Professional Documents

Culture Documents

Cazafallas

Cazafallas

Uploaded by

oscarCopyright:

Available Formats

You might also like

- Chevrolet 327 V8 Engine Rebuild ManualDocument120 pagesChevrolet 327 V8 Engine Rebuild ManualAlissa Davis0% (1)

- Manual Taller Luv Dimax Motor C24se PDFDocument486 pagesManual Taller Luv Dimax Motor C24se PDFjuan davidNo ratings yet

- F70 - 100 MPD Rev12Document832 pagesF70 - 100 MPD Rev12oscarNo ratings yet

- Draft Report R-2Document23 pagesDraft Report R-2HINDIA HEPLNo ratings yet

- Cazafallas 4Document1 pageCazafallas 4oscarNo ratings yet

- Cazafallas 3Document1 pageCazafallas 3oscarNo ratings yet

- Cazafallas 2Document4 pagesCazafallas 2oscarNo ratings yet

- Cazafallas 1Document3 pagesCazafallas 1oscarNo ratings yet

- Avon UTC 1535c5Document32 pagesAvon UTC 1535c5juana100% (1)

- Engine WIll Not Crank or Cranks QST 30Document3 pagesEngine WIll Not Crank or Cranks QST 30hinggasetiawan46No ratings yet

- Method Statement For Testing & Commissioning of Diesel GeneratorDocument6 pagesMethod Statement For Testing & Commissioning of Diesel Generatorvin ss100% (1)

- Models J05C-TD, J08C-TP and J08C-TRDocument20 pagesModels J05C-TD, J08C-TP and J08C-TRKomatsu Perkins HitachiNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Repair Options: Cat 777D Off-Highway TruckDocument4 pagesRepair Options: Cat 777D Off-Highway TruckmkNo ratings yet

- Lubrication ProgramDocument114 pagesLubrication ProgramcutedawNo ratings yet

- 07.2-110 Testing, Adjusting EngineDocument16 pages07.2-110 Testing, Adjusting EngineMariusz NowakowskiNo ratings yet

- 15 PDFDocument8 pages15 PDFKrzyś UrynowiczNo ratings yet

- Troubeshootings 8 Wheeler DHTC Detc-1Document27 pagesTroubeshootings 8 Wheeler DHTC Detc-1khan11k100% (1)

- Sive Aways Stop: Fuel System 2-9Document2 pagesSive Aways Stop: Fuel System 2-9PabloNo ratings yet

- 05 Fuel SystemDocument109 pages05 Fuel SystemUtomo BudidarmoNo ratings yet

- Engine FuelDocument24 pagesEngine FuelЮра Петренко100% (1)

- Eue-Lab Final See2Document29 pagesEue-Lab Final See2Harsha SamagaraNo ratings yet

- 4 Tec Troubleshooting ChartDocument11 pages4 Tec Troubleshooting ChartnelsoncoNo ratings yet

- Precommissioning Procedure For Diesel GeneratorDocument2 pagesPrecommissioning Procedure For Diesel GeneratorBabu100% (1)

- Split-UnitDocument6 pagesSplit-UnitKhairul AnwarNo ratings yet

- Isuzu TF Series Gasoline Engine Workshop ManualDocument20 pagesIsuzu TF Series Gasoline Engine Workshop Manualjames100% (41)

- Standby Generator Set Pre-Operation Checklist: Before Starting The EngineDocument4 pagesStandby Generator Set Pre-Operation Checklist: Before Starting The EngineMartie ClustersNo ratings yet

- A042g474 Rev2Document2 pagesA042g474 Rev2Rahul AR XNo ratings yet

- Solución de ProblemasDocument49 pagesSolución de ProblemasAntonio FrancoNo ratings yet

- C1 BlockDocument3 pagesC1 BlockAkhilesh YadavNo ratings yet

- Isuzu 4JA1 Section 6Document249 pagesIsuzu 4JA1 Section 6Niti KlinKaew100% (1)

- Cat 950GDocument10 pagesCat 950GManuel BarahonaNo ratings yet

- RDB 535 Fault Finding ChartDocument1 pageRDB 535 Fault Finding ChartFrancisco DuranNo ratings yet

- 650.01 DieselGenerator Operating 2013.08.12Document18 pages650.01 DieselGenerator Operating 2013.08.12Tuan Linh VoNo ratings yet

- Engine: Workshop ManualDocument360 pagesEngine: Workshop ManualAutomotriz JTMotorsNo ratings yet

- Startup Inspection ChecklistDocument2 pagesStartup Inspection ChecklistMouayed Zeadan100% (1)

- Arken Kullanim Kitapcigi Ingilizce Yeni - 1Document48 pagesArken Kullanim Kitapcigi Ingilizce Yeni - 1TrainingNo ratings yet

