Professional Documents

Culture Documents

UMA0082W-ButterflyValves375-376-377 385-386-387-EN

UMA0082W-ButterflyValves375-376-377 385-386-387-EN

Uploaded by

Duri DuriCopyright:

Available Formats

You might also like

- Hydraulic Wellhead Control Panel For Gas WellDocument105 pagesHydraulic Wellhead Control Panel For Gas WellAlok100% (2)

- Ib0600383engc PDFDocument293 pagesIb0600383engc PDFJoshuesito Cruz100% (3)

- Instruction Manual FR-D740 & FR-D720S 2009Document296 pagesInstruction Manual FR-D740 & FR-D720S 2009Rene ErkmanNo ratings yet

- Actuator srn0053401s OmalDocument25 pagesActuator srn0053401s OmalAhmed MoharramNo ratings yet

- Fr-A8Nc: Inverter Instruction ManualDocument102 pagesFr-A8Nc: Inverter Instruction Manualkhaja avezNo ratings yet

- Varia DorDocument296 pagesVaria DorGabriel Esteban VenegasNo ratings yet

- Fr-A8Nc: Inverter Instruction ManualDocument98 pagesFr-A8Nc: Inverter Instruction Manualtaleb 6269No ratings yet

- FR-E720-0.1K (SC) To 15K (SC) FR-E740-0.4K (SC) To 15K (SC) FR-E720S-0.1K (SC) To 2.2K (SC) FR-E710W-0.1K To 0.75KDocument349 pagesFR-E720-0.1K (SC) To 15K (SC) FR-E740-0.4K (SC) To 15K (SC) FR-E720S-0.1K (SC) To 2.2K (SC) FR-E710W-0.1K To 0.75KHoa Nguyen VanNo ratings yet

- D700 Instruction Guide PDFDocument300 pagesD700 Instruction Guide PDFLâm MộcNo ratings yet

- Manual Del Variador F700 InglesDocument341 pagesManual Del Variador F700 InglesMiguel RojasNo ratings yet

- Manual FR - A8nceDocument90 pagesManual FR - A8nceSamuel Martinez RomeroNo ratings yet

- Ib 0600168 EngdDocument112 pagesIb 0600168 EngdLuiz SilvaNo ratings yet

- Fre 700Document320 pagesFre 700Giang BùiNo ratings yet

- Mitsubishi d700 Manual - 001Document1 pageMitsubishi d700 Manual - 001Amit PaulNo ratings yet

- VSD FR-D700 Ib0600353enggDocument301 pagesVSD FR-D700 Ib0600353enggChris GavevaNo ratings yet

- Mitsubishi FR A7NC ManualDocument106 pagesMitsubishi FR A7NC ManualIlham AnandaNo ratings yet

- Mitsubishi FR-F700 ManualDocument280 pagesMitsubishi FR-F700 ManualGaby Djin ThemixNo ratings yet

- F 700 Users ManualDocument270 pagesF 700 Users ManualallanbatiancilaNo ratings yet

- Fracture ToughnessDocument286 pagesFracture ToughnessHusen TaufiqNo ratings yet

- FR-F740-EC (European Version Version Applied Manual) - Ib0600193engaDocument262 pagesFR-F740-EC (European Version Version Applied Manual) - Ib0600193engafreitaswalterNo ratings yet

- FR Cc2 ManualDocument176 pagesFR Cc2 Manualesau hernandezNo ratings yet

- Pulse Valve User Manual 2892 DDocument14 pagesPulse Valve User Manual 2892 DGrant SukatiNo ratings yet

- Get0792 001aDocument97 pagesGet0792 001aintegrasir369No ratings yet

- KDR728BTJ Stereo JVCDocument87 pagesKDR728BTJ Stereo JVCHernánLeograndeNo ratings yet

- SwitchDocument2 pagesSwitchFinewoods ColombiaNo ratings yet

- Inverter F800 Instruction Manual (Hardware) : Fr-F802 (Separated Converter Type)Document108 pagesInverter F800 Instruction Manual (Hardware) : Fr-F802 (Separated Converter Type)xuan leNo ratings yet

- E500 Ac Drive Genis Kullanim KilavuzuDocument247 pagesE500 Ac Drive Genis Kullanim KilavuzuQamar AltafNo ratings yet

- KD R428 PDFDocument55 pagesKD R428 PDFJose HerreraNo ratings yet

- JVC KD-S28Document55 pagesJVC KD-S28fcjjcfNo ratings yet

- Mitsubishi f800 Manual 1 150Document150 pagesMitsubishi f800 Manual 1 150rodrigoNo ratings yet

- FR-F800 Instruction Manual PDFDocument614 pagesFR-F800 Instruction Manual PDFelivandrojuniorNo ratings yet

- FR-F700-NA (North American Version Applied Manual) - Ib0600217engbDocument270 pagesFR-F700-NA (North American Version Applied Manual) - Ib0600217engbfreitaswalterNo ratings yet

- FR-F800 Detailed (B)Document638 pagesFR-F800 Detailed (B)Leandro SilvaNo ratings yet

- Mitsubishi FR Configurator SW3 ManualDocument167 pagesMitsubishi FR Configurator SW3 Manualahmadba70No ratings yet

- Manual - F800 ProfibusDocument96 pagesManual - F800 ProfibusalmaroadieNo ratings yet

- I-De-3010.0j-1223-940-Ie3-231 - 0 - Emergency Offloading System - GaDocument4 pagesI-De-3010.0j-1223-940-Ie3-231 - 0 - Emergency Offloading System - GaDiego NogueiraNo ratings yet

