Professional Documents

Culture Documents

Understanding Flash Fire and Auto Ignition

Understanding Flash Fire and Auto Ignition

Uploaded by

cotteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Understanding Flash Fire and Auto Ignition

Understanding Flash Fire and Auto Ignition

Uploaded by

cotteCopyright:

Available Formats

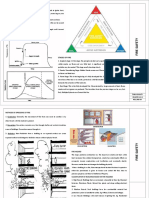

UNDERSTANDING FLASH, FIRE AND AUTO IGNITION

Heat transfer fluids are exceptionally safe if specified correctly for the application and some basic

guidelines are followed with respect to their use and handling.

First off, it’s important to understand your fluid’s fire safety ratings. These are characterized by a

fluid’s flash, fire and auto ignition points.

Flash Point

The temperature at which the vapors produced from a fluid will ignite (flash off) with the presence of an ignition source

(the fluid will not burn at this point). While some applications and revised fire safety standards may require a high flash

point fluid to be used, it is still quite common to operate systems at temperatures above the flash point of the fluid.

Fire Point

The temperature at which the fluid will sustain a fire if ignited by an outside ignition source. Heat transfer systems are

commonly run at temperatures above a fluid’s fire point as the fluid is contained within the system, far removed from

ignition sources.

Auto Ignition

The minimum temperature at which a fluid will spontaneously ignite without an external ignition source, such as a flame

or spark. Never operate a system above a fluid’s auto ignition temperature.

In summary, thermal fluids are intended to be used above their flash and fire points but never above their auto ignition

temperatures. Within a properly designed system, a fluid can be used right up to its maximum bulk fluid temperature

rating which is usually much higher than either its flash point or fire point. To better understand how you can safely heat

past these limits, you need to consider how each relates to a heat transfer system

In the case of the flash point, vapors would need to collect or become trapped in a relatively confined space AND

have an ignition source to cause a ‘flash’. This combination is very unlikely to happen within a properly engineered/

constructed system and a workplace operating with even only a moderate degree of safety.

In the case of the fire point, again through proper system design there should be no air/oxygen contact (needed for a

fire) at the heat source (boiler, electric immersion heater). Also, during normal operation, the fluid is contained within the

system and well away from external ignition sources.

Extenuating Circumstances - Leaks

In the ‘real world’ however, there are circumstances that can pose potential fire hazards that you should be aware of,

namely from leaks. When a system leaks, it could result in a few potentially hazardous scenarios:

1. The fluid drips onto a hot surface or open ignition source (e.g. electric pumps) where it could potentially ignite.

2. If a fluid leaks and collects within the system’s pipe or reactor jacket insulation, it is of particular safety concern.

This is especially true when open cell insulation is used and it is for this reason closed cell insulation is highly

recommended. If the fluid becomes trapped within the open cell insulation it can oxidize. The fluid produces heat

as it oxidizes, which remains trapped between the process piping or reactor jacket and the insulation. As the fluid

continues to degrade, its fire safety points are reduced and, compounded with the heat created from its degradation,

the fluid can start to smolder. This could result in an auto ignition-type fire should air be introduced to the mix.*

* It is extremely important to remember that should any part of your heat transfer system start to leak or smoke

that you approach it with caution and have proper fire extinguishing media close at hand – particularly if you see

smoldering insulation. Instinctively, workers will often want to cut away the smoldering insulation to investigate the

cause of the smoke. This immediately introduces the source of air needed to potentially cause an auto ignition fire.

1 800 446 4910 | www.durathermfluids.com

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Final - Fire Safety in High Rise BuildingsDocument37 pagesFinal - Fire Safety in High Rise BuildingsAshwini AnandNo ratings yet

- Compression Packing Technical Manual 4th EditionDocument127 pagesCompression Packing Technical Manual 4th Editioncvishwas273256No ratings yet

- Cambridge 7 - 15 PDFDocument56 pagesCambridge 7 - 15 PDFdisisokNo ratings yet

- Thermal Fluid System Clean OutDocument2 pagesThermal Fluid System Clean OutLord KrsnikNo ratings yet

- Warning and Emergency Systems: Takeoff and Landing Gear WarningsDocument5 pagesWarning and Emergency Systems: Takeoff and Landing Gear WarningsJuly TadeNo ratings yet