- Vdocuments - MX - Naza Ria MPV PDFDocument93 pagesVdocuments - MX - Naza Ria MPV PDFalangku09100% (2)

- Grand Cherokee 2008 5.7LDocument254 pagesGrand Cherokee 2008 5.7LlefontNo ratings yet

- R-ME-HC-S-020 Governor System Test RecordDocument9 pagesR-ME-HC-S-020 Governor System Test Recordrotimi olalekan fataiNo ratings yet

- Engine Will Not Crank QSK 30Document2 pagesEngine Will Not Crank QSK 30hinggasetiawan46No ratings yet

- Suzuki Vitara Fuel Pressure and Its Circuit CheckDocument3 pagesSuzuki Vitara Fuel Pressure and Its Circuit CheckmGraci520No ratings yet

- 5 Engine ArrangementDocument98 pages5 Engine Arrangementhendra hardyNo ratings yet

- Lycoming Reciprocating Engine Break-In and Oil ConsumptionDocument7 pagesLycoming Reciprocating Engine Break-In and Oil ConsumptionChristian Enrique Casique PajarNo ratings yet

- Engine Acceleration or Response PoorDocument11 pagesEngine Acceleration or Response PoorDung PhamNo ratings yet

- General Service Checklist - BIKE PDFDocument7 pagesGeneral Service Checklist - BIKE PDFmanasNo ratings yet

- Application Engineering Bulletin: Electronic Throttle Control Specifications Automotive Industrial G-DriveDocument3 pagesApplication Engineering Bulletin: Electronic Throttle Control Specifications Automotive Industrial G-DriveMiguel Angel Cortes PrietoNo ratings yet

- Cim Display Screen Does Not Display and Backlight Does Not LightDocument10 pagesCim Display Screen Does Not Display and Backlight Does Not LightМестный АвторитетNo ratings yet

- 1106D Fuel System Diagnosis ProcedureDocument2 pages1106D Fuel System Diagnosis ProceduredubimouNo ratings yet

- Troubleshooting qsx15 Engine Difficult To StartDocument6 pagesTroubleshooting qsx15 Engine Difficult To StartAli ArdinNo ratings yet

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- DCS No 4 - Low Fuel Avg - DSLDocument2 pagesDCS No 4 - Low Fuel Avg - DSLservicemanager.bkdNo ratings yet

- Fault Code 372Document4 pagesFault Code 372Enrrique LaraNo ratings yet

- Service Program - CE Excapator KOREADocument8 pagesService Program - CE Excapator KOREAtele123No ratings yet

- Engine FuelDocument19 pagesEngine FuelJohn fredy cuervoNo ratings yet

- Engine Electrical EeDocument17 pagesEngine Electrical EePedro LopezNo ratings yet

- Fle Power 4000iDocument45 pagesFle Power 4000iGary SatherNo ratings yet

- DCS No 2 - Engine Not Starting - DSLDocument2 pagesDCS No 2 - Engine Not Starting - DSLservicemanager.bkdNo ratings yet

- 15 Air Metering-Acceleration SystemDocument17 pages15 Air Metering-Acceleration Systemapinya doungsoilNo ratings yet

- 8 Tobia - Maintenance of DEG (Mechanical)Document38 pages8 Tobia - Maintenance of DEG (Mechanical)Epeli RokodrokayaNo ratings yet

- InformationDocument8 pagesInformationoscarNo ratings yet

- CD HighlightsDocument2 pagesCD HighlightsoscarNo ratings yet

- Manual CessnaDocument74 pagesManual CessnaoscarNo ratings yet

- Service Bulletin: Dowty Aerospace PropellersDocument23 pagesService Bulletin: Dowty Aerospace PropellersoscarNo ratings yet

- Failure To Follow Procedures While Performing Aircraft Inspections CFR 91Document20 pagesFailure To Follow Procedures While Performing Aircraft Inspections CFR 91oscarNo ratings yet

- Mccauley Industsal Corporation: 00X 1. Aoofcvfll Sia. - Oaiion. Ohio 0411 Code 511 26X.3541 Addrc S Mccjui4YDocument4 pagesMccauley Industsal Corporation: 00X 1. Aoofcvfll Sia. - Oaiion. Ohio 0411 Code 511 26X.3541 Addrc S Mccjui4YoscarNo ratings yet

- Pegado de botaPS5710-SPMDocument7 pagesPegado de botaPS5710-SPMoscarNo ratings yet

- Service Bulletin 177B: June 30.1992Document3 pagesService Bulletin 177B: June 30.1992oscarNo ratings yet

