Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

49 viewsMandatory Documents Clause of IATF 16949

Mandatory Documents Clause of IATF 16949

Uploaded by

Parthiban DCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CDI-FM-02 Change Request - NO 05Document1 pageCDI-FM-02 Change Request - NO 05Parthiban DNo ratings yet

- Work Instruction For Milling - 1 BoardDocument1 pageWork Instruction For Milling - 1 BoardParthiban DNo ratings yet

- Rework RegisterDocument6 pagesRework RegisterParthiban DNo ratings yet

- Final Inspection Defects Samples ListDocument2 pagesFinal Inspection Defects Samples ListParthiban DNo ratings yet

- Insert Life SheetDocument2 pagesInsert Life SheetParthiban DNo ratings yet

- SAFETY WORK INS PICTORIAL - 2 BoardDocument2 pagesSAFETY WORK INS PICTORIAL - 2 BoardParthiban DNo ratings yet

- Instrument Error MoonitoringDocument1 pageInstrument Error MoonitoringParthiban DNo ratings yet

- 1378 Packing MethodDocument2 pages1378 Packing MethodParthiban DNo ratings yet

- Gauge Revise Price Eco GreenDocument1 pageGauge Revise Price Eco GreenParthiban DNo ratings yet

- Gauge ListDocument1 pageGauge ListParthiban DNo ratings yet

- Pfmea ListDocument1 pagePfmea ListParthiban DNo ratings yet

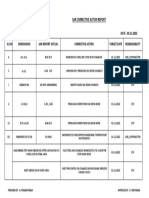

- 1406 CarDocument1 page1406 CarParthiban DNo ratings yet

- Defect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byDocument6 pagesDefect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byParthiban DNo ratings yet

- Essae 20.06.20Document3 pagesEssae 20.06.20Parthiban DNo ratings yet

- QUALITY POLICY - 4 BoardDocument2 pagesQUALITY POLICY - 4 BoardParthiban DNo ratings yet

- Machine Breakdown DetailsDocument12 pagesMachine Breakdown DetailsParthiban DNo ratings yet

- Essae 8.03.23Document4 pagesEssae 8.03.23Parthiban DNo ratings yet

- Prepared By: Parthiban Approved By: K.R.RajasekarDocument1 pagePrepared By: Parthiban Approved By: K.R.RajasekarParthiban DNo ratings yet

- Master List of Documents 2022Document3 pagesMaster List of Documents 2022Parthiban DNo ratings yet

Mandatory Documents Clause of IATF 16949

Mandatory Documents Clause of IATF 16949

Uploaded by

Parthiban D0 ratings0% found this document useful (0 votes)

49 views2 pagesOriginal Title

Mandatory documents Clause of IATF 16949

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

49 views2 pagesMandatory Documents Clause of IATF 16949

Mandatory Documents Clause of IATF 16949

Uploaded by

Parthiban DCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Mandatory documents Clause of IATF 16949:2016

SL Clause description Clause No.

NO

.

1. Scope of the Quality Management System 4.3

2. Documented process for the management of product safety related products 4.4.1.2

and manufacturing processes

3. Quality Policy 5.2

4. Responsibilities and authorities to ensure that customer requirements are met 5.3.1

5. Quality Objectives and Plans for Achieving Them 6.2

6. Documented process for managing calibration/verification records 7.1.5.2.1

7. Documented process for identification of training needs including awareness 7.2.1

and achieving awareness

8. Documented process to verify competence of internal auditors 7.2.3

9. Documented process to motivate employees 7.3.2

10. Quality manual 7.5.1.1

11. Record retention policy 7.5.3.2.1

12. Documented process for review, distribution and implementation of customer 7.5.3.2.2

engineering standards/specifications

13. Procedure for design and development 8.3.1.1

14. Documented process to identify special characteristics 8.3.3.3

15. Documented supplier selection process 8.4.1.2

16. Documented process to identify and control externally provided processes, 8.4.2.1

products and services

17. Documented process to ensure compliance with statutory and regulatory 8.4.2.2

requirements of purchased processes, products and services

18. Documented process and criteria for supplier evaluation 8.4.2.4

19. Documented process to control and react to changes in product Realization 8.5.6.1

20. Documented process for management of the use of alternate control Methods 8.5.6.1.1

21. Documented process for rework confirmation 8.7.1.4

22. Documented process for repair confirmation 8.7.1.5

23. Documented process for disposition of nonconforming product 8.7.1.7

24. Documented internal audit process 9.2.2.1

25. Documented process for problem solving 10.2.3

26. Documented process to determine the use of error-proofing Methodologies 10.2.4

27. Documented process for continual improvement 10.3.1

Mandatory records Clause of IATF 16949:2016

SL Clause description Clause

NO. No.

