Professional Documents

Culture Documents

Yk 250 XG

Yk 250 XG

Uploaded by

jet.heOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yk 250 XG

Yk 250 XG

Uploaded by

jet.heCopyright:

Available Formats

YK250XG

Articulated robots

Standard type: Small type

YA

Arm length 250mm Maximum payload 5kg

Linear conveyor

LCM100

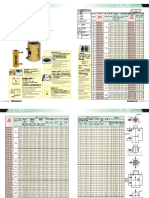

Ordering method

modules

YK250XG 150 RCX340-4

Model Z axis stroke Tool flange Hollow shaft Cable Controller / Safety Option A Option B Option C Option D Option E Absolute

Motor-less single

Robonity TRANSERVO

Number of controllable axes standard (OP.A) (OP.B) (OP.C) (OP.D) (OP.E) battery

axis actuator

150: 150mm No entry: None No entry: None 3L: 3.5m

F: With tool flange S: With hollow shaft 5L: 5m

10L: 10m Specify various controller setting items. RCX340 P.566

single-axis robots

Compact

Specifications Controller

X-axis Y-axis Z-axis R-axis Controller Power capacity (VA) Operation method

Axis Arm length 100 mm 150 mm 150 mm - Programming /

Single-axis robots

specifications Rotation angle +/-140 ° +/-144 ° - +/-360 ° I/O point trace /

FLIP-X

Remote command /

AC servo motor output 200 W 150 W 50 W 100 W RCX340 1000

Operation

Deceleration Transmission Motor to speed reducer Direct-coupled using RS-232C

mechanism method Speed reducer to output Direct-coupled communication

Repeatability Note 1 +/-0.01 mm +/-0.01 mm +/-0.004 °

single-axis robots

PHASER

Maximum speed 4.5 m/sec 1.1 m/sec 1020 °/sec

Linear motor

Maximum payload 5 kg (Standard specification), 4 kg (Option specifications Note 4) Note. The movement range can be limited by changing the positions

of X and Y axis mechanical stoppers. (The movement range is

Standard cycle time: with 2kg payload Note 2 0.43 sec set to the maximum at the time of shipment.)

R-axis tolerable moment of inertia Note 3 0.05 kgm2 (0.5 kgfcms2) See our robot manuals (installation manuals) for detailed

information.

User wiring 0.2 sq × 10 wires Note. To set the standard coordinates with high accuracy, use a

User tubing (Outer diameter) ϕ4×3 standard coordinate setting jig (option). Refer to the user’s

Cartesian

manual (installation manual) for more details.

XY-X

robots

Travel limit 1.Soft limit 2.Mechanical stopper (X,Y,Z axis)

Our robot manuals (installation manuals) can be

Robot cable length Standard: 3.5 m Option: 5 m, 10 m downloaded from our website at the address below:

Weight 18.5 kg https://global.yamaha-motor.com/business/robot/

Note 1. This is the value at a constant ambient temperature. (X,Y axes)

Note 2. When reciprocating 300mm in horizontal and 25mm in vertical directions.

Note 3. The acceleration coefficient is set automatically in accordance with the tip weight and R-axis moment of inertia settings.

YK-X

SCARA

robots

Note 4. Maximum payload of option specifications (with tool flange attached or with user wiring and tubing routed through spline shaft) is 4kg.

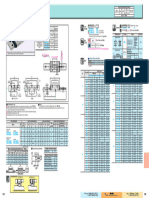

YK250XG

Pick & place

YP-X

robots

142

93

104

60 60

144°

144°

140°

140

R9

90

140°

CLEAN

R250

User tubing 1 (ϕ4 black) 30 62 4-ϕ9 R

15

227

User tubing 2 (ϕ4 red) 50 88 M8 bolt for installation, 4 bolts used 0

User tubing 3 (ϕ4 blue) 138 (Base size)

36° The arm may be in contact with the

D-sub connector for user wiring (No. 1 to 10 usable) 36° machine harness in an area inside from

148

CONTROLLER INFORMATION

the inner limit of this working envelope.

Cross section B-B So, do not operate the arm in this area.

129

56 150 100 Maximum 280 during arm rotation • Note that the robot cannot be used at a position where

Machine the base flange or robot cable interferes with the spline

661 harness 640 in the working envelope shown above.

