Professional Documents

Culture Documents

Assignment 1 Corrosion 2023

Assignment 1 Corrosion 2023

Uploaded by

Takudzwa MbengoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment 1 Corrosion 2023

Assignment 1 Corrosion 2023

Uploaded by

Takudzwa MbengoCopyright:

Available Formats

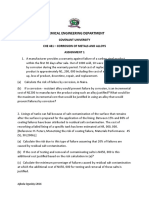

Assignment 1 : Corrosion Engineering

1. Linings of tanks can fail because of salt contamination of the surface that remains after the surface is

prepared for the application of the lining. Between 25% and 75% of coating failures have been attributed

to residual salt contamination. The cost of reworking a failed lining of a specific tank has been estimated

at $ 878,060.

(a) Calculate the risk due to this type of failure assuming that 44% of failures are caused by residual salt

contamination. [4 marks]

(b) If the cost of testing and removal of contaminating salts is $ 17140, is this additional cost justified

based on the risk calculation in ( a )? [4marks]

(c) Calculate the minimum percentage of failures caused by residual salt contamination at which the

additional cost of $ 214100 for testing and removal of these salts is justified. [4 marks]

(d) Briefly discuss the significance of the Pilling-Bedworth rule. [1 marks]

2. When studying corrosion kinetics of steel, the rate of corrosion can either be increased or decreased

due to a lot of factors. Draw relevant sketches and explain the effect of the following conditions:

i. Effect of increasing temperature

ii. Effect of increasing chromium alloying element

iii. Effect of increasing the stirring rate

iv. Effect of increasing molybdenum

v. Effect of increasing Chloride ions [5marks]

3.a Why does corrosion of water filled steel tanks occur below the water line? [5marks]

b. What is Electroplating? Give the uses of Electroplating. [5marks]

c. Briefly discuss the economic aspects of corrosion. Give a clear distinction between direct and indirect

costs [5marks]

d. Explain using labelled diagrams where appropriate the difference between pitting and crevice

corrosion with regards to initiation and mechanism? In your diagrams and answer you should

differentiate between the initiation stages and stable stages of these mechanisms. [6marks]

e. Define and discuss about the use of inhibitors in corrosion control. [6marks]

f. What are the factors that affect the rate of corrosion? [3marks]

g. A sample of zinc anode corrodes uniformly with a current density of 5.32 x 10-7 A/cm2 in an

aqueous solution. What is the corrosion rate of zinc in mdd? [5 marks]

Due date 15 june 2023

You might also like

- Practice Exam #3 Flashcards - QuizletDocument24 pagesPractice Exam #3 Flashcards - Quizletks_irdeNo ratings yet

- File 5Document12 pagesFile 5hseaseelalhadharaNo ratings yet

- R07 Set No. 2Document8 pagesR07 Set No. 2rajashekhar2000No ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Corrosion Fatigue Phenomena Learned From Failure AnalysisDocument10 pagesCorrosion Fatigue Phenomena Learned From Failure AnalysisDavid Jose Velandia MunozNo ratings yet

- Arab Academy FPR Science & Technology COLLEGE OF Engineering & TechnologyDocument4 pagesArab Academy FPR Science & Technology COLLEGE OF Engineering & TechnologyNicolas EleftheriouNo ratings yet

- Tribological Characteristics of Nickel-Aluminium Bronze CuAl10Ni5Fe4 Against 30CrMnSiA Steel After The Prior Corrosion TreatmentDocument6 pagesTribological Characteristics of Nickel-Aluminium Bronze CuAl10Ni5Fe4 Against 30CrMnSiA Steel After The Prior Corrosion TreatmentFathia AlkelaeNo ratings yet

- Water Journal Desalination PlantsDocument8 pagesWater Journal Desalination PlantsfastreturnNo ratings yet

- COLLEGE OF Engineering & TechnologyDocument9 pagesCOLLEGE OF Engineering & TechnologyNicolas EleftheriouNo ratings yet

- 1 - Piping CBT API 571 AnsDocument5 pages1 - Piping CBT API 571 AnsAMALENDU PAULNo ratings yet

- University of Mauritius University of Mauritius University of Mauritius University of MauritiusDocument4 pagesUniversity of Mauritius University of Mauritius University of Mauritius University of MauritiusYannick HowNo ratings yet

- Applied Chemistry-Ii (May-2018 Solution) : Power AlcoholDocument18 pagesApplied Chemistry-Ii (May-2018 Solution) : Power AlcoholKenneth C.LinojNo ratings yet

- CHY270 Corrosion Science: Answer All Questions Part-A (10 X 2 20 Marks)Document2 pagesCHY270 Corrosion Science: Answer All Questions Part-A (10 X 2 20 Marks)Ramprasad RajagopalanNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- CO2 Corrosion in Oil & Gas - Part 1Document6 pagesCO2 Corrosion in Oil & Gas - Part 1ChemiboyNo ratings yet

- API 570 - Practice Qns (API 571) 2019Document5 pagesAPI 570 - Practice Qns (API 571) 2019StevenQuek100% (2)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- F April 2019: Course: Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100Document1 pageF April 2019: Course: Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100Sandhya SundarNo ratings yet

- Hard Chrome Replacement by HVOF Sprayed CoatingsDocument9 pagesHard Chrome Replacement by HVOF Sprayed CoatingsR2osNo ratings yet

- Accelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of Reservoir Length and Concrete MixesDocument9 pagesAccelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of Reservoir Length and Concrete MixesAlmas XamiNo ratings yet