- Huong Dan Cai DatDocument108 pagesHuong Dan Cai DatĐình Vũ CaoNo ratings yet

- Fr-A8Np: Inverter Instruction ManualDocument92 pagesFr-A8Np: Inverter Instruction ManualAlberto Suazo BasaezNo ratings yet

- Instruction Manual Profibus-Dp Fr-A8npDocument92 pagesInstruction Manual Profibus-Dp Fr-A8npIssao WatanabeNo ratings yet

- Drawn On Zuken E3 File Stored in Teamcenter Engineering Do Not Scale Do Not Modify Manually All Dimensions in MMDocument19 pagesDrawn On Zuken E3 File Stored in Teamcenter Engineering Do Not Scale Do Not Modify Manually All Dimensions in MMOunna PechNo ratings yet

- Washing Machine 2006 MOON - Service ManualDocument31 pagesWashing Machine 2006 MOON - Service ManualMarcGarciaNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- FR A520 PDFDocument257 pagesFR A520 PDFNguyen LuongNo ratings yet

- Ib 0600634 EngaDocument142 pagesIb 0600634 Engaibrahim AdıbelliNo ratings yet

- Mitsubishi A800 ManualDocument714 pagesMitsubishi A800 ManualAlejandro Garcia50% (2)

- (For VIEW) NJoy UserManual UPS Balder 1500 3000Document37 pages(For VIEW) NJoy UserManual UPS Balder 1500 3000Octavian TontzNo ratings yet

- Simbolos & IdentificacaoDocument81 pagesSimbolos & IdentificacaoDenis SilvaNo ratings yet

- Bien TanDocument262 pagesBien TanLê Đăng HòaNo ratings yet

- User'S Manual: (Specification and Part Names)Document10 pagesUser'S Manual: (Specification and Part Names)Hewa PCNo ratings yet

- MV110 en Ds053rev12Document29 pagesMV110 en Ds053rev12elkin carrilloNo ratings yet

- Polypropylene Strapping Machine: Technical DataDocument9 pagesPolypropylene Strapping Machine: Technical DataSkander BhsNo ratings yet

- Healthview Mono Interconnect Diagram: Section 6Document15 pagesHealthview Mono Interconnect Diagram: Section 6alexis marcanoNo ratings yet

- Iphone 6 Schematic Kythuatphone - VN PDFDocument55 pagesIphone 6 Schematic Kythuatphone - VN PDFmichelle0% (1)

- Mitsubishi E500 ManualDocument221 pagesMitsubishi E500 ManualNguyen Thanh Dai100% (1)

- lb2300 Single Cup PDFDocument21 pageslb2300 Single Cup PDFHUY NGUYENNo ratings yet

- 51AKB / 51AKC: Owner'S ManualDocument10 pages51AKB / 51AKC: Owner'S ManualAlfonso ArroyoNo ratings yet

- Ib 0600531 EnggDocument165 pagesIb 0600531 EnggĐinh Vạn ThànhNo ratings yet

- Druckmessumformer, Typ S-10 Pressure Transmitter, Model S-10 Transmetteur de Pression, Type S-10 Transmisor de Presión, Modelo S-10Document100 pagesDruckmessumformer, Typ S-10 Pressure Transmitter, Model S-10 Transmetteur de Pression, Type S-10 Transmisor de Presión, Modelo S-10Bob RhemNo ratings yet

- Price List Vacuum Pumps 2-2022 PDFDocument26 pagesPrice List Vacuum Pumps 2-2022 PDFЭльшад АскеровNo ratings yet

- Cilindros FESTODocument16 pagesCilindros FESTOjoliporNo ratings yet

- Awwa C561 Fabricated Stainless Steel Slide GatesDocument36 pagesAwwa C561 Fabricated Stainless Steel Slide GatesLuis DanielNo ratings yet

- Specification Plumbing SystemDocument16 pagesSpecification Plumbing SystemGhiovani DayananNo ratings yet

- 8490-25a Emsco FC-1600 7500psiDocument13 pages8490-25a Emsco FC-1600 7500psimrcaglarNo ratings yet

- IPC IntroductionDocument41 pagesIPC Introductionram salunkheNo ratings yet

- 2063 72040 Tipicos InstrumentacionDocument42 pages2063 72040 Tipicos InstrumentacionZillur RahmanNo ratings yet

- A17Document1 pageA17liviu_dovaNo ratings yet

- Project Standard Specification: Pipe Expansion Fittings and Loops 15121 - Page 1/5Document5 pagesProject Standard Specification: Pipe Expansion Fittings and Loops 15121 - Page 1/5adel rihanaNo ratings yet

- Installation, Operation & Maintenance Manual - Original VersionDocument11 pagesInstallation, Operation & Maintenance Manual - Original VersionAli AafaaqNo ratings yet

- PMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetDocument2 pagesPMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetfarhaNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- Flender - Gear MotorDocument42 pagesFlender - Gear Motorikuzma_10% (1)

- TG-06: COA Guidelines For Container Interchange Criteria CIC-2Document6 pagesTG-06: COA Guidelines For Container Interchange Criteria CIC-2Sev BangunNo ratings yet

- KSR Float Level Switch NewDocument20 pagesKSR Float Level Switch NewMadel D.No ratings yet

- DKC RamblockDocument13 pagesDKC RamblockFLAVIO DOSE RAMIREZNo ratings yet

- API 650 Part 9 - 2001 Welded TanksDocument20 pagesAPI 650 Part 9 - 2001 Welded TanksHassan Ali SadiqNo ratings yet

- Instrument Manifold Systems: Instrument, Direct, and Remote-Mount Manifolds and Modular SystemsDocument30 pagesInstrument Manifold Systems: Instrument, Direct, and Remote-Mount Manifolds and Modular Systemskumar100% (1)