- Text NotescriptDocument4 pagesText NotescriptoscarNo ratings yet

- Service Bulletin 176EDocument6 pagesService Bulletin 176EoscarNo ratings yet

- Service Bulletin 234BDocument17 pagesService Bulletin 234BoscarNo ratings yet

- Alert Service Bulletin: ASB251ADocument5 pagesAlert Service Bulletin: ASB251AoscarNo ratings yet

- Alert Service Bulletin: TitleDocument7 pagesAlert Service Bulletin: TitleoscarNo ratings yet

- Service Bulletin 239CDocument14 pagesService Bulletin 239CoscarNo ratings yet

- IPLEX VIEWER PLUS Instructions - Eng PDFDocument42 pagesIPLEX VIEWER PLUS Instructions - Eng PDFoscarNo ratings yet

- Service Bulletin: Dowty Aerospace PropellersDocument6 pagesService Bulletin: Dowty Aerospace PropellersoscarNo ratings yet

- Presurizacion f50Document15 pagesPresurizacion f50oscarNo ratings yet

- Astm Specifications For Concrete Masonry Units: TEK 1-1FDocument4 pagesAstm Specifications For Concrete Masonry Units: TEK 1-1FEric HernándezNo ratings yet

- Budget Plan 2Document14 pagesBudget Plan 2Abbie BalsarzaNo ratings yet

- 20220725Document39 pages20220725Zenon CondoriNo ratings yet

- 1 s2.0 S1359431115011898 MainDocument11 pages1 s2.0 S1359431115011898 MainPatrice PariNo ratings yet

- Noninvasive Brain-Computer Interfaces: Gerwin Schalk, Brendan Z. AllisonDocument21 pagesNoninvasive Brain-Computer Interfaces: Gerwin Schalk, Brendan Z. AllisonQuốc ViệtNo ratings yet

- Department of Labor: PassaicDocument2 pagesDepartment of Labor: PassaicUSA_DepartmentOfLaborNo ratings yet

- Smallware InventoryDocument7 pagesSmallware Inventoryye min aungNo ratings yet

- Navasakam Grievance Application: Family DetailsDocument2 pagesNavasakam Grievance Application: Family DetailsmANOHARNo ratings yet

- A Stingless Bee Hive Design For A Broader ClimateDocument4 pagesA Stingless Bee Hive Design For A Broader ClimateMarlon Manaya Garrigues100% (1)

- 1319577545GTWN082711Document32 pages1319577545GTWN082711CoolerAdsNo ratings yet

- GrammarDocument23 pagesGrammarYMNo ratings yet

- Object Oriented Programming Using C++ Viva Questions Coders LodgeDocument7 pagesObject Oriented Programming Using C++ Viva Questions Coders LodgeGulchetan SinghNo ratings yet

- IFRS 11 Joint ArrangementsDocument6 pagesIFRS 11 Joint Arrangementsmcastillo3313No ratings yet

- Expedition DiaryDocument23 pagesExpedition DiaryAnkur JhunjhunwalaNo ratings yet

- Ex Lecture1Document2 pagesEx Lecture1AlNo ratings yet

- 9 Cir vs. Baier-Nickel DGSTDocument2 pages9 Cir vs. Baier-Nickel DGSTMiguelNo ratings yet

- Column Evaluation & Handling (QC-033)Document40 pagesColumn Evaluation & Handling (QC-033)muhammad fahadNo ratings yet

- FORM V Abstract Under The Payment of Wages Act, 1936 (English Version)Document2 pagesFORM V Abstract Under The Payment of Wages Act, 1936 (English Version)anant nagvekarsNo ratings yet

- Great Mantras For SuccessDocument4 pagesGreat Mantras For Successsatchap11No ratings yet

- Arlec Wireless SecurityDocument10 pagesArlec Wireless Securityalfi56kNo ratings yet

- Sauer90 ServiceManual PDFDocument72 pagesSauer90 ServiceManual PDFeng13100% (7)

- Gmail - Attain Good Health With Healthy GutDocument3 pagesGmail - Attain Good Health With Healthy GutnityamnayakNo ratings yet

- 3500 Most Common Chinese CharactersDocument2 pages3500 Most Common Chinese CharactersSub 2 PewdsNo ratings yet

- Assessment For Learning A Practical GuideDocument108 pagesAssessment For Learning A Practical Guidesh1999100% (1)

- Residence Time Distribution For Chemical ReactorsDocument71 pagesResidence Time Distribution For Chemical ReactorsJuan Carlos Serrano MedranoNo ratings yet

- Igcse Economics Rev NotesDocument69 pagesIgcse Economics Rev Noteskityk60% (5)