- r09220805 MechanicalunitoperationsDocument7 pagesr09220805 MechanicalunitoperationsadityaNo ratings yet

- Repair RehabilitatioDocument16 pagesRepair RehabilitatioDipak GajbharNo ratings yet

- Kenny Corrosion StudiesDocument38 pagesKenny Corrosion StudiesOtaru kehindeNo ratings yet

- Corrosion in TankersDocument30 pagesCorrosion in TankersNikola KolevNo ratings yet

- Ballarpur Institute of Technology Sessional Examination-I Applied Chemistry Time: 2Hrs Max Marks: 40 Section A Que.1Document3 pagesBallarpur Institute of Technology Sessional Examination-I Applied Chemistry Time: 2Hrs Max Marks: 40 Section A Que.1Praful KakdeNo ratings yet

- Welding of Hydrogen-Charged Steel For Modification or RepairDocument9 pagesWelding of Hydrogen-Charged Steel For Modification or Repairramadoss_alwar7307No ratings yet

- Primary and Remedial CementingDocument108 pagesPrimary and Remedial CementingPablo Santo100% (2)

- Section 4 API-651 Practice QuestionsDocument34 pagesSection 4 API-651 Practice QuestionsJosephInbarajan100% (4)

- Module 4Document10 pagesModule 4QuintusNo ratings yet

- Assginment 1 - CHE 431Document2 pagesAssginment 1 - CHE 431ifiokNo ratings yet

- Corrosion ControlDocument8 pagesCorrosion ControlHà Thị TrúcNo ratings yet

- Challenges in Corrosion: Costs, Causes, Consequences, and ControlFrom EverandChallenges in Corrosion: Costs, Causes, Consequences, and ControlNo ratings yet

- 11 - Development and Evaluation of The InternalDocument11 pages11 - Development and Evaluation of The InternalJedaías J.No ratings yet

- ECE Question Papers - Chemistry - 1 SemDocument25 pagesECE Question Papers - Chemistry - 1 Semg3murtuluNo ratings yet

- Final Exam (Closed Book) : Answer SheetDocument13 pagesFinal Exam (Closed Book) : Answer SheetDAMIAN ALEJANDRO100% (1)

- 0620 w08 QP 2Document16 pages0620 w08 QP 2MERCY LAWNo ratings yet

- API 510 ClosedDocument15 pagesAPI 510 ClosedHarmish mewadaNo ratings yet

- Time Zones 1 & 2: Answer Each Section in Separate BookletsDocument12 pagesTime Zones 1 & 2: Answer Each Section in Separate BookletsIdlan IzharNo ratings yet

- Chloride Effects On Corrosions RateDocument18 pagesChloride Effects On Corrosions Rateعمر المالكيNo ratings yet

- Image MarkedDocument2 pagesImage MarkedlakshitaNo ratings yet

- Deterioration and Restoration of Concret PDFDocument10 pagesDeterioration and Restoration of Concret PDF폴로 쥰 차No ratings yet

- Tribhuvan University Institute of EngineeringDocument7 pagesTribhuvan University Institute of EngineeringManjesh MishraNo ratings yet

- Page 1 of 2Document2 pagesPage 1 of 2ncNo ratings yet

- Master of Civil Engg. Examination, 2006Document2 pagesMaster of Civil Engg. Examination, 2006shaswataaNo ratings yet

- x40602 - Concrete Technology PDFDocument12 pagesx40602 - Concrete Technology PDFJay PatelNo ratings yet

- Corrosion CATDocument1 pageCorrosion CATHenry MuneneNo ratings yet

- Api 510 Preparatory Final Exam (Closed Book) : Answers in A Separate Answer SheetDocument14 pagesApi 510 Preparatory Final Exam (Closed Book) : Answers in A Separate Answer SheetCss Sfaxien100% (1)

- API-571 CL SCCDocument7 pagesAPI-571 CL SCCimtiazkiani100% (1)

- CONICET Digital Nro. DDocument9 pagesCONICET Digital Nro. DNora al-anssariNo ratings yet

- Ship Construction Ch. Mate. Question 2020Document6 pagesShip Construction Ch. Mate. Question 2020مرتضى جبار السودانيNo ratings yet

- COLLEGE OF Engineering & TechnologyDocument4 pagesCOLLEGE OF Engineering & TechnologyNicolas EleftheriouNo ratings yet

- Carbonate Stress Corrosion Cracking (ACSCC)Document11 pagesCarbonate Stress Corrosion Cracking (ACSCC)Ajmi HmidaNo ratings yet

- Corrosion Report PDFDocument22 pagesCorrosion Report PDFFong Wei Jun0% (1)

- Api 571 Parte 12Document14 pagesApi 571 Parte 12Obe Mendoza100% (2)

- Aluminium Brass Corrosion Rate TableDocument1 pageAluminium Brass Corrosion Rate Tablenktiah1207No ratings yet

- 208 217Document10 pages208 217amit_iitNo ratings yet

- Wang 2020Document16 pagesWang 202020-110 Bryan SiahaanNo ratings yet

- Semester 1 Examinations 2018/2019: Programme (S)Document7 pagesSemester 1 Examinations 2018/2019: Programme (S)fuckoffmanNo ratings yet

- Critical Chloride Content and Its Influence On Service Life PredictionsDocument4 pagesCritical Chloride Content and Its Influence On Service Life PredictionsAmanda VegaNo ratings yet

- Assignment 2 Applied Chemistry (2023-24)Document1 pageAssignment 2 Applied Chemistry (2023-24)schoolvodNo ratings yet