Professional Documents

Culture Documents

2-1 - Plate Tolerance Guide Asme Ii

2-1 - Plate Tolerance Guide Asme Ii

Uploaded by

Khaled bouhlelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2-1 - Plate Tolerance Guide Asme Ii

2-1 - Plate Tolerance Guide Asme Ii

Uploaded by

Khaled bouhlelCopyright:

Available Formats

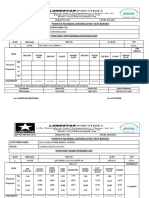

Title : Ref. Document : REV.

PAG DE

E

PLATE TOLERANCE XXXXX 00 1

QUALITY SYSTEM 1

QUALITY

DEPARTMENT GUIDE Date :

Document G

ASME II – 2021 25-04-2021 type :

Guide

1- Reference:

ASME II ED 2010 PART A – SA 20

2- Marking Checking:

Required marking:

1- Heat number

MARKING 2- Plate number

By stamping and unless

3- Logo of manufacturer

by painting

4- Type/grade/class

Supplementary marking:

1- LVT: when impact tested

MARKING Min 300mm 2- MT: Heat treated

3- G: Only when HT is required but not performed

Min 1800mm

Logo of manufacturer

A516 GR70 MT LVT A 516 GR70 MT LVT

Example 010699/AO HN°

28Q21507A Plate N° TYPE CLASS GRADE SUP. MARKING

3- Dimensional Checking:

Thickness Tolerance (+) in (mm)

5 5.5 6 7 8 9 10 11 12 14 16 18 20 22 25 28 30 32 35 38 40 45 50

1500 to 1800 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8

1800 to 2100 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.8 2.0

2100 to 2400 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.9 0.9 0.9 0.9 1.0 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.8 2.0

2400 to 2700 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.9 0.9 0.9 1.0 1.0 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 2.0 2.3

2700 to 3000 0.8 0.8 0.9 0.9 0.9 1.0 1.0 1.0 1.0 1.0 1.0 1.1 1.2 1.3 1.3 1.4 1.5 1.6 1.7 1.8 2.0 2.3 2.5

3000 to 3300 0.9 0.9 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.1 1.1 1.2 1.2 1.3 1.5 1.8 1.8 2.0 2.3 2.3 2.5 2.8 3.0

All width Thickness Tolerance (-) = 0,3 (mm)

Width Tolerance (+) For original plate (not cutted) Width And Length Tolerance (+/-) For

cutted plate

1270 to 1520 1520 to 1650 1650 to 1780 1780 to 2030 2030 and over

Thickness To 50 50 to 100

38 41 44 47 51

Width and Length 13 16

Width Tolerance (-) = 0 (mm)

4- Form checking: WAVINESS TOLERANCE (mm) Plate up to 4000 mm in length

Flatness Nbr of Waves

Tolerance 1 2 3 4 5 6 7

13 13 10 8 5 5 3 2

FLATNESS TOLERANCE (mm)* 14 14 11 8 6 5 3 2

for plate up to 4000 mm in length 16 16 13 10 6 5 3 2

Width 6 to 10 10 to 12 12 to 20 20 to 25 25 to 50 50 to100 17 17 13 10 8 5 5 2

1500 to 1800 24 16 16 16 14 13 19 19 14 11 8 6 5 2

21 21 16 11 8 6 5 2

1800 to 2100 29 19 16 16 14 13 22 22 17 13 10 6 5 2

2100 to 2400 32 22 19 16 16 13 24 24 17 13 10 8 6 5

2400 to 2700 35 25 25 19 16 13 25 25 19 14 11 8 6 5

29 29 22 16 13 10 6 5

2700 to 3000 38 29 25 22 16 14 32 32 24 17 13 10 8 6

5- Visual Inspection 35 35 27 19 14 11 8 6

Depth for all imperfection shall not reduce the thickness of the plate with 38 38 29 22 16 13 10 6

maximum 3mm.

