Professional Documents

Culture Documents

Tesco HPU

Tesco HPU

Uploaded by

Enrrique Vega MecatronicCopyright:

Available Formats

You might also like

- Draw WorkDocument5 pagesDraw WorkriobmNo ratings yet

- Saint Gobain Bushing Install RequirementsDocument21 pagesSaint Gobain Bushing Install RequirementsJeremy100% (1)

- Drawworks Specification: Project Name: 3000 HP Modular Platform Drilling Rig Project Number: 00548Document4 pagesDrawworks Specification: Project Name: 3000 HP Modular Platform Drilling Rig Project Number: 00548sorangel_1230% (1)

- TDS 04 09 PibDocument11 pagesTDS 04 09 PibNavin SinghNo ratings yet

- Stem Reports - Site 20Document4 pagesStem Reports - Site 20Mohamed El-SawahNo ratings yet

- A Soil-Nailed Excavation For The Brisbane Airport Link Project, AustraliaDocument12 pagesA Soil-Nailed Excavation For The Brisbane Airport Link Project, AustraliaRivaiNo ratings yet

- Wellsite Gas Watch - Wireless Portable Monitor 100Document50 pagesWellsite Gas Watch - Wireless Portable Monitor 100YoshizatoNo ratings yet

- 10810096-MAN - Rev 1 - MUX Pod and Control (Updated 4-16-20) - Compactado-CompactadoDocument611 pages10810096-MAN - Rev 1 - MUX Pod and Control (Updated 4-16-20) - Compactado-CompactadoJoão Vitor PionaNo ratings yet

- CLE14000DPcerev9 09 PDFDocument139 pagesCLE14000DPcerev9 09 PDFAdhie WaelacxhNo ratings yet

- Triplex Pump: TPH 400 Main SpecificationsDocument2 pagesTriplex Pump: TPH 400 Main SpecificationsAttou Housseyn100% (1)

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraee100% (1)

- MA-RG Series: Helical-Bevel Gear Mud AgitatorDocument80 pagesMA-RG Series: Helical-Bevel Gear Mud Agitatorfeka niniNo ratings yet

- IND Drawworks DLS 163Document11 pagesIND Drawworks DLS 163Jose Luis MazzoniNo ratings yet

- IDM Basic Training - ModrillDocument30 pagesIDM Basic Training - ModrillThomas Du100% (1)

- INSTRUMENT - AUTODRILLER - AOI - TECH MANUAL - IOM-111 Automatic Drilling Control SystemDocument53 pagesINSTRUMENT - AUTODRILLER - AOI - TECH MANUAL - IOM-111 Automatic Drilling Control SystemKapil AgarwalNo ratings yet

- Series 5000B4 Manual - Revision D 12 30 2010Document16 pagesSeries 5000B4 Manual - Revision D 12 30 2010mektroNo ratings yet

- Technical Manual and Parts CatalogDocument14 pagesTechnical Manual and Parts CatalogRicardo Vazquez Salinas100% (1)

- Drawwork Lewco LDW1000KDocument4 pagesDrawwork Lewco LDW1000KCarlosSantamaria0% (1)

- TDS-94-01-PIB TDS 主轴磨损余量Document7 pagesTDS-94-01-PIB TDS 主轴磨损余量xlzyydf2015No ratings yet

- 10745350-Pib Sola 24v电源故障Document4 pages10745350-Pib Sola 24v电源故障xlzyydf2015No ratings yet

- Safety & Operating Manual: Power Crimp 707 CrimperDocument20 pagesSafety & Operating Manual: Power Crimp 707 CrimpervankarpNo ratings yet

- Baylor Brake 2025BDocument116 pagesBaylor Brake 2025BTAHRI BELGACEMNo ratings yet

- Frac Rhino-TC Pumping Trailer OP ManualDocument50 pagesFrac Rhino-TC Pumping Trailer OP ManualAlessonNo ratings yet

- ZP375 Rotary Table User ManualDocument18 pagesZP375 Rotary Table User ManualYasir AbdooNo ratings yet

- Ton Torque ManometrosDocument16 pagesTon Torque ManometrosEliecer DiazNo ratings yet

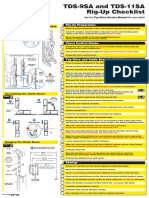

- TDS-11SA Rig Up ChecklistDocument2 pagesTDS-11SA Rig Up Checklistluis lopezNo ratings yet

- DrawworksDocument1 pageDrawworksLeonardo Rachen RodriguezNo ratings yet

- Viscosimetro OfiteDocument20 pagesViscosimetro OfitejomarlucaNo ratings yet

- Cat Walk InfoDocument428 pagesCat Walk InfoEmmanuel Soberano Hernandez100% (1)

- 1.3 Sustructure Assembly DrawingsDocument31 pages1.3 Sustructure Assembly Drawingsdanielra85No ratings yet

- Part Number 60-42 Revision A: Installation, Operation, Maintenance AND Illustrated Parts BreakdownDocument98 pagesPart Number 60-42 Revision A: Installation, Operation, Maintenance AND Illustrated Parts BreakdownLuis Eduardo Albarracin RugelesNo ratings yet

- Hydro-Weight Master Indicator System: Service ManualDocument39 pagesHydro-Weight Master Indicator System: Service ManualAbdallah ElhendyNo ratings yet

- RCP-7.5 Drilling fluid agitator RCP-7.5 搅拌器: Parts List 9-D)Document6 pagesRCP-7.5 Drilling fluid agitator RCP-7.5 搅拌器: Parts List 9-D)waleedNo ratings yet

- Budgetary Quotation Summary - Sensor Update: M/D TotcoDocument8 pagesBudgetary Quotation Summary - Sensor Update: M/D Totcocmrig74No ratings yet

- 50 20 PDFDocument68 pages50 20 PDFLuis Eduardo Albarracin Rugeles0% (1)

- Hawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 To 120Document165 pagesHawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 To 120ahnafNo ratings yet

- P-Quip LTD: Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. NoDocument7 pagesP-Quip LTD: Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. Noعلي الطائيNo ratings yet

- CR191102 - Spare Parts Mud Pump 9T1000Document77 pagesCR191102 - Spare Parts Mud Pump 9T1000nickNo ratings yet

- Cobra Kcobra MCDocument2 pagesCobra Kcobra MCEd CalheNo ratings yet

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDocument6 pagesCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- PB DDM 026Document3 pagesPB DDM 026Jim SharpNo ratings yet

- Land Rig 2000 HP - Saipem - Saudi ArabianDocument169 pagesLand Rig 2000 HP - Saipem - Saudi ArabianJoseph OkidimNo ratings yet

- Mud Pump Parts ExpendablesDocument82 pagesMud Pump Parts ExpendablesAnonymous Yo43Kif0No ratings yet

- D392004720 MKT 001 PDFDocument28 pagesD392004720 MKT 001 PDFsorangel_123No ratings yet

