Professional Documents

Culture Documents

Yk 350 XG

Yk 350 XG

Uploaded by

jet.heOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yk 350 XG

Yk 350 XG

Uploaded by

jet.heCopyright:

Available Formats

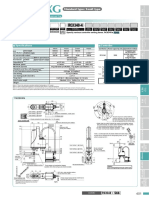

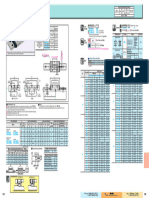

YK350XG

Articulated robots

Standard type: Small type

YA

Arm length 350mm Maximum payload 5kg

Linear conveyor

LCM100

Ordering method

modules

YK350XG 150 RCX340-4

Model Z axis stroke Tool flange Hollow shaft Cable Controller / Safety Option A Option B Option C Option D Option E Absolute

Motor-less single

Robonity TRANSERVO

Number of controllable axes standard (OP.A) (OP.B) (OP.C) (OP.D) (OP.E) battery

axis actuator

150: 150mm No entry: None No entry: None 3L: 3.5m

F: With tool flange S: With hollow shaft 5L: 5m

10L: 10m Specify various controller setting items. RCX340 P.566

single-axis robots

Compact

Specifications Controller

X-axis Y-axis Z-axis R-axis Controller Power capacity (VA) Operation method

Axis Arm length 200 mm 150 mm 150 mm - Programming /

Single-axis robots

specifications Rotation angle +/-140 ° +/-144 ° - +/-360 ° I/O point trace /

FLIP-X

Remote command /

AC servo motor output 200 W 150 W 50 W 100 W RCX340 1000

Operation

Deceleration Transmission Motor to speed reducer Direct-coupled using RS-232C

mechanism method Speed reducer to output Direct-coupled communication

Repeatability Note 1 +/-0.01 mm +/-0.01 mm +/-0.004 °

single-axis robots

PHASER

Maximum speed 5.6 m/sec 1.1 m/sec 1020 °/sec

Linear motor

Maximum payload 5 kg (Standard specification), 4 kg (Option specifications Note 4) Note. The movement range can be limited by changing the positions

of X and Y axis mechanical stoppers. (The movement range is

Standard cycle time: with 2kg payload Note 2 0.44 sec set to the maximum at the time of shipment.)

R-axis tolerable moment of inertia Note 3 0.05 kgm2 (0.5 kgfcms2) See our robot manuals (installation manuals) for detailed

information.

User wiring 0.2 sq × 10 wires Note. To set the standard coordinates with high accuracy, use a

User tubing (Outer diameter) ϕ4×3 standard coordinate setting jig (option). Refer to the user’s

Cartesian

manual (installation manual) for more details.

XY-X

robots

Travel limit 1.Soft limit 2.Mechanical stopper (X,Y,Z axis)

Our robot manuals (installation manuals) can be

Robot cable length Standard: 3.5 m Option: 5 m, 10 m downloaded from our website at the address below:

Weight 19 kg https://global.yamaha-motor.com/business/robot/

Note 1. This is the value at a constant ambient temperature. (X,Y axes)

Note 2. When reciprocating 300mm in horizontal and 25mm in vertical directions.

Note 3. The acceleration coefficient is set automatically in accordance with the tip weight and R-axis moment of inertia settings.

YK-X

SCARA

robots

Note 4. Maximum payload of option specifications (with tool flange attached or with user wiring and tubing routed through spline shaft) is 4kg.

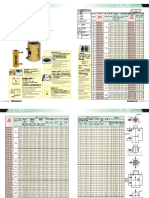

YK350XG

Pick & place

YP-X

robots

142

93

144°

144°

60

104

140°

R1

140

90

140°

18

60

CLEAN

R350

116°

User tubing 1 (ϕ4 black) 30 62

116°

303

4-ϕ9

User tubing 2 (ϕ4 red) 50 88 M8 bolt for installation, 4 bolts used

User tubing 3 (ϕ4 blue)

R190

R150

138 (Base size) 148 If the robot enters the inside of the corner of

CONTROLLER INFORMATION

R190 and dimension 148, the Z-axis upper

Cross section B-B D-sub connector for user wiring (No. 1 to 10 usable) end stopper may be in contact with the base

129 or the arm may be in contact with the machine

56 150 200 Maximum 330 during arm rotation harness. So, do not perform such motion.