- Fisher GX Control Valve and Actuator System: Scope of ManualDocument44 pagesFisher GX Control Valve and Actuator System: Scope of ManualSaasiNo ratings yet

- Flanges: SI SMEDocument16 pagesFlanges: SI SMEbalaNo ratings yet

- Chemtrol Samil - Instrument D/SDocument48 pagesChemtrol Samil - Instrument D/SAnonymous OFP2ygPIdNo ratings yet

- Chapter 9Document24 pagesChapter 9alcaponeNo ratings yet

- Stainless Steel Flow Control Equipment For The Food, Dairy, Beverage, Pharmaceutical, Biotech, Personal CareDocument6 pagesStainless Steel Flow Control Equipment For The Food, Dairy, Beverage, Pharmaceutical, Biotech, Personal CareJuanpablo OXNo ratings yet

- ER-56-03 EN Packager Standards Skid Design and FabricationDocument4 pagesER-56-03 EN Packager Standards Skid Design and FabricationCamilo Andres Cardozo FajardoNo ratings yet

- DANAIS MT II CL 150 ENDocument28 pagesDANAIS MT II CL 150 ENLasombra DelPatoNo ratings yet

- Sump Discharge Piping - ISOMETRIC DrawingDocument9 pagesSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNo ratings yet

- Calculation Cover Sheet: File Calc No Project Title Client Proj No Phase/CTRDocument26 pagesCalculation Cover Sheet: File Calc No Project Title Client Proj No Phase/CTRM ANo ratings yet

- Knife Gate ValveDocument7 pagesKnife Gate ValveAbdul RaheemNo ratings yet

- Sec 410-4625Document12 pagesSec 410-4625Automa Viet NamNo ratings yet

UMA0082W-ButterflyValves375-376-377 385-386-387-EN

UMA0082W-ButterflyValves375-376-377 385-386-387-EN

Uploaded by

Duri DuriOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UMA0082W-ButterflyValves375-376-377 385-386-387-EN

UMA0082W-ButterflyValves375-376-377 385-386-387-EN

Uploaded by

Duri DuriCopyright:

Available Formats

IT

EN

DE

FR

ES

INSTRUCTION MANUAL

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 1

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

INDEX:

FR

Pag.

GENERAL FEATURES

ES

1. 3

2. WORKING CONDISTIONS 3

3. OPERATING INFORMATION 4

4. SAFETY INFORMATION 5

5. INSTALLATION INSTRUCTION 6

6. MATERIALIAL AND THEIR DURABILITY 7

7. MAINTENANCE 7

8. VERSIONI SPECIALI 9

9. STORAGE 9

10. TROUBLE SHOOTING 10

11. DISPOSAL OF PRODUCTS AT THE END OF LIFE 11

12. DECLARATION CONFORMITY 11

Environmentally friendly: Environmentally friendly: under the green leaf icon you can find the

instructions for a correct and environmentally friendly handling of the product.

All data and features in this manual may be changed at any time and with no notice for the implementation of technical improvements.

Therefore they can not be considered as binding for the delivery.

FOREWORD

The present User’s Installation and Maintenance Manual has been edited in conformity with:

-2014/68/EU Directive “Pressure equipment” PED

-2006/42/EC Directive “Machinery” MD

-2014/34/EU Directive “Equipment and protection systems designated to be used in potentially explosive atmospheres” ATEX

The following standards/technical specifications also apply:

-UNI CEN/TS 764-6 Pressure equipment Part 6: Operating instructions structure and contents.

It’s up to the reader to find his own product, and the correct operating conditions, possibly referring to the attached drawings.

Below you will find the safety instructions, the minimum information for storage / warehousing, the installation, the commissioning, the

maintenance and the instructions for disposal of products at the end of their life.

The company disclaims any liability for damage caused by improper use, even if partial, in respect to the information contained in

this manual.

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 2

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

1. GENERAL FEATURES

FR

OMAL butterfly valves, available in wafer or lug version from DN 40 to DN 600 (lug DN 300), are designed and manufactured to be

used in most applications in all industrial fields.

ES

- General requirements in accordance with UNI EN593

- Face to face as per EN 558 series 20

- Tightness at 16 bar or 10 bar according to EN 12266-1 rate A

- Integral sealing (with liner vulcanized on hard ring) which avoids any contact between fluid and valve body.

- Sealing design allowing perfect adherence to the valve body and perfect tightness to the flanges, without additional parts.

- Clamping between flanges does not influence the torque of the valve.

- Lapped disc edges that allows better tightness, reduced torque and low wear of the liner.

- Bushes to support the shaft.

- Coupling between stem and disc with two shafts (better Kv) carried out with no additional fittings (e.g. screws, bolts, pins, etc.) to

avoid any risk of corrosion and breaking.

- Valve neck with top work as per EN ISO 5211 for easy connections with all different types of actuators.

- All components properly treated against corrosion.

2. WORKING CONDITIONS

2.1 Fluids

Valves are designed and tested to be used with all fluids belonging to Group 1, as per 2014/68/EU either liquid or gaseous.

The operator or the Engineering company in charge of the project will be responsible for the selection of the valve materials che-

mically and physically compatible with the intercepted fluid. To the best of their abilities OMAL technical staff will be pleased to help

customers select the best product for a specific application. However the operator or the Engineering company will be responsible

for the final selection.

2.2 Working pressure

The Omal butterfly valves are designed for a continuous use at: PN 16 bar from DN 40 to DN 300, PN 10 bar from DN 350 to DN

600. The Maximum Working pressure must be equal to PN valve.

2.3 Working temperature

The butterfly valves type 375 - 376 - 377 - 385 - 386 - 387 series (A 536 spheroidal cast iron body) are designed and tested for a

continuous use keeping the PN value unchanged throughout the whole range of temperatures. Below the maximum and minimum

working temperatures for seal material:

NBR: - 23°C + 82°C

EPDM: - 25°C + 135°C

FKM: - 10°C + 190°C

WARNING

Elastomer working temperatures are to be considered as approximate temperatures with inert fluids. A slight chemical sensitivity of

the elastomers to the intercepted fluids can dramatically reduce the working temperature range.

