Professional Documents

Culture Documents

Cazafallas 2

Cazafallas 2

Uploaded by

oscarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cazafallas 2

Cazafallas 2

Uploaded by

oscarCopyright:

Available Formats

Troubleshooting

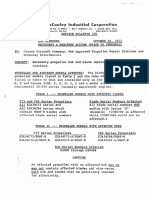

8-3. Continental Continuous Flow Fuel Injection System

Engine Will Not Start .............................................................................see Section 8-3.1

Fluctuating or Erroneous Fuel Flow.......................................................see Section 8-3.2

Poor Acceleration ..................................................................................see Section 8-3.3

Fuel Injector Operational Check ............................................................see Section 8-3.4

8-3.1. Engine Will Not Start

Engine will not Start

Turn off aircraft power and check

Fuel Flow OK? YES

ground below system drains.

NO

Check fuel level in tank. NOT Excess

Engine flooded. Clear

Fuel Selector Valve = ON OK fuel present below YES

excess fuel and retry.

system drains?

OK Correct input conditions

and retry. NO

Fuel Disconnect cylinder drain

Pressure NO tubes at check valve .

OK?

Perform Engine Fuel Go to Section

Operational Check present in cylinder NO 8-3.4.

(Section 6). drain tubes?

NOT

OK YES

YES

OK Disconnect airframe drain Clear obstruction,

Replace Engine Driven NOT

line at check valve. Check reconnect fittings and retry

Fuel Pump. OK

drain line for obstruction. Engine Start.

OK

Replace check valve.

Perform Fuel Injection

NOT

System Operational Check OK

(Section 8).

Go to Section

8-6

8-12 Standard Practice Maintenance Manual

15 Sep 2019

Troubleshooting

8-3.2. Fluctuating or Erroneous Fuel Flow

Fluctuating Or Erroneous Fuel

Flow Indications

Check fuel line routing, heat shield, NOT

Correct fuel line installation.

and fire sleeve installation. OK

NOT Adjust fuel system,

Perform Engine Operation Check OK if necessary.

Check fuel flow gauge and lines Repair or replace fuel flow gauge

NOT

according to Airframe Manufacturer’s OK or lines according to Airframe

instructions. Manufacturer’s instructions.

Repair or replace crew compartment

indicator according to Airframe

Manufacturer’s instructions.

8-3.3. Poor Acceleration

Poor Acceleration

Perform Engine Operational Check

NOT Adjust according to Airframe

(see Chapter 6) to verify fuel system OK Manufacturer’s instructions.

operation.

Check throttle and fuel control linkage

for proper operation.

Perform Ignition Harness and Spark Plug

Diagnostics (see Section 8.6.1).

Standard Practice Maintenance Manual 8-13

15 Sep 2019

Troubleshooting

8-3.4. Fuel Injector Operational Check

Fuel Injector Operational Check

Perform a visual inspection of the

fuel injection system (Section 6).

Perform a Fuel System Inspection

(Section 6).

Correct discrepancies discovered

during inspection.

• Disconnect the fuel line from each fuel

injector assembly. Remove the injector

assemblies from the cylinders

(Section 6).

• Connect the fuel lines to the respective fuel

injector assemblies; torque the fuel lines

(see Appendix B).

• Connect a section of fuel rated clear tubing

to the open end of each injector. Place the

open ends of the tubing in separate

containers (catch cans) to collect the fuel.

Master Power Switch……………....ON

Fuel Selector Valve………………...ON

OK

Boost Pump….……………………...ON

Throttle…………………………...….IDLE

Boost Pump….……………...OFF

Fuel Selector Valve………...OFF

Check fuel supply hoses from fuel tank to

Master Power Switch……....OFF

fuel pump for leaks. Check fuel hoses and NOT

Repair leaking aircraft fuel lines

connections from fuel pump to the fuel OK

according to airframe manufacturer’s

manifold valve for leaks.

instructions. Repair leaking engine fuel

hoses or lines (Section 10).