• Note that the robot cannot be used at a position where

Machine harness 620 the base flange or robot cable interferes with the spline

661

Maximum 660 in the working envelope shown above.

613 during arm rotation • X-axis mechanical stopper position : 142°

r ϕ11

• Y-axis mechanical stopper position : 146°

te

diamew

Hollo

B B 4-M3 × 0.5 through-hole (No phase relation to R-axis origin.)

7.8

468 As this hole is intended for the wiring/tubing clamp, do not

428 attach a large load to it.

↓F

7.8

47

Extra small

User tubing 1 (ϕ4 black) ϕ27 7.8 7.8

Orbit /

type

42 57 780.5 View of F

5

283

150

User tubing 2 (ϕ4 red)

264 D-sub connector

235 246

222 for user wiring

230

Small type

202 User tubing 3 (ϕ4 blue) (No. 1 to 10 usable)

187

30 12

183 174

A A 167

138.5 +/-2

0

ϕ16h7-0.018

4

User tool 95

installation ϕ35 Z-axis upper end mechanical 79

Large type inverse type

150

range stopper position 4mm rise 61 138.5 +/-2

45

86

150

during Z-axis return-to-origin 12

0 0 0 0

28 26

11.5

Z-axis lower end M4 ground terminal

Width across flat 15

11.5

4

mechanical stopper position

Option:

Wall mount / & drip-proof

1

54

ϕ1

50 70 20 User wiring/tubing through spline type

R27 (Min. cable bending radius)

ter

me

Do not move the cable.

dia

10 10

w

39 39

llo

Ho

Keep enough space for the maintenance

work at the rear of the base.

Dust-proof

Cross section A-A Tapped hole for user wiring 6-M3 × 0.5 Depth 6 4-ϕ9

type

The weight of the tool attached here should be added to the tip mass.

Controller RCX340 u 566 403

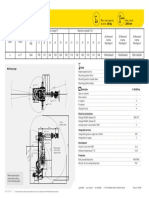

YK350XG

Articulated robots

YA

Linear conveyor

LCM100

modules

Motor-less single

Robonity TRANSERVO

axis actuator

single-axis robots

Compact

Single-axis robots

FLIP-X

single-axis robots

PHASER

Linear motor

Cartesian

XY-X

robots

YK-X

SCARA

robots

YK350XG Tool flange mount type

Pick & place

YP-X

robots

142

93

144°

144°

60

104

140°

R11

140°

140

90

8

60

CLEAN

116

0

30 62 R35

116°

303

4-ϕ9

°

50 88 M8 bolt for installation, 4 bolts used

0

R150

138 (Base size)

R19

164 If the robot enters the inside of the corner

of R190 and dimension 164, the tool flange

CONTROLLER INFORMATION

Machine harness may be in contact with the base or the arm

may be in contact with the machine

harness. So, do not perform such motion.

• Note that the robot cannot be used at a position where

the base flange or robot cable interferes with the tool

flange in the working envelope shown above.

• X-axis mechanical stopper position : 142°

1

ter ϕ1

• Y-axis mechanical stopper position : 146°

diamew

Hollo

User tubing 1 (ϕ4 black) 4-M3 × 0.5 through-hole (No phase relation to R-axis origin.)

7.8

As this hole is intended for the wiring/tubing clamp, do not

User tubing 2 (ϕ4 red) attach a large load to it.

D-sub connector

7.8

for user wiring

User tubing 3 (ϕ4 blue) (No. 1 to 10 usable) 7.8 7.8

Extra small

181 View of F

Orbit /

↓F

type

149 D

134.5+/-2 ϕ27

95 780.5

79

5

150

61

150

45

86

Small type

12

0 0

M4 ground terminal 28 26

15.5

Holl

R27 (Min. cable bending radius)

ow

50 70 20 54

Do not move the cable.

dia

Large type inverse type

181

m

22

ete

4-ϕ4.5 through-hole

.6

Keep enough space ϕ 35 149 D

r

10 10

39 39

ϕ11

for the maintenance 134.5 +/-2

150

work at the rear of

90°

the base. 0

22

15.5

6 .

4

Tapped hole for user wiring 6-M3 × 0.5 Depth 6

22

.