- Presentation On Loan Management-3 Problem/ Distressed Loans: Course Name: Bank Fund ManagementDocument17 pagesPresentation On Loan Management-3 Problem/ Distressed Loans: Course Name: Bank Fund ManagementNafisa MonsurNo ratings yet

- Ecg in AtheletsDocument32 pagesEcg in AtheletsOnon EssayedNo ratings yet

- Jargeous - Product - Catalog Ver 1220 Compressed PDFDocument16 pagesJargeous - Product - Catalog Ver 1220 Compressed PDFFirdaus YahyaNo ratings yet

Cazafallas

Cazafallas

Uploaded by

oscarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cazafallas

Cazafallas

Uploaded by

oscarCopyright:

Available Formats

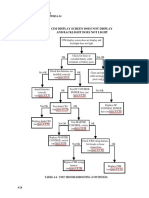

Troubleshooting

8-1. General Troubleshooting

Troubleshooting procedures vary for engines with carburetors versus fuel injected

engines. Refer to Section 8-1.2 for fuel injected engines and Section 8-1.1 for engines

with carburetors.

8-1.1. General Troubleshooting for Engines equipped with a Carburetor

Engine Will Not Start

Check switch positions:

Starter Master Power Switch……………….....ON

NOT

turns when ignition switch OK

Fuel Selector Valve…………...……….ON

is engaged? Throttle………………..………….¼ OPEN

Ignition Switch...………….…..….…BOTH

OK

Switches NOT Reposition switches and

Go to positioned properly? OK retry

Section 8-5

OK

Service or replace battery

Check battery condition NOT according to Airframe

OK Manufacturer’s

instructions.

OK

Check Ignition Switch

wiring according to Repair wiring according to

NOT

Airframe Manufacturer’s

Airframe Manufacturer’s OK

instructions.

instructions.

OK

Service with fuel approved

NOT

Check Fuel Level in tank(s) OK

for engine model

(Section 7)

OK

Go to

Section

8-1.4

8-2 Standard Practice Maintenance Manual

15 Sep 2019

Troubleshooting

8-1.2. General Troubleshooting for Engines with Continental Continuous Flow

Fuel Injection Systems

Engine Will Not Start

Master Power Switch……………….....ON

Fuel Selector Valve…………...……….ON

Mixture Control……….……....FULL RICH NOT Reposition switches and

Throttle………………..………….¼ OPEN OK retry

Boost Pump………………………per POH

Ignition Switch...………….…..….…BOTH

OK

Service or replace battery

Starter turns when ignition NOT NOT according to Airframe

Check battery condition

switch is engaged? OK OK Manufacturer’s

instructions.

OK OK

Engine turns with starter? NOT Check Ignition Switch

OK wiring according to Repair wiring according to

NOT

Airframe Manufacturer’s

Airframe Manufacturer’s OK

instructions.

OK Replace starter instructions.

adapter OK

Check fuel level in tanks NOT Replace starter

OK

Service with

OK appropriate fuel

grade.

NOT

Check fuel pressure OK

Check for fuel line

OK obstruction

NOT

Check fuel flow OK

Refer to Ignition

OK Troubleshooting (Sect. 8-3)

Refer to Ignition

Troubleshooting (Sect. 8-7)

Standard Practice Maintenance Manual 8-3

15 Sep 2019

Troubleshooting

8-1.3. Engine Runs Rough

Engine troubleshooting techniques vary depending on the engine fuel system. For engines

equipped with a carburetor refer to Section 8-1.3.1. To troubleshoot rough running engines

equipped with continuous flow fuel injection systems, refer to Section 8-1.3.1.

8-1.3.1. Engine Runs Rough (equipped with Carburetor)

Engine Runs

Check induction air NOT Replace induction

Roughly AT IDLE Increase IDLE speed OK

filter (airframe) OK air filter

AT ANY OK

SPEED

Check for induction system NOT Correct according to Airframe

obstruction OK Manufacturer’s instructions Go to

Section 8-6

OK

NOT Correct according to Propeller

Check propeller for imbalance OK Manufacturer’s instructions

OK

Check/adjust carburetor IDLE NOT Adjust according to

mixture adjustment. OK instructions in primary ICA

OK

Check carburetor/priming system NOT

Correct leak

for leaks OK

OK

Check for loose or broken engine

NOT

mounts according to Airframe OK Replace engine mounts

Manufacturer’s instructions.

OK

Possible hydraulic lifter

malfunction or burned or warped

exhaust valves or valve seats.

Perform Cylinder Differential

Pressure Test and Borescope

Inspection (Section 6).