- XXII Paper 13Document5 pagesXXII Paper 13Anonymous GvcQ76No ratings yet

- Sprinkler System DetailsDocument13 pagesSprinkler System DetailsMd. Biplob HossainNo ratings yet

- Is It Safe - HT FceDocument3 pagesIs It Safe - HT FceskluxNo ratings yet

- Nitrogen Fire ProtectionDocument10 pagesNitrogen Fire ProtectionSirshak Mahapatra100% (1)

- Fire HazardsDocument7 pagesFire HazardsJl VicNo ratings yet

- Gas Suppresion SystemDocument50 pagesGas Suppresion SystemNavneet ShrivastavaNo ratings yet

- A Tiny Glass Bulb or Fusible Metal Link Protects Most Buildings From FireDocument8 pagesA Tiny Glass Bulb or Fusible Metal Link Protects Most Buildings From FireyuyulsukNo ratings yet

- VDS Interaction of Water Extinguishing Systems and Smoke and Heat ExtractorsDocument0 pagesVDS Interaction of Water Extinguishing Systems and Smoke and Heat Extractorsmicaziv4786No ratings yet

- Flash PointDocument30 pagesFlash Point2222222-269740No ratings yet

- Keeping The Lid On Flammable Liquids: Is Is Is Is So Wire BeforeDocument1 pageKeeping The Lid On Flammable Liquids: Is Is Is Is So Wire Beforeagrocel_bhv5591No ratings yet

- Fire FightingDocument9 pagesFire FightingtanyaNo ratings yet

- NIFPSDocument13 pagesNIFPSPulkit Sethi100% (2)

- Cause Sprinkler LeakageDocument7 pagesCause Sprinkler LeakageAmalia IstighfarahNo ratings yet

- FireDocument43 pagesFireMuhammad BilalNo ratings yet

- Flammable and Combustible LiquidsDocument23 pagesFlammable and Combustible LiquidsAnsarNo ratings yet

- Basic CombustionDocument6 pagesBasic CombustionÁkhïl VãlupådäsùNo ratings yet

- L14-Introduction To Fire-Fire Figthing SystemDocument24 pagesL14-Introduction To Fire-Fire Figthing Systemrazer hamasNo ratings yet

- Safe Flare System Design: John Zink CompanyDocument10 pagesSafe Flare System Design: John Zink CompanyAniket S Jadhav100% (4)

- Fire Sprinklers As Fire Prevention SystemsDocument6 pagesFire Sprinklers As Fire Prevention SystemsMuhammad Jamshaid KhanNo ratings yet

- Industrial Plant Fire Protection SystemsDocument10 pagesIndustrial Plant Fire Protection SystemskennnNo ratings yet

- Chapter 3 Active Fire PreventionDocument54 pagesChapter 3 Active Fire PreventionKan Fock-KuiNo ratings yet

- Boiling Point Bond WireDocument3 pagesBoiling Point Bond Wiremujahid1137No ratings yet

- Safe Gas Flare System OperationDocument5 pagesSafe Gas Flare System OperationJose Gustavo Lopez MujicaNo ratings yet

- Startup Shutdown ProceduresDocument1 pageStartup Shutdown Proceduresbiron rumangunNo ratings yet

- Lecture Notes Fire Protection SystemsDocument21 pagesLecture Notes Fire Protection Systemsu2b11517100% (1)

- 1 - FirefightingDocument46 pages1 - Firefightingmrsosa2011No ratings yet

- Slimpel Uputstvo Za UoptrebuDocument25 pagesSlimpel Uputstvo Za UoptrebuBrksaNo ratings yet

- Fire Protection Equipment and SystemDocument66 pagesFire Protection Equipment and Systemhisyam350No ratings yet

- FHC AssignmentDocument11 pagesFHC AssignmentrekhajayarajanNo ratings yet

- Your Torpedo Heater Will Not Run With The Cover OnDocument5 pagesYour Torpedo Heater Will Not Run With The Cover OnAlonica DNo ratings yet

- Fire and Explosion Thermal Fluids PDFDocument5 pagesFire and Explosion Thermal Fluids PDFVinicius NoronhaNo ratings yet

