Professional Documents

Culture Documents

101 Operational-Agility-and-Efficiency-for-Manufacturing

101 Operational-Agility-and-Efficiency-for-Manufacturing

Uploaded by

swapnil koleOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

101 Operational-Agility-and-Efficiency-for-Manufacturing

101 Operational-Agility-and-Efficiency-for-Manufacturing

Uploaded by

swapnil koleCopyright:

Available Formats

Minimize value leaks

in your production

processes

Three steps to agile, efficient operations

Inflation, panic buying, supply shortages. Overcoming these Here’s how to get there

hurdles requires new levels of agility-and a new way to work.

STEP 1

KNOW

Close the loop

You can’t fix what you can’t see.

Start by digitalizing your

workflows – from start to finish.

Time to

correct

Design closed-loop work

processes that enable

sense-&-response

To minimize or eliminate

value leaks from the

Time to production process, it is

Detect Time to

learn important to digitalize the

entire closed-loop work

process (see – know – act)

in order to achieve

efficiency and agility.

SEE ACT

Source of deviation or variability

STEP 2

Discover the leaks

Cost savings and revenue Understand and identify the various ways value

opportunities are everywhere. can leak from the production process

Here’s a list to get started.

Expenses (Cost) Revenue

Labor Materials Assets Utilities Demand

Loss from

Waiting for Quality / Line shutdown Electricity –

constrained

instructions scrap loss loss startup loss

capacity

Waiting for Equipment Electricity – Slower new product

Yield loss

materials breakdown loss excess use loss introduction

Sub-optimal methods Giveaway / Setup & Thermal Damage to

& procedures overages loss changeover loss dissipation loss brand reputation

Inadequate skills Water – SIP /

Rework loss Startup loss

& training CIP loss

Minor stoppages Gas & Steam –

Receiving loss

loss excess use loss

Emission /

Expediting costs Speed loss

effluents penalties

Returns / Quality detect &

recalls costs rework loss

Warranty & Waiting for

replacement Parts materials

Waiting on people

Rework loss

(QA, Technician, etc.)

Source: Visual Decisions

STEP 3

Capture and connect

Give your users unlimited access to real-time,

contextualized operational insights with

Capture & contextualize real-time

AVEVATM Operations Control. With one single

information across all sources

integrated context for plant data, your teams

can make better decisions to increase of plant data

efficiency and agility.

Essential information by operations team

Plant/Field Control Room Enterprise

(Equipment-centric) (Site-centric) (Global/Regional)

Financial Supply Chain

Energy MES Energy ERP

Dashboards Predictive Analytics Dashboards Predictive Analytics

3D Models Mobile Rounds 3D Models

Operator Training Workflow Workflow

Extended Reality Trends Extended Reality Collaboration Tools Collaboration Tools

KPIs Collaboration Tools KPIs Trends KPIs Trends

KPIs

Process Screens Historian Process Screens Historian Process Screens Data Modeling

Tablet RFID tags Controllers IoT Sensors

Learn more about AVEVA Operations Control

For more information, contact sales partner:

© 2022 AVEVA Group plc and its subsidiaries. All rights reserved.

AVEVA and the AVEVA logo are a trademark or

registered trademark of AVEVA Group plc in the U.S. and other countries.

You might also like

- Lean Cheat SheetDocument2 pagesLean Cheat Sheetankush0% (2)

- Mistaking The CEO For A GigoloDocument39 pagesMistaking The CEO For A GigoloKey KimNo ratings yet

- S4H - 747 How To Approach Remote CutoverDocument29 pagesS4H - 747 How To Approach Remote CutoverAsfaqNo ratings yet

- Production Cutover PlanningDocument38 pagesProduction Cutover Planningprasvis208100% (3)

- Asc 1236144 103 PDFDocument210 pagesAsc 1236144 103 PDFLuiz Ribeiro100% (2)

- Pig Calculation Tables: Date Batch Nr. Number of PigletsDocument7 pagesPig Calculation Tables: Date Batch Nr. Number of PigletsUrs SchaffnerNo ratings yet

- Reduce Downtime by 50% Halve Peck Time Increase Throughput by 20%Document6 pagesReduce Downtime by 50% Halve Peck Time Increase Throughput by 20%selimNo ratings yet