OK

Throttle……………...Wide Open

Verify fuel flows into the catch

cans with no fuel leaks from the

fuel lines to the fuel injectors.

Repair leaking engine fuel Confirm equal and consistent fuel

YES Leaks detected?

lines or manifold valve flow.

Boost Pump….……………...OFF

Fuel Selector Valve………...OFF

NO Master Power Switch……....OFF

Continued NOTE: Position tuned nozzles will

on next vary flow rates according to the

page jets used. Expect a variance of up

to 30% from one nozzle to

another

8-14 Standard Practice Maintenance Manual

15 Sep 2019

Troubleshooting

Fuel Injector

Operational Remove fuel injectors from the fuel lines.

Check, cont. Connect clear tubing to the fuel lines and

terminate the tubing in catch cans:

Master Power Switch……....ON

Fuel Selector Valve………...ON

Flow NO Boost Pump….……………...ON

consistent and Throttle……………………….Wide Open

equal Fuel Flow……….……………Check

Boost Pump….……………...OFF

Fuel Selector Valve………...OFF

Master Power Switch……....OFF

Throttle……………………....IDLE/CUTOFF

Flow

consistent and NO

equal

YES

YES

Repair/Replace faulty fuel

Repair faulty fuel injector(s) manifold valve

Assemble, torque and leak check

Perform Fuel System Operational

the Fuel Injection System parts

Check (Section 6).

removed for troubleshooting.

Standard Practice Maintenance Manual 8-15

15 Sep 2019

You might also like

- SM - 47 Hemi Engines Repair Manual Easy WayDocument449 pagesSM - 47 Hemi Engines Repair Manual Easy WayΜιχάλης Χατζηαντρέας50% (6)

- Chevrolet 327 V8 Engine Rebuild ManualDocument120 pagesChevrolet 327 V8 Engine Rebuild ManualAlissa Davis0% (1)

- Isuzu Engine C24SE Workshop ManualDocument486 pagesIsuzu Engine C24SE Workshop ManualFiorano 599 GT88% (8)

- Drone CurriculumDocument9 pagesDrone CurriculumMarvellousNo ratings yet

- Grand Cherokee 2011 3.6LDocument471 pagesGrand Cherokee 2011 3.6LSPRAYCROM TRADING100% (1)

- Troubleshooting C4 4 Marine Generator SetDocument92 pagesTroubleshooting C4 4 Marine Generator SetAsep Shaifurrahman100% (6)

- Engine Jeep Patriot 2.0Document296 pagesEngine Jeep Patriot 2.0Yoga Ariant100% (1)

- ENGINE 5.7L - Service Information - Ram Pickup PDFDocument291 pagesENGINE 5.7L - Service Information - Ram Pickup PDFcharles100% (1)

- Prophecies in Islam & Prophet Muhammad - A.aliDocument82 pagesProphecies in Islam & Prophet Muhammad - A.aliZaky MuzaffarNo ratings yet

- Manual Taller Luv Dimax Motor C24se PDFDocument486 pagesManual Taller Luv Dimax Motor C24se PDFjuan davidNo ratings yet

- 2016 Grand Cherokee - 3.0L TURBO DIESEL PDFDocument665 pages2016 Grand Cherokee - 3.0L TURBO DIESEL PDFprueba2No ratings yet

- Systems Operation Testing and Adjusting: 4012-46A Industrial EngineDocument12 pagesSystems Operation Testing and Adjusting: 4012-46A Industrial Enginenam vo100% (1)

- F70 - 100 MPD Rev12Document832 pagesF70 - 100 MPD Rev12oscarNo ratings yet

- Vertex - Destiny's GateDocument7 pagesVertex - Destiny's GateBogdan Catrinoiu100% (2)

- Ib Unit - The Arrival-Immigration-Visual ExperienceDocument6 pagesIb Unit - The Arrival-Immigration-Visual Experienceapi-284054906No ratings yet

- Concrete WorkDocument1 pageConcrete WorkChandru100% (1)

- D399 Industrial EngineDocument49 pagesD399 Industrial EngineMohamed SaiedNo ratings yet