- Oteco Inc. 3" Reset Relief Valve 3" LPT Inlet & Outlet Installation & Maintenance Manual PART NO. 130350Document12 pagesOteco Inc. 3" Reset Relief Valve 3" LPT Inlet & Outlet Installation & Maintenance Manual PART NO. 130350VRV.RELATORIO.AVARIA RELATORIO.AVARIANo ratings yet

- Engineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Document2 pagesEngineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Bala KrishnanNo ratings yet

- Teda Xq140 12a Tubing TongDocument61 pagesTeda Xq140 12a Tubing TongRicardo CabreraNo ratings yet

- 13.62 5K Model 7022 Manual PDFDocument30 pages13.62 5K Model 7022 Manual PDFPato GonzalezNo ratings yet

- Iron Roughnecks BrochureDocument9 pagesIron Roughnecks BrochureMahmoud MorsiNo ratings yet

- Model pl5 Service Manual PDFDocument31 pagesModel pl5 Service Manual PDFingcalderonNo ratings yet

- TEM FluidEnds MPDocument15 pagesTEM FluidEnds MPGeorge BuitragoNo ratings yet

- Gardner Denver PZK Parts BookDocument30 pagesGardner Denver PZK Parts BookPrime Energy Warehouse-YemenNo ratings yet

- BB CatalogDocument12 pagesBB CatalogriobudimanNo ratings yet

- 600ws Plunger OmegaDocument37 pages600ws Plunger Omegaariel feNo ratings yet

- Parts Clamps TypeCDocument2 pagesParts Clamps TypeCedinson piñerosNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Rev 0Document26 pagesRev 0Хусниддин ГаниевNo ratings yet

- HXI System DescriptionDocument24 pagesHXI System DescriptionFrancisco Wilton bezerraNo ratings yet

- Tesco HCS 750 Troubleshooting Guide PDFDocument86 pagesTesco HCS 750 Troubleshooting Guide PDFLuther MoletaNo ratings yet

- HCI (S) Top Drive SystemDocument19 pagesHCI (S) Top Drive SystemHugo TejadaNo ratings yet

- 250-HXI-700 - Oct 13 2010Document184 pages250-HXI-700 - Oct 13 2010Carlos100% (1)

- EMI 400HP Operations GuideDocument122 pagesEMI 400HP Operations GuideMitul PatelNo ratings yet

- 24 - Vstired Tapones ParkerDocument1 page24 - Vstired Tapones ParkerEnrrique Vega MecatronicNo ratings yet

- RR Weatherford T & Q Series BrochureDocument107 pagesRR Weatherford T & Q Series BrochureEnrrique Vega MecatronicNo ratings yet

- General: Instruction Manual For Zb-400Ii Plunger PumpDocument2 pagesGeneral: Instruction Manual For Zb-400Ii Plunger PumpEnrrique Vega MecatronicNo ratings yet

- Conexion 2 7/8" EUE Conexion 2 7/8" NU: Marvin J Polo 28/04/2022Document1 pageConexion 2 7/8" EUE Conexion 2 7/8" NU: Marvin J Polo 28/04/2022Enrrique Vega MecatronicNo ratings yet

- 3SB35000AA11 Datasheet enDocument3 pages3SB35000AA11 Datasheet enEnrrique Vega MecatronicNo ratings yet

- Heavy Duty Valves: Series 140, 200, 920, 5620Document2 pagesHeavy Duty Valves: Series 140, 200, 920, 5620Enrrique Vega MecatronicNo ratings yet

- 500E2 Product Guide ImperialDocument16 pages500E2 Product Guide ImperialEnrrique Vega MecatronicNo ratings yet

- FI750 User ManualDocument36 pagesFI750 User ManualEnrrique Vega MecatronicNo ratings yet

- September Inventory 21 - NPDocument3 pagesSeptember Inventory 21 - NPEnrrique Vega MecatronicNo ratings yet

- 01furtun Hidraulic PTFEDocument73 pages01furtun Hidraulic PTFEEnrrique Vega MecatronicNo ratings yet

- Standards CatalogDocument26 pagesStandards CatalogEnrrique Vega MecatronicNo ratings yet

- Reinforced Concrete Piles - The Inside StoryDocument2 pagesReinforced Concrete Piles - The Inside StoryBogdanBNo ratings yet

- Water Meter ActarisDocument4 pagesWater Meter ActarisNavneet SinghNo ratings yet

- Turboelectric Propulsion in Commercial AvaitionDocument18 pagesTurboelectric Propulsion in Commercial AvaitionjuanNo ratings yet

- How To Install VW OEM R32 RearDocument16 pagesHow To Install VW OEM R32 Reardan utzuNo ratings yet

- Procedure To Complete Iavl When Idle Speed Needs To Be ReducedDocument5 pagesProcedure To Complete Iavl When Idle Speed Needs To Be ReducedZNN9002No ratings yet

- Pipe Sizing and Pressure Drop CalculationsDocument14 pagesPipe Sizing and Pressure Drop CalculationsArindom100% (1)

- HAZOP ExampleDocument3 pagesHAZOP Exampleshaggy hopkinsNo ratings yet

- Dynamic Loading and Testing of Bridges in Ontario PDFDocument11 pagesDynamic Loading and Testing of Bridges in Ontario PDFChathurika Supeshala GamageNo ratings yet

- TUFF Static Scissor Lift TablesDocument1 pageTUFF Static Scissor Lift TablesRarisgrup OficialNo ratings yet

- Box Fan Afl FBDJ 580 3 D Fb-Fe0ad-2768 8187 PDFDocument3 pagesBox Fan Afl FBDJ 580 3 D Fb-Fe0ad-2768 8187 PDFRivai GoBlogNo ratings yet

- Ge.l3w.15.bf 0 10 11 12 13Document9 pagesGe.l3w.15.bf 0 10 11 12 13Callany AnycallNo ratings yet

- Technical Specification Carbon Steel Heat Exchangers: Project No: 338033Document14 pagesTechnical Specification Carbon Steel Heat Exchangers: Project No: 338033jdgh1986No ratings yet

- Bff3242 Heat Transfer 21516Document9 pagesBff3242 Heat Transfer 21516nadiyaxx0% (1)

- Bike - Speed Vs RPMDocument6 pagesBike - Speed Vs RPMjohari23No ratings yet

- 019 - OM Hollowgram Wheel Sets - 134944 - ENDocument16 pages019 - OM Hollowgram Wheel Sets - 134944 - ENLowman JuniorNo ratings yet

- Pembelian Barang Sinar KaryaDocument249 pagesPembelian Barang Sinar KaryaNIKEN RAHMAWATINo ratings yet

- Report - HAZOP ReportDocument29 pagesReport - HAZOP ReportRajkumar Soni0% (1)

- Fundamentals Machining Material Removal ProcessDocument113 pagesFundamentals Machining Material Removal ProcessDarwisy AhmadNo ratings yet

- Mechanical EngineerDocument2 pagesMechanical EngineerMalikAlrahabiNo ratings yet

