Professional Documents

Culture Documents

Piping Design

Piping Design

Uploaded by

RAJASEKAR KingOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Design

Piping Design

Uploaded by

RAJASEKAR KingCopyright:

Available Formats

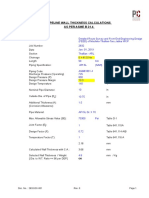

1 2" Oil Line

1.1 General

1 Design Code - ASME B 31.3 Ed. 2020

2 Allowance C - 3.0 mm

3 Internal Design Pressure P - 2100 Psig

4 Material of construction - SA 106 Gr. B / SA 234 WPB / SA 105

5 Minimum Design Metal Temperature - 20 Deg F

6 Design Temperature - 130 Deg F

7 Fluid Service (As per B31.3) - Normal Fluid Service

8 Yield Stress Ys - 30000 Psi

9 Tensile Stress Ts - 60000 Psi

Allowable Stress value crietria for Material @ Design

10 S1 - 20000 Psi

Temp as per 302.3.2(d) = one third of Tensile stress

Allowable Stress value crietria for Material @ Design

11 S2 - 20000 Psi

Temp as per 302.3.2(d) = two third of yield stress

Allowable Stress value crietria for Material @ Design

12 S - 20000 Psi

Temp as per 302.3.2(d) = Min of S1 & S2

13 Quality Factor E - 1.0

14 Co-efficient from Table 304.1.1 Y - 0.4

15 Weld joint strength reduction factor W - 1

1.2 Wall Thickness Calculation (Para. 304.1.1 & 3.4.1.2 )

1 Pipe Size - 2" inch

2 Selected Schedule / Thk - As per UT

3 Out Side Diameter D - 60.3 mm

PD

4 Minimum Required Thk. t= +C t - 6.038 mm

2(SEW +PY )

5 Selected Thk. - 8.78 mm

6 Min. Permissible Thk. (NIL Mill Tolerance) - 8.78 mm

Selected thickness is acceptable as Minimum Permissible thickness is greater than the Required thickness.

1.3 Hydro Test Pressure Calculation (Para. 345.4.2 )

PT = 1.5 P ST / S

Where,

P - Internal design Gauge Pressure

PT - Minimum Test Gauge Pressure

S - Stress value for material at Design Temperature from Table A-1

ST - Stress value for material at Test Temperature from Table A-1

Stress value for Material @ Test Temp - 20000 Psi 20000

Hydro Test Pressure - 3150.0 Psi

You might also like

- Analysis Report On Metal Sample From Sphere (v5)Document27 pagesAnalysis Report On Metal Sample From Sphere (v5)Philippe brüggerNo ratings yet

- Omni AccidentDocument27 pagesOmni AccidentVikas NigamNo ratings yet

- Calculation Sheet: WT-CAL-CO2-003Document4 pagesCalculation Sheet: WT-CAL-CO2-003babu100% (1)

- Design Data: 2" Threadolet CalculationDocument2 pagesDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- Pipe Thickness Calculation For Internal PressureDocument12 pagesPipe Thickness Calculation For Internal PressurefsijestNo ratings yet

- Design of Pressure Vessel by Using ASME Sec-VIII Div-1Document6 pagesDesign of Pressure Vessel by Using ASME Sec-VIII Div-1jhaamit4No ratings yet

- Design Calculation of Recycle Oil Injection Insert (Sheet-37)Document30 pagesDesign Calculation of Recycle Oil Injection Insert (Sheet-37)hgagselim2012No ratings yet

- 2body Wall Thickness Calculation-Check ValveDocument2 pages2body Wall Thickness Calculation-Check Valvecannyengineering.sNo ratings yet

- WT Calculation - Pipelines With CRA CladDocument6 pagesWT Calculation - Pipelines With CRA CladShankar VadivelNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George Racz100% (1)

- Pipe ThicknessDocument1 pagePipe ThicknessalvinchuanNo ratings yet

- Basis of Design - Pig Reciever 16 Design 2014Document27 pagesBasis of Design - Pig Reciever 16 Design 2014Andreas SchlagerNo ratings yet

- Basis of Design - PIG LAUNCHER 16 DESIGN 2014Document27 pagesBasis of Design - PIG LAUNCHER 16 DESIGN 2014Andreas Schlager100% (1)

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- PIPECALC ASME B31.4 - Rev 2Document24 pagesPIPECALC ASME B31.4 - Rev 2Mohsin RazaNo ratings yet

- Pipe Wall Thickness Calculations: Burnex Burner HeadDocument16 pagesPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156No ratings yet

- 3flange Bolt Torque Calculation Per Api 6aDocument2 pages3flange Bolt Torque Calculation Per Api 6acannyengineering.sNo ratings yet