- CH 9Document13 pagesCH 9bollab654No ratings yet

- FASTTOOLS Offshore Solution Brochure - BU53U91A01-01E-A.usDocument5 pagesFASTTOOLS Offshore Solution Brochure - BU53U91A01-01E-A.usdang dinh hoangNo ratings yet

- Value Streams: Fundamentals of Manufacturing Excellence ProgramDocument30 pagesValue Streams: Fundamentals of Manufacturing Excellence ProgramTuan AnhNo ratings yet

- PPC Unit 1Document10 pagesPPC Unit 1saiNo ratings yet

- Line Balancing PresentationDocument39 pagesLine Balancing Presentationelmaakoul oussama67% (3)

- ANDRITZ Separation - Intelligence For Machine and Process ControlDocument20 pagesANDRITZ Separation - Intelligence For Machine and Process ControlMostafaNo ratings yet

- 4 EI ModuleDocument78 pages4 EI ModuleAhsaan1993No ratings yet

- Jefford Vinson E. Valdehueza Final Exam DTE-2A Submitted To: Consorcio NamoccoDocument4 pagesJefford Vinson E. Valdehueza Final Exam DTE-2A Submitted To: Consorcio NamoccoJefford Vinson ValdehuezaNo ratings yet

- Operational Transformation: Mal Poulin March 25, 2010Document30 pagesOperational Transformation: Mal Poulin March 25, 2010api-26077181No ratings yet

- 06 Process Analysis MethodsDocument19 pages06 Process Analysis MethodsTaufik NurkalihNo ratings yet

- Blueprint Order Fulfilment Overall ProcessDocument1 pageBlueprint Order Fulfilment Overall ProcessAbhijeet PawarNo ratings yet

- Waste EliminationDocument31 pagesWaste Eliminationaarun01No ratings yet

- 5S Implementation PlanDocument16 pages5S Implementation PlanSathyanarayanan GNo ratings yet

- Anderson 1820 SEPG2009Document64 pagesAnderson 1820 SEPG2009Sachin PatilNo ratings yet

- Achieving High Maturity and Agility Using KanbanDocument64 pagesAchieving High Maturity and Agility Using Kanbanjgonzalezsanz8914No ratings yet

- Value Stream MappingDocument16 pagesValue Stream MappingF13 NIECNo ratings yet

- Vestal MeridianDocument25 pagesVestal Meridianmarcioperinni1975No ratings yet

- Aguilar Alfaro Aislinn Itzel 3IM55Document5 pagesAguilar Alfaro Aislinn Itzel 3IM55Ais AlfaroNo ratings yet

- Sustainability Policy Implementation Plan PDFDocument1 pageSustainability Policy Implementation Plan PDFKitpipoj PornnongsaenNo ratings yet

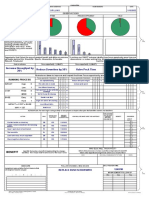

- Production Study Sheet: Effective Non Effective ActivitiesDocument3 pagesProduction Study Sheet: Effective Non Effective Activitieslodestar ieNo ratings yet

- Kaizen: Welcome All To Our Group Presentation OnDocument25 pagesKaizen: Welcome All To Our Group Presentation Onshivashankar_shankarNo ratings yet

- Lean Production System 2Document8 pagesLean Production System 2MD. Shariar IslamNo ratings yet

- LP - Process MappingDocument47 pagesLP - Process MappingMugur AchiteiNo ratings yet

- Course Material of Six Sigma Black-Belt - Improvement Phase Course Material of Six Sigma Black-Belt - Improvement PhaseDocument65 pagesCourse Material of Six Sigma Black-Belt - Improvement Phase Course Material of Six Sigma Black-Belt - Improvement Phasev menonNo ratings yet

- 1.1 SMP For Mechanical Maintance of AirtubeDocument2 pages1.1 SMP For Mechanical Maintance of AirtubePRANAV KUMAR GAUTAMNo ratings yet

- Concrete ProductsDocument11 pagesConcrete ProductsgldiasNo ratings yet

- Kaizen - TSM IntroductionDocument10 pagesKaizen - TSM IntroductionDilfaraz KalawatNo ratings yet

- MLT03 Wi2Document2 pagesMLT03 Wi2Bami-more AbiolaNo ratings yet

- Engg 411 Form 6 Work Improvement Worksheet1Document1 pageEngg 411 Form 6 Work Improvement Worksheet1SofiaJabadanEspulgarNo ratings yet