- Thermal Arc 161sDocument58 pagesThermal Arc 161srquinchia1No ratings yet

- 24941-100-30R-G01-00073 Tunra 6299 Report FinalDocument96 pages24941-100-30R-G01-00073 Tunra 6299 Report FinalcmahendrNo ratings yet

- 1 Thin Shells PDFDocument16 pages1 Thin Shells PDFMarcus Vinicius FaleiroNo ratings yet

- Hose Coupling - WikipediaDocument9 pagesHose Coupling - WikipediaAlberto DiazNo ratings yet

- Tara Pump PDFDocument3 pagesTara Pump PDFShahidur RahmanNo ratings yet

- ACMV Talk 2008 - FinalDocument111 pagesACMV Talk 2008 - FinalFrankie FanNo ratings yet

- Machine Learning - Based Backbone Curve Model of Reinforced Concrete Columns Subjected To Cyclic Loading ReversalsDocument14 pagesMachine Learning - Based Backbone Curve Model of Reinforced Concrete Columns Subjected To Cyclic Loading ReversalsEman SalehNo ratings yet

- ALTAIR - EHTC - OCT - 2010 - PJH - Final - Fatigue Analysis of Welded Structures Using Ncode DesignLifeDocument23 pagesALTAIR - EHTC - OCT - 2010 - PJH - Final - Fatigue Analysis of Welded Structures Using Ncode DesignLifesvk_ntNo ratings yet

- Pulleys CalculationDocument21 pagesPulleys CalculationRALPH JULES SARAUS100% (1)

Tesco HPU

Tesco HPU

Uploaded by

Enrrique Vega MecatronicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tesco HPU

Tesco HPU

Uploaded by

Enrrique Vega MecatronicCopyright:

Available Formats

System Description

250 HXI 700 Top Drive System

PLC System

250TON HXI 700HP with D4P-700 Power Unit

DOCUMENT NAME: 1570012 REV 1

SYSTEM DESCRIPTION COPYRIGHT AND DISCLAIMER

Tesco Corporation ("TESCO") has made every effort to ensure that this document contains accurate

and current information for the TESCO top drive, however, the document is intended to be used in

conjunction with a complete training program and on-site supervision and TESCO does not

warrant or guarantee that the information contained herein is either complete or accurate in every

respect, and the reader hereby protects, indemnifies and holds harmless Tesco Corporation together

with its directors, officers, employees and agents from and against all liability for personal injury,

death or property damage to any person arising directly or indirectly from the use by the reader of the

information contained in the document.

This equipment was filled at the factory with TESCO ULTREX™ brand fluids and greases. To ensure

maximum performance and to avoid cross-contamination, we strongly recommend the continued

usage of TESCO ULTREX™ lubricants, unless otherwise specified.

TESCO ULTREX™ is a trademark and TESCO® is a registered trademark of Tesco Corporation.

Tesco Corporation © 2009

Contact Information

Corporate Head Office

3993 W. Sam Houston Parkway No., Suite 100

Houston, Texas, 77043

USA

www.tescocorp.com

www.tescoparts.com

Telephone: (713) 359-7000

Fax: (713) 359-7001

After Market Sales and Service Contact

Toll Free North America: 1-877-TESCO-77

International: 713-359-7295

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 I WWW.TESCOPARTS.COM

REVISION INFORMATION SYSTEM DESCRIPTION

Revision Information

Version Date Description of Changes

Rev 0 July 2008 First release of document

Rev 1 April 2009 Add CE-ATEX information

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 II WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

CHAPTER 1: ABOUT THIS DOCUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHAPTER 2: TOP DRIVE SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction and General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Top Drive Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Load Collar and Load Nut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mudsaver Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pipe Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Counter-Balance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Top Drive Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Handling Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Auxiliary (Open-Loop) Hydraulic Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power (Closed-Loop) Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Auxiliary (Open-Loop) Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Case Drain Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Torque Arrest System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Torque Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Extend Frame and Extend Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Torque Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Torque Beam and T-bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Driller’s Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Emergency Shut Down (E.S.D.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Air interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Elevators and Elevator Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Subs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Grabber Drill Pipe Guides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Rotary Table Stabilizer Bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Rotary Hose and Standpipe Extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Torque Arrest System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Driller’s Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Other Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 III WWW.TESCOPARTS.COM

TABLE OF CONTENTS SYSTEM DESCRIPTION

This page has been left blank intentionally.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 IV WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

Warning! Before operating and servicing this top drive

system, always read and follow all safety

! instructions such as the warnings and cautions

mentioned below and throughout the manual.

Top Drive System users risk injury to themselves and to others if the top drive is used

improperly and/or safety precautions are not followed. TESCO advises personnel who

work with or near the equipment to always wear proper personal protective equipment

(PPE). Proper PPE consists of, but is not limited to, the following:

• hearing protection (ear defenders)

• hard hat

• safety glasses

• steel toe shoes

• fall protection when working above 6.5 ft (2 m), or the minimum height

requirement as directed by local jurisdiction.

Caution: This equipment is designed and certified for use in a

hazardous environment. When maintenance requires replacement

! of parts, only identical parts can be used. Using alternate, non-iden-

tical parts as a substitution may void compliance and certification.

Caution: Always perform the correct lock-out procedures as

! recommended by the Safety or Loss Prevention department

before implementing maintenance.

Caution: Only authorized personnel can install and operate the top

! drive system.

Caution: Only trained personnel must perform inspections and

! related activities.

Caution: Safe access must be provided to all areas where

! adjustments and maintenance are necessary.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 V WWW.TESCOPARTS.COM

SAFETY INSTRUCTIONS SYSTEM DESCRIPTION

Caution: This equipment can generate noise up to 100 decibels at

the prime mover and 86 decibels at the top drive. Hearing protection

! suitable for this noise level must be worn when operating this

equipment.

Warning! Electrical voltages of different potentials are used

throughout the TESCO top drive components

(480 VAC, 380 VAC, 208 VAC, 120 VAC). It is

imperative that only qualified personnel install,

! maintain and/or troubleshoot the electrical

systems. A severe hazard exists to personnel not

accustomed to, or familiar with, electrical hazards

and procedures.

Warning! Accumulators used in the auxiliary hydraulic

system are under pressure from gas. Release

! this pressure before any maintenance is done on

the auxiliary hydraulic system.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 VI WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION ABOUT THIS DOCUMENT

CHAPTER 1: ABOUT THIS DOCUMENT

This document contains a description of the major components of the 250TON HXI 700HP

Top Drive System.

A complete 250 HXI 700 Top Drive System consists of the following:

• top drive

• hydraulic power unit

• interconnecting service loop and reel

• driller’s panel

• torque arrest system

• associated buildings, containers and equipment

This document provides a brief description of each major component, as well as a list of

available spares and options.

Important Note: Illustrations contained herein are provided for reference purposes only,

equipment shown may differ from the actual unit appearance.

