirements with the

symbol(s), which indicated that the mean and +/- 3 sigma values were to be reported.

The specification minimum, maximum or range was established using 3 sigma data.

For 2011 and beyond, refer to Table 1 for number of samples required for each test to

establish specification limits.

3.1.2 This specification is based on virgin materials. Materials with post-consumer, post

industrial, or repolymerised recycled materials as defined by WRS-M99P42-A1 are

preferred and should be used whenever feasible.

3.1.3 The use of regrind is permitted, for economic / environmental reasons, with compliance

as indicated in Ford Engineering CAD and Drafting Standard E-4

3.1.4 Materials used in interior applications must meet the requirements outlined in WSS-

M99P2222-D1/Latest, Performance, Vehicle Interior Environment Quality

Material/Component Requirements. Data must be included in material submission

package.

3.1.5 Performance Criteria:

Parts using this specification shall meet the appropriate performance specifications:

WSS-M15P4-F/Latest, for interior mold-in-color applications. Parts must fulfill

applicable SDS/CDS requirements.

Date Action Revisions Rev. 0

2012 12 04 Activated L. Shen, APA

Controlled document at www.MATS.ford.com Copyright © 2012, Ford Global Technologies, LLC Page 1 of 8

ENGINEERING MATERIAL SPECIFICATION

WSS-M4D924-B1

3.2 SAMPLE PREPERATION

Unless otherwise specified all tests shall be carried out on injection molded, one-end gated test

specimens. The test specimens A and D shall be molded using molding conditions defined in

ISO 2580-2. No annealing is allowed. See Table 1 and 2 for the number of specimens required.

Specimens shall be as follows:

Specimen A 150 minimum x 10 x 4.0 +/- 0.2 mm (ISO 527-2, Specimen Type 1A)

Specimen B 355 x 100 x 1.0 +/- 0.1 mm (ISO 3795)

Specimen C 145 x 60 x 3.2 +/- 0.2 mm

Specimen D Center of Specimen A. 80 x 10 x 4.0 +/- 0.2 mm

Specimen E 100 mm diameter x 3.2 mm

Specimen F 80 mm diameter x 3.2 mm

Specimen G 90 mm x 200 mm

Specimen H 50 +/- 1 mm diameter x 3.2 +/- 0.2 mm

Specimen I 100 mm x 150 mm, min

3.3 APPEARANCE

3.3.1 Weathering Resistance Rating 4 min

2

(FLTM BO 116-01, 977.6 kJ/m exposure,

Specimen C from smooth polished mold,

ISO 105-A02 / AATCC Evaluation Procedure 1)

Every 526.4 kJ/m2 remove the samples from the weather-

ometer and allow them to cool for one hour. Conduct a tactile

evaluation and report any tackiness. Visually evaluate and

report any spewing or other exudation.

After exposure the material shall show no fading or color

change in excess of the specified AATCC rating. In addition,

there shall be no cracking, crazing or other deterioration.

Use regional choice for initial approval and report the color

house used. See Table 2 for additional color durability

submission requirements.

3.4 MATERIAL PROPERTIES

3.4.1 Density 1.08 - 1.20 g/cm3

(ISO 1183, Method A)

3.4.2 Tensile Strength at Yield 48 MPa min

(ISO 527-1 & ISO 527-2, Specimen A,

50 mm/minute test speed)

3.4.3 Elongation at Yield 3.0 % min

(ISO 527-1 & ISO 527-2, Specimen A,

50 mm/minute test speed)

3.4.4 Tensile Modulus 2.3 GPa min

(ISO 527-1 & ISO 527-2, Specimen A,

1 mm/minute test speed)

Copyright © 2012, Ford Global Technologies, LLC Page 2 of 8

ENGINEERING MATERIAL SPECIFICATION

WSS-M4D924-B1

3.4.5 Flexural Modulus 2.0 GPa min

(ISO 178, Specimen D,

64 mm support span, 2 mm/minute test speed)

3.4.6 Impact Strength, Notched Charpy

(ISO 179-1/1eA, Specimen D)

2

3.4.6.1 At 23 +/- 2 °C 28 kJ/m , min

Report Break Type

2

3.4.6.2 At -40 +/- 2 °C 9 kJ/m , min

Report Break Type

The test specimen must be conditioned for minimum of 6

hours at the above specified temperature prior to impact

test. Low temperature testing shall be done within the cold

chamber, if not possible, test may be conducted outside,

but within 5 seconds.

