Professional Documents

Culture Documents

ETL-02344 R1 Visual & Dimensional Procedure

ETL-02344 R1 Visual & Dimensional Procedure

Uploaded by

Anil Krishna JangitiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ETL-02344 R1 Visual & Dimensional Procedure

ETL-02344 R1 Visual & Dimensional Procedure

Uploaded by

Anil Krishna JangitiCopyright:

Available Formats

Elmac Technologies Limited

Visual & Dimensional Inspection Procedure

ELMAC GENERIC FINAL ASSEMBLY VISUAL &

DIMENSIONAL INSPECTION PROCEDURE

All Elmac Flame Arrestors are to be visually and dimensionally checked upon completion of final

assembly.

GENERAL VISUAL INSPECTION REQUIREMENTS

If the Flame Arrestor is supplied painted, paint should cover the entire flame arrestor body-

half and element sub-assemblies, not including stainless steel components (unless otherwise

specified), flange raised-faces and bolting, and specified machined areas.

All sharp edges should be adequately de-burred.

Flange raised faces should be free from scratches or marks that may prevent sealing.

All fasteners/bolting should be stamped with the material grade as a minimum, and (if

coated), no chips or defects should be visually present on the fastener coating. All edges

should be free of burrs.

For in-line Flame Arresters only – Connection flanges should be aligned appropriately (Bolt

holes T.D.C). Element flanges should be vertically aligned to prevent misalignment when

installed into pipework.

NAMEPLATE INSPECTION

It is crucial that nameplate and tagging information is checked for visual defects that may affect

traceability. All standard Elmac CE Nameplates should be riveted to the Element flange periphery,

ensuring the rivets are in a suitable position where they will not come loose at any time.

Figure 1 - ISO 16852 Arrestor Assembly Label

1 First Issue (Project-Specific Document). L.Whitfield 22/08/2019

Rev. Description Issued By Date

Description: GENERIC

VISUAL & DIMENSIONAL INSPECTION

PROCEDURE

Drawn By: L.Whitfield Date: 22/08/2019 Elmac Technologies Limited, Greenfield, Holywell,

Flintshire, United Kingdom CH8 9DP

Checked By: K.Holmberg Date: 22/08/2019

Tel: +44 (0) 1352 717 600 The information contained herein is confidential Document No.

Fax: +44 (0) 1352 717 642 and is the property of Elmac Technologies Ltd. Revision

The information is issued on the understanding that ETL-02344

E-Mail: sales@elmactechnologies.com no part thereof be disclosed to a third party without 1

Web: http://www.elmactechnologies.com

written consent of Elmac Technologies Ltd. Page 1 of 8

Elmac Technologies Limited

Visual & Dimensional Inspection Procedure

Figure 2 - Standard Nameplate & Addition Tag arrangement for end-of-line units

The correct CE nameplate should be marked in accordance with Elmac’s product marking record. The

relevant marking informaiton can also be found on the job route card.

Figure 3 - CE Label Marking example

1 First Issue (Project-Specific Document). L.Whitfield 22/08/2019

Rev. Description Issued By Date

Description: GENERIC

VISUAL & DIMENSIONAL INSPECTION

PROCEDURE

Drawn By: L.Whitfield Date: 22/08/2019 Elmac Technologies Limited, Greenfield, Holywell,

Flintshire, United Kingdom CH8 9DP

Checked By: K.Holmberg Date: 22/08/2019

Tel: +44 (0) 1352 717 600 The information contained herein is confidential Document No.

Fax: +44 (0) 1352 717 642 and is the property of Elmac Technologies Ltd. Revision

The information is issued on the understanding that ETL-02344

E-Mail: sales@elmactechnologies.com no part thereof be disclosed to a third party without 1

Web: http://www.elmactechnologies.com

written consent of Elmac Technologies Ltd. Page 2 of 8

Elmac Technologies Limited

Visual & Dimensional Inspection Procedure

Additional tag plates (if requested) should be attached by one of the following methods (unless

otherwise stated):

Attachment by means of wiring the additional tag plate to the bird screen (if end-of-line) or on

an appropriate stud bolt located next to the CE label (Ref. Figure 2).

Attachment by means of riveting the tag plate to the element central body flange periphery

(Ref. Figure 4).

An additional adhesive CE label should also be attached to the element with the relevant element

model and serial number. For end-of-line units, the Element model information will be stamped to the

outer circumference of the element crimped-ribbon core.

