Professional Documents

Culture Documents

Cimentación para Depósitos de Reserva de Agua - ING

Cimentación para Depósitos de Reserva de Agua - ING

Uploaded by

Hussam AbdoalKelaqOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cimentación para Depósitos de Reserva de Agua - ING

Cimentación para Depósitos de Reserva de Agua - ING

Uploaded by

Hussam AbdoalKelaqCopyright:

Available Formats

w w w. f i re p i p i n g .

c o m

FIRE WATER TANKS

FOUNDATIONS

REQUIREMENTS

Engineered FIRE PIPING, S.L.

Polígono Industrial La Malena. C/del Pino 17. Yuncos - 452100 (TOLEDO)

TLF.: +34 902 551 558 | FAX: +34 902 551 663 | Mail: tanks@firepiping.com

w w w. f i re p i p i n g . c o m

FIRE WATER TANKS FOUNDATIONS

Introduction:

The purpose of this document is to advise how and offer the right information about how the tank

concrete base should be built, avoiding problems during tank assembly process.

The calculations, technical direction, built process and the quality control of tank foundation civil

works, are Customer responsibility. This manual is only intended to advise the Customer.

Assembly Procedure:

Engineered Fire Piping water tanks assembling processes require the use of hydraulic lifters. In such

way, all the assembling works could be done on the floor avoiding the risks of works at height,

warranting to installers a 100% safety level.

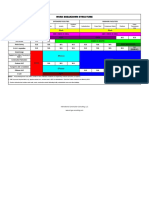

DAY 1:

Once on site, first step is to set out the tank shape on the tank foundation then, the first tank’s

ring assembly can start, including the installation of the upper reinforcement angles, the metal

roof structure and the upper connections of the tank. Once the hydraulic lifters are in place and

anchored, the second tank ring is also assembled, and the roof components installation is done.

DAY 2 AND FOLLOWING:

The remaining tank’s rings parts will be assembled.

LAST DAY:

Once all the rings are finished, we will proceed to assemble the lower reinforcement angles, which

will be anchored to the foundation; then the lower flanges are installed and the hydraulic lifters are

removed, the expansive rubber or hydrotite is applied. To easier the second step internal civil work

jobs a metal sheet will not be installed. This last metal plate will be fixed when the all the internal civil

works are done.

Once the tank is finished, the client will be asked to approve and sign the conformity sheet that the

fitters will provide.

Considerations prior to the execution of the concrete base:

A minimum distance of 50 cm (recommended 1 metre) must be left from any point on the perimeter

of the tank to any installation or building, to facilitate assembly due to the use of hydraulic jacks.

The geotechnical study of the terrain will be at the client’s expense.

Soil strength shall be higher than 1,5 Kg/cm2.

Engineered FIRE PIPING, S.L.

Polígono Industrial La Malena. C/del Pino 17. Yuncos - 452100 (TOLEDO)

TLF.: +34 902 551 558 | FAX: +34 902 551 663 | Mail: tanks@firepiping.com

w w w. f i re p i p i n g . c o m

FIRE WATER TANKS FOUNDATIONS

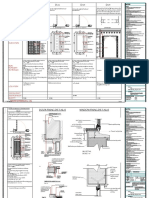

Excavation:

• The concrete layer shall be evenly settled on the bottom of the excavation.

• The marked perimeter shall be excavated to a depth equal to the necessary rock infill (80 mm).

• If cleaning concrete HA-150 is poured, the depth to be dug is 100 mm. It’s highly recommended to remove

the soil organic parts

• Then, an 80 mm layer of levelled and compacted rock infill shall be poured. When used cleaning concrete,

the layer thickness shall be 100 mm

• The concrete reinforced base shall have a 225 mm high cylinder shape.

1 • Build the necessary height formwork throughout the perimeter of the foundation.

st • Double 150x150x12 mm mesh will be fitted. Using spacers, the first mesh will be placed 50

mm apart the rock infill layer. the second mesh will be placed 100 mm far from the first one.