- Hydroseeding WorkDocument26 pagesHydroseeding WorkSamsiah TolaNo ratings yet

- Delta Calculations LTSW Module 2 EXERCISEDocument20 pagesDelta Calculations LTSW Module 2 EXERCISEdraganNo ratings yet

- Forty Nine PROCESSES OF PM BaselineDocument2 pagesForty Nine PROCESSES OF PM BaselineChristopher OjoNo ratings yet

- Teoria Do MSR ADocument4 pagesTeoria Do MSR AAlexandre Valeriano da SilvaNo ratings yet

- SDH Maintenance Guide For Huawei MSTP Product Family V1.0Document1 pageSDH Maintenance Guide For Huawei MSTP Product Family V1.0MotokNo ratings yet

- DevelopmentThatPays ScrumToScrumban CheatSheet 0 - 1 PDFDocument1 pageDevelopmentThatPays ScrumToScrumban CheatSheet 0 - 1 PDFnetcito1No ratings yet

- Life Cycle Posters 11x17 - AGILEDocument1 pageLife Cycle Posters 11x17 - AGILEAhmedNo ratings yet

- Autonomous Maintenance Part 1Document40 pagesAutonomous Maintenance Part 1mdkhandaveNo ratings yet

- D3 - T4 - Rules-092015Document68 pagesD3 - T4 - Rules-092015trollmindNo ratings yet

- Module 27. Process CapabilityDocument44 pagesModule 27. Process Capabilitytaghavi1347No ratings yet

- 08 Mistake Proofing v20130529Document58 pages08 Mistake Proofing v20130529Adrian JoelNo ratings yet

- Line Balance 059Document39 pagesLine Balance 059smitaNo ratings yet

- BPG - 5S-System (Fivess)Document28 pagesBPG - 5S-System (Fivess)Roland von KurnatowskiNo ratings yet

- Process Analysis - HoutDocument12 pagesProcess Analysis - HoutANN MARY JOSE PGP 2023-25 BatchNo ratings yet

- Resume: Wasi M AhmedDocument1 pageResume: Wasi M AhmedWasim ahmedNo ratings yet

- 4.2 Costs-Scale-of-Production-and-Break-Even-Analysis - HandoutDocument16 pages4.2 Costs-Scale-of-Production-and-Break-Even-Analysis - Handoutdenny_sitorusNo ratings yet

- Commerce Department SESSION: 2 2021/2022 Dpa10023-Computer Application in Accounting Laboratory Exercise 3 (5%)Document5 pagesCommerce Department SESSION: 2 2021/2022 Dpa10023-Computer Application in Accounting Laboratory Exercise 3 (5%)faza7672No ratings yet

- LEAN SCM Hidden FactoryDocument33 pagesLEAN SCM Hidden FactoryJulian KalacNo ratings yet

- SCRUM (Mind Mapping)Document1 pageSCRUM (Mind Mapping)Rounak VijayNo ratings yet

- How To Accelerate The ProjectDocument7 pagesHow To Accelerate The Projectpriyow2000No ratings yet

- 02-Value Proposition CanvasDocument11 pages02-Value Proposition CanvasMae Antonette TabanaoNo ratings yet

- Road To I PT Final PosterDocument1 pageRoad To I PT Final PosterChristian Trésor KandoNo ratings yet

- Bu01a02a01 01enDocument15 pagesBu01a02a01 01enNguyen ThuongNo ratings yet

- S4H - 1614 Implementing SAP S4HANA Cloud Private EditionDocument12 pagesS4H - 1614 Implementing SAP S4HANA Cloud Private EditionYasai MoyashiNo ratings yet

- Excavation ChecklistDocument4 pagesExcavation ChecklistCINQO HSENo ratings yet

- Analysis within the Systems Development Life-Cycle: Book 3 Activity Analysis — The DeliverablesFrom EverandAnalysis within the Systems Development Life-Cycle: Book 3 Activity Analysis — The DeliverablesNo ratings yet

- A Case Study Based Digitalization TrainingDocument6 pagesA Case Study Based Digitalization Trainingswapnil koleNo ratings yet

- Building Capabilities For AgilityDocument6 pagesBuilding Capabilities For Agilityswapnil koleNo ratings yet

- 101 Wellness GuideDocument16 pages101 Wellness Guideswapnil koleNo ratings yet

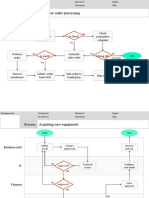

- Example - Flowchart - 101Document4 pagesExample - Flowchart - 101swapnil koleNo ratings yet