6

Wall mount / & drip-proof

6+

4-ϕ9 Option:

22

The weight of the tool attached here should

/-0

2

be added to the tip mass. ↑E User wiring/tubing through spline type

.0

0

ϕ30 h7-0.021

2

22 .02

ϕ 55 ϕ4 H7 0

+0.012

/-0

.6

7+

through-hole

Detailed drawing D View of E

Dust-proof

type

404 Controller RCX340 u 566

You might also like

- Wittmann R9 Robot User ManualDocument235 pagesWittmann R9 Robot User ManualLuis Martin80% (5)

- Toyota 8FBN PDFDocument7 pagesToyota 8FBN PDFweda utama100% (1)

- Arc Welding Solution: With Yaskawa MotomanDocument26 pagesArc Welding Solution: With Yaskawa MotomanMayank Jain0% (1)

- Annovi Reverberi XTV-2.1 Operating & Parts ManualDocument18 pagesAnnovi Reverberi XTV-2.1 Operating & Parts Manualinscribe100% (1)

- Escorts F15 Pick and Carry Crane PDFDocument2 pagesEscorts F15 Pick and Carry Crane PDFVenugopal Sri50% (2)

- Yk 250 XGDocument2 pagesYk 250 XGjet.heNo ratings yet

- Yk 400 XGDocument2 pagesYk 400 XGjet.heNo ratings yet

- YK1200X 400 RCX340-4: Standard Type: Large TypeDocument1 pageYK1200X 400 RCX340-4: Standard Type: Large TypeJuan David Valderrama ArtunduagaNo ratings yet

- Ordering Method: Specifications Allowable Overhang Static Loading MomentDocument1 pageOrdering Method: Specifications Allowable Overhang Static Loading MomentCentro turistico Los rosalesNo ratings yet

- Datasheet CR35iADocument1 pageDatasheet CR35iAsantiagoNo ratings yet

- 1000481-HSGP-5010-00-30-009 - H 1Document1 page1000481-HSGP-5010-00-30-009 - H 1hasan.mohamed2305No ratings yet

- SC-350S/D, SC - 350S/D, SC - 600S/D: All-Axis Servo Driven Type Take-Out RobotDocument1 pageSC-350S/D, SC - 350S/D, SC - 600S/D: All-Axis Servo Driven Type Take-Out Robotbagas prakosoNo ratings yet

- M-900 Robot Working Range: 330 KG 3203 MMDocument1 pageM-900 Robot Working Range: 330 KG 3203 MMjosjcrsNo ratings yet

- Emcoder Incremetal Das Serras Extrusoras E50-series-INSDocument1 pageEmcoder Incremetal Das Serras Extrusoras E50-series-INSEle isNo ratings yet

- Datasheet P-50iB-10LDocument1 pageDatasheet P-50iB-10LGabyReyesValdezNo ratings yet

- CR-35 Robot Working Range: 35 KG 1813 MMDocument1 pageCR-35 Robot Working Range: 35 KG 1813 MMGuilhermeNo ratings yet

- Datasheet M 1ia 05ADocument1 pageDatasheet M 1ia 05AHugo SalazarNo ratings yet

- Datasheet LRMate-200iD-7LCDocument1 pageDatasheet LRMate-200iD-7LCPremium WzorceNo ratings yet

- Long Z: User's ManualDocument60 pagesLong Z: User's Manualchinaaaa6No ratings yet

- sc70 enDocument1 pagesc70 enRick ChenNo ratings yet

- Heli Doc-20230117-Wa0001.Document1 pageHeli Doc-20230117-Wa0001.ATILLANo ratings yet

- Scara Robot: High Speed HandlingDocument2 pagesScara Robot: High Speed HandlingXanti Zabala Da RosaNo ratings yet

- ATS EngDocument1 pageATS EngOctavianus LinNo ratings yet

- Autonics E30s ManualDocument1 pageAutonics E30s ManualAndrez BermudezNo ratings yet

- Datasheet-Cr7ia L EnglishDocument1 pageDatasheet-Cr7ia L EnglishNgộ Không TônNo ratings yet

- Datasheet M 3ia 12HDocument1 pageDatasheet M 3ia 12H63 MGNo ratings yet

- Manual Chain Hoist Hand Pallet Truck Electric Chain Hoist (SSDHL - Model)Document2 pagesManual Chain Hoist Hand Pallet Truck Electric Chain Hoist (SSDHL - Model)Muhammed ShamseerNo ratings yet

- Datasheet M-710iC-45MDocument1 pageDatasheet M-710iC-45MEdgar Ivan BorbollaNo ratings yet