All label markings should be clearly visible and additional tag plates should be free of burrs.

Figure 4 - General Nameplate Arrangement for in-line units

1 First Issue (Project-Specific Document). L.Whitfield 22/08/2019

Rev. Description Issued By Date

Description: GENERIC

VISUAL & DIMENSIONAL INSPECTION

PROCEDURE

Drawn By: L.Whitfield Date: 22/08/2019 Elmac Technologies Limited, Greenfield, Holywell,

Flintshire, United Kingdom CH8 9DP

Checked By: K.Holmberg Date: 22/08/2019

Tel: +44 (0) 1352 717 600 The information contained herein is confidential Document No.

Fax: +44 (0) 1352 717 642 and is the property of Elmac Technologies Ltd. Revision

The information is issued on the understanding that ETL-02344

E-Mail: sales@elmactechnologies.com no part thereof be disclosed to a third party without 1

Web: http://www.elmactechnologies.com

written consent of Elmac Technologies Ltd. Page 3 of 8

Elmac Technologies Limited

Visual & Dimensional Inspection Procedure

DIMENSIONAL INSPECTION REQUIREMENTS

Care should be taken when performing dimensional checks upon each stage of manufacture.

All dimensions should be in accordance with the standard Elmac Technical File data or contract-

specific drawings.

Critical dimensions should be within the tolerances stated on the relevant drawings. These

dimensions are generally as follows:

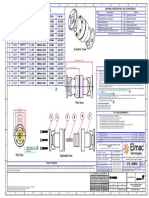

FOR IN-LINE UNITS

Figure 5 - Dimensional details for in-line units

The ‘raised-face to raised-face’ sub-assembly length (+/- 3.0mm)

The overall unit length (+/- 6.0mm)

Note: Figure 5 is a general representation of a completely assembled in-line Flame Arrester.

Dimensions will vary dependant on size (nominal bore) and contract-specific requirements.

1 First Issue (Project-Specific Document). L.Whitfield 22/08/2019

Rev. Description Issued By Date

Description: GENERIC

VISUAL & DIMENSIONAL INSPECTION

PROCEDURE

Drawn By: L.Whitfield Date: 22/08/2019 Elmac Technologies Limited, Greenfield, Holywell,

Flintshire, United Kingdom CH8 9DP

Checked By: K.Holmberg Date: 22/08/2019

Tel: +44 (0) 1352 717 600 The information contained herein is confidential Document No.

Fax: +44 (0) 1352 717 642 and is the property of Elmac Technologies Ltd. Revision

The information is issued on the understanding that ETL-02344

E-Mail: sales@elmactechnologies.com no part thereof be disclosed to a third party without 1

Web: http://www.elmactechnologies.com

written consent of Elmac Technologies Ltd. Page 4 of 8

Elmac Technologies Limited

Visual & Dimensional Inspection Procedure

FOR END-OF-LINE UNITS

Figure 6 – Dimensional details of end-of-line units

The ‘raised-face’ to flat-face dimensions (+/- 3.0mm)

The overall unit height (+/- 5.0mm)

Note: Figure 6 is a general representation of a completely assembled end-of-line Flame

Arrester. Dimensions will vary dependant on size (nominal bore) and contract-specific

requirements.

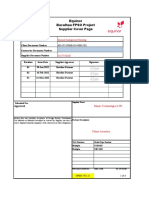

Once all relevant visual and dimensions checks have been performed, a generic report should be

completed (if required as per contract-specific requirements). Refer to attachment 1 for a typical visual

& dimensional report template.

1 First Issue (Project-Specific Document). L.Whitfield 22/08/2019

Rev. Description Issued By Date

Description: GENERIC

VISUAL & DIMENSIONAL INSPECTION

PROCEDURE

Drawn By: L.Whitfield Date: 22/08/2019 Elmac Technologies Limited, Greenfield, Holywell,

Flintshire, United Kingdom CH8 9DP

Checked By: K.Holmberg Date: 22/08/2019

Tel: +44 (0) 1352 717 600 The information contained herein is confidential Document No.