P Mesh steel class shall be B 500 S or equivalent.

H • Concrete shall be HA-35 type or similar (350 kg of cement per m3 of concrete). For mastic

A tanks, requiring a second concrete layer, the first layer shall have a roughness surface

S • To avoid membrane damage, on internal lined tanks, the concrete base surface must be

as smooth as possible.

E

• Once the tank is levelled and anchored it’s time to move to second step. Before the new

concrete layer is done, a couple of Hydrotite sealant strips shall be placed on site, the first

one shall be spaced 80 mm from the surface of the existent concrete layer, and the second

one, 80 mm from the top of the new concrete layer. The second layer shall be waterproof

concrete HA-35 type or equivalent.

When the internal and external concrete bedding are built, the following should be considered:

INTERNAL:

• The thickness shall be at least 200 mm. In any case, it must be 30 mm thicker than the

2 upper perimeter joint

nd • Double 150x150x12 mm mesh will be fitted. Using spacers, the first mesh will be placed 50

mm apart the first concrete layer surface, the second mesh will be placed 100 mm far from

P the first one.

H • Approximately a distance of 50 mm shall exist between the tank shell and the edge of the

A steel mesh. To avoid corrosion and damage of the hydrotite strips, mesh will never be in

contact with the tank shell.

S

E EXTERNAL:

• To connect both concrete layers a perimeter ring of 12 mm diameter corrugated steel rods

embedded 300 mm apart and fixed be means of an epoxy resin is used. Rod length shall

be 50 mm less that the final concrete layer top level..

• The external formwork shall be built once the tank is fully assembled, having the necessary

height, according to the external second concrete layer dimensions.

• Final thickness of this layer shall be 300 mm.

• Two horizontal lines of 12 mm diameter round corrugated steel bars shall be installed. First

level shall be 50 mm far from the bottom concrete layer and the second one 100 mm apart

the first one.

To avoid cracks and cavities, the concrete shall be carefully vibrated, especially in both external and

internal areas closest to the tank’s shell. It is preferable to build both sides at the same time.

Engineered FIRE PIPING, S.L.

Polígono Industrial La Malena. C/del Pino 17. Yuncos - 452100 (TOLEDO)

TLF.: +34 902 551 558 | FAX: +34 902 551 663 | Mail: tanks@firepiping.com

You might also like

- Specification 2 Strorey Residential (By Division)Document11 pagesSpecification 2 Strorey Residential (By Division)Trisha Casiño88% (17)

- Method Statement For Roofing & SidingDocument7 pagesMethod Statement For Roofing & SidingJoe_Average88% (8)

- Outline Specifications (One 1 Storey Residential)Document5 pagesOutline Specifications (One 1 Storey Residential)mark manalang67% (3)

- Infrastructure Method of ConstructionDocument19 pagesInfrastructure Method of ConstructionMohamed El-shaarawiNo ratings yet

- Health Insurance Off The GridDocument163 pagesHealth Insurance Off The GridDaryl Kulak100% (4)

- Cell Filled Concrete PavementDocument23 pagesCell Filled Concrete PavementDEVIKA ANIL80% (15)

- Technical Specifications CanopyDocument5 pagesTechnical Specifications CanopyNaman SharmaNo ratings yet

- Sample Project Specs 10 STOREY COMMERCIALDocument3 pagesSample Project Specs 10 STOREY COMMERCIALBernie RomeroNo ratings yet

- Project Specification: Title: Bruna Bautista Ville CPM Location: Rizal Santiago CityDocument7 pagesProject Specification: Title: Bruna Bautista Ville CPM Location: Rizal Santiago Citymelvin bautistaNo ratings yet

- Technical SpecificationsDocument3 pagesTechnical SpecificationsJohnNo ratings yet

- Detailed Technical Specification For Civil WorkDocument8 pagesDetailed Technical Specification For Civil WorkShivhar Menkudle100% (2)