2.4 Lubrication

The butterfly valves are factory lubricated for the standard working condition life. During maintenance and reassembling, check that

the lubricant to be used is suitable for contact with the seal material, with the fluid intercepted and with the operating conditions.

2.5 External protection

OMAL butterfly valves are suitable for indoor and outdoor installation. The cast-iron body is external protected from corrosion by

160÷200 microns of epoxy painting. The shaft and the disc are in stainless steel or protected by the corrosion

This normally allows to satisfy applications where a protection class C3 is required according to ISO 12944-6

2.6 Marking and classification

The following information are marked on the butterfly valves body and / or with an additional label:

• Manufacturer’s brand and name

• Nominal Size

• Nominal pressure

• Heat number

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 3

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

• Address of the manufacturer

• Model / Product Code

• Min./max. Temperature

FR

• Production date

• Materials (body, disc and seal)

ES

• CE marking according to Directive 2014/68/EU

3. OPERATING INFORMATION

The butterfly valves can be supplied bare shaft, provided with a lever for manual operation or equipped with an electric or pneumatic

actuator.

3.1 Handle-operated

If a valve is provided with a handle, the handle will have to be assembled in such a way that, viewed from above, it will have to be

turned clockwise to close the valve and counterclockwise to open it. With a closed valve, the handle needs to be in its normal position

with respect to the pipeline while with an open valve it needs to be parallel to the pipeline. The handle needs to be stopped (and even

locked) in ten different positions angularly equidistant from one another all along the valve stroke.

3.2 Automated valve

The automated valves can be used in a lot of applications where it is necessary also to guarantee full control, efficiency and duration

in service. The connection between valve and actuator can be of three types:

A) DIRECT MOUNTING

B) MOUNTING PLATE CONNECTION

C) BRACKET & JOINT CONNECTION

A B C

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 4

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

A) DIRECT MOUNTING

Valve actuator direct mounting is the best solution to avoid plays between valve stem and actuator drive shaft. For a direct mounting

you should have the same standard flange connection on valve and actuator as well as the valve stem dimensions that fit perfectly

FR

with the actuator drive. Before installation please verify that the actuator and valve flange ISO connections are the same size; verify

that the valve stem size and shape is suitable for direct mounting, if necessary use a drive reduction. Fit the valve stem into the actua-

ES

tor drive shaft connection, and bolt together the two ISO flanges.

B) MOUNTING PLATE CONNECTION

In case direct mounting is not possible cause of little differences in actuator/valve flanges or drives sizes, mounting plates adapters

with suitable flanges dimensions allows an easy connection living a sufficient space for the valve/actuator drive adapter.

C) BRACKET & JOINT CONNECTION

Wherever for technical reason the plant installation requires a distance between actuator and valve, or the valve flange and/or stem

are not standard, and in any case, where the valve/actuator connection could not be possible, a bracket and joint is the right answer.

The Bracket is a steel bridge that allows to connect the valve with is own flange connection in one side and with the suitable actuator

connection into the opposite side, living a space in between for a steel joint connection.

The joint allows a drive connection between the actuator and the valve stem indispensable in case of stem key drive and flat head.

Chose the suitable flange bracket and the required joint connections to fix the actuator onto the valve very tight without any plays.

OMAL actuator with its draining channels system on the flange connection pattern is especially designed for valve direct mounting.

This system allows to drop away any possible flow coming from the valve stem that with valve/actuator direct mounting could damage

the actuator.

Coppia di serraggio delle viti

SIZE TORQUE Nm

M5 5-6

M6 10-11

M8 20-23

M10 45-50

M12 80-85

3.2.1 Cycle time

The cycle time depends on the operating device put on the valve. Please read the instructions about the installed actuator. The inter-

face between valve and actuator complies with ISO 5211

3.2.2 Valve stroke

the construction type of the valve (centric drive) guarantees the seal a few degrees before complete closure, depending on the size.

The actuated valves are adjusted during assembly to limit the actuator closing to 87 ° - 88 °, an angle that allows the valve seal to

the nominal pressures, avoiding unnecessary increase of the drive torques. Increasing the run up to 90 °, provide a long life of the

product in service

The stroke adjustment up to 90 °, allows the recovery of the wear of the gaskets greatly increasing the life of the product.

For the assembly of valves with actuators and actuator stroke adjustment refer to the specific documentation available on the website:

www.omal.it

4. SAFETY INFORMATION

• When you receive a product, make sure it is in perfect conditions. Do not install a product which comes in a damaged box

especially if it shows signs of damage.

• While the valve is being installed, make sure that the pipeline and the working environment are perfectly clean. The presen-

ce of dirt and particles can seriously affect the tightness of the valve. If you use a sealing product, either tape or paste, make sure that

it will not end up in the valve body or in the sealing areas.

• If an aggressive or dangerous fluid flows through the valve, make sure the material the valve is made of is compatible with

the fluid. If you have any doubt, please contact OMAL technical staff who will carefully evaluate the chemical compatibility of the fluid

with the valve.

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 5

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

• A valve is a safe product provided that it is properly installed between flanges on a plant. If you want to test a valve at the

bench, especially a pneumatically operated one, make sure there are protections enough to prevent objects and parts of your body

FR

to get caught between the butterfly and the valve body. Please remember that a valve closes in less than a second and with

enough energy to damage itself and a careless operator.