Other Imperfection indicated in Plate Inspection Instruction (Prg.3) and exceed the tolerance in this paragraph is not permitted

Dmax. = 0.3 mm

D: Depth of Imperfection NT: Nominal thickness

Prepared by Checked by Approved by

Nom et prénom KHALED BOUHLEL

Fonction

Date / Signature

COPYRIGHT 2017© FAB PSI (Note) For more details, refer to code

You might also like

- MTC For BoltDocument2 pagesMTC For Boltrizwan40% (5)

- Installation Manual RB 1500 - Rev.3Document40 pagesInstallation Manual RB 1500 - Rev.3John Lak0% (1)

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- Cloud Computing Basics - T. B. RehmanDocument198 pagesCloud Computing Basics - T. B. Rehmantim.howell8050No ratings yet

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Document2 pagesWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiNo ratings yet

- 000 SLT2101316 Pe PiDocument27 pages000 SLT2101316 Pe PijaidikarimNo ratings yet

- Technical Specification: Pipes and Fittings (Note 2)Document1 pageTechnical Specification: Pipes and Fittings (Note 2)Beatriz BerçotNo ratings yet

- OM - DD - F - 07 Master List of DrawingsDocument10 pagesOM - DD - F - 07 Master List of DrawingssharanNo ratings yet

- Flexmetprotect C-CNM-M: Technical Data SheetDocument1 pageFlexmetprotect C-CNM-M: Technical Data Sheetminni choubeyNo ratings yet

- SA MP LE: Company NameDocument4 pagesSA MP LE: Company NameAnonymous P8XHEXyIZLNo ratings yet

- Tie G 00Document1 pageTie G 00Siddharth DevNo ratings yet

- Eeaa090571-2 - r0.24.02.2022 - Layout and RCC Details of Columns 1Document1 pageEeaa090571-2 - r0.24.02.2022 - Layout and RCC Details of Columns 1Mohd RosleeNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Specification: Pressure and Temperature Controls Electro-Pneumatic Prs-Armstrong IndiaDocument1 pageSpecification: Pressure and Temperature Controls Electro-Pneumatic Prs-Armstrong IndiaHajiNo ratings yet

- Pt. Duraquipt Cemerlang: Your Trusted Partner in Industrial Pump SolutionDocument1 pagePt. Duraquipt Cemerlang: Your Trusted Partner in Industrial Pump Solutionjunio egieNo ratings yet

- RADES-56-GCD-MC-TS-MTT-3003 - REV. 0 - Painting SpecificationsDocument14 pagesRADES-56-GCD-MC-TS-MTT-3003 - REV. 0 - Painting SpecificationsHaythem Ben ZidNo ratings yet

- K20 178 1 A Contact Oven Press 80TDocument20 pagesK20 178 1 A Contact Oven Press 80Tjouheyna hedhliNo ratings yet

- Data Sheet For Automatic Tank Gauging (Atg)Document2 pagesData Sheet For Automatic Tank Gauging (Atg)Indra SUdirmanNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- 01 - 25284124-8230-26-000-0010 - REV.01 - Line List - C4 ImportDocument1 page01 - 25284124-8230-26-000-0010 - REV.01 - Line List - C4 ImportRajeev KumarNo ratings yet

- Sigma Power Control Systems Pvt. Ltd. 77/1+2, Vishnu Malti Ind. Estate, Shivane Pune 411 023Document1 pageSigma Power Control Systems Pvt. Ltd. 77/1+2, Vishnu Malti Ind. Estate, Shivane Pune 411 023Chaitanya RajguruNo ratings yet

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocument1 pageFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- 000 SLT2101318 El DGDocument115 pages000 SLT2101318 El DGjaidikarimNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Taper BlockDocument2 pagesTaper BlockVKL QualityNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- 2324MTC037 11359Document1 page2324MTC037 11359Shrikrushna DalviNo ratings yet

- Elbow 12 XS 90D LR - OkDocument1 pageElbow 12 XS 90D LR - OkJovianto PrisilaNo ratings yet

- KG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Document5 pagesKG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Madheswaran DharmapuriNo ratings yet

- AL-905-R-11202 Spec AG01 Rev. T02Document3 pagesAL-905-R-11202 Spec AG01 Rev. T02altipatlarNo ratings yet

- SS 310 Mill TC - 16,18,20,22,40Document1 pageSS 310 Mill TC - 16,18,20,22,40rajiv.raskarNo ratings yet