8-4 Standard Practice Maintenance Manual

15 Sep 2019

Troubleshooting

8-1.3.2. Engine Runs Rough (equipped with Continental Continuous Flow Fuel

Injection System)

Engine Runs Rough at IDLE

Check air filter for cleanliness NOT Replace air filter according to the

(see Aircraft Manufacturer’s OK Aircraft Maintenance Manual.

maintenance instructions).

OK

Perform Induction System Torque loose fasteners to

NOT

Inspection; look for induction OK Appendix B specifications.

system leaks.

OK

Go to

Perform Ignition System NOT Section

Inspection (Section 6). OK 8-6.1

OK

Perform Engine Operational Adjust fuel pressure to meet

NOT

Check (Section 6). OK

engine specifications

(Section 6).

OK

Possible hydraulic lifter

malfunction or burned or warped

exhaust valves or valve seats.

Perform Cylinder Differential

Pressure Test and Borescope

Inspection (Section 6).

Engine Runs Rough at High

Speed

Check engine mount legs for Replace engine mount legs on

NOT

cracks; check mount leg fastener OK

condition. Torque fasteners to

torque. Appendix B specifications.

OK

Go to

Perform Ignition System NOT OK

Section

Inspection (Section 6). 8-6.1

OK

Check propeller for imbalance. NOT Correct according to propeller

OK manufacturer’s instructions

Standard Practice Maintenance Manual 8-5

15 Sep 2019

Troubleshooting

8-1.4. Engine Will Not Run

Engine will not run at IDLE

Verify aircraft fuel selector is set

to fullest tank.

OK

Fuel System? Carburetor

Cont. Flow

Fuel Injection

Perform Engine

NOT Turn aircraft boost NOT Operational Check and

Check Fuel Pressure. OK pump ON OK adjust fuel pressure as

required (Section 6).

NOT

OK

OK

Replace Engine Driven

Fuel Pump

Correct according

Check for induction system leaks NOT to airframe NOT Check for induction system

or obstructions. OK manufacturer’s OK leaks or obstructions.

instructions

OK

OK NOT

OK

Check idle mixture and

priming system for leaks

Probable worn or fouled spark

plugs. Perform Ignition System OK

Inspection (Section 6). Go to Possible carburetor

Section malfunction. Replace with

8-6.1. serviceable carburetor or

repair replace faulty

components

8-6 Standard Practice Maintenance Manual

15 Sep 2019

Troubleshooting

Engine Starts, Runs Briefly,

then Stops

Verify aircraft fuel selector is set

to fullest tank.

OK

Check Fuel Tank ventilation Clear the fuel tank vent line

NOT

according to the Aircraft OK according to Aircraft Maintenance

Maintenance Manual. Manual.

OK

Check aircraft fuel strainer

NOT Clean the fuel strainer according to

according to the Aircraft OK Aircraft Maintenance Manual.

Maintenance Manual.

OK

Collect fuel sample from tank. NOT Perform Contaminated Fuel System

Inspect for contamination. OK Inspection (Section 6).

OK

Replace engine driven fuel pump

(if equipped)

8-1.5. Engine Indication Malfunctions

Abnormal Engine Indications

Go to

NOT Section

Abnormal fuel system indication. OK 8-3

OK

Go to

Abnormal lubrication system NOT Section

indication. OK 8-7

Standard Practice Maintenance Manual 8-7

15 Sep 2019

Troubleshooting

8-1.6. Engine Performance Malfunctions

Engine Runs Rich at Cruise Power ..........................................................see Section 8-3

Engine Misses at High Speed ..................................................................see Section 8-8

Poor Engine Performance

Go to

Inspect Induction System NOT Section

(Section 6). OK 8-2

OK

NOT Correct according to Airframe

Check throttle rigging OK Manufacturer’s instructions

OK

Check spark plug condition NOT Replace spark plugs

(Section 6). OK (Section 6).

OK

Cont. Flow

Carburetor Fuel System?

Fuel Injection

Check IDLE Mixture

adjustment and/or Perform Engine

accelerator pump Operational Check

operation, and/or priming (see Section 6).

system for leaks

OK NOT

NOT OK OK

Replace with serviceable

carburetor or repair/adjust NOT OK

faulty components.

Perform Cylinder

NOT Go to

Differential Pressure OK Section

Check (Section 6).

8-3

OK

Go to Repair according to

Section Section 6

8-10 Instructions.