3.4.7 Heat Deflection Temperature 92 °C min

(ISO 75-1 & ISO 75-2, Specimen D, flatwise,

0.34 +/- 0.1 mm deflection at 1.80 MPa)

All specimens dry as molded. If not tested immediately after molding, specimens must

be stored in a sealed, moisture-proof container filled with silica gel.

3.4.8 Vicat Softening Temperature 116 °C min

(ISO 306, Specimen D, Bath - silicone oil,

temperature raise 50 +/- 5 °C/h.

Dial gage reset to 'O' after addition

of 5 kg weight, at 50 N load)

All specimens dry as molded. If not tested immediately after molding, specimens must

be stored in a sealed, moisture-proof container filled with silica gel.

3.4.9 Heat Aging Performance

(ISO 188, 150 +/- 50 air

changes/h, 1000 h at 90+/- 2 °C.

After heat aging test specimens are

to be conditioned in a desiccator for

3 - 5 h at 23 +/- 2 °C. Unaged property

values shall be determined at the time

of the aged properties determination)

3.4.9.1 Tensile Strength at Yield, Change +/- 25% max

(Test method per para 3.4.2)

3.4.9.2 Impact Strength, Notched Charpy, Change +/- 25% max

(Test Method per para 3.4.6.1,

specimens to be notched before

heat aging)

Copyright © 2012, Ford Global Technologies, LLC Page 3 of 8

ENGINEERING MATERIAL SPECIFICATION

WSS-M4D924-B1

3.4.10 Hydrolytic Stability

(ISO 188, humidity aging at 90 °C/70% RH

for 500 h or 80 °C/70% RH for 1000 h

After humidity aging test specimens are

to be conditioned for 24 h at 23 +/- 2 °C

50% RH. Unaged property values shall be determined

at the time of the aged properties determination)

3.4.10.1 Impact Strength, Notched Charpy, Change +/- 50% max

(Test Method per para 3.4.6.1,

specimens to be notched before

humidity aging)

3.4.11 Odor Rating 3 max

(FLTM BO 131-03, Specimen G)

3.4.12 Fogging Photometric

(SAE J1756, Specimen F, 3 h at 100 °C heating, 21 °C cooling

plate, post test conditioning 16 h)

Fog Number 70 min

Formation of clear film, droplets or crystals is cause for rejection.

3.4.13 Flammability

(ISO 3795/SAE J369,

Specimen B smooth surface)

Burn Rate 100 mm/minute max

3.5 MATERIAL PROPERTIES – REPORT ONLY

Values are retained in Ford Materials Database www.fmd.ford.com.

3.5.1 Melt Flow Rate Report Value, g/10 minutes

(ISO 1133, 260 °C, 5 kg)

The material shall be dried for 4 h minimum at 100 °C in a mechanical convection

oven immediately preceding the test.