- BasitDocument13 pagesBasitTalha ranaNo ratings yet

- FlammableDocument30 pagesFlammableDwiayuAdindaNo ratings yet

- Equipment Operation: Safety GuidelinesDocument4 pagesEquipment Operation: Safety GuidelinesasxceNo ratings yet

- 10 - Fire Protection and Prevention (My Notes)Document6 pages10 - Fire Protection and Prevention (My Notes)Mohamed Abdullah KhojaliNo ratings yet

- Design of Automatic Fire Sprinkler SystemDocument41 pagesDesign of Automatic Fire Sprinkler SystemISH-QUENo ratings yet

- The Building Owners Guide To Fire Sprinkler and Fire Pump SystemsDocument17 pagesThe Building Owners Guide To Fire Sprinkler and Fire Pump SystemsTamouh ZakrtNo ratings yet

- Water Based Suppression SystemsDocument2 pagesWater Based Suppression SystemsdebasisdgNo ratings yet

- Types of Burners and Combustion Systems - HEATER TREATER IMPORTANTDocument5 pagesTypes of Burners and Combustion Systems - HEATER TREATER IMPORTANTadewunmi olufemiNo ratings yet

- Overpressure and Thermal ReliefDocument6 pagesOverpressure and Thermal ReliefHamid Alilou100% (1)

- Special Report Make The Most Heat Transfer ParathermDocument12 pagesSpecial Report Make The Most Heat Transfer ParathermFabioSalaNo ratings yet

- 200005A - P1 - Flash Point ApparatusDocument11 pages200005A - P1 - Flash Point Apparatusaruthlugnesha2001No ratings yet

- Fire Protection SystemsDocument9 pagesFire Protection SystemsDiscord GamingNo ratings yet

- oIL REFINERY FIRE NOTESDocument6 pagesoIL REFINERY FIRE NOTESAlabi GodfavourNo ratings yet

- Group4 - Moule 6Document61 pagesGroup4 - Moule 6Neil Matthew Jarabelo DandanNo ratings yet

- Machinery Space FireDocument3 pagesMachinery Space FireenglisgoNo ratings yet

- Fire Fighting - BasicDocument1 pageFire Fighting - BasicCostisNo ratings yet

- Flares - Types, Parts, Components, Operation and TroubleshootingDocument27 pagesFlares - Types, Parts, Components, Operation and TroubleshootingBahaa AbdelnasserNo ratings yet

- Flash Point by Abel's ApparatusDocument3 pagesFlash Point by Abel's ApparatusAbhishek JoshiNo ratings yet

- Exhaust Temp Spreads PDFDocument2 pagesExhaust Temp Spreads PDFzoveisi100% (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- The Home Owner's Guide to HVAC: The Envelope and Green TechnologiesFrom EverandThe Home Owner's Guide to HVAC: The Envelope and Green TechnologiesNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Pall Electrostatic DischargeDocument3 pagesPall Electrostatic DischargePat YNo ratings yet

- King Na Lube EP 5000Document8 pagesKing Na Lube EP 5000cotteNo ratings yet

- Mobil AGL Gear Lubricant: Performance ProfileDocument2 pagesMobil AGL Gear Lubricant: Performance ProfilecotteNo ratings yet

- List of Products Related To Danieli Standard 0.000.001 - Rev.15Document11 pagesList of Products Related To Danieli Standard 0.000.001 - Rev.15cotteNo ratings yet

- Changeover - From - Mineral - Oil PAO To Polyglycol KluberDocument2 pagesChangeover - From - Mineral - Oil PAO To Polyglycol KlubercotteNo ratings yet

- CMD Gear Lubricant RecommendationsDocument7 pagesCMD Gear Lubricant RecommendationscotteNo ratings yet

- Voith Gear Pump RecommendationDocument28 pagesVoith Gear Pump RecommendationcotteNo ratings yet

- EuropeanBiogas AssociationDocument24 pagesEuropeanBiogas AssociationcotteNo ratings yet

- Amine Selection For Metalworking Applications: HuntsmanDocument4 pagesAmine Selection For Metalworking Applications: HuntsmancotteNo ratings yet

- Engineering Thermodynamics Solutions ManualDocument32 pagesEngineering Thermodynamics Solutions ManualMahesh NadarNo ratings yet