- Datasheet LRMate-200iD-4S - KUKADocument1 pageDatasheet LRMate-200iD-4S - KUKAJOSE MANUELNo ratings yet

- Datasheet M-1iA-05SDocument1 pageDatasheet M-1iA-05Sketan rsNo ratings yet

- M900iB 400LDocument1 pageM900iB 400LLeonardo AlexNo ratings yet

- Ec140b 09Document6 pagesEc140b 09Fadli HernandoNo ratings yet

- Datasheet Cr4ia enDocument1 pageDatasheet Cr4ia enMohit JaniNo ratings yet

- I107e r88m-g G-Series Servo Motors Datasheet enDocument10 pagesI107e r88m-g G-Series Servo Motors Datasheet ennguyenquocNo ratings yet

- MM 35 38CLRGDocument2 pagesMM 35 38CLRGHarvey Ian Pagatpatan AquinoNo ratings yet

- M-900 Robot Working Range: 360 KG 2655 MMDocument1 pageM-900 Robot Working Range: 360 KG 2655 MMKAKAKNo ratings yet

- Datasheet M 900ib 360Document1 pageDatasheet M 900ib 360ariyanto prasetioNo ratings yet

- FN1016 2SD2390Document1 pageFN1016 2SD2390jcarlos1960No ratings yet

- ZF As Tronic Schematic - EDocument2 pagesZF As Tronic Schematic - EBienvenu Massouangui50% (2)

- E40 Series INSDocument1 pageE40 Series INSSrinivas ElecNo ratings yet

- Sunstar KM-2300Document2 pagesSunstar KM-2300jairo rodriguez100% (1)

- Miniature Linear Guides: - Wide RailsDocument1 pageMiniature Linear Guides: - Wide Railsphatdang1996No ratings yet

- R7801e 5Document2 pagesR7801e 5ArifNo ratings yet

- EZ03 BrochureDocument2 pagesEZ03 BrochureXanti Zabala Da RosaNo ratings yet

- Escorts F15 Pick and Carry Cranes PDFDocument2 pagesEscorts F15 Pick and Carry Cranes PDFVenugopal SriNo ratings yet

- Escorts F15 Pick and Carry Crane PDFDocument2 pagesEscorts F15 Pick and Carry Crane PDFVenugopal SriNo ratings yet

- And Versatile: Strong, CompactDocument2 pagesAnd Versatile: Strong, Compactperop123No ratings yet

- SLG-250/80 - HL: Steel Plate Screw RubberDocument4 pagesSLG-250/80 - HL: Steel Plate Screw RubberJosue GonzalezNo ratings yet

- Silent Zero Piler - Scz-Eco600sDocument1 pageSilent Zero Piler - Scz-Eco600sPHÁT NGUYỄN THẾNo ratings yet

- E40S/E40H/E40HB/E80H SERIES: Rotary Encoder (Incremental Type)Document1 pageE40S/E40H/E40HB/E80H SERIES: Rotary Encoder (Incremental Type)Rubens RosaNo ratings yet

- Datasheet R 2000ic 165FDocument1 pageDatasheet R 2000ic 165FSalvador BarrónNo ratings yet

- 16 LS 600h L / LS 600h (Before Nov. 2009 Production) (Cont. Next Page)Document3 pages16 LS 600h L / LS 600h (Before Nov. 2009 Production) (Cont. Next Page)Waleed AlshgaaaNo ratings yet

- LLW R01 2017KW GBDocument28 pagesLLW R01 2017KW GBkatagi74No ratings yet

- Interactive Hydraulic Schematic 740AJ, 800A, 800AJ: 1. Select Function Arrow On Sheet A To Activate Hydraulic CircuitDocument4 pagesInteractive Hydraulic Schematic 740AJ, 800A, 800AJ: 1. Select Function Arrow On Sheet A To Activate Hydraulic CircuitRafael MeloNo ratings yet

- DS4510 5010Document2 pagesDS4510 5010Andie Hart100% (1)

- Datasheet LRMate-200iD-7WPDocument1 pageDatasheet LRMate-200iD-7WPperop123No ratings yet

- Datasheet N 813 01-2019 WebDocument6 pagesDatasheet N 813 01-2019 WebjyNo ratings yet

- When Technology AND Humanity Cross: Claudine Tul-IdDocument48 pagesWhen Technology AND Humanity Cross: Claudine Tul-IdElvin Villa100% (1)