Maximum 660 • X-axis mechanical stopper position : 142°

during arm rotation

Ho mete

614 • Y-axis mechanical stopper position : 146°

dia

llow r ϕ

4-M3 × 0.5 through-hole (No phase relation to R-axis origin.)

7.8

11

B B As this hole is intended for the wiring/tubing clamp, do not

468 attach a large load to it.

428

7.8

↓F

ϕ27 7.8 7.8

42 57 780.5 View of F

Extra small

5

User tubing 1 (ϕ4 black)

150

Orbit /

283

type

47

264 D-sub connector

235 246 User tubing 2 (ϕ4 red) for user wiring

230 222

202 (No. 1 to 10 usable)

30 12

187 174 User tubing 3 (ϕ4 blue)

183

Small type

A A 167

4

138.5 +/-2 0

User tool ϕ16 h7-0.018

95

installation ϕ35 79

150

range 61 138.5 +/-2

45

86

150

12

0 0 0

Large type inverse type

0

28 26

11.5

Z-axis lower end M4 ground terminal

11.5

4

mechanical stopper position Z-axis upper end mechanical stopper

position 4mm rise during Z-axis return-to-origin Option:

Width across flat 15

User wiring/tubing through spline type

1

ϕ1

er

et

Wall mount / & drip-proof

54

m

50 70 20

dia

R27 (Min. cable bending radius)

w

Do not move the cable.

llo

Ho

10 10

39 39

Cross section A-A Keep enough space for the maintenance

work at the rear of the base.

Dust-proof

Tapped hole for user wiring 6-M3 × 0.5 Depth 6

4-ϕ9

type

The weight of the tool attached here should be

added to the tip mass.

Controller RCX340 u 566 401

YK250XG

Articulated robots

YA

Linear conveyor

LCM100

modules

Motor-less single

Robonity TRANSERVO

axis actuator

single-axis robots

Compact

Single-axis robots

FLIP-X

single-axis robots

PHASER

Linear motor

Cartesian

XY-X

robots

YK-X

SCARA

robots

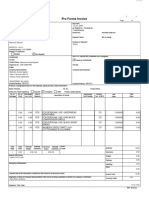

YK250XG Tool flange mount type

Pick & place

YP-X

robots

142

93

164

144°

144°

140°

R3

104

60 60

140°

0

140

R91

90

84

R250

CLEAN

R

226

15

30 62 4-ϕ9 0

50 88 M8 bolt for installation, 4 bolts used

The arm may be in contact with the

138 (Base size) 33° machine harness in an area inside from

164 33° the inner limit of this working envelope.

So, do not operate the arm in this area.

CONTROLLER INFORMATION

• Note that the robot cannot be used at a position where

Machine harness the base flange or robot cable interferes with the tool

flange in the working envelope shown above.

• X-axis mechanical stopper position : 142°

Ho mete

• Y-axis mechanical stopper position : 146°

dia

llow r ϕ

4-M3 × 0.5 through-hole (No phase relation to R-axis origin.)

7.8

11

As this hole is intended for the wiring/tubing clamp, do not

attach a large load to it.

7.8

↓F

ϕ27 7.8 7.8

780.5 View of F

User tubing 1 (ϕ4 black)

5

150

D-sub connector

Extra small

User tubing 2 (ϕ4 red) for user wiring

Orbit /

(No. 1 to 10 usable)

type

181 User tubing 3 (ϕ4 blue)

149 D

134.5 +/-2

95 181

79

Small type

149

150

61 134.5 +/-2

45 D

86

150

12

Holl

0 0 0

ow

28 26

15.5

15.5

dia

M4 ground terminal

me

22

ϕ35 4-ϕ4.5 through-hole Option:

.6

ter

Large type inverse type

ϕ11

User wiring/tubing through spline type

R27 (Min. cable bending radius)

90°

50 70 20 54 Do not move the cable.