Table 1-1: Where to find more information

For information on Refer to

• installation Installation Guide

• rig up

• commissioning

• pre-operational checklists

• rig out procedures

• setting torque and speed Operations Guide

• driller's panel functions and operating descriptions

• making connections

• drilling ahead

• tripping

• freeing stuck pipe

• load path inspections Maintenance Guide

• maintenance/service schedules

• component disassembly and reassembly

TESCO manufactured parts and part numbers Parts List

troubleshooting Troubleshooting Guide (where available)

• electrical schematics System schematics

• hydraulic schematics

• cooling schematics

available options and spares TESCO representative

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 1 WWW.TESCOPARTS.COM

ABOUT THIS DOCUMENT SYSTEM DESCRIPTION

This page has been left blank intentionally.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 2 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

CHAPTER 2: TOP DRIVE SYSTEM DESCRIPTION

INTRODUCTION AND GENERAL SPECIFICATIONS

The 250 HXI 700 Top Drive System is designed for use on land-based drilling rigs and

workover rigs. The top drive is powered using an independent hydraulic power unit.

To create the optimum power supply system required for each of its top drives, TESCO combines

industry proven prime movers, hydraulic pump drives, pumps and filtration equipment.

The 250 HXI 700 Top Drive is powered using a 700 hp (522kW) Caterpillar C18 prime mover

with a four-pump drive.

Metric unit conversions (in brackets) have been provided for convenience only. All

product specifications use the original Imperial units unless indicated otherwise.

Note: All weight values are approximate.

Table 2-1: 250-HXI-700 Top Drive specifications

Imperial Metric

Rated capacity through load collar 250 Ton 227 tonne

Rated horsepower 700 hp 522 kW

Max. continuous drill torque 24,000 ft-lb 3,254.5 daN-m

Make-up/Breakout torque 32,000 ft-lb 4,339.4 daN-m

Max. speed 200 rpm

Weight of the top drive plus: 14,000 lb 6350 kg

• elevators

• elevator links

• yoke + links (counterbalance system)

Length (250T, with 9 ft. links) 17.5 ft. 5.3 m

Width 4 ft. 1.2 m

Quill connection NC50

Hazardous area certification CSA Class 1 Div II or II 2 G

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 3 WWW.TESCOPARTS.COM

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

Table 2-2: Torque Arrest System specifications

Imperial Metric

Weight of the following: 8,400 lb 3,810 kg

• torque track (92 ft long)

• anchor beam

• torque bushing

• extend frame

• clamps

Standard track length 92 to 146 ft 28.4 to 44.5 m

Hazardous area certification II 2 G

Table 2-3: Hydraulic Power Unit specifications

Imperial Metric

Total weight, wet 31,020 lb (includes weight of 14 070 kg

service loop)

Dimensions 31.5(L) x 5.5(W) x 9.2(H) ft. 9.6(L) x 1.7(W) x 2.8(H) m

Closed-loop flow 262 gpm max. 992 l/min max.

Closed-loop pressure 4,600 psi max. 31,716 kPa max.

Auxiliary hydraulic power flow 11 to 22 gpm max. 41.6 to 83.3 l/min max.

Auxiliary hydraulic pressure 3,000 psi max. 20,684 kPa max.

Motor voltage 480 (380) VAC, 20 (15) hp, 60 (50) Hz

Hazardous area certification CSA general purpose or safe area

Table 2-4: Service Loop specifications

Imperial Metric

Weight of the following: 11,700 lb 5307 kg

• reels

• cables

• hoses

Length 225 ft 68.6 m

Hazardous area certification CSA Class 1 Div II or II 2 G

Table 2-5: Driller’s Panel specifications

Imperial Metric

Weight 80 lb 36.3 kg

Dimensions 33.5 (L) x 15.5 (W) x 7 (H) in. 0.85 (L) x 0.39 (W) x 0.18 (H) m

Hazardous area certification CSA class 1 Div II or II 3 G /

II 2 G (with optional purge kit)

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 4 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

TOP DRIVE COMPONENTS

Figure 2-1: 250 HXI 700 Top Drive general assembly

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 5 WWW.TESCOPARTS.COM

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

Gearbox

• The gearbox is an integrated gearbox and swivel containing the main swivel bearing

and gear train to drive the quill.

• Single reduction helical gears (2.28:1) are utilized for high capacity, extended service

life, and maximum efficiency.

• The gear train is driven with a single bi-directional, hydraulic vane type motor. It has

a pressure rating of 4,500 psi (31,026 kPa) continuous, and 5,000 psi (34,474 kPa)

intermittent.

• The gearbox is flooded with oil for maximum gear and bearing lubrication and

reliability.

Load Collar and Load Nut

The load collar and load nut transfer loads from the elevator links to the quill.

Mudsaver Valve

The mudsaver valve is a double-ball crank valve that acts as a mudsaver. It replaces the upper

and lower kelly cock. The valve does not descend below the rotary table, except in emergency

situations, and it is always easily accessible. The mudsaver valve actuator can be operated

remotely from the driller’s panel.

Caution: The actuated upper ball valve is not for well control;

it functions solely as a mudsaver. The manual operating lower

! valve is for well control. Ensure that the valve selected can fit

into the existing casing.

Pipe Handling

The pipe handling abilities of the 250 HXI 700 Top Drive include the following:

• Pipe Handler Rotation: The HXI pipe handler rotate mechanism, powered by a single

hydraulic motor, provides 360° rotation and can be locked into any orientation. This

feature is used to resolve grabber torque when making or breaking connections.

• Elevator Link Tilt Cylinders: These allow extension and retraction of the elevators 35°

forward from the vertical position and 55° backward from the vertical position.

• Grabber (back-up wrench): The grabber acts as a back-up tong for making or breaking

connections at any point in the mast. The grabber will accommodate tool joints from

3-1/8 in. (8 cm) to 8-3/4 in. (22 cm) OD.

Note: For tool joints smaller than 4-3/4 in. (12 cm) OD, non-standard dies or a shim

kit must be installed. Grabber intensifier pressures must also be adjusted when

smaller OD pipe is used.

Counter-Balance

The top drive features an automatic thread feed compensation for make up and break out

operations.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 6 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

Top Drive Power

The top drive main motor is powered by four axial piston pumps, which are driven by a 700 hp

(522 kW) diesel prime mover. All top drive robotic functions are powered by an auxiliary

power hydraulic system. Both the prime mover and auxiliary power hydraulic system are

located on the power unit skid.

Handling Frame

The top drive is shipped in its own handling frame. This frame allows the top drive to be

transported and handled using standard rig moving equipment.

POWER UNIT

The primary function of the power unit is to provide hydraulic power to the top drive to

rotate the main top drive motor. This is achieved by a closed-loop hydraulic circuit, in which

a diesel engine or prime mover drives four variable displacement pumps that provides the

flow of hydraulic fluid to the top drive motor through the service loop. The return hydraulic

fluid is fed back directly to the variable displacement pumps. Some of the return flow is

tapped off by the hot oil shuttle valve and is circulated through an air-to-liquid cooler before

it is returned to a hydraulic fluid reservoir.