3.5.2 Coefficient of Linear Thermal Expansion

(ISO 11359-2, -30°C to 30°C)

-5

Flow Report Value, E mm/mm/ °C

Cross Flow Report Value, E-5 mm/mm/ °C

3.5.3 Molding Shrinkage

(Report method used, sample size and value)

After 48 h at 23 +/- 2 °C

Flow Report Value, %

Cross Flow Report Value, %

Copyright © 2012, Ford Global Technologies, LLC Page 4 of 8

ENGINEERING MATERIAL SPECIFICATION

WSS-M4D924-B1

3.5.4 Impact Strength, Notched Izod

(ISO 180/1A, Specimen D)

3.5.4.1 At 23 +/- 2 °C Report Value, kJ/m2

Report Break Type

3.5.4.2 At -40 +/- 2 °C Report Value, kJ/m2

Report Break Type

The test specimen must be conditioned for minimum of 6 hours at the above specified

temperature prior to impact test. Low temperature testing shall be done within the cold

chamber, if not possible, test may be conducted outside, but within 5 seconds.

3.5.5 Impact Strength Multi-axial

(ASTM D 3763, Impact velocity: 6.6 m/s

Specimen E, smooth surface injection molded specimen)

Max Load Energy at 23 +/- 2 ºC Report J Energy Absorbed

100 % Ductile

Max Load Energy at -10 +/- 2 ºC Report J Energy Absorbed

80 % Ductile min

A ductile failure is defined as a crack that does not radiate more than 10 mm from the

center of the impact point.

Test specimens must be conditioned for minimum of 6 h at test temperature prior to

impact testing. Low temperature testing shall be conducted within the same

environmental chamber as the clamp mechanism of the impact device. Specimens can

be transported from the conditioning environment to the testing environment, provided

the transfer is within 5 seconds.

3.5.6 Poisson's Ratio Report Ratio

(ISO 527-1/2, Specimen A

1 mm/minute test speed)

3.5.7 Supplemental Information

The following curves are to be submitted with the data packages:

FTIR

TGA

DSC

CLTE

Engineering Stress/Strain at 23 °C

4. GENERAL INFORMATION

The information given below is provided for clarification and assistance in meeting the requirements of

this specification. Contact gmfs@ford.com for questions concerning Engineering Material

Specifications.

Copyright © 2012, Ford Global Technologies, LLC Page 5 of 8

ENGINEERING MATERIAL SPECIFICATION

WSS-M4D924-B1

4.1 TYPICAL PROPERTIES USING TEST METHODS IN SECTION 3.5

Typical

Para. Test Units

Values

3.5.1 Melt Flow Rate 3 g/10 minutes

3.5.2 Coefficient of Linear Thermal Expansion;

-5

Flow 7.9 E mm/mm/ºC

Cross Flow 7.8 E-5 mm/mm/ºC

3.5.3 Molding Shrinkage after 48 h at 23 +/- 2

°C;

(For specific method and sample size,

contact Materials Engineering)

Flow 0.96 %

Cross Flow 0.84 %

3.5.4.1 Impact Strength, Notched Izod;

45 kJ/m2

At 23 +/- 2 °C

3.5.4.2 Impact Strength, Notched Izod; 2

17 kJ/m

At -40 +/- 2 °C

3.5.5 Impact Strength, Multiaxial; Max Load

Energy at 23 +/- 2 °C; 44.9 J

6.6 m/s

3.5.5 Impact Strength, Multiaxial; Max Load

Energy at -10 +/- 2 °C; 50.1 J

6.6 m/s

3.5.6 Poisson's Ratio 0.35 N/A

4.2 MATERIAL IDENTIFICATION FOR RECYCLING PURPOSES >PC+ABS<

(ISO 1043/11469)

Copyright © 2012, Ford Global Technologies, LLC Page 6 of 8

ENGINEERING MATERIAL SPECIFICATION

WSS-M4D924-B1

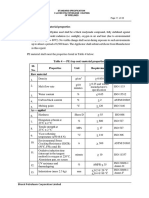

Table 1: Minimum Sample Size

New Manufacturing Location for

Initial Approval

Previously Approved Material

Minimum Specimens Total Test Specimens Total Test

Para. Test Lots per Lot Specimens

Lots

per lot Specimens

3.1 WSS-M99P1111-A

WSS-M99P2222-B1/Latest – Total 1 1 1 per test

Carbon, Hazardous Substances,

3.1.4 Formaldehyde, Acraldehyde,

Acetaldehyde (See below for Odor and

Fogging)