22

22

.6

4

.6

.6

+/

10 10

39 39

22

-0

.0

2

↑E

2

Wall mount / & drip-proof

0

Keep enough space for ϕ30 h7 -0.021

2

.0

the maintenance work at ϕ55

-0

Tapped hole for user wiring 6-M3 × 0.5 Depth 6 ϕ4 H7 +0.012

.6

+/

the rear of the base. through-hole

4-ϕ9

22

0

7

The weight of the tool attached here should

be added to the tip mass. Detailed drawing D View of E

Dust-proof

type

402 Controller RCX340 u 566

You might also like

- Allison HT HTB CLT CLBT Electronic Control Transmissions Tips ManualDocument51 pagesAllison HT HTB CLT CLBT Electronic Control Transmissions Tips ManualMauricio Gomez Gomez100% (1)

- Toyota 8FBN PDFDocument7 pagesToyota 8FBN PDFweda utama100% (1)

- ECG Apib PDFDocument68 pagesECG Apib PDFArthur KakarekoNo ratings yet

- Annovi Reverberi XTV-2.1 Operating & Parts ManualDocument18 pagesAnnovi Reverberi XTV-2.1 Operating & Parts Manualinscribe100% (1)

- Inventory ManagementDocument3 pagesInventory Managementmani_932218609No ratings yet

- Yk 350 XGDocument2 pagesYk 350 XGjet.heNo ratings yet

- YK1200X 400 RCX340-4: Standard Type: Large TypeDocument1 pageYK1200X 400 RCX340-4: Standard Type: Large TypeJuan David Valderrama ArtunduagaNo ratings yet

- Yk 400 XGDocument2 pagesYk 400 XGjet.heNo ratings yet

- Ordering Method: Specifications Allowable Overhang Static Loading MomentDocument1 pageOrdering Method: Specifications Allowable Overhang Static Loading MomentCentro turistico Los rosalesNo ratings yet

- Emcoder Incremetal Das Serras Extrusoras E50-series-INSDocument1 pageEmcoder Incremetal Das Serras Extrusoras E50-series-INSEle isNo ratings yet

- Datasheet CR35iADocument1 pageDatasheet CR35iAsantiagoNo ratings yet

- 1000481-HSGP-5010-00-30-009 - H 1Document1 page1000481-HSGP-5010-00-30-009 - H 1hasan.mohamed2305No ratings yet

- Datasheet M 1ia 05ADocument1 pageDatasheet M 1ia 05AHugo SalazarNo ratings yet

- M-900 Robot Working Range: 330 KG 3203 MMDocument1 pageM-900 Robot Working Range: 330 KG 3203 MMjosjcrsNo ratings yet

- MM 35 38CLRGDocument2 pagesMM 35 38CLRGHarvey Ian Pagatpatan AquinoNo ratings yet

- SC-350S/D, SC - 350S/D, SC - 600S/D: All-Axis Servo Driven Type Take-Out RobotDocument1 pageSC-350S/D, SC - 350S/D, SC - 600S/D: All-Axis Servo Driven Type Take-Out Robotbagas prakosoNo ratings yet

- Heli Doc-20230117-Wa0001.Document1 pageHeli Doc-20230117-Wa0001.ATILLANo ratings yet

- Datasheet P-50iB-10LDocument1 pageDatasheet P-50iB-10LGabyReyesValdezNo ratings yet

- Ec140b 09Document6 pagesEc140b 09Fadli HernandoNo ratings yet

- E6 Servo Full Manual PDFDocument2 pagesE6 Servo Full Manual PDFRomain JRNo ratings yet

- CR-35 Robot Working Range: 35 KG 1813 MMDocument1 pageCR-35 Robot Working Range: 35 KG 1813 MMGuilhermeNo ratings yet

- FireNET Plus Wiring DiagramDocument1 pageFireNET Plus Wiring DiagramYusuf HungundNo ratings yet

- Datasheet M-1iA-05SDocument1 pageDatasheet M-1iA-05Sketan rsNo ratings yet

- MY - 3-1-6 Specification - Slim Low Static Ducted Twenty Series PDFDocument1 pageMY - 3-1-6 Specification - Slim Low Static Ducted Twenty Series PDFAbipraya UNRINo ratings yet

- LLW R01 2017KW GBDocument28 pagesLLW R01 2017KW GBkatagi74No ratings yet

- Datasheet LRMate-200iD-7LCDocument1 pageDatasheet LRMate-200iD-7LCPremium WzorceNo ratings yet

- DS4510 5010Document2 pagesDS4510 5010Andie Hart100% (1)

- Proyecto Salina Cruz Mediana TensionDocument1 pageProyecto Salina Cruz Mediana TensionCarlos SalvadorNo ratings yet

- Datasheet M 3ia 12HDocument1 pageDatasheet M 3ia 12H63 MGNo ratings yet

- Main Crane CC 2800-1 Main Crane 80t C-054-14 Tailing Crane SL6000 Tailing Crane 43.2t C-054-14Document2 pagesMain Crane CC 2800-1 Main Crane 80t C-054-14 Tailing Crane SL6000 Tailing Crane 43.2t C-054-14Bangun DjiwandonoNo ratings yet