Piggybacked onto the variable displacement pumps are two vane pumps, used to “charge” the

closed-loop circuit due to the extract of hydraulic fluid by the hot oil shuttle relief (HOSR) /

reverse relief manifold and internal leakage of the pumps and top drive motor. Two other vane

pumps, also piggybacked onto the variable displacement pumps, are used to circulate additional

hydraulic fluid through the cooler to keep the hydraulic fluid in the reservoir from overheating.

The speed of the top drive motor varies by adjusting the displacement of the pumps. The

power unit is controlled by a PLC. The top drive operator only needs to select the desired

speed and the PLC will adjust the pump displacement to achieve the selected speed.

The secondary function of the power unit is to provide auxiliary hydraulic power to the top

drive to operate the robotic functions. A small auxiliary power unit, located on the power unit

skid, provides the auxiliary hydraulic power.

The power unit consists of two modules that are bolted together – the engine or prime

mover module and the hose reel/auxiliary HPU module. The engine module contains the

following equipment:

• prime mover

• pump drive and pumps

• closed-loop manifolds and hoses

• closed-loop hydraulic fluid reservoir and cooler

• main electrical panel and PLC panel

The hose reel/auxiliary HPU module contains the following equipment:

• auxiliary HPU

• hose reel with service loop

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 7 WWW.TESCOPARTS.COM

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

Figure 2-2: 250 HXI 700 power unit configuration

1. Prime Mover 5. Cooler

2. Pump Drive and Pumps 6. Main Panel

3. Closed-Loop Hydraulic 7. PLC Panel

Fluid Reservoir 8. Auxiliary HPU

4. Closed-Loop Manifolds 9. Service Loop and Hose Reel

Prime Mover

The prime mover for this power unit is a 700 hp (522 kW) Caterpillar C18 diesel engine. It is

equipped with a dual purpose radiator (air-to-liquid radiator for the engine coolant and an

air-to-air cooler for the compressed intake air), an air starter, turbo chargers, air filter,

exhaust system with built-in spark arrestor in the muffler, instrumentation panel, and the

appropriate safety and emergency shutoffs.

Pump Drive and Pumps

The pump drive is a gearbox mounted directly onto the prime mover. The gear ratio of the

pump drive is 1:1.3. A heavy duty coupling provides the connection to the prime mover

flywheel. The following equipment is attached to the pump drive:

• Four 130cc variable displacement, bi-directional axial piston pumps

• Four 58cc vane pumps, piggybacked onto the variable displacement pumps

• An internal lubrication-circulation pump

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 8 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

Closed-Loop Manifolds and Hoses

The closed-loop manifolds include:

• One charge filter manifold with one filter canister rated at 6,500 psi (44,816 kPa)

working pressure and 100 US gpm (378.5 liters/min.) flow. This filter manifold

ensures that the hydraulic fluid charged back into the closed-loop is filtered.

• One reverse filter manifold with four filter canisters each rated at 6,500 psi (44,816 kPa)

and 100 US gpm (378.5 liters/min.) flow. This filter manifold filters the return oil before

it enters the variable displacement pumps.

• One forward filter manifold with one filter canister rated at 6,500 psi (44,816 kPa) working

pressure and 100 US gpm (378.5 liters/min.) flow. It filters the return fluid when the top

drive operates in reverse.

• One hot oil shuttle relief (HOSR)/reverse relief manifold. This manifold contains the hot

oil shuttle relief valve and can be adjusted as required to bleed off some return oil and

send it through the cooler. Also, a reverse relief valve is located on this manifold to limit

the reverse flow pressure.

All hoses used in the closed-loop circuit are rated at 5,000 psi (34,474 kPa) working pressure.

Hydraulic Oil Reservoir and Cooler

The hydraulic oil reservoir contains the closed-loop hydraulic fluid and has a capacity of 330

US gallons (1,249 liters). Two vane pumps extract hydraulic fluid from the tank to charge the

closed-loop system. Another two vane pumps circulate the hydraulic fluid in the reservoir

through an air-to-liquid cooler to ensure the temperature of the hydraulic fluid remains below a

set value (190ºF/88ºC). The reservoir is equipped with a level switch, a heater, a temperature

gauge, two return oil filters and a temperature transducer. The function of the temperature

transducer is to signal the PLC to start the cooler fan once the temperature of the hydraulic

fluid in the tank rises above a set value (100ºF/38ºC).

Main Electrical Panel and PLC Panel

The main electrical panel contains the 480VAC and 120VAC distribution centers, breakers for

electrical equipment, cooling fan conductors and the 24VDC control power distribution center.

High voltage terminals are covered to avoid accidental contact when the panel door is open.

The PLC panel contains the PLC that controls the functions of the power unit and top drive.

Various alarm indicators are located on the panel door for easy troubleshooting.

Auxiliary (Open-Loop) Hydraulic Power Unit

The main function of the auxiliary hydraulic power unit (HPU) is to provide the top drive

and other ancillary equipment (such as CDS, power tongs, stabbing equipment, etc.) with

auxiliary hydraulic power. The auxiliary HPU is a standalone HPU mounted on the main

power unit skid. It contains two pressure compensated pumps, a 40 US gallon (151 liter)

auxiliary hydraulic fluid reservoir and a hydraulic fluid cooler. The pumps can be run simul-

taneously or individually depending on the auxiliary hydraulic flow demand. Each pump is

able to supply 11 US gpm (41.6 liters/min.) of hydraulic fluid. The auxiliary hydraulic circuit

is completely separate from the closed-loop circuit.

The auxiliary hydraulic system also has a small oil cooler with a hydraulically driven fan.

The fan can be turned on and off using a bypass valve located below the cooler on the cooler

manifold.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 9 WWW.TESCOPARTS.COM

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

Figure 2-3: Auxiliary hydraulic power unit

1. Electrical Panel 4. Secondary Pump

2. Auxiliary Hydraulic Fluid 5. Return Manifold

Reservoir 6. Pressure Manifold

3. Primary Pump 7. Cooler

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 10 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

SERVICE LOOP

The service loop hoses are spooled onto the hose reel for shipping and storage.

Power (Closed-Loop) Hydraulic Hoses

• Two 240 ft. (73 m) × 2 in. (5 cm), 5,000 psi (34,474 kPa) hoses (one supply, one return);

these supply closed-loop hydraulic oil from the pump drive module to the top drive motor.

These hoses are made up of four 120 ft. (36.6 m) sections.

Auxiliary (Open-Loop) Hydraulic Hoses

• One 225 ft. (68.6 m) × 3/4 in. (2 cm), 2,500 psi (17,237 kPa) hydraulic supply hose, and

one 225 ft. (68.6 m) × 1 in. (2.5 cm), 2,500 psi (17,237 kPa) hydraulic return hose. The

hoses supply hydraulic oil from the auxiliary HPU to the top drive robotics system. Each

hose is made up of three 75 ft. (23 m) sections.