8-8 Standard Practice Maintenance Manual

15 Sep 2019

You might also like

- Chevrolet 327 V8 Engine Rebuild ManualDocument120 pagesChevrolet 327 V8 Engine Rebuild ManualAlissa Davis0% (1)

- Manual Taller Luv Dimax Motor C24se PDFDocument486 pagesManual Taller Luv Dimax Motor C24se PDFjuan davidNo ratings yet

- F70 - 100 MPD Rev12Document832 pagesF70 - 100 MPD Rev12oscarNo ratings yet

- Draft Report R-2Document23 pagesDraft Report R-2HINDIA HEPLNo ratings yet

- Cazafallas 4Document1 pageCazafallas 4oscarNo ratings yet

- Cazafallas 3Document1 pageCazafallas 3oscarNo ratings yet

- Cazafallas 2Document4 pagesCazafallas 2oscarNo ratings yet

- Cazafallas 1Document3 pagesCazafallas 1oscarNo ratings yet

- Avon UTC 1535c5Document32 pagesAvon UTC 1535c5juana100% (1)

- Engine WIll Not Crank or Cranks QST 30Document3 pagesEngine WIll Not Crank or Cranks QST 30hinggasetiawan46No ratings yet

- Method Statement For Testing & Commissioning of Diesel GeneratorDocument6 pagesMethod Statement For Testing & Commissioning of Diesel Generatorvin ss100% (1)

- Models J05C-TD, J08C-TP and J08C-TRDocument20 pagesModels J05C-TD, J08C-TP and J08C-TRKomatsu Perkins HitachiNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Repair Options: Cat 777D Off-Highway TruckDocument4 pagesRepair Options: Cat 777D Off-Highway TruckmkNo ratings yet

- Lubrication ProgramDocument114 pagesLubrication ProgramcutedawNo ratings yet

- 07.2-110 Testing, Adjusting EngineDocument16 pages07.2-110 Testing, Adjusting EngineMariusz NowakowskiNo ratings yet

- 15 PDFDocument8 pages15 PDFKrzyś UrynowiczNo ratings yet

- Troubeshootings 8 Wheeler DHTC Detc-1Document27 pagesTroubeshootings 8 Wheeler DHTC Detc-1khan11k100% (1)

- Sive Aways Stop: Fuel System 2-9Document2 pagesSive Aways Stop: Fuel System 2-9PabloNo ratings yet

- 05 Fuel SystemDocument109 pages05 Fuel SystemUtomo BudidarmoNo ratings yet

- Engine FuelDocument24 pagesEngine FuelЮра Петренко100% (1)

- Eue-Lab Final See2Document29 pagesEue-Lab Final See2Harsha SamagaraNo ratings yet

- 4 Tec Troubleshooting ChartDocument11 pages4 Tec Troubleshooting ChartnelsoncoNo ratings yet

- Precommissioning Procedure For Diesel GeneratorDocument2 pagesPrecommissioning Procedure For Diesel GeneratorBabu100% (1)

- Split-UnitDocument6 pagesSplit-UnitKhairul AnwarNo ratings yet

- Isuzu TF Series Gasoline Engine Workshop ManualDocument20 pagesIsuzu TF Series Gasoline Engine Workshop Manualjames100% (41)

- Standby Generator Set Pre-Operation Checklist: Before Starting The EngineDocument4 pagesStandby Generator Set Pre-Operation Checklist: Before Starting The EngineMartie ClustersNo ratings yet

- A042g474 Rev2Document2 pagesA042g474 Rev2Rahul AR XNo ratings yet

- Solución de ProblemasDocument49 pagesSolución de ProblemasAntonio FrancoNo ratings yet

- C1 BlockDocument3 pagesC1 BlockAkhilesh YadavNo ratings yet

- Isuzu 4JA1 Section 6Document249 pagesIsuzu 4JA1 Section 6Niti KlinKaew100% (1)

- Cat 950GDocument10 pagesCat 950GManuel BarahonaNo ratings yet

- RDB 535 Fault Finding ChartDocument1 pageRDB 535 Fault Finding ChartFrancisco DuranNo ratings yet

- 650.01 DieselGenerator Operating 2013.08.12Document18 pages650.01 DieselGenerator Operating 2013.08.12Tuan Linh VoNo ratings yet

- Engine: Workshop ManualDocument360 pagesEngine: Workshop ManualAutomotriz JTMotorsNo ratings yet

- Startup Inspection ChecklistDocument2 pagesStartup Inspection ChecklistMouayed Zeadan100% (1)

- Arken Kullanim Kitapcigi Ingilizce Yeni - 1Document48 pagesArken Kullanim Kitapcigi Ingilizce Yeni - 1TrainingNo ratings yet

- Vdocuments - MX - Naza Ria MPV PDFDocument93 pagesVdocuments - MX - Naza Ria MPV PDFalangku09100% (2)

- Grand Cherokee 2008 5.7LDocument254 pagesGrand Cherokee 2008 5.7LlefontNo ratings yet

- R-ME-HC-S-020 Governor System Test RecordDocument9 pagesR-ME-HC-S-020 Governor System Test Recordrotimi olalekan fataiNo ratings yet