- Core & Shell BOQ - ArchDocument58 pagesCore & Shell BOQ - ArchashokNo ratings yet

- LMRC PROJECT REPORTDocument12 pagesLMRC PROJECT REPORTApoorv DixitNo ratings yet

- UntitledDocument9 pagesUntitledGada RobaleNo ratings yet

- PROJECTDocument3 pagesPROJECTErin Trisha Kristel GaspanNo ratings yet

- General Specifications (One Storey)Document5 pagesGeneral Specifications (One Storey)joyce karen cadacioNo ratings yet

- Method Statement For Installation of Pre-Finished Engineering Flooring and SkirtingDocument7 pagesMethod Statement For Installation of Pre-Finished Engineering Flooring and SkirtingGary LoNo ratings yet

- T Proc Notices Notices 080 K Notice Doc 78664 503093314Document18 pagesT Proc Notices Notices 080 K Notice Doc 78664 503093314Mahmoud FarahatNo ratings yet

- Refractory Work Procedure of Clinker Cooler and Kiln HoodDocument10 pagesRefractory Work Procedure of Clinker Cooler and Kiln HoodLong LêNo ratings yet

- Construction SpecificationsDocument4 pagesConstruction SpecificationsAndrei SobrepeñaNo ratings yet

- Sope of Work For New Office (1) IRCDocument7 pagesSope of Work For New Office (1) IRCdavidtitangohNo ratings yet

- Specification of Toilet BlockDocument2 pagesSpecification of Toilet BlockKuldeep ChakerwartiNo ratings yet

- 29.12.2016 PipingDocument12 pages29.12.2016 PipingharshNo ratings yet

- Diy Manual: Thermo-Block Magyarország KFTDocument15 pagesDiy Manual: Thermo-Block Magyarország KFTVladimir DabovicNo ratings yet

- Costruction SpecificationDocument5 pagesCostruction Specificationjendel manahanNo ratings yet

- Nature of Work - 111820Document5 pagesNature of Work - 111820Santi NgoranNo ratings yet

- DSRDocument17 pagesDSRAniket DNo ratings yet

- Architectural Treatment For Joint GapsDocument25 pagesArchitectural Treatment For Joint GapsRoze-Anne JopsonNo ratings yet

- Slab Concrete NotesDocument10 pagesSlab Concrete NotesJimmi VlahosNo ratings yet

- Hollow Core Planks Application and Design GuideDocument46 pagesHollow Core Planks Application and Design Guidemixi1978100% (1)

- Book 600Document5 pagesBook 600krishansoni1965No ratings yet

- PROJECTDocument66 pagesPROJECTASHLEY CAPINANo ratings yet

- Civil Rate Schedule - NewDocument38 pagesCivil Rate Schedule - NewRam Kumar100% (1)

- Swara Sug Media Corporation General Construction SpecificationsDocument3 pagesSwara Sug Media Corporation General Construction SpecificationsLimar SetatraNo ratings yet

- Technical Specifications MidsayapDocument9 pagesTechnical Specifications MidsayapDAP Ysabelle Marie FuentesNo ratings yet

- DetailsDocument5 pagesDetailsAggie Qui100% (1)

- Block Works & Plastering DraftDocument4 pagesBlock Works & Plastering DraftEljo AndsNo ratings yet

- Ocbre Spec.Document12 pagesOcbre Spec.Rana MahatoNo ratings yet

- Concrete Strip Roads For The FarmDocument4 pagesConcrete Strip Roads For The FarmRoshanNo ratings yet

- Scope of Work DuplexDocument7 pagesScope of Work Duplexjet toledo100% (1)

- Slotted Drain SpecsDocument2 pagesSlotted Drain SpecsmeenhonNo ratings yet

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDocument3 pagesSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariNo ratings yet

- Animal Feed EFFORTDocument16 pagesAnimal Feed EFFORTHaftamu Tekle100% (1)