Case Drain Hose

• One 225 ft (68.6 m) x 3/4 in. (2 cm), 2,500 psi (17,237 kPa) hydraulic hose; this returns

motor case drain flow from the top drive to the auxiliary hydraulic fluid reservoir at the

auxiliary HPU. The drain hose is made up of three 75 ft. (23 m) sections.

Control Cables

The 225 ft (68.6 m) control cable is coiled onto a cable hanger located on the power unit.

The 160 ft (48.8 m) control cable remains attached to the main electrical panel on the power

unit and is coiled onto a cable hanger, located on the power unit, for storage.

• One 225 ft (68.6 m) 37-conductor cable: this cable connects the PLC panel to the top

drive.

• One 160 ft. (48.8 m) 4TP communication cable: this cable connects the driller’s panel to

the PLC panel on the power unit.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 11 WWW.TESCOPARTS.COM

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

TORQUE ARREST SYSTEM

The torque arrest system consists of the following components:

• torque bushing

• extend frame

• extend arms

• extend hydraulic cylinders

• torque track

• T-bar

• torque beam, torque beam clamps, stabilization devices, and all required rig up items

Torque Bushing

The torque bushing is attached to the extend frame. It transfers reactive torque from the top

drive to the torque track. Ultra High Molecular Weight (UHMW) Polyethylene inserts reduce

friction as the top drive moves along the torque track. No lubrication is required.

Extend Frame and Extend Arms

The extend frame is pinned to the top drive. It allows the top drive to extend away from the

torque track, enabling improved pipe handling.

Torque Track

The torque track, in conjunction with the torque beam and T-bar, transfers reactive torque to

the lower section of the mast and the substructure. The track is suspended from the crown by a

cable hanging assembly, and is mounted with a simple clamp anchoring arrangement. Track

components can be configured to fit most mast heights.

Torque Beam and T-bar

The torque beam is mounted to the mast, typically to the lowest strongback. It is then connected

to the torque track via a T-bar. An offset torque anchor beam and post is available for use on

service rigs. This torque anchoring system compensates for the 3.5° lean of the service rig mast.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 12 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

Figure 2-4: HXI torque arrest system

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 13 WWW.TESCOPARTS.COM

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

DRILLER ’S PANEL

The driller’s panel is a stainless steel enclosure that is mounted on the drill floor during

installation procedures. It contains all controls, indicators, mounts, gauges and connectors

required to operate the top drive. There is an optional air-purge system available for the

driller’s panel. All controls are electrically activated hydraulic (24 VDC) non-earth ground.

SAFETY INTERLOCKS

Emergency Shut Down (E.S.D.)

There are two E.S.D. circuits, each with its own specific function.

E.S.D. on the Driller’s Panel

The red E.S.D. mushroom button on the driller’s panel trips the C18 air solenoid valve. The

quill stops rotating. This E.S.D. also deactivates the auxiliary hydraulic pump. All devices that

operate or rotate at the drill floor become inactive.

E.S.D. on the Engine Panel

The red E.S.D. mushroom button on the door of the CAT engine panel activates the fuel

shut-off valve and shuts down the C18 engine.

Air interlocks

Drawworks Interlock and Override

The drum clutch interlock stops the air supply to the drum clutch so that the driller cannot

hoist the top drive while the grabber is closed. A push button on the brake handle is used to

override this lockout feature during slide drilling operations, etc.

Mud Pump Interlock

The mud pump air interlock is designed to disallow operation of the mud pump unless the

mudsaver valve is open.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 14 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

Figure 2-5: Driller’s panel

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 15 WWW.TESCOPARTS.COM

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

OPTIONS

The following options are available. For more detailed information, contact a TESCO

representative.

Elevators and Elevator Links

Elevators rated at 150 and 250 tons (136.1 and 226.8 tonnes), associated inserts for various

drill pipe sizes, and accessories are available. A variety of link lengths is also available.

Subs

A complete selection of commonly used saver, casing, cross-over and drill collar handling

subs is available. Non-standard subs can be manufactured if requested; delivery can be

determined at time of order.

Grabber Drill Pipe Guides

These are used to guide the drill string into the grabber box. The drill pipe guide must match

the box of the drill pipe in use. There is a range of sizes available.

Rotary Table Stabilizer Bushings

These urethane bushings fit the standard rotary table profile and protect the table and Blowout

Preventer (BOP) from excessive wear. There is a range of sizes available.

Rotary Hose and Standpipe Extension

All equipment and accessories for these modifications are available.

Torque Arrest System

Optional equipment for non-standard and large mast torque arrest systems is available.

Alarms

The following optional alarm are available:

• extend alert features

Driller’s Panel

Driller’s panel with hazardous area certification of II 2 G is available.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 16 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

Other Available Options

• Air purge system for the driller’s panel and top drive junction box.

• Workshop/parts containers with workbench and storage cupboards, complete with

interior lighting, optional stepdown transformer, power outlets and space heater.

• Video monitoring system, with cameras mounted in the derrick at the monkey board

and crown levels.

A complete list of all available options and accessories is available from a local TESCO

representative.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 17 WWW.TESCOPARTS.COM

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

This page has been left blank intentionally.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 18 WWW.TESCOPARTS.COM

SYSTEM DESCRIPTION ENGINEERING SIGN-OFF

ENGINEERING SIGN-OFF

This sign-off sheet indicates that this document has been approved for release by the

Engineering Department at TESCO.

Document Completed By Signature Date Signed

Edward Chan 20 May 2009

Document Reviewed/Approved Date Signed

20 May 09

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 19 WWW.TESCOPARTS.COM

ENGINEERING SIGN-OFF SYSTEM DESCRIPTION

This page has been left blank intentionally.

CONTACT: 1-877-TESCO-77 250TON HXI 700HP WWW.TESCOCORP.COM

INTL: 713-359-7295 20 WWW.TESCOPARTS.COM

You might also like

- Draw WorkDocument5 pagesDraw WorkriobmNo ratings yet

- Saint Gobain Bushing Install RequirementsDocument21 pagesSaint Gobain Bushing Install RequirementsJeremy100% (1)

- Drawworks Specification: Project Name: 3000 HP Modular Platform Drilling Rig Project Number: 00548Document4 pagesDrawworks Specification: Project Name: 3000 HP Modular Platform Drilling Rig Project Number: 00548sorangel_1230% (1)

- TDS 04 09 PibDocument11 pagesTDS 04 09 PibNavin SinghNo ratings yet

- Stem Reports - Site 20Document4 pagesStem Reports - Site 20Mohamed El-SawahNo ratings yet

- A Soil-Nailed Excavation For The Brisbane Airport Link Project, AustraliaDocument12 pagesA Soil-Nailed Excavation For The Brisbane Airport Link Project, AustraliaRivaiNo ratings yet

- Wellsite Gas Watch - Wireless Portable Monitor 100Document50 pagesWellsite Gas Watch - Wireless Portable Monitor 100YoshizatoNo ratings yet