Fax: +44 (0) 1352 717 642 and is the property of Elmac Technologies Ltd. Revision

The information is issued on the understanding that ETL-02344

E-Mail: sales@elmactechnologies.com no part thereof be disclosed to a third party without 1

Web: http://www.elmactechnologies.com

written consent of Elmac Technologies Ltd. Page 5 of 8

Elmac Technologies Limited

Visual & Dimensional Inspection Procedure

ATTACHMENT 1 – TYPICAL VISUAL & DIMENSIONAL

REPORT TEMPLATE

1 First Issue (Project-Specific Document). L.Whitfield 22/08/2019

Rev. Description Issued By Date

Description: GENERIC

VISUAL & DIMENSIONAL INSPECTION

PROCEDURE

Drawn By: L.Whitfield Date: 22/08/2019 Elmac Technologies Limited, Greenfield, Holywell,

Flintshire, United Kingdom CH8 9DP

Checked By: K.Holmberg Date: 22/08/2019

Tel: +44 (0) 1352 717 600 The information contained herein is confidential Document No.

Fax: +44 (0) 1352 717 642 and is the property of Elmac Technologies Ltd. Revision

The information is issued on the understanding that ETL-02344

E-Mail: sales@elmactechnologies.com no part thereof be disclosed to a third party without 1

Web: http://www.elmactechnologies.com

written consent of Elmac Technologies Ltd. Page 6 of 8

Elmac Technologies Limited

Visual & Dimensional Inspection Procedure

1 First Issue (Project-Specific Document). L.Whitfield 22/08/2019

Rev. Description Issued By Date

Description: GENERIC

VISUAL & DIMENSIONAL INSPECTION

PROCEDURE

Drawn By: L.Whitfield Date: 22/08/2019 Elmac Technologies Limited, Greenfield, Holywell,

Flintshire, United Kingdom CH8 9DP

Checked By: K.Holmberg Date: 22/08/2019

Tel: +44 (0) 1352 717 600 The information contained herein is confidential Document No.

Fax: +44 (0) 1352 717 642 and is the property of Elmac Technologies Ltd. Revision

The information is issued on the understanding that ETL-02344

E-Mail: sales@elmactechnologies.com no part thereof be disclosed to a third party without 1

Web: http://www.elmactechnologies.com

written consent of Elmac Technologies Ltd. Page 7 of 8

Elmac Technologies Limited

Visual & Dimensional Inspection Procedure

1 First Issue (Project-Specific Document). L.Whitfield 22/08/2019

Rev. Description Issued By Date

Description: GENERIC

VISUAL & DIMENSIONAL INSPECTION

PROCEDURE

Drawn By: L.Whitfield Date: 22/08/2019 Elmac Technologies Limited, Greenfield, Holywell,

Flintshire, United Kingdom CH8 9DP

Checked By: K.Holmberg Date: 22/08/2019

Tel: +44 (0) 1352 717 600 The information contained herein is confidential Document No.

Fax: +44 (0) 1352 717 642 and is the property of Elmac Technologies Ltd. Revision

The information is issued on the understanding that ETL-02344

E-Mail: sales@elmactechnologies.com no part thereof be disclosed to a third party without 1

Web: http://www.elmactechnologies.com

written consent of Elmac Technologies Ltd. Page 8 of 8

You might also like

- Pay PalsDocument33 pagesPay Palssiluej3No ratings yet

- 01 Aa Videojet 1220 1520 Service ManualDocument324 pages01 Aa Videojet 1220 1520 Service ManualAmmar WZ100% (2)

- SM EnglishDocument318 pagesSM EnglishFikri AbdurrazaqmuhammadNo ratings yet

- 01 Aa Videojet 1710 Service Manual PDFDocument309 pages01 Aa Videojet 1710 Service Manual PDFNoah SmithNo ratings yet

- 1710W Service Manual Eng (001-204)Document204 pages1710W Service Manual Eng (001-204)Jose DavidNo ratings yet

- Automotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedFrom EverandAutomotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedRating: 4 out of 5 stars4/5 (3)

- Til 1719Document4 pagesTil 1719FRANCISCO JOSE GARCIA IBAÑEZNo ratings yet

- LTE and the Evolution to 4G Wireless: Design and Measurement ChallengesFrom EverandLTE and the Evolution to 4G Wireless: Design and Measurement ChallengesMoray RumneyRating: 5 out of 5 stars5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Security Architect: Careers in information securityFrom EverandSecurity Architect: Careers in information securityRating: 3.5 out of 5 stars3.5/5 (1)

- LTE Signaling: Troubleshooting and OptimizationFrom EverandLTE Signaling: Troubleshooting and OptimizationRating: 3.5 out of 5 stars3.5/5 (2)