ES

• Before installing a valve, make sure that the operating temperature and pressure are compatible with the parameters stated

by the manufacturer.

• If a valve is used as an END OF LINE valve, please remember that it has not been tested for that specific function. For an

END OF LINE application, please note that the valve PN corresponds to 60% of the PN stated for an installation in a pipeline.

• Never try to disassemble a valve or any of its parts when there is fluid in the pipeline regardless of the pressure

• Never remove the valve shafts when there is pressure in the pipeline as the butterfly could be swallowed by the fluid under

pressure in the pipeline

5. INSTALLATION

While carrying out the risk assessment for this kind of product as per 2014/68/EU - PED it was impossible to fully evaluate the risks

related to traffic, wind, earthquakes etc as every evaluation was strictly related to the type of application and installation.

The owner of the plant will have to carry out this evaluation, where necessary, along with the risk assesment for the plant itself.

OMAL butterfly valves are very easy to install and if you follow some basic installation procedures, the product will perform at its best.

• never try to force a valve between flanges which are not open enough to allow the insertion of the valve as you might seriou-

sly damage the sealing areas on the flanges (fig. 1)

• while you insert the valve between the flanges and you subsequently block them, the disc must be kept in an half-open

position without exceeding the valve edges (fig. 2)

• support the butterfly by means of two tie-rods which, going through the holes on the flanges and the slots on the valve body,

will allow a first generic centering between the flanges. Slightly close the 4 tie-rods (opposite to one another) until the valve is slightly

fixed and then center the valve body carefully with respect to the pipeline flanges (a mistake of +- 1mm on a DN 50 and proportionally

of +-5mm on a DN 300 is more than acceptable).

Close the 4 tie-rods until the valve is fully blocked, open the butterfly completely (fig 3) and then insert and close all other bolts requi-

red by the flanges.

The valve is not particularly sensitive to the torque generated by closing the bolts on the flanges. Please apply the torque stated in

the relevant standard also considering the material of bolting.

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 6

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

6. MATERIALS AND THEIR DURABILITY

FR

To ensure the full reliability of the valve, it is recommended to carry out at least once a year, a check of the efficiency level of the

plant, changing all the worn-out parts promptly where leakage or straining occur, both inside the pipeline and towards the outside of

the valve. The life time of the consumable parts can be summarized as follows. Spare parts kits are available for valves maintenan-

ES

ce.

DN 40÷80 100 125 150 200 250 300 350 400 450 500 600

Num. of cycles 100.000 90.000 90.000 80.000 70.000 60.000 50.000 45.000 40.000 35.000 30.000 20.000

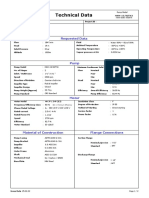

7. MAINTENANCE

The product maintenance must be done by trained and qualified people with proper tools, we recommend checking the correct

replacement performing a tightness and functional tested on the valves.

- Remove the spring pins with a punch (9) or the shaft retention flanges, in the case of measures of more than ND 300.

- Remove the upper (4) and lower (5) shafts. For measures of more than ND 300, the lower shaft is not prevalent and can be remo-

ved using an M16 bolt.

- Remove the disc (2). The operation is facilitated by rotating the disk 15° from the closed position.

- Remove the main seal (3) noting that in the flange are, it has two different diameters; obviously, it must be extracted by pushing

on the smaller diameter. It is recommended to use a hydraulic press with thrust plate diameter of 15 mm more than the valve ND.

- Check that the o-rings (6), also came out with the main seal; if not, remove them from the valve body.

- Remove the upper bushing (7)

- The bushings (8) are not normally replaced during maintenance. Should it be necessary to remove them, contact our technical

department for instructions.

- Place the o-rings (6) and (10) in their seats after thorough greasing.

- Insert the main seal (3) into the valve body, aligning the shaft holes as well as possible with the corresponding holes in the body.

- Insert the disc (2), aligning the shaft holes as well as possible with the corresponding holes in the seal. Keep the disc rotated at

15°.

- insert the upper bushing (7)

- Reposition the shafts in their relative seats, until the groove of the rod reaches the same level as the pin hole (up to ND 300 only).

During insertion, there may be a slight resistance due to the slight misalignment of the components; use moderate force to insert

the shafts; where necessary re-check the alignment of the components. Pay attention to the groove on the head of the upper shaft,

which must be exactly in line with the butterfly valve position. Insert the pins or assemble the shaft holder flanges.

- Always run a valve seal test before recommissioning the system.

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 7

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

1 Body

2 Disc

FR

3* Liner

4 Upper shaft

ES

5 Lower shaft

6* Lower O-ring

7* Upper bush LUG BODY

8 Shaft bush

9* Elastic pin

10* Shaft O-ring

* Spare parts kit (KGF)

9

8

10

8

6 2

*

3 5

DN 350 ÷ DN 600

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 8

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

WARNING

To make sure there is no pressure in the pipeline, before servicing a valve. If a dangerous or aggressive fluid flows through the pipe-

line, always wash the pipeline as suggested by the manufacturer. Always wear suitable protections while you open the connections

FR

between valve and pipeline.

As products change and evolve in time, please order and use original spare parts only (as per specific instructions accompanying

ES

each product). When you place an order, always mention the product code and the production date stamped on the valve and you will

get the latest possible version of the spare part you need. If you have any doubt, please contact OMAL technical staff who will help

you keep the product as efficient as possible.

8. SPECIAL VERSION

The butterfly valves, suitable for use in potentially explosive atmospheres in compliance with the requirements of Directive 2014/34 /

EU, is available on request by applying an antistatic device which keeps the valve body, stem and disc in continuity and serves as a

grounding point.