- 10810096-MAN - Rev 1 - MUX Pod and Control (Updated 4-16-20) - Compactado-CompactadoDocument611 pages10810096-MAN - Rev 1 - MUX Pod and Control (Updated 4-16-20) - Compactado-CompactadoJoão Vitor PionaNo ratings yet

- CLE14000DPcerev9 09 PDFDocument139 pagesCLE14000DPcerev9 09 PDFAdhie WaelacxhNo ratings yet

- Triplex Pump: TPH 400 Main SpecificationsDocument2 pagesTriplex Pump: TPH 400 Main SpecificationsAttou Housseyn100% (1)

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraee100% (1)

- MA-RG Series: Helical-Bevel Gear Mud AgitatorDocument80 pagesMA-RG Series: Helical-Bevel Gear Mud Agitatorfeka niniNo ratings yet

- IND Drawworks DLS 163Document11 pagesIND Drawworks DLS 163Jose Luis MazzoniNo ratings yet

- IDM Basic Training - ModrillDocument30 pagesIDM Basic Training - ModrillThomas Du100% (1)

- INSTRUMENT - AUTODRILLER - AOI - TECH MANUAL - IOM-111 Automatic Drilling Control SystemDocument53 pagesINSTRUMENT - AUTODRILLER - AOI - TECH MANUAL - IOM-111 Automatic Drilling Control SystemKapil AgarwalNo ratings yet

- Series 5000B4 Manual - Revision D 12 30 2010Document16 pagesSeries 5000B4 Manual - Revision D 12 30 2010mektroNo ratings yet

- Technical Manual and Parts CatalogDocument14 pagesTechnical Manual and Parts CatalogRicardo Vazquez Salinas100% (1)

- Drawwork Lewco LDW1000KDocument4 pagesDrawwork Lewco LDW1000KCarlosSantamaria0% (1)

- TDS-94-01-PIB TDS 主轴磨损余量Document7 pagesTDS-94-01-PIB TDS 主轴磨损余量xlzyydf2015No ratings yet

- 10745350-Pib Sola 24v电源故障Document4 pages10745350-Pib Sola 24v电源故障xlzyydf2015No ratings yet

- Safety & Operating Manual: Power Crimp 707 CrimperDocument20 pagesSafety & Operating Manual: Power Crimp 707 CrimpervankarpNo ratings yet

- Baylor Brake 2025BDocument116 pagesBaylor Brake 2025BTAHRI BELGACEMNo ratings yet

- Frac Rhino-TC Pumping Trailer OP ManualDocument50 pagesFrac Rhino-TC Pumping Trailer OP ManualAlessonNo ratings yet

- ZP375 Rotary Table User ManualDocument18 pagesZP375 Rotary Table User ManualYasir AbdooNo ratings yet

- Ton Torque ManometrosDocument16 pagesTon Torque ManometrosEliecer DiazNo ratings yet

- TDS-11SA Rig Up ChecklistDocument2 pagesTDS-11SA Rig Up Checklistluis lopezNo ratings yet

- DrawworksDocument1 pageDrawworksLeonardo Rachen RodriguezNo ratings yet

- Viscosimetro OfiteDocument20 pagesViscosimetro OfitejomarlucaNo ratings yet

- Cat Walk InfoDocument428 pagesCat Walk InfoEmmanuel Soberano Hernandez100% (1)

- 1.3 Sustructure Assembly DrawingsDocument31 pages1.3 Sustructure Assembly Drawingsdanielra85No ratings yet

- Part Number 60-42 Revision A: Installation, Operation, Maintenance AND Illustrated Parts BreakdownDocument98 pagesPart Number 60-42 Revision A: Installation, Operation, Maintenance AND Illustrated Parts BreakdownLuis Eduardo Albarracin RugelesNo ratings yet

- Hydro-Weight Master Indicator System: Service ManualDocument39 pagesHydro-Weight Master Indicator System: Service ManualAbdallah ElhendyNo ratings yet

- RCP-7.5 Drilling fluid agitator RCP-7.5 搅拌器: Parts List 9-D)Document6 pagesRCP-7.5 Drilling fluid agitator RCP-7.5 搅拌器: Parts List 9-D)waleedNo ratings yet

- Budgetary Quotation Summary - Sensor Update: M/D TotcoDocument8 pagesBudgetary Quotation Summary - Sensor Update: M/D Totcocmrig74No ratings yet

- 50 20 PDFDocument68 pages50 20 PDFLuis Eduardo Albarracin Rugeles0% (1)

- Hawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 To 120Document165 pagesHawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 To 120ahnafNo ratings yet

- P-Quip LTD: Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. NoDocument7 pagesP-Quip LTD: Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. Noعلي الطائيNo ratings yet

- CR191102 - Spare Parts Mud Pump 9T1000Document77 pagesCR191102 - Spare Parts Mud Pump 9T1000nickNo ratings yet

- Cobra Kcobra MCDocument2 pagesCobra Kcobra MCEd CalheNo ratings yet

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDocument6 pagesCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- PB DDM 026Document3 pagesPB DDM 026Jim SharpNo ratings yet

- Land Rig 2000 HP - Saipem - Saudi ArabianDocument169 pagesLand Rig 2000 HP - Saipem - Saudi ArabianJoseph OkidimNo ratings yet

- Mud Pump Parts ExpendablesDocument82 pagesMud Pump Parts ExpendablesAnonymous Yo43Kif0No ratings yet

- D392004720 MKT 001 PDFDocument28 pagesD392004720 MKT 001 PDFsorangel_123No ratings yet

- Oteco Inc. 3" Reset Relief Valve 3" LPT Inlet & Outlet Installation & Maintenance Manual PART NO. 130350Document12 pagesOteco Inc. 3" Reset Relief Valve 3" LPT Inlet & Outlet Installation & Maintenance Manual PART NO. 130350VRV.RELATORIO.AVARIA RELATORIO.AVARIANo ratings yet

- Engineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Document2 pagesEngineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Bala KrishnanNo ratings yet

- Teda Xq140 12a Tubing TongDocument61 pagesTeda Xq140 12a Tubing TongRicardo CabreraNo ratings yet

- 13.62 5K Model 7022 Manual PDFDocument30 pages13.62 5K Model 7022 Manual PDFPato GonzalezNo ratings yet

- Iron Roughnecks BrochureDocument9 pagesIron Roughnecks BrochureMahmoud MorsiNo ratings yet

- Model pl5 Service Manual PDFDocument31 pagesModel pl5 Service Manual PDFingcalderonNo ratings yet

- TEM FluidEnds MPDocument15 pagesTEM FluidEnds MPGeorge BuitragoNo ratings yet

- Gardner Denver PZK Parts BookDocument30 pagesGardner Denver PZK Parts BookPrime Energy Warehouse-YemenNo ratings yet

- BB CatalogDocument12 pagesBB CatalogriobudimanNo ratings yet

- 600ws Plunger OmegaDocument37 pages600ws Plunger Omegaariel feNo ratings yet

- Parts Clamps TypeCDocument2 pagesParts Clamps TypeCedinson piñerosNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Rev 0Document26 pagesRev 0Хусниддин ГаниевNo ratings yet