- Engine Will Not Crank QSK 30Document2 pagesEngine Will Not Crank QSK 30hinggasetiawan46No ratings yet

- Suzuki Vitara Fuel Pressure and Its Circuit CheckDocument3 pagesSuzuki Vitara Fuel Pressure and Its Circuit CheckmGraci520No ratings yet

- 5 Engine ArrangementDocument98 pages5 Engine Arrangementhendra hardyNo ratings yet

- Lycoming Reciprocating Engine Break-In and Oil ConsumptionDocument7 pagesLycoming Reciprocating Engine Break-In and Oil ConsumptionChristian Enrique Casique PajarNo ratings yet

- Engine Acceleration or Response PoorDocument11 pagesEngine Acceleration or Response PoorDung PhamNo ratings yet

- General Service Checklist - BIKE PDFDocument7 pagesGeneral Service Checklist - BIKE PDFmanasNo ratings yet

- Application Engineering Bulletin: Electronic Throttle Control Specifications Automotive Industrial G-DriveDocument3 pagesApplication Engineering Bulletin: Electronic Throttle Control Specifications Automotive Industrial G-DriveMiguel Angel Cortes PrietoNo ratings yet

- Cim Display Screen Does Not Display and Backlight Does Not LightDocument10 pagesCim Display Screen Does Not Display and Backlight Does Not LightМестный АвторитетNo ratings yet

- 1106D Fuel System Diagnosis ProcedureDocument2 pages1106D Fuel System Diagnosis ProceduredubimouNo ratings yet

- Troubleshooting qsx15 Engine Difficult To StartDocument6 pagesTroubleshooting qsx15 Engine Difficult To StartAli ArdinNo ratings yet

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- DCS No 4 - Low Fuel Avg - DSLDocument2 pagesDCS No 4 - Low Fuel Avg - DSLservicemanager.bkdNo ratings yet

- Fault Code 372Document4 pagesFault Code 372Enrrique LaraNo ratings yet

- Service Program - CE Excapator KOREADocument8 pagesService Program - CE Excapator KOREAtele123No ratings yet

- Engine FuelDocument19 pagesEngine FuelJohn fredy cuervoNo ratings yet

- Engine Electrical EeDocument17 pagesEngine Electrical EePedro LopezNo ratings yet

- Fle Power 4000iDocument45 pagesFle Power 4000iGary SatherNo ratings yet

- DCS No 2 - Engine Not Starting - DSLDocument2 pagesDCS No 2 - Engine Not Starting - DSLservicemanager.bkdNo ratings yet

- 15 Air Metering-Acceleration SystemDocument17 pages15 Air Metering-Acceleration Systemapinya doungsoilNo ratings yet

- 8 Tobia - Maintenance of DEG (Mechanical)Document38 pages8 Tobia - Maintenance of DEG (Mechanical)Epeli RokodrokayaNo ratings yet

- InformationDocument8 pagesInformationoscarNo ratings yet

- CD HighlightsDocument2 pagesCD HighlightsoscarNo ratings yet

- Manual CessnaDocument74 pagesManual CessnaoscarNo ratings yet

- Service Bulletin: Dowty Aerospace PropellersDocument23 pagesService Bulletin: Dowty Aerospace PropellersoscarNo ratings yet

- Failure To Follow Procedures While Performing Aircraft Inspections CFR 91Document20 pagesFailure To Follow Procedures While Performing Aircraft Inspections CFR 91oscarNo ratings yet

- Mccauley Industsal Corporation: 00X 1. Aoofcvfll Sia. - Oaiion. Ohio 0411 Code 511 26X.3541 Addrc S Mccjui4YDocument4 pagesMccauley Industsal Corporation: 00X 1. Aoofcvfll Sia. - Oaiion. Ohio 0411 Code 511 26X.3541 Addrc S Mccjui4YoscarNo ratings yet

- Pegado de botaPS5710-SPMDocument7 pagesPegado de botaPS5710-SPMoscarNo ratings yet

- Service Bulletin 177B: June 30.1992Document3 pagesService Bulletin 177B: June 30.1992oscarNo ratings yet

- Text NotescriptDocument4 pagesText NotescriptoscarNo ratings yet

- Service Bulletin 176EDocument6 pagesService Bulletin 176EoscarNo ratings yet

- Service Bulletin 234BDocument17 pagesService Bulletin 234BoscarNo ratings yet

- Alert Service Bulletin: ASB251ADocument5 pagesAlert Service Bulletin: ASB251AoscarNo ratings yet

- Alert Service Bulletin: TitleDocument7 pagesAlert Service Bulletin: TitleoscarNo ratings yet