- CazafallasDocument7 pagesCazafallasoscarNo ratings yet

- Isuzu TF Series Gasoline Engine Workshop ManualDocument20 pagesIsuzu TF Series Gasoline Engine Workshop Manualjames100% (41)

- Cazafallas 1Document3 pagesCazafallas 1oscarNo ratings yet

- Grand Cherokee 2008 5.7LDocument254 pagesGrand Cherokee 2008 5.7LlefontNo ratings yet

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- 1.8L FP EngineDocument327 pages1.8L FP EngineKamil Charmik LužaNo ratings yet

- Diagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts HardDocument11 pagesDiagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts HardAlejandro HernandezNo ratings yet

- Grand Cherokee 2011 5.7LDocument300 pagesGrand Cherokee 2011 5.7Lramon fuenmayorNo ratings yet

- 05 Fuel SystemDocument109 pages05 Fuel SystemUtomo BudidarmoNo ratings yet

- Eue-Lab Final See2Document29 pagesEue-Lab Final See2Harsha SamagaraNo ratings yet

- 2500 HD 2014 5.7LDocument287 pages2500 HD 2014 5.7LJuan PerezNo ratings yet

- Engine Mechanical SystemDocument181 pagesEngine Mechanical Systemsled novaNo ratings yet

- Engine FuelDocument24 pagesEngine FuelЮра Петренко100% (1)

- Ram 1500-2013-3.6Document480 pagesRam 1500-2013-3.6luis67% (3)

- Diesel Engine Troubleshooting and MaintenanceDocument8 pagesDiesel Engine Troubleshooting and MaintenanceIhsan Ahmed100% (2)

- Avon UTC 1535c5Document32 pagesAvon UTC 1535c5juana100% (1)

- 75 Ts GuideDocument3 pages75 Ts GuideasursNo ratings yet

- Troubeshootings 8 Wheeler DHTC Detc-1Document27 pagesTroubeshootings 8 Wheeler DHTC Detc-1khan11k100% (1)

- 1500 2014 5.7LDocument285 pages1500 2014 5.7LLuis Ramon Arguello RealNo ratings yet

- Arken Kullanim Kitapcigi Ingilizce Yeni - 1Document48 pagesArken Kullanim Kitapcigi Ingilizce Yeni - 1TrainingNo ratings yet

- Description: Service InformationDocument26 pagesDescription: Service Informationc22rpr4rymNo ratings yet

- Engine: Workshop ManualDocument360 pagesEngine: Workshop ManualAutomotriz JTMotorsNo ratings yet

- Vdocuments - MX - Naza Ria MPV PDFDocument93 pagesVdocuments - MX - Naza Ria MPV PDFalangku09100% (2)

- Testeo y Ajuste 3208Document88 pagesTesteo y Ajuste 3208CRIATHIANNo ratings yet

- 300 2013 6.4LDocument302 pages300 2013 6.4LLuis Ramon Arguello RealNo ratings yet

- 02-Engine Mechanical System PDFDocument129 pages02-Engine Mechanical System PDFSigit Indrawan100% (1)

- STC Oil Control Valve (Mechanical) - 5Document2 pagesSTC Oil Control Valve (Mechanical) - 5Parveen KashyapNo ratings yet

- 5 Engine ArrangementDocument98 pages5 Engine Arrangementhendra hardyNo ratings yet

- Compass 2008 2.0LDocument234 pagesCompass 2008 2.0LDavid Ulloa SalazarNo ratings yet

- 07 1963 CH-Engine Tune-UpDocument3 pages07 1963 CH-Engine Tune-UpJose LaproviteraNo ratings yet

- Engine Electrical EeDocument17 pagesEngine Electrical EePedro LopezNo ratings yet

- Fuel System & Carburetion: Fuel Pump Recirculation System Reed Valve Assembly Auto EnrichnerDocument16 pagesFuel System & Carburetion: Fuel Pump Recirculation System Reed Valve Assembly Auto EnrichnerJim LassNo ratings yet