- HXI System DescriptionDocument24 pagesHXI System DescriptionFrancisco Wilton bezerraNo ratings yet

- Tesco HCS 750 Troubleshooting Guide PDFDocument86 pagesTesco HCS 750 Troubleshooting Guide PDFLuther MoletaNo ratings yet

- HCI (S) Top Drive SystemDocument19 pagesHCI (S) Top Drive SystemHugo TejadaNo ratings yet

- 250-HXI-700 - Oct 13 2010Document184 pages250-HXI-700 - Oct 13 2010Carlos100% (1)

- EMI 400HP Operations GuideDocument122 pagesEMI 400HP Operations GuideMitul PatelNo ratings yet

- 24 - Vstired Tapones ParkerDocument1 page24 - Vstired Tapones ParkerEnrrique Vega MecatronicNo ratings yet

- RR Weatherford T & Q Series BrochureDocument107 pagesRR Weatherford T & Q Series BrochureEnrrique Vega MecatronicNo ratings yet

- General: Instruction Manual For Zb-400Ii Plunger PumpDocument2 pagesGeneral: Instruction Manual For Zb-400Ii Plunger PumpEnrrique Vega MecatronicNo ratings yet

- Conexion 2 7/8" EUE Conexion 2 7/8" NU: Marvin J Polo 28/04/2022Document1 pageConexion 2 7/8" EUE Conexion 2 7/8" NU: Marvin J Polo 28/04/2022Enrrique Vega MecatronicNo ratings yet

- 3SB35000AA11 Datasheet enDocument3 pages3SB35000AA11 Datasheet enEnrrique Vega MecatronicNo ratings yet

- Heavy Duty Valves: Series 140, 200, 920, 5620Document2 pagesHeavy Duty Valves: Series 140, 200, 920, 5620Enrrique Vega MecatronicNo ratings yet

- 500E2 Product Guide ImperialDocument16 pages500E2 Product Guide ImperialEnrrique Vega MecatronicNo ratings yet

- FI750 User ManualDocument36 pagesFI750 User ManualEnrrique Vega MecatronicNo ratings yet

- September Inventory 21 - NPDocument3 pagesSeptember Inventory 21 - NPEnrrique Vega MecatronicNo ratings yet

- 01furtun Hidraulic PTFEDocument73 pages01furtun Hidraulic PTFEEnrrique Vega MecatronicNo ratings yet

- Standards CatalogDocument26 pagesStandards CatalogEnrrique Vega MecatronicNo ratings yet

- Reinforced Concrete Piles - The Inside StoryDocument2 pagesReinforced Concrete Piles - The Inside StoryBogdanBNo ratings yet

- Water Meter ActarisDocument4 pagesWater Meter ActarisNavneet SinghNo ratings yet

- Turboelectric Propulsion in Commercial AvaitionDocument18 pagesTurboelectric Propulsion in Commercial AvaitionjuanNo ratings yet

- How To Install VW OEM R32 RearDocument16 pagesHow To Install VW OEM R32 Reardan utzuNo ratings yet

- Procedure To Complete Iavl When Idle Speed Needs To Be ReducedDocument5 pagesProcedure To Complete Iavl When Idle Speed Needs To Be ReducedZNN9002No ratings yet

- Pipe Sizing and Pressure Drop CalculationsDocument14 pagesPipe Sizing and Pressure Drop CalculationsArindom100% (1)

- HAZOP ExampleDocument3 pagesHAZOP Exampleshaggy hopkinsNo ratings yet

- Dynamic Loading and Testing of Bridges in Ontario PDFDocument11 pagesDynamic Loading and Testing of Bridges in Ontario PDFChathurika Supeshala GamageNo ratings yet

- TUFF Static Scissor Lift TablesDocument1 pageTUFF Static Scissor Lift TablesRarisgrup OficialNo ratings yet

- Box Fan Afl FBDJ 580 3 D Fb-Fe0ad-2768 8187 PDFDocument3 pagesBox Fan Afl FBDJ 580 3 D Fb-Fe0ad-2768 8187 PDFRivai GoBlogNo ratings yet

- Ge.l3w.15.bf 0 10 11 12 13Document9 pagesGe.l3w.15.bf 0 10 11 12 13Callany AnycallNo ratings yet

- Technical Specification Carbon Steel Heat Exchangers: Project No: 338033Document14 pagesTechnical Specification Carbon Steel Heat Exchangers: Project No: 338033jdgh1986No ratings yet

- Bff3242 Heat Transfer 21516Document9 pagesBff3242 Heat Transfer 21516nadiyaxx0% (1)

- Bike - Speed Vs RPMDocument6 pagesBike - Speed Vs RPMjohari23No ratings yet

- 019 - OM Hollowgram Wheel Sets - 134944 - ENDocument16 pages019 - OM Hollowgram Wheel Sets - 134944 - ENLowman JuniorNo ratings yet

- Pembelian Barang Sinar KaryaDocument249 pagesPembelian Barang Sinar KaryaNIKEN RAHMAWATINo ratings yet

- Report - HAZOP ReportDocument29 pagesReport - HAZOP ReportRajkumar Soni0% (1)

- Fundamentals Machining Material Removal ProcessDocument113 pagesFundamentals Machining Material Removal ProcessDarwisy AhmadNo ratings yet

- Mechanical EngineerDocument2 pagesMechanical EngineerMalikAlrahabiNo ratings yet

- Thermal Arc 161sDocument58 pagesThermal Arc 161srquinchia1No ratings yet

- 24941-100-30R-G01-00073 Tunra 6299 Report FinalDocument96 pages24941-100-30R-G01-00073 Tunra 6299 Report FinalcmahendrNo ratings yet

- 1 Thin Shells PDFDocument16 pages1 Thin Shells PDFMarcus Vinicius FaleiroNo ratings yet

- Hose Coupling - WikipediaDocument9 pagesHose Coupling - WikipediaAlberto DiazNo ratings yet

- Tara Pump PDFDocument3 pagesTara Pump PDFShahidur RahmanNo ratings yet

- ACMV Talk 2008 - FinalDocument111 pagesACMV Talk 2008 - FinalFrankie FanNo ratings yet

- Machine Learning - Based Backbone Curve Model of Reinforced Concrete Columns Subjected To Cyclic Loading ReversalsDocument14 pagesMachine Learning - Based Backbone Curve Model of Reinforced Concrete Columns Subjected To Cyclic Loading ReversalsEman SalehNo ratings yet

- ALTAIR - EHTC - OCT - 2010 - PJH - Final - Fatigue Analysis of Welded Structures Using Ncode DesignLifeDocument23 pagesALTAIR - EHTC - OCT - 2010 - PJH - Final - Fatigue Analysis of Welded Structures Using Ncode DesignLifesvk_ntNo ratings yet

- Pulleys CalculationDocument21 pagesPulleys CalculationRALPH JULES SARAUS100% (1)