3.3.1 Weathering Resistance 1 1 1

3.4.1 Density 1 3 3

3.4.2 Tensile Strength at Yield * 3 5 15 1 5 5

3.4.3 Elongation at Yield * 3 5 15 1 5 5

3.4.4 Tensile Modulus 1 10 10

3.4.5 Flexural Modulus* 3 10 30 1 10 10

Impact Strength, Notched Charpy (per 3 10 30 1 10 10

3.4.6

condition)*

3.4.7 Heat Deflection Temperature* 3 2 6 1 2 2

3.4.8 Vicat Softening Temperature* 3 2 6 1 2 2

3.4.9 Heat Aging Performance

3.4.9.1 Tensile Strength at Yield, Change 1 5 5

Impact Strength, Notched Charpy, 1 10 10

3.4.9.2

Change

3.4.10 Hydrolytic Stability 1 10 10

3.4.11 Odor 1 9 9

3.4.12 Fogging Photometric 1 3 3

3.4.13 Flammability 1 5 5

3.5.1 Melt Flow Rate 1 1 1

Coefficient of Linear Thermal Expansion 1 3 3

3.5.2

(per condition)

3.5.3 Molding Shrinkage 1 5 5 1 5 5

Impact Strength, Notched Izod (per 1 10 10

3.5.4

condition)

Impact Strength, Multiaxial (per 3 10 30 1 10 10

3.5.5

condition)*

3.5.6 Poisson's Ratio 1 5 5

Curves

- IR

- TGA 1 1 1 per test

3.5.7

- DSC

- CLTE

- Stress/Strain Curves at 23 °C

* For these requirements the 3 sigma value from the raw data is used to meet the requirements.

Copyright © 2012, Ford Global Technologies, LLC Page 7 of 8

ENGINEERING MATERIAL SPECIFICATION

WSS-M4D924-B1

Table 2: Minimum Color Property Testing

Specimens Total Test Color Test

Para. Test Method Lots

per Lot Specimens Direction

3.3.1 Weathering Resistance Every color

1 1 1

3.4.2 Tensile Strength at Yield As directed by

1 5 5 Materials

Engineering

3.4.5 Flexural Modulus As directed by

1 10 10 Materials

Engineering

3.4.6.1 Impact Strength, Notched Charpy As directed by

At 23 +/- 2 °C 1 10 10 Materials

Engineering

3.4.11 Odor As directed by

1 9 9 Materials

Engineering

3.4.13 Flammability 1 5 5 Every color

Copyright © 2012, Ford Global Technologies, LLC Page 8 of 8

You might also like

- ASTM-D543 (2014) - Evaluating The Resistance of Plastics To Chemical ReagentsDocument7 pagesASTM-D543 (2014) - Evaluating The Resistance of Plastics To Chemical ReagentsAndre Castelo100% (1)

- Performance, Acoustical and Insulators, Interior Assemblies WSS-M99P32-E1 1. ScopeDocument6 pagesPerformance, Acoustical and Insulators, Interior Assemblies WSS-M99P32-E1 1. Scopeerik0007No ratings yet

- Astm D 3159 - 04Document5 pagesAstm D 3159 - 04phaindika100% (1)

- Engineering Material Specification: Controlled Document at Page 1 of 6Document6 pagesEngineering Material Specification: Controlled Document at Page 1 of 6erik0007No ratings yet

- Design of Steel Structures by Prof Damodar Maity PDFDocument793 pagesDesign of Steel Structures by Prof Damodar Maity PDFlakshminarayanstr100% (6)

- Engineering Material SpecificationDocument5 pagesEngineering Material Specificationerik0007No ratings yet