- Final ExaminationDocument7 pagesFinal ExaminationAwanNo ratings yet

- Hdpe Pipe Wall Thickness CalculationsDocument1 pageHdpe Pipe Wall Thickness CalculationsTsouki Tsouki100% (1)

- Superheated Steam Condensate TankDocument4 pagesSuperheated Steam Condensate TankGanesh BhardwajNo ratings yet

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- IBR Calualations (28.12.22)Document10 pagesIBR Calualations (28.12.22)Sumit MishraNo ratings yet

- Cal DRW 23 276Document1 pageCal DRW 23 276ไม่บอก อย่าหลอกถามNo ratings yet

- ASME B31.4-Wall Thickness Calc For 6 InchDocument2 pagesASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoNo ratings yet

- New PA Column - THK CalcDocument8 pagesNew PA Column - THK CalcSabariMechyNo ratings yet

- SHELLDocument6 pagesSHELLSalz EngineeringNo ratings yet

- Nozzle Check 211039CDocument3 pagesNozzle Check 211039CGaurav BedseNo ratings yet

- Superheated Steam SeparatorDocument4 pagesSuperheated Steam SeparatorGanesh BhardwajNo ratings yet

- Pipe Thickness Calculation AS Per ASME 31.3Document11 pagesPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNo ratings yet

- Example-Design of Thick CylindersDocument12 pagesExample-Design of Thick Cylindershairi zainalNo ratings yet

- IP11 - Calculation of Min. Allowable Thickness & Test Pressure For Process Furnace TubesDocument2 pagesIP11 - Calculation of Min. Allowable Thickness & Test Pressure For Process Furnace TubessajiNo ratings yet

- ASMEU2 (2-1) - Head THKDocument7 pagesASMEU2 (2-1) - Head THKjs.from5208No ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Design Calculations For Pressure VesselsDocument43 pagesDesign Calculations For Pressure VesselsMoises Alvarez LeandroNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Bolt Up CalculationDocument12 pagesBolt Up CalculationAniket GaikwadNo ratings yet

- Level 1 ID Anomaly 60097 Joint Number 120Document2 pagesLevel 1 ID Anomaly 60097 Joint Number 120Anonymous AtAGVssJNo ratings yet

- 06745JS2 (7) - Strength Calculations of Module4 (IBR)Document23 pages06745JS2 (7) - Strength Calculations of Module4 (IBR)Pratik Ray Chaudhury100% (3)

- Northstart Meat Mercant Inc PDFDocument22 pagesNorthstart Meat Mercant Inc PDFAppleuk SudarNo ratings yet

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- Ibr Thickness Calculation: DefinitionDocument5 pagesIbr Thickness Calculation: DefinitionVipul SharmaNo ratings yet

- Sample Vessel Design (Sec - VIII Div.1)Document34 pagesSample Vessel Design (Sec - VIII Div.1)Chano Hanok100% (1)

- Progen: Pipe Thickness Calculation As Per IBR 350 Eqn.Document4 pagesProgen: Pipe Thickness Calculation As Per IBR 350 Eqn.P s JagatheesanNo ratings yet

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- Calculation Noozle - Heat ExchangerDocument6 pagesCalculation Noozle - Heat Exchangercalinvasco190670No ratings yet

- WRC CalculationsDocument20 pagesWRC Calculationsanu radha50% (2)

- Pvelite PruebaDocument6 pagesPvelite PruebaLuis Cordova RamonNo ratings yet

- ASME B31.8 Riser CalcDocument12 pagesASME B31.8 Riser CalcSalz EngineeringNo ratings yet

- Design Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021Document1 pageDesign Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021pratyaNo ratings yet

- MP Condensate Flash VesselDocument4 pagesMP Condensate Flash VesselGanesh BhardwajNo ratings yet

- Example E4.3.1Document6 pagesExample E4.3.1Dario100% (1)

- Piping Sizing Final Rev01 12Document1 pagePiping Sizing Final Rev01 12aNo ratings yet

- E.3.2 - MDMT Using MathcadDocument2 pagesE.3.2 - MDMT Using MathcadrobertantoreniNo ratings yet

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- ASME B31.4 Riser CalcDocument14 pagesASME B31.4 Riser CalcCastorNoroñoNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- ASME B31.8 Riser CalcDocument23 pagesASME B31.8 Riser Calcisrar khan100% (2)

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Standards 1Document1 pageStandards 1RAJASEKAR KingNo ratings yet

- Utg FormateDocument1 pageUtg FormateRAJASEKAR KingNo ratings yet

- Time SheetDocument1 pageTime SheetRAJASEKAR KingNo ratings yet

- Copling CalculationDocument22 pagesCopling CalculationRAJASEKAR KingNo ratings yet