- Joint Report On Corporate Practice of Dentistry in The Medicaid Program July 2013Document1,517 pagesJoint Report On Corporate Practice of Dentistry in The Medicaid Program July 2013Dentist The MenaceNo ratings yet

- Ar9k Ce Iec 61439 Cert PDFDocument1 pageAr9k Ce Iec 61439 Cert PDFDaniel grandonNo ratings yet

- IECEx CML 18.0190XDocument6 pagesIECEx CML 18.0190XAndrada Maria TudorNo ratings yet

- C Tick MarkingDocument6 pagesC Tick MarkingGigi FiloteNo ratings yet

- Faa TC-20-10Document82 pagesFaa TC-20-10K SiriusNo ratings yet

- Electron Machine ATEX EU Type Examination CertificateDocument3 pagesElectron Machine ATEX EU Type Examination Certificatealemrajabi.safatNo ratings yet

- Ge Oil & Gas: Vcmi and Vpro Ionet Transceiver Chip ReliabilityDocument7 pagesGe Oil & Gas: Vcmi and Vpro Ionet Transceiver Chip Reliabilityzizu1234No ratings yet

- SBOM20807 - Sherook A. Ghaly - Case (1, 2, 3, 4, Final) ASSIGNMENT 1 External AuditDocument5 pagesSBOM20807 - Sherook A. Ghaly - Case (1, 2, 3, 4, Final) ASSIGNMENT 1 External AuditSherook AbdelMoneim GhalyNo ratings yet

- Certificate: PC1864/PC1832/PC1616 - Control and Indicating EquipmentDocument4 pagesCertificate: PC1864/PC1832/PC1616 - Control and Indicating EquipmentJoaquim DiasNo ratings yet

- Sonatrach Mark - VI Maintenance VOL - I PDFDocument1,016 pagesSonatrach Mark - VI Maintenance VOL - I PDFمحمد أبو لؤي100% (6)

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- What Is The Technical FileDocument6 pagesWhat Is The Technical Filejohan janssensNo ratings yet

- INTERNAL - Typical Instruments Installation Details For PackagesDocument61 pagesINTERNAL - Typical Instruments Installation Details For PackagesRhona Mae Piodena ToroyNo ratings yet

- 823c2 Compal LA-7912PDocument63 pages823c2 Compal LA-7912Pwotanel100% (1)

- Iecex Certificate of Conformity: Iec Cer Tification System For Explosive Atmospher EsDocument3 pagesIecex Certificate of Conformity: Iec Cer Tification System For Explosive Atmospher EsdrangosaNo ratings yet

- Eu-Type Examination: CertificateDocument3 pagesEu-Type Examination: CertificateDnyDnyNo ratings yet

- Prsdsa199 - AK350 Fade-Out ThinnerDocument16 pagesPrsdsa199 - AK350 Fade-Out ThinnerDavidNo ratings yet

- SIL4001DDocument3 pagesSIL4001Djesus francoNo ratings yet

- Compal La-8981p r1.0 SchematicsDocument34 pagesCompal La-8981p r1.0 SchematicsKiran VeesamNo ratings yet

- IECEx SIM 09.0001X 007Document19 pagesIECEx SIM 09.0001X 007waleedusman44No ratings yet

- Avl - Asl May 2015Document125 pagesAvl - Asl May 2015Ali100% (1)

- IECEx INE 14.0028U 004Document9 pagesIECEx INE 14.0028U 004waleedusman44No ratings yet

- Technical Reference Manual: MAN0019, Rev. GDocument50 pagesTechnical Reference Manual: MAN0019, Rev. GJuan OrozcoNo ratings yet

- Artex Sil 4011 CDocument2 pagesArtex Sil 4011 CBrunoNo ratings yet

- Intellian v85nx User ManualDocument105 pagesIntellian v85nx User ManualAsad VakiliNo ratings yet

- Installation: 8-1. Objectives of An Information Technology Equipment FacilityDocument15 pagesInstallation: 8-1. Objectives of An Information Technology Equipment Facilityue3b2No ratings yet

- ATEX RPA455xDocument4 pagesATEX RPA455xFabio Emanuele BrandaNo ratings yet

- Amazon Amz-L81 - Compal La-3161p Hel80 - Rev 0Document43 pagesAmazon Amz-L81 - Compal La-3161p Hel80 - Rev 0Andre BigoNo ratings yet