- Ford - Wsk-m4d684-A2 Abs - PC ConsoleDocument5 pagesFord - Wsk-m4d684-A2 Abs - PC ConsoleCamila SanchesNo ratings yet

- WSS M99P32 D1Document6 pagesWSS M99P32 D1jose luisNo ratings yet

- Wsf-M4d618-A 31au05Document4 pagesWsf-M4d618-A 31au05Yan WendelNo ratings yet

- 01ML0030 ES-08009 - C - Especificação de MPDocument2 pages01ML0030 ES-08009 - C - Especificação de MPRafah1212No ratings yet

- Campus® Datasheet: Alcom Pa6 900/1 Cf15 Im - Pa6-Cf15 Mocom Compounds GMBH & Co. KGDocument2 pagesCampus® Datasheet: Alcom Pa6 900/1 Cf15 Im - Pa6-Cf15 Mocom Compounds GMBH & Co. KGLuis PalenzuelaNo ratings yet

- WSS M5G58 A2Document5 pagesWSS M5G58 A2Muthu GaneshNo ratings yet

- D 3771 - 00 - Rdm3nzetukveDocument5 pagesD 3771 - 00 - Rdm3nzetukvePrakash MakadiaNo ratings yet

- D 3903 - 00 - Rdm5mdmtukveDocument5 pagesD 3903 - 00 - Rdm5mdmtukvePrakash MakadiaNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Trim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. ScopeDocument11 pagesTrim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. Scopeerik0007No ratings yet

- 3layer Coating - 03Document5 pages3layer Coating - 03Christian EzeaguNo ratings yet

- Engineering Material SpecificationDocument3 pagesEngineering Material SpecificationRicardo VitorianoNo ratings yet

- Unsintered Polytetrafluoroethylene (PTFE) Extruded Film or TapeDocument4 pagesUnsintered Polytetrafluoroethylene (PTFE) Extruded Film or TapeShiv PandeyNo ratings yet

- Rdso SPN TC 97 2012Document13 pagesRdso SPN TC 97 2012Rahul MauryaNo ratings yet

- Ford WSS-M8P25-CDocument5 pagesFord WSS-M8P25-CPablo AnguianoNo ratings yet

- Powder Coat Performance Spec WSS M70J5 C1Document9 pagesPowder Coat Performance Spec WSS M70J5 C1Michal BílekNo ratings yet

- Me6052 PDS Reg - World en V4 PDS World 4158 10058878Document3 pagesMe6052 PDS Reg - World en V4 PDS World 4158 10058878TANMAY NAYAKNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- D 2116 - 02 - RdixmtyDocument6 pagesD 2116 - 02 - Rdixmtyjamaljamal20No ratings yet

- PDS Perfecto XEPDocument3 pagesPDS Perfecto XEP邢焕震No ratings yet

- ASTM-D543 (2006) - Evaluating The Resistance of Plastics To Chemical Reagents PDFDocument7 pagesASTM-D543 (2006) - Evaluating The Resistance of Plastics To Chemical Reagents PDFAndre Castelo100% (1)

- WSS M16J19 BDocument10 pagesWSS M16J19 BJuan Angel DechimaNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- TMS6900Document14 pagesTMS6900Josue Garcia QuiniNo ratings yet

- Unsintered Polytetrafluoroethylene (PTFE) Extruded Film or TapeDocument3 pagesUnsintered Polytetrafluoroethylene (PTFE) Extruded Film or TapeAndres Camilo BenitezNo ratings yet

- Wabco: SpecificationDocument4 pagesWabco: Specificationரஞ்சன் ஞானயோளிNo ratings yet

- Jotatemp 1000Document5 pagesJotatemp 1000Mangesh MohiteNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- Printed, Pressure-Sensitive Adhesive Labels For Use in Extreme Distribution EnvironmentsDocument7 pagesPrinted, Pressure-Sensitive Adhesive Labels For Use in Extreme Distribution EnvironmentsasmaNo ratings yet