- Basket Strainer 2Document2 pagesBasket Strainer 2RAJASEKAR KingNo ratings yet

- Journal of The American Ceramic Society - 2021 - Wang - Surface Structure and Quenching Effects in BiFeO3 BaTiO3 CeramicsDocument11 pagesJournal of The American Ceramic Society - 2021 - Wang - Surface Structure and Quenching Effects in BiFeO3 BaTiO3 CeramicsEngr.M.Umair JamalNo ratings yet

- AWWA-C207 (2018) - Steel Pipe Flanges For Waterworks ServiceDocument40 pagesAWWA-C207 (2018) - Steel Pipe Flanges For Waterworks ServicePubcrawlNo ratings yet

- Crack Width Calculation For Rectangular RC BeamDocument1 pageCrack Width Calculation For Rectangular RC BeamRomyMohanNo ratings yet

- Specifications For Repair Work of ChimneyDocument2 pagesSpecifications For Repair Work of ChimneyAkshay AmbadeNo ratings yet

- An Experimental Study On Self-Healing Concrete With Effect of Different Bacteria On The Strength of Concrete Nandyala Prudviraj1, Kadapa ShammadDocument8 pagesAn Experimental Study On Self-Healing Concrete With Effect of Different Bacteria On The Strength of Concrete Nandyala Prudviraj1, Kadapa ShammadGR DesignsNo ratings yet

- 1 s2.0 S2666893922000895 MainDocument10 pages1 s2.0 S2666893922000895 MainJeet LukhiNo ratings yet

- BW Qline Catalogue EN 2021 GL 316 PreviewDocument12 pagesBW Qline Catalogue EN 2021 GL 316 PreviewRaviTeja BhamidiNo ratings yet

- Green WaterTreatment Solution - PresentationDocument17 pagesGreen WaterTreatment Solution - Presentationsrekumar kumarNo ratings yet

- Kitz Stainless Steel Catalog New PDFDocument58 pagesKitz Stainless Steel Catalog New PDFel_apache10No ratings yet

- Sraco-Const-Doc-Mos-08 - Concrete Masonry Units and PlasteringDocument13 pagesSraco-Const-Doc-Mos-08 - Concrete Masonry Units and PlasteringMohammed Perwez AlamNo ratings yet

- DataSheetDocument3 pagesDataSheetGomathi Sankar0% (1)

- Stone Mastic Asphalt: A Seminar Report OnDocument17 pagesStone Mastic Asphalt: A Seminar Report Onprajakta chaudhari100% (1)

- Reinforced Concrete Beam: Location of D' & DTDocument6 pagesReinforced Concrete Beam: Location of D' & DTJheo TorresNo ratings yet

- Ikeuchi: Air Nozzle CatalogDocument72 pagesIkeuchi: Air Nozzle Catalogsmail ben loulouNo ratings yet

- Chapter 2 Matter Test 2011-12Document4 pagesChapter 2 Matter Test 2011-12Sheryl Jane P. SilangNo ratings yet

- Salt Making 1 Salt Making 1Document1 pageSalt Making 1 Salt Making 1Mr BobNo ratings yet

- CH-4 Metal and Non Metal 8th (FINAL)Document24 pagesCH-4 Metal and Non Metal 8th (FINAL)Abhishek PatidarNo ratings yet

- Formulating Polyurea Coatings and CaulksDocument5 pagesFormulating Polyurea Coatings and CaulksAhmed TahaNo ratings yet

- NALCO 7330: C Ooling Water Treatment BiocideDocument3 pagesNALCO 7330: C Ooling Water Treatment BiocideFazal KhanNo ratings yet

- Microsoft Word - 2nd Storey Slab Checking PDFDocument5 pagesMicrosoft Word - 2nd Storey Slab Checking PDFsundarNo ratings yet

- Impact Dynamics, Theory and Experiment - (J. A. Zukas) PDFDocument66 pagesImpact Dynamics, Theory and Experiment - (J. A. Zukas) PDFpezz07No ratings yet

- Info Type HuileDocument28 pagesInfo Type HuileApexiNo ratings yet

- Joshi Project ReportDocument51 pagesJoshi Project ReportSandeep Reddy NandyalaNo ratings yet

- Mixer Settler Type ExtractionDocument7 pagesMixer Settler Type ExtractionVirender RanaNo ratings yet

- Acoplamientos RexnordDocument20 pagesAcoplamientos RexnordRodrigo Orias LoyolaNo ratings yet

- Basic Corrosion CPDocument83 pagesBasic Corrosion CPSaeed AnwarNo ratings yet

- AS 1627.1-2003 Metal Finishing - Preparation and PretreatmenDocument21 pagesAS 1627.1-2003 Metal Finishing - Preparation and PretreatmenDang Thanh TuanNo ratings yet

- 2 - Tension MemberDocument72 pages2 - Tension MemberYetty OktavianitaNo ratings yet