- 10080-1-ENGG-DBD-CI-007 - 0 - Design Basis For Fire and Gas SystemDocument36 pages10080-1-ENGG-DBD-CI-007 - 0 - Design Basis For Fire and Gas SystemDinesh Boopalan100% (2)

- Gym9 DC CeDocument1 pageGym9 DC CeJorge Manuel Perez RodriguezNo ratings yet

- CH 648 C/652 C COMBINES Electrical Component and Battery Discharge Risk - Rp7958 MandatoryDocument2 pagesCH 648 C/652 C COMBINES Electrical Component and Battery Discharge Risk - Rp7958 MandatoryMessi EmetievNo ratings yet

- EMC Pro1040 Pro1050 2182013 ODCùl ENDocument75 pagesEMC Pro1040 Pro1050 2182013 ODCùl ENTayfun SezişNo ratings yet

- CENG0133 - C - Customer - Safety - and - Regulatory - InformationDocument23 pagesCENG0133 - C - Customer - Safety - and - Regulatory - InformationRohit PanwarNo ratings yet

- Pc4000 InspectionDocument18 pagesPc4000 Inspectioncarmenbuleandra0% (1)

- FLT M02 0004Document44 pagesFLT M02 0004DanielDeFrancescoNo ratings yet

- 504511950000-HEX 80wkDocument14 pages504511950000-HEX 80wksurijanti447No ratings yet

- 1683587578BHEL India 2Document18 pages1683587578BHEL India 2Senthil KumarNo ratings yet

- Irregularities, Frauds and the Necessity of Technical Auditing in Construction IndustryFrom EverandIrregularities, Frauds and the Necessity of Technical Auditing in Construction IndustryNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Challenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsFrom EverandChallenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsNo ratings yet

- Contract Strategies for Major Projects: Mastering the Most Difficult Element of Project ManagementFrom EverandContract Strategies for Major Projects: Mastering the Most Difficult Element of Project ManagementNo ratings yet

- Electrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceFrom EverandElectrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceNo ratings yet

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- Trilogy of Connectors: Basic Principles and Connector Design ExplanationsFrom EverandTrilogy of Connectors: Basic Principles and Connector Design ExplanationsRating: 5 out of 5 stars5/5 (1)

- TP-MAG-ASME Issue 1Document15 pagesTP-MAG-ASME Issue 1Anil Krishna JangitiNo ratings yet

- 2 Inch UCB Lite Cast Joint EfficiencyDocument3 pages2 Inch UCB Lite Cast Joint EfficiencyAnil Krishna JangitiNo ratings yet

- Elmac Material SelectionDocument1 pageElmac Material SelectionAnil Krishna JangitiNo ratings yet

- Elmac BibleDocument82 pagesElmac BibleAnil Krishna JangitiNo ratings yet

- IMS005-QM001-QAP-037 Remote Inspection ProcedureDocument13 pagesIMS005-QM001-QAP-037 Remote Inspection ProcedureAnil Krishna JangitiNo ratings yet

- Pulse BOM 0001 01Document3 pagesPulse BOM 0001 01Anil Krishna JangitiNo ratings yet

- KM-OPS-GD-010 SGL Inspection PlanDocument1 pageKM-OPS-GD-010 SGL Inspection PlanAnil Krishna JangitiNo ratings yet

- ISO-1302-1992 - Surface FinishDocument11 pagesISO-1302-1992 - Surface FinishAnil Krishna JangitiNo ratings yet

- 1 s2.0 S187770581101160X MainDocument6 pages1 s2.0 S187770581101160X MainAnil Krishna JangitiNo ratings yet

- KM-GM-PR-001 Management ReviewDocument10 pagesKM-GM-PR-001 Management ReviewAnil Krishna JangitiNo ratings yet

- KM-GM-PR-002 Annual Packaging SubmissionsDocument6 pagesKM-GM-PR-002 Annual Packaging SubmissionsAnil Krishna JangitiNo ratings yet

- Yib 09 4800090967 ZVC01 00001 0000 06Document3 pagesYib 09 4800090967 ZVC01 00001 0000 06Anil Krishna JangitiNo ratings yet

- Etl 03016 Rev. 3 Ucb 025 ModelDocument1 pageEtl 03016 Rev. 3 Ucb 025 ModelAnil Krishna JangitiNo ratings yet

- Ahw 10 4800090967 ZVC01 00002 0000 06Document3 pagesAhw 10 4800090967 ZVC01 00002 0000 06Anil Krishna JangitiNo ratings yet