- 528 JED Specification JED-612 008 en BDocument5 pages528 JED Specification JED-612 008 en Bரஞ்சன் ஞானயோளிNo ratings yet

- TDS 515 Jotamastic 87 Euk GBDocument6 pagesTDS 515 Jotamastic 87 Euk GBManuel LópezNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- JotundatasheetsDocument172 pagesJotundatasheetsAli MudhafarNo ratings yet

- Steel Master 1200 WF PDSDocument5 pagesSteel Master 1200 WF PDSshameelNo ratings yet

- Jed-330 008 DDocument4 pagesJed-330 008 DRanjan GnanaoliNo ratings yet

- Engineering Standards: Material Specification General GM222MDocument2 pagesEngineering Standards: Material Specification General GM222MFelipe De la cruzNo ratings yet

- D 6098 - 97 Rdywotgtotc - 2Document5 pagesD 6098 - 97 Rdywotgtotc - 2Luis Sidnei MachadoNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- Certificates Cement BoardDocument4 pagesCertificates Cement Boardlingatong110372No ratings yet

- Organic Coat GMW 14670 PDFDocument4 pagesOrganic Coat GMW 14670 PDFYosua Dimas Agus SriyantoNo ratings yet

- J STD 020Document13 pagesJ STD 020Wandyy GonçalvesNo ratings yet

- Engineering Material SpecificationDocument9 pagesEngineering Material SpecificationVeysel Emre BozkurtNo ratings yet

- Astm D 2565-23Document7 pagesAstm D 2565-23Mohammed EldakhakhnyNo ratings yet

- Barrier SmartpackDocument5 pagesBarrier SmartpackMhd EbalNo ratings yet

- IGS-M-TP-014-2-C (2) Sep. 2008: 3 Ply Co-Extruded Plastic Tape For Field Joint and Rehabilitation of Steel PipelineDocument13 pagesIGS-M-TP-014-2-C (2) Sep. 2008: 3 Ply Co-Extruded Plastic Tape For Field Joint and Rehabilitation of Steel PipelineTa GiNo ratings yet

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- D543 37526Document7 pagesD543 37526roshniNo ratings yet

- CR C14 LD2420KDocument3 pagesCR C14 LD2420KJaime222No ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- Castrol Perfecto XPG 46 - Data SheetDocument3 pagesCastrol Perfecto XPG 46 - Data Sheetanibal_rios_rivasNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Astm D2565Document7 pagesAstm D2565Veronica GozdalskaNo ratings yet

- Fundamentals of Metal Forming ProcessesDocument23 pagesFundamentals of Metal Forming ProcessesVinayak Bhustalimath50% (2)

- Tie BreakDocument33 pagesTie Breaksuribala100% (3)

- KOCO - Threaded Studs - Load ChartDocument2 pagesKOCO - Threaded Studs - Load Chartwaweng22No ratings yet

- MOM Mod5@AzDOCUMENTS - inDocument13 pagesMOM Mod5@AzDOCUMENTS - inMahadev MetriNo ratings yet

- Design of RC Members Under FlexureDocument16 pagesDesign of RC Members Under FlexureMelkamu DemewezNo ratings yet

- A Guide To Lifting Beams and SpreadersDocument19 pagesA Guide To Lifting Beams and SpreadersG.SWAMINo ratings yet

- Optim MC Structural SteelDocument5 pagesOptim MC Structural SteelAugusto BlancoNo ratings yet

- Section 6.0 MatterDocument46 pagesSection 6.0 MatterKennedy MudawarimaNo ratings yet

- Design of Rope Drum and Chain HoistsDocument19 pagesDesign of Rope Drum and Chain Hoistssuresh_501100% (1)

- Seismic Performance of Steel-Reinforced Concrete Composite Columns in Existing and Modern ConstructionDocument19 pagesSeismic Performance of Steel-Reinforced Concrete Composite Columns in Existing and Modern ConstructionNarsingha KharosekarNo ratings yet