- It600 Wiring Centre Kl10rf 004Document2 pagesIt600 Wiring Centre Kl10rf 004NataLeeNo ratings yet

- Datasheet-Cr7ia L EnglishDocument1 pageDatasheet-Cr7ia L EnglishNgộ Không TônNo ratings yet

- Long Arm Excavator SeriesDocument4 pagesLong Arm Excavator SeriesBryson PlazosNo ratings yet

- ERV ERV: Energy Recovery Ventilator Energy Recovery VentilatorDocument2 pagesERV ERV: Energy Recovery Ventilator Energy Recovery VentilatorEddie IeqNo ratings yet

- Datasheet LRMate-200iD-4S - KUKADocument1 pageDatasheet LRMate-200iD-4S - KUKAJOSE MANUELNo ratings yet

- Autonics E30s ManualDocument1 pageAutonics E30s ManualAndrez BermudezNo ratings yet

- CAME Technical-Manual 002ZF1NDocument12 pagesCAME Technical-Manual 002ZF1NFrancesco AltobelliNo ratings yet

- Manual Chain Hoist Hand Pallet Truck Electric Chain Hoist (SSDHL - Model)Document2 pagesManual Chain Hoist Hand Pallet Truck Electric Chain Hoist (SSDHL - Model)Muhammed ShamseerNo ratings yet

- ATS EngDocument1 pageATS EngOctavianus LinNo ratings yet

- Hollow Shaft Encoder WDG 100 HDocument5 pagesHollow Shaft Encoder WDG 100 HAntonio Carlos CardosoNo ratings yet

- Datasheet Cr4ia enDocument1 pageDatasheet Cr4ia enMohit JaniNo ratings yet

- Long Z: User's ManualDocument60 pagesLong Z: User's Manualchinaaaa6No ratings yet

- Centrala Comanda SalusDocument2 pagesCentrala Comanda SalusCristian MironNo ratings yet

- Miniature Linear Guides: - Wide RailsDocument1 pageMiniature Linear Guides: - Wide Railsphatdang1996No ratings yet

- E 0 PDFDocument1 pageE 0 PDFSketch UpNo ratings yet

- M900iB 400LDocument1 pageM900iB 400LLeonardo AlexNo ratings yet

- Scara Robot: High Speed HandlingDocument2 pagesScara Robot: High Speed HandlingXanti Zabala Da RosaNo ratings yet

- I107e r88m-g G-Series Servo Motors Datasheet enDocument10 pagesI107e r88m-g G-Series Servo Motors Datasheet ennguyenquocNo ratings yet

- E40 Series INSDocument1 pageE40 Series INSSrinivas ElecNo ratings yet

- ZF As Tronic Schematic - EDocument2 pagesZF As Tronic Schematic - EBienvenu Massouangui50% (2)

- Hirayama Brochure HICLAVE PDFDocument2 pagesHirayama Brochure HICLAVE PDFDwi Putri Apriyanti50% (2)

- Forklift Engine Powered Dan Electric PoweredDocument40 pagesForklift Engine Powered Dan Electric PoweredRaka RakaNo ratings yet

- FN1016 2SD2390Document1 pageFN1016 2SD2390jcarlos1960No ratings yet

- Mepe 3 3W, 11kV: Project Title: Site Name: Bago StationDocument2 pagesMepe 3 3W, 11kV: Project Title: Site Name: Bago StationAung Thein OoNo ratings yet

- sc70 enDocument1 pagesc70 enRick ChenNo ratings yet

- OPzV GelDocument1 pageOPzV GelSINES France100% (1)

- And Versatile: Strong, CompactDocument2 pagesAnd Versatile: Strong, Compactperop123No ratings yet

- Jak1 Aur El DWG A 0 9038 (F)Document1 pageJak1 Aur El DWG A 0 9038 (F)Budi HahnNo ratings yet

- 2.1 Brosur Spesifikasi Toyota 8FDJ35 Series 8 3,5Document4 pages2.1 Brosur Spesifikasi Toyota 8FDJ35 Series 8 3,5purbo adiwNo ratings yet

- Golsta - Southland Abidjan - Shop DWG LatestDocument47 pagesGolsta - Southland Abidjan - Shop DWG LatestSouleymane KoneNo ratings yet