1. Results of risk analysis 6.1.2.1

2. Preventive action record 6.1.2.2

3. Contingency plan 6.1.2.3

4. Records of customer acceptance of alternative measurement methods 7.1.5.1.1

5. Maintenance and calibration record 7.1.5.2.1

6. Competence Records 7.2

7. List of qualified internal auditors 7.2.3

8. Documented information on trainer’s competency 7.2.3

9. Documented information on employee’s awareness 7.3.1

10. Registry of customer complaints 8.2

11. Product/service requirements review records 8.2.3.2

12. Record about design and development outputs review 8.3.2

13. Documented information on software development capability selfassessment 8.3.2.3

14. Records about product design and development inputs 8.3.3.1

15. Records about manufacturing process design input requirements 8.3.3.2

16. Records of design and development controls 8.3.4

17. Documented product approval 8.3.4.4

18. Records of design and development outputs 8.3.5

19. Manufacturing process design output 8.3.5.2

20. Design and development changes records 8.3.6

21. Documented approval or waiver of the customer regarding the changes in 8.3.6.1

design

22. Documented revision level of software and hardware as part of the change 8.3.6.1

record

23. Records of second-party audit reports 8.4.2.4.1

24. Characteristics of product to be produced and service to be provided 8.5.1

25. Control plan 8.5.1.1

26. Total productive maintenance system 8.5.1.5

27. Records of traceability 8.5.2.1

28. Records about customer property 8.5.3

29. Production/service provision change control records 8.5.6

30. Documented approval by the customer prior to implementation of the Change 8.5.6.1

31. Record of conformity of product/service with acceptance criteria 8.6

32. Record of expiration date or quantity authorized under concession 8.7.1.1

33. Record on disposition of reworked product 8.7.1.4

34. Record of customer authorization for concession of the product to be repaired 8.7.1.5

35. Notification to the customer about the nonconformity 8.7.1.6

36. Record of nonconforming outputs 8.7.2

37. Monitoring and measurement results 9.1.1

38. Internal audit program 9.2

39. Results of internal audits 9.2

40. Results of the management review 9.3

41. Action plan when customer performance targets are not met 9.3.3.1

42. Results of corrective actions 10.1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CDI-FM-02 Change Request - NO 05Document1 pageCDI-FM-02 Change Request - NO 05Parthiban DNo ratings yet

- Work Instruction For Milling - 1 BoardDocument1 pageWork Instruction For Milling - 1 BoardParthiban DNo ratings yet

- Rework RegisterDocument6 pagesRework RegisterParthiban DNo ratings yet

- Final Inspection Defects Samples ListDocument2 pagesFinal Inspection Defects Samples ListParthiban DNo ratings yet

- Insert Life SheetDocument2 pagesInsert Life SheetParthiban DNo ratings yet

- SAFETY WORK INS PICTORIAL - 2 BoardDocument2 pagesSAFETY WORK INS PICTORIAL - 2 BoardParthiban DNo ratings yet

- Instrument Error MoonitoringDocument1 pageInstrument Error MoonitoringParthiban DNo ratings yet

- 1378 Packing MethodDocument2 pages1378 Packing MethodParthiban DNo ratings yet

- Gauge Revise Price Eco GreenDocument1 pageGauge Revise Price Eco GreenParthiban DNo ratings yet

- Gauge ListDocument1 pageGauge ListParthiban DNo ratings yet

- Pfmea ListDocument1 pagePfmea ListParthiban DNo ratings yet

- 1406 CarDocument1 page1406 CarParthiban DNo ratings yet

- Defect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byDocument6 pagesDefect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byParthiban DNo ratings yet

- Essae 20.06.20Document3 pagesEssae 20.06.20Parthiban DNo ratings yet

- QUALITY POLICY - 4 BoardDocument2 pagesQUALITY POLICY - 4 BoardParthiban DNo ratings yet

- Machine Breakdown DetailsDocument12 pagesMachine Breakdown DetailsParthiban DNo ratings yet

- Essae 8.03.23Document4 pagesEssae 8.03.23Parthiban DNo ratings yet

- Prepared By: Parthiban Approved By: K.R.RajasekarDocument1 pagePrepared By: Parthiban Approved By: K.R.RajasekarParthiban DNo ratings yet

- Master List of Documents 2022Document3 pagesMaster List of Documents 2022Parthiban DNo ratings yet