- Isuzu 4JA1 Section 6Document249 pagesIsuzu 4JA1 Section 6Niti KlinKaew100% (1)

- Engine Difficult To Start or Will Not Start (No Exhaust Smoke)Document3 pagesEngine Difficult To Start or Will Not Start (No Exhaust Smoke)Jose A PerezNo ratings yet

- Sierra 4.8L 5.3L 6.0L 2002Document405 pagesSierra 4.8L 5.3L 6.0L 2002Jose Gonzalez VazquezNo ratings yet

- Weber Carburetor Troubleshooting Guide: Operating ConditionsDocument8 pagesWeber Carburetor Troubleshooting Guide: Operating ConditionsRyan Hadi WicaksonoNo ratings yet

- PSP-00088EAF 2023/1 1/04 19:19:18-06:00 SENR2132 © 2023 Caterpillar IncDocument86 pagesPSP-00088EAF 2023/1 1/04 19:19:18-06:00 SENR2132 © 2023 Caterpillar IncMario Núñez ObandoNo ratings yet

- 71 00 PDFDocument38 pages71 00 PDFNasr PooyaNo ratings yet

- Chevrolet Captiva Service Manual 00Document19 pagesChevrolet Captiva Service Manual 00krisdiarto@gmail.com100% (2)

- Description: 2012 Jeep Grand Cherokee Overland 2012 Jeep Grand Cherokee OverlandDocument469 pagesDescription: 2012 Jeep Grand Cherokee Overland 2012 Jeep Grand Cherokee OverlandHarim Noe Guerrero LongoriaNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Engine Cranks But Will Not StartDocument52 pagesEngine Cranks But Will Not Startphuong lamhoang100% (8)

- Двигатель 4н Lg4h We 0553Document711 pagesДвигатель 4н Lg4h We 0553Dmitry Bondar100% (1)

- 2.4l EngineDocument237 pages2.4l EngineRene SanchezNo ratings yet

- Patriot 2008 2.4LDocument260 pagesPatriot 2008 2.4LCynthia MartinezNo ratings yet

- Fault Code 779Document6 pagesFault Code 779Enrrique Lara100% (1)

- Suntec Fuel Unit Test ManualDocument17 pagesSuntec Fuel Unit Test ManualsunnygyadavNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- CD HighlightsDocument2 pagesCD HighlightsoscarNo ratings yet

- CazafallasDocument7 pagesCazafallasoscarNo ratings yet

- InformationDocument8 pagesInformationoscarNo ratings yet

- Pegado de botaPS5710-SPMDocument7 pagesPegado de botaPS5710-SPMoscarNo ratings yet

- Mccauley Industsal Corporation: 00X 1. Aoofcvfll Sia. - Oaiion. Ohio 0411 Code 511 26X.3541 Addrc S Mccjui4YDocument4 pagesMccauley Industsal Corporation: 00X 1. Aoofcvfll Sia. - Oaiion. Ohio 0411 Code 511 26X.3541 Addrc S Mccjui4YoscarNo ratings yet

- Failure To Follow Procedures While Performing Aircraft Inspections CFR 91Document20 pagesFailure To Follow Procedures While Performing Aircraft Inspections CFR 91oscarNo ratings yet

- Text NotescriptDocument4 pagesText NotescriptoscarNo ratings yet

- Service Bulletin: Dowty Aerospace PropellersDocument23 pagesService Bulletin: Dowty Aerospace PropellersoscarNo ratings yet

- Manual CessnaDocument74 pagesManual CessnaoscarNo ratings yet

- Service Bulletin 234BDocument17 pagesService Bulletin 234BoscarNo ratings yet

- Service Bulletin 239CDocument14 pagesService Bulletin 239CoscarNo ratings yet

- Service Bulletin 176EDocument6 pagesService Bulletin 176EoscarNo ratings yet

- Service Bulletin 177B: June 30.1992Document3 pagesService Bulletin 177B: June 30.1992oscarNo ratings yet