The butterfly valves in compliance with the Atex Directive are suitable for being applied on equipments belonging to GROUP II Category

2, suitable for zones 1 & 2 GAS and 21 & 22 DUST.

9. STORAGE

Choose clean sites for storage, not excessively humid and with temperatures between –10 and +60°C. If the products are to be stored

for long periods of time, it is best not to remove them from their protective packaging. Keep the valves in the package during storage.

If the valves are not packaged, must be protected the ends in order to avoid liquid or other to penetrate during storage and thus damage

the disc or the seals.

If the valves are to be stored for long periods of time, then they should be inspected periodically: check in particular the possible presen-

ce of rust, oxidation, paint nicks or even partial unscrewing of the closures. It is also recommended to perform a complete dry cycle of

opening and closing of the valve.

The seals are subject to aging and lose of their characteristics: for this reason, after storage periods of more than two years, it is recom-

mended to check the functionality and the seals before mounting the valve in the line.

Protect the seals from sun light (UV rays cause seal aging).

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 9

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

10. TROUBLE SHOOTING

FR

POTENTIAL EFFECTS OF FAILURE POTENTIAL FAILURE MODE SOLUTIONS

Check the maneuvering system

ES

Incomplete closing of the disc

/ Contact OMAL

Replace worn parts as per instruction

Liner worn

manual

Valve leakage Chemical incompatibility with valve con-

Contact OMAL

struction materials (gasket and / or lens)

Check the chemical compatibility between

Disc worn the media and the construction materials

/ Contact OMAL

Replace worn parts as per instruction

manual

Damage on the stem seat or disc liner Check the chemical compatibility between

Leakage from Upper or Lower Shaft

the media and the construction materials

/ Contact OMAL

Damage on body Contact OMAL

Driving system fault

Disc / stem gripping

Valve blocked Contact OMAL

Stem break

Actuator- valve connection’s break

Disc / stem gripping Contact OMAL

Check the chemical incompatibility with

Increased maneuvering time / shoo-

Liner hardening valve construction materials.

ting motion

/Contact OMAL

Partial actuator gripping Contact OMAL

Actuator cannot perform the maneuver Check actuator dimensioning and verify

Insufficient air supply to produce the that actuator fluid pressure is equal to or

required torque greater than nominal pressure on plate

Mechanical stop (if present) not properly

Adjust the stroke limiters

adjusted

Inadequate rotation angle

Stem gripping Contact OMAL

Remove the valve and check its operation

Possible presence of blocked foreign body

on the bench

Incorrect fIxing between actuator outlet Check for proper connecting kit between

hole and valve stem valve and actuator

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 10

INSTRUCTION MANUAL

IT

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

EN

DE

11. DISPOSAL OF PRODUCTS AT THE END OF LIFE

FR

The OMAL butterfly valves are designed so that when they are at the end of their life cycle they can be completely disassembled,

separating the different materials for the proper disposal and/or recovery. All materials have been selected to ensure minimal envi-

ronmental impact, health and safety of personnel during their installation and maintenance, provided that, during use, they are not

ES

contaminated by hazardous substances.

The personnel in charge of the product disposal/recovery, must be qualified and equipped with appropriate personal protective equi-

pment (PPE), according to the product size and the type of service for which the device was intended. The management of waste

generated during the installation, maintenance or due to the product disposal, is governed by the rules in force in the country where

the product is installed, in any case, the following are general guidelines:

- The metal components (cast iron/steel…) can be restored as raw material;

- Seals/sealing elements (NBR, FKM, EPDM...), as contaminated by fluids from other materials and lubrication, must be disposed of.

- The packaging materials that come with the product, should be transferred to the differentiated collection system available in the

country.

12. DECLARATION CONFORMITY

OMAL butterfly valves have been designed, manufactured and tested to meet the requirements of the following European standards

and are marked, where provided, with the relative CE conformity marking:

• 2014/68/EU Directive “Pressure equipment” PED

• 2006/42/EC Directive “Machinery” MD

• 2014/34/EU Directive “Equipment and protective systems intended for use in potentially explosive atmospheres” ATEX

• Regulation (EC) No 1907/2006 and successive Concerning the Registration, Evaluation, Authorization and Restriction of

Chemicals REACH

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph. +39 030 8900145 • Fax +39 030 8900423 • info@omal.it • www.omal.it

Rif. UMA0082W - 06/18 EN - 11

You might also like

- Hydraulic Wellhead Control Panel For Gas WellDocument105 pagesHydraulic Wellhead Control Panel For Gas WellAlok100% (2)

- Ib0600383engc PDFDocument293 pagesIb0600383engc PDFJoshuesito Cruz100% (3)

- Instruction Manual FR-D740 & FR-D720S 2009Document296 pagesInstruction Manual FR-D740 & FR-D720S 2009Rene ErkmanNo ratings yet

- Actuator srn0053401s OmalDocument25 pagesActuator srn0053401s OmalAhmed MoharramNo ratings yet

- Fr-A8Nc: Inverter Instruction ManualDocument102 pagesFr-A8Nc: Inverter Instruction Manualkhaja avezNo ratings yet

- Varia DorDocument296 pagesVaria DorGabriel Esteban VenegasNo ratings yet

- Fr-A8Nc: Inverter Instruction ManualDocument98 pagesFr-A8Nc: Inverter Instruction Manualtaleb 6269No ratings yet

- FR-E720-0.1K (SC) To 15K (SC) FR-E740-0.4K (SC) To 15K (SC) FR-E720S-0.1K (SC) To 2.2K (SC) FR-E710W-0.1K To 0.75KDocument349 pagesFR-E720-0.1K (SC) To 15K (SC) FR-E740-0.4K (SC) To 15K (SC) FR-E720S-0.1K (SC) To 2.2K (SC) FR-E710W-0.1K To 0.75KHoa Nguyen VanNo ratings yet