- Local Media5476555320402902187Document14 pagesLocal Media5476555320402902187Aina HaravataNo ratings yet

- Irb 6620lxDocument2 pagesIrb 6620lxAlexandru RaduNo ratings yet

- Application of Robotics in Mining IndustryDocument5 pagesApplication of Robotics in Mining IndustryalfavectorNo ratings yet

- Design of Bore Well Rescue System Using Morphological Chart: December 2016Document6 pagesDesign of Bore Well Rescue System Using Morphological Chart: December 2016MakeshNo ratings yet

- Smart Luggage SystemDocument8 pagesSmart Luggage SystemIJRASETPublicationsNo ratings yet

- 890 A Bad RobotDocument10 pages890 A Bad Robotapi-291898450No ratings yet

- Modeling and Analysis of A 6 DOF Robotic Arm Manipulator: January 2012Document8 pagesModeling and Analysis of A 6 DOF Robotic Arm Manipulator: January 2012Bijay KumarNo ratings yet

- How It Works - Book of Robots 2nd EditionDocument148 pagesHow It Works - Book of Robots 2nd EditionFan Charles100% (1)

- Mechatronics: Worldskills Occupational StandardsDocument8 pagesMechatronics: Worldskills Occupational Standardsyoussif IbrahimNo ratings yet

- Smartphone Operated Multifunctional Farming VehicleDocument6 pagesSmartphone Operated Multifunctional Farming VehicleVIVA-TECH IJRINo ratings yet

- Upper-Iintermediate 03 Written TestDocument6 pagesUpper-Iintermediate 03 Written TestFahima LayoulNo ratings yet

- SWS Free Chapter Darren BartleyDocument14 pagesSWS Free Chapter Darren BartleyDisney PattersonNo ratings yet

- Robotics: Past, Present & Future in India: H.S. Gill P. M. Menghal Vaibhaw Kala Archana SinghDocument7 pagesRobotics: Past, Present & Future in India: H.S. Gill P. M. Menghal Vaibhaw Kala Archana SinghNaveenSharmaNo ratings yet

- Finalized Report Lab 1Document23 pagesFinalized Report Lab 1hanifNo ratings yet

- Popular Mechanics 2010-04Document139 pagesPopular Mechanics 2010-04BookshebooksNo ratings yet

- Iiot ReportDocument18 pagesIiot ReportAnkita PradhanNo ratings yet

- En 2. Andor Machines For Bottling and Packaging IndustriesDocument40 pagesEn 2. Andor Machines For Bottling and Packaging IndustriesAshraf AbdualkareemNo ratings yet

- Ger Maas and Frans Van GasselDocument10 pagesGer Maas and Frans Van GasselvibishnanNo ratings yet

- Experimental Investigation Into Influence of Negative Attitudes Toward Robots On Human-Robot InteractionDocument13 pagesExperimental Investigation Into Influence of Negative Attitudes Toward Robots On Human-Robot InteractionBenjamin MeguiraNo ratings yet

- Recent Building TechnologyDocument9 pagesRecent Building TechnologyPeaceNo ratings yet

- Learning Task Essay Writing (Picture Analysis)Document2 pagesLearning Task Essay Writing (Picture Analysis)BSIT 1A Yancy CaliganNo ratings yet

- Unit Ix: TOPIC: Artificial Intelligence GRAMMAR: Modal Verbs/past Perfect/past ContinuousDocument43 pagesUnit Ix: TOPIC: Artificial Intelligence GRAMMAR: Modal Verbs/past Perfect/past ContinuousAida ShalaevaNo ratings yet

- Design and Implementation of A Low Cost 3D Printed Humanoid Robotic PlatformDocument6 pagesDesign and Implementation of A Low Cost 3D Printed Humanoid Robotic PlatformPranav KompallyNo ratings yet

- Car Progression SystemsDocument12 pagesCar Progression SystemsEduardo LopesNo ratings yet

- RoboticsDocument43 pagesRoboticsChristian MendezNo ratings yet

- Transformation From 5G For Verticals Towards A 6GDocument6 pagesTransformation From 5G For Verticals Towards A 6GShraddha ChopraNo ratings yet

- R3 - IPlant The Greenhouse RobotDocument6 pagesR3 - IPlant The Greenhouse RobotSajani N. BannekaNo ratings yet

- Fanuc R-2000iA Series PDFDocument4 pagesFanuc R-2000iA Series PDFAntonio RodriguezNo ratings yet