- SECTION 33 05 13 Manholes: Revised 03/2012Document52 pagesSECTION 33 05 13 Manholes: Revised 03/2012FAISAL NAZEERNo ratings yet

- Construction ProcessDocument8 pagesConstruction ProcessLa BeamNo ratings yet

- SPECS ManiegoDocument3 pagesSPECS ManiegoLimar SetatraNo ratings yet

- Tanks BOQ FinalDocument19 pagesTanks BOQ Finalmustafe67% (3)

- Specification of Pipe InsulationDocument6 pagesSpecification of Pipe InsulationNoldz SantosNo ratings yet

- Assignment 3 CEPM1 - SanchezRobertDocument11 pagesAssignment 3 CEPM1 - SanchezRobertRjohn SanchezNo ratings yet

- General ConditionsDocument6 pagesGeneral ConditionsBryan Nicolas IbeNo ratings yet

- Plano de Balanza Camionera 3x18mDocument1 pagePlano de Balanza Camionera 3x18mRoberto Santos Silva100% (3)

- Method Statement For AAC Block WorksDocument3 pagesMethod Statement For AAC Block Worksaboodeissa97No ratings yet

- BoqDocument24 pagesBoqsrinivasmantry88No ratings yet

- Ericson Maniego General Construction SpecificationsDocument3 pagesEricson Maniego General Construction SpecificationsLimar SetatraNo ratings yet

- Speci 2Document12 pagesSpeci 2Desmond BakiNo ratings yet

- Rev DrainDocument6 pagesRev DrainRaj RahulNo ratings yet

- B17 SpecsDocument7 pagesB17 SpecsbenbenpastorNo ratings yet

- Trojan Sleeper Installation GuideDocument5 pagesTrojan Sleeper Installation GuideqsNo ratings yet

- SpecificationsDocument7 pagesSpecificationsCarlo Emozero Ibuyan100% (1)

- Kurha Kakoda Estimate 03.08.2015Document56 pagesKurha Kakoda Estimate 03.08.2015MihirNo ratings yet

- CIA 5677-2018-RFP - Volume 2 - Tank 7 Tender DocumentDocument323 pagesCIA 5677-2018-RFP - Volume 2 - Tank 7 Tender DocumentHussam AbdoalKelaqNo ratings yet

- Journal Pone 0282657Document18 pagesJournal Pone 0282657Hussam AbdoalKelaqNo ratings yet

- PZ9 OD0 QIriskassessmentDocument18 pagesPZ9 OD0 QIriskassessmentHussam AbdoalKelaqNo ratings yet

- Project Financial and Economic ModelingDocument3 pagesProject Financial and Economic ModelingHussam AbdoalKelaqNo ratings yet

- Risk Assessment of Abrasive Blasting Environment in Pressure Vessel FabricationDocument16 pagesRisk Assessment of Abrasive Blasting Environment in Pressure Vessel FabricationHussam AbdoalKelaqNo ratings yet

- PROJECT STANDARD AND SPECIFICATIONS Maintenance of Foundations and Structures Rev01webDocument5 pagesPROJECT STANDARD AND SPECIFICATIONS Maintenance of Foundations and Structures Rev01webHussam AbdoalKelaqNo ratings yet

- Project Cost and Schedule Overview.Document4 pagesProject Cost and Schedule Overview.Hussam AbdoalKelaqNo ratings yet

- Method Statement 02 Demolition WorksDocument5 pagesMethod Statement 02 Demolition WorksHussam AbdoalKelaqNo ratings yet

- TanksssDocument4 pagesTanksssHussam AbdoalKelaqNo ratings yet

- Work Breakdown Structure.Document1 pageWork Breakdown Structure.Hussam AbdoalKelaqNo ratings yet

- Consulting,, LLCDocument2 pagesConsulting,, LLCHussam AbdoalKelaqNo ratings yet