- D700 Instruction Guide PDFDocument300 pagesD700 Instruction Guide PDFLâm MộcNo ratings yet

- Manual Del Variador F700 InglesDocument341 pagesManual Del Variador F700 InglesMiguel RojasNo ratings yet

- Manual FR - A8nceDocument90 pagesManual FR - A8nceSamuel Martinez RomeroNo ratings yet

- Ib 0600168 EngdDocument112 pagesIb 0600168 EngdLuiz SilvaNo ratings yet

- Fre 700Document320 pagesFre 700Giang BùiNo ratings yet

- Mitsubishi d700 Manual - 001Document1 pageMitsubishi d700 Manual - 001Amit PaulNo ratings yet

- VSD FR-D700 Ib0600353enggDocument301 pagesVSD FR-D700 Ib0600353enggChris GavevaNo ratings yet

- Mitsubishi FR A7NC ManualDocument106 pagesMitsubishi FR A7NC ManualIlham AnandaNo ratings yet

- Mitsubishi FR-F700 ManualDocument280 pagesMitsubishi FR-F700 ManualGaby Djin ThemixNo ratings yet

- F 700 Users ManualDocument270 pagesF 700 Users ManualallanbatiancilaNo ratings yet

- Fracture ToughnessDocument286 pagesFracture ToughnessHusen TaufiqNo ratings yet

- FR-F740-EC (European Version Version Applied Manual) - Ib0600193engaDocument262 pagesFR-F740-EC (European Version Version Applied Manual) - Ib0600193engafreitaswalterNo ratings yet

- FR Cc2 ManualDocument176 pagesFR Cc2 Manualesau hernandezNo ratings yet

- Pulse Valve User Manual 2892 DDocument14 pagesPulse Valve User Manual 2892 DGrant SukatiNo ratings yet

- Get0792 001aDocument97 pagesGet0792 001aintegrasir369No ratings yet

- KDR728BTJ Stereo JVCDocument87 pagesKDR728BTJ Stereo JVCHernánLeograndeNo ratings yet

- SwitchDocument2 pagesSwitchFinewoods ColombiaNo ratings yet

- Inverter F800 Instruction Manual (Hardware) : Fr-F802 (Separated Converter Type)Document108 pagesInverter F800 Instruction Manual (Hardware) : Fr-F802 (Separated Converter Type)xuan leNo ratings yet

- E500 Ac Drive Genis Kullanim KilavuzuDocument247 pagesE500 Ac Drive Genis Kullanim KilavuzuQamar AltafNo ratings yet

- KD R428 PDFDocument55 pagesKD R428 PDFJose HerreraNo ratings yet

- JVC KD-S28Document55 pagesJVC KD-S28fcjjcfNo ratings yet

- Mitsubishi f800 Manual 1 150Document150 pagesMitsubishi f800 Manual 1 150rodrigoNo ratings yet

- FR-F800 Instruction Manual PDFDocument614 pagesFR-F800 Instruction Manual PDFelivandrojuniorNo ratings yet

- FR-F700-NA (North American Version Applied Manual) - Ib0600217engbDocument270 pagesFR-F700-NA (North American Version Applied Manual) - Ib0600217engbfreitaswalterNo ratings yet

- FR-F800 Detailed (B)Document638 pagesFR-F800 Detailed (B)Leandro SilvaNo ratings yet

- Mitsubishi FR Configurator SW3 ManualDocument167 pagesMitsubishi FR Configurator SW3 Manualahmadba70No ratings yet

- Manual - F800 ProfibusDocument96 pagesManual - F800 ProfibusalmaroadieNo ratings yet

- I-De-3010.0j-1223-940-Ie3-231 - 0 - Emergency Offloading System - GaDocument4 pagesI-De-3010.0j-1223-940-Ie3-231 - 0 - Emergency Offloading System - GaDiego NogueiraNo ratings yet

- Huong Dan Cai DatDocument108 pagesHuong Dan Cai DatĐình Vũ CaoNo ratings yet

- Fr-A8Np: Inverter Instruction ManualDocument92 pagesFr-A8Np: Inverter Instruction ManualAlberto Suazo BasaezNo ratings yet

- Instruction Manual Profibus-Dp Fr-A8npDocument92 pagesInstruction Manual Profibus-Dp Fr-A8npIssao WatanabeNo ratings yet

- Drawn On Zuken E3 File Stored in Teamcenter Engineering Do Not Scale Do Not Modify Manually All Dimensions in MMDocument19 pagesDrawn On Zuken E3 File Stored in Teamcenter Engineering Do Not Scale Do Not Modify Manually All Dimensions in MMOunna PechNo ratings yet

- Washing Machine 2006 MOON - Service ManualDocument31 pagesWashing Machine 2006 MOON - Service ManualMarcGarciaNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- FR A520 PDFDocument257 pagesFR A520 PDFNguyen LuongNo ratings yet

- Ib 0600634 EngaDocument142 pagesIb 0600634 Engaibrahim AdıbelliNo ratings yet

- Mitsubishi A800 ManualDocument714 pagesMitsubishi A800 ManualAlejandro Garcia50% (2)

- (For VIEW) NJoy UserManual UPS Balder 1500 3000Document37 pages(For VIEW) NJoy UserManual UPS Balder 1500 3000Octavian TontzNo ratings yet

- Simbolos & IdentificacaoDocument81 pagesSimbolos & IdentificacaoDenis SilvaNo ratings yet

- Bien TanDocument262 pagesBien TanLê Đăng HòaNo ratings yet

- User'S Manual: (Specification and Part Names)Document10 pagesUser'S Manual: (Specification and Part Names)Hewa PCNo ratings yet