- Alert Service Bulletin: TitleDocument7 pagesAlert Service Bulletin: TitleoscarNo ratings yet

- Presurizacion f50Document15 pagesPresurizacion f50oscarNo ratings yet

- Alert Service Bulletin: ASB251ADocument5 pagesAlert Service Bulletin: ASB251AoscarNo ratings yet

- Service Bulletin: Dowty Aerospace PropellersDocument6 pagesService Bulletin: Dowty Aerospace PropellersoscarNo ratings yet

- IPLEX VIEWER PLUS Instructions - Eng PDFDocument42 pagesIPLEX VIEWER PLUS Instructions - Eng PDFoscarNo ratings yet

- Lesson 2 - Victimology and VictimDocument19 pagesLesson 2 - Victimology and VictimHernandez JairineNo ratings yet

- Research II Kerson Leaves2.0Document36 pagesResearch II Kerson Leaves2.0Marvielyn100% (1)

- Notes:: Dialog Plant Services Sdn. BHDDocument1 pageNotes:: Dialog Plant Services Sdn. BHDTengku ZhafriNo ratings yet

- Improving Machine Translation With Conditional Sequence Generative Adversarial NetsDocument10 pagesImproving Machine Translation With Conditional Sequence Generative Adversarial Netsmihai ilieNo ratings yet

- Manual de Program. CPU Mitsubishi - R04CPUDocument156 pagesManual de Program. CPU Mitsubishi - R04CPUJefferson MisaelNo ratings yet

- Curriculum Till DE-39 PDFDocument173 pagesCurriculum Till DE-39 PDFubaid umarNo ratings yet

- SIKA Marine 2016Document164 pagesSIKA Marine 2016pcatruongNo ratings yet

- Super Notes Flamingo PoemsDocument23 pagesSuper Notes Flamingo PoemsVishnuNo ratings yet

- Teaching English Through StoryDocument8 pagesTeaching English Through StoryChaerunnisaNo ratings yet

- Contemporary World FinalDocument22 pagesContemporary World FinalApril Grace Genobatin BinayNo ratings yet

- ISO 22301 Lead Implementer - Two Page BrochureDocument2 pagesISO 22301 Lead Implementer - Two Page BrochurePECBCERTIFICATIONNo ratings yet

- Science X QP Set BDocument7 pagesScience X QP Set BYogesh KhannaNo ratings yet

- 4-23 Chihulyrecycledtextureslumpbowls ReavisDocument7 pages4-23 Chihulyrecycledtextureslumpbowls Reavisapi-302485915No ratings yet

- SafeBoda Data Intern JDDocument2 pagesSafeBoda Data Intern JDMusah100% (1)

- 2exam LogisticsDocument6 pages2exam LogisticsJessica LaguatanNo ratings yet

- Sky Star 300Document2 pagesSky Star 300Onitry RecordNo ratings yet

- ICDs and CFSsDocument10 pagesICDs and CFSsDat BoiNo ratings yet

- The Emoji Factor: Humanizing The Emerging Law of Digital SpeechDocument33 pagesThe Emoji Factor: Humanizing The Emerging Law of Digital SpeechCityNewsTorontoNo ratings yet

- Eaton Guide Specification Notes and Instructions To SpecwriterDocument17 pagesEaton Guide Specification Notes and Instructions To SpecwriterIsrael Luna PenasNo ratings yet

- Seam 6 Prelim ModuleDocument36 pagesSeam 6 Prelim ModuleI Hack YouNo ratings yet

- Biology HL Student GuideDocument134 pagesBiology HL Student GuideYesenia JassoNo ratings yet

- Ga8238 PDFDocument3 pagesGa8238 PDFAstri Indra MustikaNo ratings yet

- Saim NotesDocument120 pagesSaim NotesJagmohan Bisht0% (1)

- Elearning Brochure HL7Document2 pagesElearning Brochure HL7Raju RajputNo ratings yet

- Sales Force Data LoaderDocument41 pagesSales Force Data LoaderhertzelNo ratings yet