- E40S/E40H/E40HB/E80H SERIES: Rotary Encoder (Incremental Type)Document1 pageE40S/E40H/E40HB/E80H SERIES: Rotary Encoder (Incremental Type)Rubens RosaNo ratings yet

- Red Hat System Administration I 3.4 PracticeDocument9 pagesRed Hat System Administration I 3.4 PracticestefygrosuNo ratings yet

- One Thing Piano Chords - One DirectionDocument3 pagesOne Thing Piano Chords - One DirectionJose AntonioNo ratings yet

- Pega74 Install Tomcat Db2Document43 pagesPega74 Install Tomcat Db2Amit GujralNo ratings yet

- 6.1 Differential Calculus 01 Solutions.pDocument1 page6.1 Differential Calculus 01 Solutions.pGerard VillonesNo ratings yet

- SBL BPP Kit-2019 Copy 457Document1 pageSBL BPP Kit-2019 Copy 457Reever RiverNo ratings yet

- Scott Meech Etec 500 Journal AssignmentDocument7 pagesScott Meech Etec 500 Journal Assignmentapi-373684092No ratings yet

- CXA 1238 DatasheetDocument58 pagesCXA 1238 DatasheetHoan TranNo ratings yet

- Basics of Capital BudgetingDocument26 pagesBasics of Capital BudgetingChaitanya JagarlapudiNo ratings yet

- Neuman Double Binds, Triadic Binds PDFDocument14 pagesNeuman Double Binds, Triadic Binds PDFWillem OuweltjesNo ratings yet

- QA Lead Position Interview Questions and AnswersDocument10 pagesQA Lead Position Interview Questions and AnswersAkshay KhotNo ratings yet

- Programmer Manual 5326 PDFDocument869 pagesProgrammer Manual 5326 PDFHector QuirozNo ratings yet

- ARA 111 (PREPARATORY ARABIC) - First Sem 2021Document15 pagesARA 111 (PREPARATORY ARABIC) - First Sem 2021Mohaimen GuroNo ratings yet

- EUNIC Culture Report, 2014Document103 pagesEUNIC Culture Report, 2014Bernd ReiterNo ratings yet

- Math Olympiad JuniorDocument3 pagesMath Olympiad JuniorRobert HarryNo ratings yet

- Unit 4 HandoutsDocument8 pagesUnit 4 HandoutsRegan rautNo ratings yet

- Iran (Persian) Architecture & Folk Arts: Shan Jasper O. TorresDocument24 pagesIran (Persian) Architecture & Folk Arts: Shan Jasper O. TorresGlenda DenosoNo ratings yet

- Breach of ContractDocument27 pagesBreach of ContractTsholofelo50% (4)

- Class 5, History of ComputersDocument30 pagesClass 5, History of ComputersSmriti TiwariNo ratings yet

- Submitted: 20Xx-Mm-Dd Published: 20Xx-Mm-Dd Doi: - /silamparijournalsport....... XXXX Accepted: 20Xx-Mm-Dd UrlDocument10 pagesSubmitted: 20Xx-Mm-Dd Published: 20Xx-Mm-Dd Doi: - /silamparijournalsport....... XXXX Accepted: 20Xx-Mm-Dd UrldyarufitaNo ratings yet

- Amul Vs Baskin FinalDocument38 pagesAmul Vs Baskin FinalPramod PrajapatiNo ratings yet

- FACTURADocument1 pageFACTURAAnny CañasNo ratings yet

- GEMs of Heaven - GOD's Eternal Memory StonesDocument5 pagesGEMs of Heaven - GOD's Eternal Memory StonesswijcomNo ratings yet

- Gutindex 2009Document170 pagesGutindex 2009Lankesh ZadeNo ratings yet

- 2020년 중소기업 전략기술로드맵 28 조선Document449 pages2020년 중소기업 전략기술로드맵 28 조선박선호No ratings yet

- NBD SyllabusDocument2 pagesNBD Syllabusbibby.higginsNo ratings yet

- Explain FOUR Measures Which Governments Can Use To Encourage Entrepreneurial Activities in The Caribbean Region.Document2 pagesExplain FOUR Measures Which Governments Can Use To Encourage Entrepreneurial Activities in The Caribbean Region.Bridget SequeaNo ratings yet

- Certene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneDocument1 pageCertene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneRoberto De Mesa PNo ratings yet