- MV110 en Ds053rev12Document29 pagesMV110 en Ds053rev12elkin carrilloNo ratings yet

- Polypropylene Strapping Machine: Technical DataDocument9 pagesPolypropylene Strapping Machine: Technical DataSkander BhsNo ratings yet

- Healthview Mono Interconnect Diagram: Section 6Document15 pagesHealthview Mono Interconnect Diagram: Section 6alexis marcanoNo ratings yet

- Iphone 6 Schematic Kythuatphone - VN PDFDocument55 pagesIphone 6 Schematic Kythuatphone - VN PDFmichelle0% (1)

- Mitsubishi E500 ManualDocument221 pagesMitsubishi E500 ManualNguyen Thanh Dai100% (1)

- lb2300 Single Cup PDFDocument21 pageslb2300 Single Cup PDFHUY NGUYENNo ratings yet

- 51AKB / 51AKC: Owner'S ManualDocument10 pages51AKB / 51AKC: Owner'S ManualAlfonso ArroyoNo ratings yet

- Ib 0600531 EnggDocument165 pagesIb 0600531 EnggĐinh Vạn ThànhNo ratings yet

- Druckmessumformer, Typ S-10 Pressure Transmitter, Model S-10 Transmetteur de Pression, Type S-10 Transmisor de Presión, Modelo S-10Document100 pagesDruckmessumformer, Typ S-10 Pressure Transmitter, Model S-10 Transmetteur de Pression, Type S-10 Transmisor de Presión, Modelo S-10Bob RhemNo ratings yet

- Price List Vacuum Pumps 2-2022 PDFDocument26 pagesPrice List Vacuum Pumps 2-2022 PDFЭльшад АскеровNo ratings yet

- Cilindros FESTODocument16 pagesCilindros FESTOjoliporNo ratings yet

- Awwa C561 Fabricated Stainless Steel Slide GatesDocument36 pagesAwwa C561 Fabricated Stainless Steel Slide GatesLuis DanielNo ratings yet

- Specification Plumbing SystemDocument16 pagesSpecification Plumbing SystemGhiovani DayananNo ratings yet

- 8490-25a Emsco FC-1600 7500psiDocument13 pages8490-25a Emsco FC-1600 7500psimrcaglarNo ratings yet

- IPC IntroductionDocument41 pagesIPC Introductionram salunkheNo ratings yet

- 2063 72040 Tipicos InstrumentacionDocument42 pages2063 72040 Tipicos InstrumentacionZillur RahmanNo ratings yet

- A17Document1 pageA17liviu_dovaNo ratings yet

- Project Standard Specification: Pipe Expansion Fittings and Loops 15121 - Page 1/5Document5 pagesProject Standard Specification: Pipe Expansion Fittings and Loops 15121 - Page 1/5adel rihanaNo ratings yet

- Installation, Operation & Maintenance Manual - Original VersionDocument11 pagesInstallation, Operation & Maintenance Manual - Original VersionAli AafaaqNo ratings yet

- PMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetDocument2 pagesPMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetfarhaNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- Flender - Gear MotorDocument42 pagesFlender - Gear Motorikuzma_10% (1)

- TG-06: COA Guidelines For Container Interchange Criteria CIC-2Document6 pagesTG-06: COA Guidelines For Container Interchange Criteria CIC-2Sev BangunNo ratings yet

- KSR Float Level Switch NewDocument20 pagesKSR Float Level Switch NewMadel D.No ratings yet

- DKC RamblockDocument13 pagesDKC RamblockFLAVIO DOSE RAMIREZNo ratings yet

- API 650 Part 9 - 2001 Welded TanksDocument20 pagesAPI 650 Part 9 - 2001 Welded TanksHassan Ali SadiqNo ratings yet

- Instrument Manifold Systems: Instrument, Direct, and Remote-Mount Manifolds and Modular SystemsDocument30 pagesInstrument Manifold Systems: Instrument, Direct, and Remote-Mount Manifolds and Modular Systemskumar100% (1)

- Fisher GX Control Valve and Actuator System: Scope of ManualDocument44 pagesFisher GX Control Valve and Actuator System: Scope of ManualSaasiNo ratings yet

- Flanges: SI SMEDocument16 pagesFlanges: SI SMEbalaNo ratings yet

- Chemtrol Samil - Instrument D/SDocument48 pagesChemtrol Samil - Instrument D/SAnonymous OFP2ygPIdNo ratings yet

- Chapter 9Document24 pagesChapter 9alcaponeNo ratings yet

- Stainless Steel Flow Control Equipment For The Food, Dairy, Beverage, Pharmaceutical, Biotech, Personal CareDocument6 pagesStainless Steel Flow Control Equipment For The Food, Dairy, Beverage, Pharmaceutical, Biotech, Personal CareJuanpablo OXNo ratings yet

- ER-56-03 EN Packager Standards Skid Design and FabricationDocument4 pagesER-56-03 EN Packager Standards Skid Design and FabricationCamilo Andres Cardozo FajardoNo ratings yet

- DANAIS MT II CL 150 ENDocument28 pagesDANAIS MT II CL 150 ENLasombra DelPatoNo ratings yet

- Sump Discharge Piping - ISOMETRIC DrawingDocument9 pagesSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNo ratings yet

- Calculation Cover Sheet: File Calc No Project Title Client Proj No Phase/CTRDocument26 pagesCalculation Cover Sheet: File Calc No Project Title Client Proj No Phase/CTRM ANo ratings yet

- Knife Gate ValveDocument7 pagesKnife Gate ValveAbdul RaheemNo ratings yet

- Sec 410-4625Document12 pagesSec 410-4625Automa Viet NamNo ratings yet