- 6890 Alcatel Lucent Delivering Comprehensive Enterprise DCC SecurityDocument11 pages6890 Alcatel Lucent Delivering Comprehensive Enterprise DCC SecurityAlexanderNo ratings yet

- A Low-Power Digital PWM DCDC Converter Based On PaDocument6 pagesA Low-Power Digital PWM DCDC Converter Based On Pasolo4000No ratings yet

- OpenELIS Lab Data - Admin Guide (For Bahmni)Document6 pagesOpenELIS Lab Data - Admin Guide (For Bahmni)Hiến LưuNo ratings yet

- Logarithmic FunctionsDocument20 pagesLogarithmic FunctionsThomas WashNo ratings yet

- P s l τ t s s τ s l P: Visit us at: www.nodia.co.inDocument1 pageP s l τ t s s τ s l P: Visit us at: www.nodia.co.inSameerChauhanNo ratings yet

- Product: Torsional Vibration Meter - Type 2523Document4 pagesProduct: Torsional Vibration Meter - Type 2523jhon vargas100% (1)

- Bca604T: Web ProgrammingDocument4 pagesBca604T: Web ProgrammingmohanNo ratings yet

- Automation Technology For Fabric Inspection SystemDocument7 pagesAutomation Technology For Fabric Inspection SystemSwarnabandu AthukoralaNo ratings yet

- Math Board Exam Question September 2022 April 2023Document6 pagesMath Board Exam Question September 2022 April 2023iamjbbarredoNo ratings yet

- Chapter - 3 - EERDDocument67 pagesChapter - 3 - EERDbui datNo ratings yet

- Unchallengeable MiracleDocument430 pagesUnchallengeable MiracleghozyfatahNo ratings yet

- Cryptography PHD Thesis PDFDocument7 pagesCryptography PHD Thesis PDFsuejonessalem100% (2)

- Euler's Method, Runge Kutta Methods, Predictor-Corrector MethodsDocument17 pagesEuler's Method, Runge Kutta Methods, Predictor-Corrector MethodsMyWBUT - Home for Engineers50% (2)

- Of Final BookDocument197 pagesOf Final BookSachinNo ratings yet

- Kyocera FS-1028MFP Service ManualDocument202 pagesKyocera FS-1028MFP Service Manualsatx840100% (1)

- Lesson Plan ExemplarDocument4 pagesLesson Plan ExemplarRica Manansala IbeNo ratings yet

- Rtos 1Document22 pagesRtos 1VariNo ratings yet

- Nauticus Hull - Steel Plates UnstiffenedDocument90 pagesNauticus Hull - Steel Plates Unstiffenedbosskoj100% (1)

- Top Questions For Practice Complex Number: Questions JEE Main 2022 Crash CourseDocument5 pagesTop Questions For Practice Complex Number: Questions JEE Main 2022 Crash CourseSouravNo ratings yet

- Geometry AlbumDocument107 pagesGeometry AlbumMersi Ta100% (7)

- Drill Nomenclature and Geometry: Submitted By:-Suhail Ali Sabri M.Tech, Production Engineering 2018PPE8010Document8 pagesDrill Nomenclature and Geometry: Submitted By:-Suhail Ali Sabri M.Tech, Production Engineering 2018PPE8010kumarNo ratings yet

- Capacitors: Expulsion Fuse Installation InstructionsDocument6 pagesCapacitors: Expulsion Fuse Installation InstructionscrcruzpNo ratings yet

- Mastering JMP Definitive Screening DesignsDocument39 pagesMastering JMP Definitive Screening DesignsBosco RajuNo ratings yet

- A2 Multitrac With A2 Process Controller PEI: Welding TractorsDocument5 pagesA2 Multitrac With A2 Process Controller PEI: Welding TractorsLuis Chiara LoayzaNo ratings yet

- Field Work #9Document4 pagesField Work #9Aidan MacasaNo ratings yet

- Beta Function:: M N MN X X DX MN NMDocument43 pagesBeta Function:: M N MN X X DX MN NMSanthosh SrinivasanNo ratings yet

- Parallel CircuitDocument14 pagesParallel CircuitJOSHUANo ratings yet