- Solution Manual Materials For Civil and Construction Engineers 4th Global Edition by Mamlouk & ZaniewskiDocument10 pagesSolution Manual Materials For Civil and Construction Engineers 4th Global Edition by Mamlouk & ZaniewskiDonya LabbafiNo ratings yet

- Methods Material Models and Crash Simul in LSDYNADocument56 pagesMethods Material Models and Crash Simul in LSDYNAbelkacem kisriNo ratings yet

- Brazing Allloy Cusil ABADocument12 pagesBrazing Allloy Cusil ABADheeraj SharmaNo ratings yet

- Embankment Failures at Vermon British ColumbiaDocument15 pagesEmbankment Failures at Vermon British ColumbiaSafwat El RoubyNo ratings yet

- Crip LingDocument24 pagesCrip LingMohamed NkNo ratings yet

- Non-Linear Finite Element Analysis of Light Gage Steel Shear DiapDocument346 pagesNon-Linear Finite Element Analysis of Light Gage Steel Shear DiapAlonso Aguilar Salas100% (1)

- Shear Modulus at Room Temperature: Standard Test Method ForDocument5 pagesShear Modulus at Room Temperature: Standard Test Method ForCristian DíazNo ratings yet

- Tunnelling and Underground Space Technology: L.X. Xie, W.B. Lu, Q.B. Zhang, Q.H. Jiang, M. Chen, J. ZhaoDocument15 pagesTunnelling and Underground Space Technology: L.X. Xie, W.B. Lu, Q.B. Zhang, Q.H. Jiang, M. Chen, J. ZhaoKatty MonsalveNo ratings yet

- ES654A Lecture - 12 - Viscous-Plastic RheologyDocument9 pagesES654A Lecture - 12 - Viscous-Plastic RheologyPratik ChouguleNo ratings yet

- R-KEM II ETA - Polyester Resin For ConcreteDocument16 pagesR-KEM II ETA - Polyester Resin For ConcreteLouis BirNo ratings yet

- Design of Steel and Timber Structures Examples PDFDocument78 pagesDesign of Steel and Timber Structures Examples PDFsamson100% (3)

- Bioinspired Nacre Like Steel Polyurea Composite Plate Subj - 2022 - MaterialsDocument19 pagesBioinspired Nacre Like Steel Polyurea Composite Plate Subj - 2022 - MaterialsRodrigoNo ratings yet

- Plasticity (Physics) PDFDocument4 pagesPlasticity (Physics) PDFzidaaanNo ratings yet

- Mechanics of Materials: Stress and Strain - Axial LoadingDocument21 pagesMechanics of Materials: Stress and Strain - Axial LoadingRohit KumarNo ratings yet

- A Material Model For Transversely Anisotropic Crushable Foam in Ls-DynaDocument12 pagesA Material Model For Transversely Anisotropic Crushable Foam in Ls-DynaakuoxaiNo ratings yet

- Energy Evaluation For Ramberg-Osgood Hysteretic Model: Fred Segal and Dimitri V. ValDocument7 pagesEnergy Evaluation For Ramberg-Osgood Hysteretic Model: Fred Segal and Dimitri V. ValErnesto Fidel Mandujano CardenasNo ratings yet

- KKKH3353 - Structural Steel Design - Tension MembersDocument21 pagesKKKH3353 - Structural Steel Design - Tension MembersZeyad Tareq Al Sarori100% (2)

- Chapter 4 Mechanical Properties of MetalsDocument19 pagesChapter 4 Mechanical Properties of MetalsKeith Tanaka MagakaNo ratings yet

- Stability Charts For Rock Slopes Based On The Hoek-Brown Failure CriterionDocument12 pagesStability Charts For Rock Slopes Based On The Hoek-Brown Failure CriterionHas TomoNo ratings yet