- 5s Implementation Guidelines PresentatioDocument28 pages5s Implementation Guidelines Presentatioswapnil koleNo ratings yet

- OPSYS Presentation EDDs 180619Document24 pagesOPSYS Presentation EDDs 180619gabriela.corina337006No ratings yet

- Margaret Atwood'S Maddaddam Trilogy: Postmodernism, Apocalypse, and RaptureDocument23 pagesMargaret Atwood'S Maddaddam Trilogy: Postmodernism, Apocalypse, and Rapturetordet13No ratings yet

- Sociology in Our Times The Essentials 10th Edition Kendall Test BankDocument34 pagesSociology in Our Times The Essentials 10th Edition Kendall Test Banklyeliassh5100% (27)

- The Law On Obligations and ContractsDocument7 pagesThe Law On Obligations and ContractsRomilyn GregorioNo ratings yet

- William Kentridge ReviewDocument2 pagesWilliam Kentridge Reviewtyrus63No ratings yet

- Report Writing Assignment-1Document3 pagesReport Writing Assignment-1Waqas AbbasNo ratings yet

- AP World History E09 1900 To The Present GlobalizationDocument7 pagesAP World History E09 1900 To The Present GlobalizationFatih HoxhaNo ratings yet

- As 1988.1-2006 Welding of Ferrous Castings Steel CastingsDocument8 pagesAs 1988.1-2006 Welding of Ferrous Castings Steel CastingsSAI Global - APACNo ratings yet

- 48 Sociology: B.A./B.Sc.: Elective and OptionalDocument4 pages48 Sociology: B.A./B.Sc.: Elective and OptionalMNo ratings yet

- Wykład V.L.SmithDocument20 pagesWykład V.L.SmithprnoxxxNo ratings yet

- WYOPCC Triage Assessment Composite Report and Analysis - ANTHONY RAMSDEN Case.Document16 pagesWYOPCC Triage Assessment Composite Report and Analysis - ANTHONY RAMSDEN Case.PoliceCorruptionNo ratings yet

- Cultural Immersion Assignment 3Document7 pagesCultural Immersion Assignment 3api-301812156No ratings yet

- Railways and Tourism: Deccan OdysseyDocument4 pagesRailways and Tourism: Deccan OdysseyravilullaNo ratings yet

- NF-e GuideDocument468 pagesNF-e GuideDennerAndradeNo ratings yet

- Develop A Brand NameDocument6 pagesDevelop A Brand NameMutya Neri CruzNo ratings yet

- Brach Eichler LLC: BE:10982527.1/UNI285-278205Document75 pagesBrach Eichler LLC: BE:10982527.1/UNI285-278205RHTNo ratings yet

- Day 2 Determining The Truthfulness and Accuracy of The Material ViewedDocument17 pagesDay 2 Determining The Truthfulness and Accuracy of The Material ViewedVincent Ian TañaisNo ratings yet

- Alibaba Cloud Product ScorecardDocument21 pagesAlibaba Cloud Product ScorecardpeterorNo ratings yet

- Chapter 1 and 2 - LeviDocument43 pagesChapter 1 and 2 - LeviQuinn Fu LimNo ratings yet

- St. Gregory Palama, Freedom and The SelfDocument4 pagesSt. Gregory Palama, Freedom and The SelfSoponaru StefanNo ratings yet

- Core Network NFV Proposal For TelcelDocument8 pagesCore Network NFV Proposal For TelcelTELCELINNo ratings yet

- Marcos Vs Manglapus Case DigestDocument6 pagesMarcos Vs Manglapus Case Digestzanjknight100% (1)

- 01 Laboratory Exercise 1 - PAYUANDocument41 pages01 Laboratory Exercise 1 - PAYUANPhilip Dan Jayson LarozaNo ratings yet

- Raymond's Run-SummaryDocument3 pagesRaymond's Run-SummaryLameesNo ratings yet

- Cips 2012 0012Document68 pagesCips 2012 0012Pravin ChallawarNo ratings yet

- Timetable 22-23 14 Juli 2022Document18 pagesTimetable 22-23 14 Juli 2022Luhut GultomNo ratings yet

- Day 2 Stanza 2 - 605886e13848eDocument23 pagesDay 2 Stanza 2 - 605886e13848emanjeetkaur1556No ratings yet