- ISOIL Vega T ModelDocument1 pageISOIL Vega T ModelMiftahul FajriNo ratings yet

- SMD lx5050rgb TRDocument4 pagesSMD lx5050rgb TRNikhil khadeNo ratings yet

- 01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InDocument2 pages01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InRajeev KumarNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- BH MT 199 2022 T&aDocument1 pageBH MT 199 2022 T&aDeanz KmcNo ratings yet

- Equalizing Line Mbe 6 WTRDocument2 pagesEqualizing Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

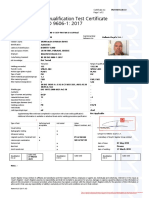

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNo ratings yet

- ASNE0419Document7 pagesASNE0419D2253SFNo ratings yet

- PQR No TECH-PS01 Rev.2 SMAW - NORMALDocument4 pagesPQR No TECH-PS01 Rev.2 SMAW - NORMALcfranciaNo ratings yet

- Description: Mechanical DataDocument2 pagesDescription: Mechanical Datadip461No ratings yet

- 285FPJ 270Document2 pages285FPJ 270dip461No ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- D-240, TTC Industrial Area, Near Uran Phata Signal, Nerul, Navi Mumbai - 400 706 Ph. +91 22 66512000Document14 pagesD-240, TTC Industrial Area, Near Uran Phata Signal, Nerul, Navi Mumbai - 400 706 Ph. +91 22 66512000ChandanSinghNo ratings yet

- UmaPET - TFDocument3 pagesUmaPET - TFLuz Angela GuerreroNo ratings yet

- 1.0A Surface Mount Schottky Barrier Rectifier: RRM O F (MAX) R (MAX)Document5 pages1.0A Surface Mount Schottky Barrier Rectifier: RRM O F (MAX) R (MAX)Сергій ПіхалоNo ratings yet

- Nipple 3in X 4in XXS Toe Boe New OkDocument1 pageNipple 3in X 4in XXS Toe Boe New OkJovianto PrisilaNo ratings yet

- M30-1645 (Elec CKT DWG) PDFDocument198 pagesM30-1645 (Elec CKT DWG) PDFAdvance CNC TechnologiesNo ratings yet

- Ele Vir Flush Ring 160 0001 To 0008Document16 pagesEle Vir Flush Ring 160 0001 To 0008rahul o gNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Test Report - MetallographyDocument2 pagesTest Report - MetallographyESHWAR CHARYNo ratings yet

- Normal SparesDocument1 pageNormal SparesPrabuNo ratings yet

- VMSTD Lift Gate PDFDocument1 pageVMSTD Lift Gate PDFHasibKaabiNo ratings yet

- 000 Emi2200987 VD PRDocument106 pages000 Emi2200987 VD PRjaidikarimNo ratings yet

- UmaPET EC104 - 140Document2 pagesUmaPET EC104 - 140Luz Angela GuerreroNo ratings yet

- Ts4040 Double Walled Brazed TubesDocument3 pagesTs4040 Double Walled Brazed TubesFCP PUNEKARNo ratings yet

- 01 - 25284124-8230-26-000-0004 - REV.02 - Piping - List - O & U UndergroundDocument2 pages01 - 25284124-8230-26-000-0004 - REV.02 - Piping - List - O & U UndergroundRajeev KumarNo ratings yet

- Modeled: Scale: 1:20 Unit: MM Dept/Nrp: Tolerance in Size DesignedDocument6 pagesModeled: Scale: 1:20 Unit: MM Dept/Nrp: Tolerance in Size DesignedHamdani HerdianaNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Tuerca 1-1-1 2HDocument1 pageTuerca 1-1-1 2Hcomercial 3No ratings yet

- WPSAmerica 2Document2 pagesWPSAmerica 2Khaled bouhlelNo ratings yet

- WPSAmerica 3Document4 pagesWPSAmerica 3Khaled bouhlelNo ratings yet

- Amerlock 400gfaDocument4 pagesAmerlock 400gfaKhaled bouhlelNo ratings yet

- QW 482Document2 pagesQW 482Khaled bouhlelNo ratings yet

- Amerlock 400AL/AL WN: High Solids Epoxy CoatingDocument2 pagesAmerlock 400AL/AL WN: High Solids Epoxy CoatingKhaled bouhlelNo ratings yet

- Amercoat 450S: Physical DataDocument2 pagesAmercoat 450S: Physical DataKhaled bouhlelNo ratings yet