- Equinor Bacalhau FPSO Project Supplier Cover Page: General Arrangement DrawingDocument3 pagesEquinor Bacalhau FPSO Project Supplier Cover Page: General Arrangement DrawingAnil Krishna JangitiNo ratings yet

- Problem 1Document8 pagesProblem 1Celine Marie AntonioNo ratings yet

- 14 MW HPP Nalter-V Cashwork PlanDocument7 pages14 MW HPP Nalter-V Cashwork PlanSyadaBatoolNo ratings yet

- Activity 2.A: Illegal Use of ElectricityDocument26 pagesActivity 2.A: Illegal Use of ElectricityMark Lawrence BuenviajeNo ratings yet

- Modern Advanced Accounting in Canada Canadian 7th Edition Hilton Test Bank PDFDocument6 pagesModern Advanced Accounting in Canada Canadian 7th Edition Hilton Test Bank PDFSpencerMoorenbds100% (44)

- Case Bears WorldDocument2 pagesCase Bears WorldAlexandra ErmakovaNo ratings yet

- CBSE Class 10 History Notes Chapter 3 - The Making of A Global WorldDocument8 pagesCBSE Class 10 History Notes Chapter 3 - The Making of A Global WorldGitika DasNo ratings yet

- Arunika Gunjaal - Haldiram SIPDocument11 pagesArunika Gunjaal - Haldiram SIPARUNIKA GUNJAALNo ratings yet

- Private Hog Farm ListDocument86 pagesPrivate Hog Farm ListDaal AgSmartNo ratings yet

- Microeconomics: How Economics Work: The Scope and Method of EconomicsDocument25 pagesMicroeconomics: How Economics Work: The Scope and Method of EconomicsSiva VarmaNo ratings yet

- Richa Gupta ResumeDocument4 pagesRicha Gupta Resumescribd@123No ratings yet

- Cambridge Steering Complex Projects Brochure 21 09 2020Document15 pagesCambridge Steering Complex Projects Brochure 21 09 2020visa707No ratings yet

- Section 2 - Amendment of Schedule-1 of Act No. 2 of 1899Document34 pagesSection 2 - Amendment of Schedule-1 of Act No. 2 of 1899ASHUTOSH MISHRANo ratings yet

- CutePDF - Support - CutePDF Writer HelpDocument3 pagesCutePDF - Support - CutePDF Writer HelpPaul Adrian Senior CiobanitaNo ratings yet

- STEVTA Act 2009 - 2010-04-20Document16 pagesSTEVTA Act 2009 - 2010-04-20devilhunterxNo ratings yet

- Financial ManagementDocument9 pagesFinancial ManagementMiconNo ratings yet

- Selection List For UPSC CoachingDocument4 pagesSelection List For UPSC CoachingRavi kiranNo ratings yet

- Revenue Memorandum CircularsDocument90 pagesRevenue Memorandum CircularsJess Esmena100% (1)

- GST Credit Note WB 2212205 A A 65120Document1 pageGST Credit Note WB 2212205 A A 65120web webNo ratings yet

- Home Browse Rental Gear How This Works Visit Our Retail Store Outdoor Advice About UsDocument3 pagesHome Browse Rental Gear How This Works Visit Our Retail Store Outdoor Advice About UsBeltous Che CheNo ratings yet

- Bonus StatementDocument1 pageBonus StatementSonu Sharma Club fanNo ratings yet

- The University Foundation Inc.: BA 101 Group 3Document45 pagesThe University Foundation Inc.: BA 101 Group 3Lance EstopenNo ratings yet

- MPS 03042024 183304Document2 pagesMPS 03042024 183304itsstradermohitNo ratings yet

- Unit 4 TQM NotesDocument35 pagesUnit 4 TQM NotesHarish100% (1)

- Application of IT in Our Daily Life PDFDocument26 pagesApplication of IT in Our Daily Life PDFjaweriaNo ratings yet

- Marketing Strategies of BSNLDocument5 pagesMarketing Strategies of BSNLRanjeet Pandit50% (2)

- Luke Firth - CVDocument2 pagesLuke Firth - CVLuke Anthony FirthNo ratings yet

- EEE 304 - Exp2Document7 pagesEEE 304 - Exp2Aurongo NasirNo ratings yet

- Money LaunderingDocument5 pagesMoney LaunderingArslan SajjadNo ratings yet