- Service Bulletin 239CDocument14 pagesService Bulletin 239CoscarNo ratings yet

- IPLEX VIEWER PLUS Instructions - Eng PDFDocument42 pagesIPLEX VIEWER PLUS Instructions - Eng PDFoscarNo ratings yet

- Service Bulletin: Dowty Aerospace PropellersDocument6 pagesService Bulletin: Dowty Aerospace PropellersoscarNo ratings yet

- Presurizacion f50Document15 pagesPresurizacion f50oscarNo ratings yet

- Astm Specifications For Concrete Masonry Units: TEK 1-1FDocument4 pagesAstm Specifications For Concrete Masonry Units: TEK 1-1FEric HernándezNo ratings yet

- Budget Plan 2Document14 pagesBudget Plan 2Abbie BalsarzaNo ratings yet

- 20220725Document39 pages20220725Zenon CondoriNo ratings yet

- 1 s2.0 S1359431115011898 MainDocument11 pages1 s2.0 S1359431115011898 MainPatrice PariNo ratings yet

- Noninvasive Brain-Computer Interfaces: Gerwin Schalk, Brendan Z. AllisonDocument21 pagesNoninvasive Brain-Computer Interfaces: Gerwin Schalk, Brendan Z. AllisonQuốc ViệtNo ratings yet

- Department of Labor: PassaicDocument2 pagesDepartment of Labor: PassaicUSA_DepartmentOfLaborNo ratings yet

- Smallware InventoryDocument7 pagesSmallware Inventoryye min aungNo ratings yet

- Navasakam Grievance Application: Family DetailsDocument2 pagesNavasakam Grievance Application: Family DetailsmANOHARNo ratings yet

- A Stingless Bee Hive Design For A Broader ClimateDocument4 pagesA Stingless Bee Hive Design For A Broader ClimateMarlon Manaya Garrigues100% (1)

- 1319577545GTWN082711Document32 pages1319577545GTWN082711CoolerAdsNo ratings yet

- GrammarDocument23 pagesGrammarYMNo ratings yet

- Object Oriented Programming Using C++ Viva Questions Coders LodgeDocument7 pagesObject Oriented Programming Using C++ Viva Questions Coders LodgeGulchetan SinghNo ratings yet

- IFRS 11 Joint ArrangementsDocument6 pagesIFRS 11 Joint Arrangementsmcastillo3313No ratings yet

- Expedition DiaryDocument23 pagesExpedition DiaryAnkur JhunjhunwalaNo ratings yet

- Ex Lecture1Document2 pagesEx Lecture1AlNo ratings yet

- 9 Cir vs. Baier-Nickel DGSTDocument2 pages9 Cir vs. Baier-Nickel DGSTMiguelNo ratings yet

- Column Evaluation & Handling (QC-033)Document40 pagesColumn Evaluation & Handling (QC-033)muhammad fahadNo ratings yet

- FORM V Abstract Under The Payment of Wages Act, 1936 (English Version)Document2 pagesFORM V Abstract Under The Payment of Wages Act, 1936 (English Version)anant nagvekarsNo ratings yet

- Great Mantras For SuccessDocument4 pagesGreat Mantras For Successsatchap11No ratings yet

- Arlec Wireless SecurityDocument10 pagesArlec Wireless Securityalfi56kNo ratings yet

- Sauer90 ServiceManual PDFDocument72 pagesSauer90 ServiceManual PDFeng13100% (7)

- Gmail - Attain Good Health With Healthy GutDocument3 pagesGmail - Attain Good Health With Healthy GutnityamnayakNo ratings yet

- 3500 Most Common Chinese CharactersDocument2 pages3500 Most Common Chinese CharactersSub 2 PewdsNo ratings yet

- Assessment For Learning A Practical GuideDocument108 pagesAssessment For Learning A Practical Guidesh1999100% (1)

- Residence Time Distribution For Chemical ReactorsDocument71 pagesResidence Time Distribution For Chemical ReactorsJuan Carlos Serrano MedranoNo ratings yet

- Igcse Economics Rev NotesDocument69 pagesIgcse Economics Rev Noteskityk60% (5)

- Presentation On Loan Management-3 Problem/ Distressed Loans: Course Name: Bank Fund ManagementDocument17 pagesPresentation On Loan Management-3 Problem/ Distressed Loans: Course Name: Bank Fund ManagementNafisa MonsurNo ratings yet

- Ecg in AtheletsDocument32 pagesEcg in AtheletsOnon EssayedNo ratings yet

- Jargeous - Product - Catalog Ver 1220 Compressed PDFDocument16 pagesJargeous - Product - Catalog Ver 1220 Compressed PDFFirdaus YahyaNo ratings yet