- Sigmaguard CSF 575Document7 pagesSigmaguard CSF 575Khaled bouhlelNo ratings yet

- Fillet Weld: Valid For Steel Welding OnlyDocument26 pagesFillet Weld: Valid For Steel Welding OnlyKhaled bouhlelNo ratings yet

- 0515 - V-II Service Training 2012Document174 pages0515 - V-II Service Training 2012Robbie MuchebaNo ratings yet

- C-Line Drives Engineering Guide 11-2006-EnDocument568 pagesC-Line Drives Engineering Guide 11-2006-EnysaadanyNo ratings yet

- Non Linear ProgrammingDocument109 pagesNon Linear ProgramminginftraNo ratings yet

- BOQ - 400/220/33kV GIS Substation For Panchshil Data Center at Airoli, Navi MumbaiDocument13 pagesBOQ - 400/220/33kV GIS Substation For Panchshil Data Center at Airoli, Navi MumbaiPrasad Pawar - ERO Power100% (1)

- Effect of Grass Carpfish DensityDocument12 pagesEffect of Grass Carpfish DensitymarofNo ratings yet

- C Part 1 - CodemithraDocument28 pagesC Part 1 - CodemithraAnirudh GowdaNo ratings yet

- MAT093 - Case Study - Template of Written ReportDocument21 pagesMAT093 - Case Study - Template of Written Reportel lyyNo ratings yet

- StrengthDocument20 pagesStrengthCriss DodgeNo ratings yet

- Para Sa CompreDocument9 pagesPara Sa CompreJunard AsentistaNo ratings yet

- 1797 In535 - en P PDFDocument16 pages1797 In535 - en P PDFMancamiaicuruNo ratings yet

- 507 Probability IIDocument21 pages507 Probability IIatikahNo ratings yet

- MuJava Supporting DocumentationDocument22 pagesMuJava Supporting DocumentationKhushboo KhannaNo ratings yet

- Coepro2 Higher Order Square MatricesDocument23 pagesCoepro2 Higher Order Square MatricesAJNo ratings yet

- Rman DocumentDocument11 pagesRman Documentsantababu100% (2)

- Java Quiz PDFDocument106 pagesJava Quiz PDFNadaBelaRadaNo ratings yet

- Vver 440Document23 pagesVver 440Bálint GrNo ratings yet

- Collisions by Archisman PanigrahiDocument5 pagesCollisions by Archisman PanigrahiArchisman PanigrahiNo ratings yet

- VHF Uhf Duoband Ant eDocument2 pagesVHF Uhf Duoband Ant eNol SatuNo ratings yet

- Natural Wormholes As Gravitational LensesDocument4 pagesNatural Wormholes As Gravitational Lensesdiegok64No ratings yet

- 2023 TJPhO v1Document11 pages2023 TJPhO v1Phúc NguyễnNo ratings yet

- Chemical Formula Writing Worksheet PDFDocument4 pagesChemical Formula Writing Worksheet PDFkezia0% (1)

- TO1-Group-5 Soil Mechanics Lab Experiment No. 4Document7 pagesTO1-Group-5 Soil Mechanics Lab Experiment No. 4Xam AcostaNo ratings yet

- Study Guide 3: WoodworkingDocument21 pagesStudy Guide 3: Woodworkingmaryjoysoliven4No ratings yet

- Technical Information Data Communication With Victron Energy Products - ENDocument13 pagesTechnical Information Data Communication With Victron Energy Products - ENMonitoreo PetasolareNo ratings yet

- RMAN Backup Types That Require NOAC On NFS Mount Points (Doc ID 2108714.1)Document2 pagesRMAN Backup Types That Require NOAC On NFS Mount Points (Doc ID 2108714.1)elcaso34No ratings yet

- Program and Programming Style: The Practice of ProgrammingDocument57 pagesProgram and Programming Style: The Practice of Programmingmna shourovNo ratings yet

- IOR & EOR in Tight Reservoirs - BakkenDocument47 pagesIOR & EOR in Tight Reservoirs - Bakkennitin lahkarNo ratings yet

- 2ndSEM2021MMW W1PPT1Document55 pages2ndSEM2021MMW W1PPT1Glenn EscañanNo ratings yet