- Invacare Envoy Nebulizer - User ManualDocument44 pagesInvacare Envoy Nebulizer - User ManualMAXWELL OLIVEIRA DOS SANTOSNo ratings yet

- Fire Alarms PDFDocument5 pagesFire Alarms PDFSaulangel CruzNo ratings yet

- COSHH Assessment FormDocument2 pagesCOSHH Assessment Formsupriyo sarkar100% (1)

- Sample Front Desk Receptionist ResumeDocument5 pagesSample Front Desk Receptionist ResumeReyvie FabroNo ratings yet

- INNOVATEXPO - Unlocking Creativity Abstract BookDocument22 pagesINNOVATEXPO - Unlocking Creativity Abstract Bookjoeltomy456No ratings yet

- Prospekt Serie 900 US 버터플라이밸브 카달로그Document8 pagesProspekt Serie 900 US 버터플라이밸브 카달로그kyeong cheol leeNo ratings yet

- Consulting Company Profile Format in PDFDocument17 pagesConsulting Company Profile Format in PDFAmir RamadanNo ratings yet

- MAD Lab ManualDocument60 pagesMAD Lab Manualarun kumarNo ratings yet

- App I Section 03050 Fill CreteDocument2 pagesApp I Section 03050 Fill CreteAnonymous M4BGwOkIpNo ratings yet

- Catalogo MartinDocument175 pagesCatalogo MartinLeonardo De la CruzNo ratings yet

- The Psychological ContractDocument5 pagesThe Psychological Contractანი გორგოძეNo ratings yet

- NC7001 NraDocument4 pagesNC7001 Nrasaran52_ece100% (1)

- 97 f150 PinoutDocument4 pages97 f150 PinoutUlises AlfaroNo ratings yet

- Quality Management PDFDocument9 pagesQuality Management PDFpakersNo ratings yet

- Thesis On Total Quality Management PDFDocument7 pagesThesis On Total Quality Management PDFf5dthdcd100% (1)

- English Language Paper 2Document24 pagesEnglish Language Paper 2Ahmed MahmoudNo ratings yet

- Motorized Gas Damper A-Hva-Rep-000-38132-BDocument31 pagesMotorized Gas Damper A-Hva-Rep-000-38132-Bja3farNo ratings yet

- AFV - Modeller July-Aug 2016Document68 pagesAFV - Modeller July-Aug 2016Prplknite100% (5)

- AllDocument2 pagesAllamarkiran vinayakNo ratings yet

- SEM-3 - Business Process Integration (BPI)Document20 pagesSEM-3 - Business Process Integration (BPI)Hee ManNo ratings yet

- Sankalp Research Paper 2023Document22 pagesSankalp Research Paper 2023Shivansh SinghNo ratings yet

- Estimate For Scrubber Tank FoundationDocument3 pagesEstimate For Scrubber Tank Foundationuche ekeNo ratings yet

- Gmail - Days Inn Hotels Confirmed Reservation NotificationDocument2 pagesGmail - Days Inn Hotels Confirmed Reservation Notificationapi-75518386No ratings yet

- Application To Pay Filing Fee in InstallmentsDocument2 pagesApplication To Pay Filing Fee in InstallmentsNatalie RowlandNo ratings yet

- A Guide To Windows in Nathers SoftwareDocument6 pagesA Guide To Windows in Nathers Softwarezumrakaraca.auNo ratings yet

- Group No - 8 MCA-507 Mini Project-II SubmissionDocument47 pagesGroup No - 8 MCA-507 Mini Project-II SubmissionThakor KiritNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0018461 A1Document6 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2007/0018461 A1Andrzej JurczyńskiNo ratings yet

- SCHLETTER Solar Mounting Systems Roof EN WebDocument19 pagesSCHLETTER Solar Mounting Systems Roof EN WebcharlesbenwariNo ratings yet

- Info - Iec61000 4 33 (Ed1.0) enDocument8 pagesInfo - Iec61000 4 33 (Ed1.0) enUntung Yudho PrakosoNo ratings yet