Professional Documents

Culture Documents

Modulating Float Valve: Model

Modulating Float Valve: Model

Uploaded by

jpalauguillemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modulating Float Valve: Model

Modulating Float Valve: Model

Uploaded by

jpalauguillemCopyright:

Available Formats

428-01

628-01

MODEL

(Full Internal Port)

Modulating Float Valve

(Reduced Internal Port)

• Accurate Level Control

• Completely Automatic Operation

• Simple Operation

• Easy Installation and Maintenance

The Cla-Val Model 428-01/628-01 Float Valve modulates to maintain a

constant liquid level in a storage tank by compensating for variations in

supply or demand. It can be installed to control the flow into or out of the tank

by either closing on a rising level or opening on a rising level. This valve is a

hydraulically operated, pilot controlled diaphragm valve.

The pilot control system consists of an integral variable orifice in the main

valve cover and a remotely mounted float control. A slight change in liquid

level moves the float control. This action varies the pressure in the valve

cover, causing the main valve to seek a new position. The integral variable

orifice automatically regulates the flow into the cover chamber until the valve

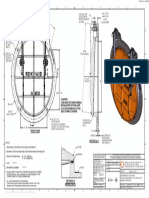

Schematic Diagram reaches a position that is in direct relation to the position of the float control.

Item Description

1 Hytrol Main Valve

2 CFM-9 Float Control

3 CK2 (Isolation Valve)

Optional Features

Item Description

A X46A Flow Clean Strainer

D Check Valves with Isolation Valve

C CV Speed Control

F Independent Operating Pressure

P X141 Pressure Gauge

S CV Speed Control

Y X43 “Y” Strainer

Installation Data Typical Applications

The valve may be installed in any position. The remote

float control may be mounted at any convenient location

above the liquid level. Float rods are available in

Isolation

l e n g t h s f r o m 2 ' t o 1 2 ' i n o n e - f o o t increments.

Control Lines 3/4" Min. I.D.

Valve

Open Tank-"Air Gap" Valve

Closes on Rising Level

A stilling well (8" min. diameter) should be provided

CFM9 Balances Tank Effluent Rate

to Equal Influent Rate.

around the float if the liquid surface is subject to

Flow

turbulence, ripples or wind.

Cla-Val 428-01/628-01

Modulating Float Valve Water Level

The float control may be installed at any elevation above

the valve providing that the amount of flowing line

pressure (in psi) is equal to or greater than the vertical

Stilling Well

distance in feet between the valve and the float control.

When a separate source of supply pressure (Option F)

is used by the pilot control system, that pressure must at

all times be constant and equal to or greater than the

pressure at the valve inlet.

DO NOT USE FOR ON-OFF SERVICE.

Note: We recommend protecting tubing and valve

from freezing temperatures.

Model 428-01 (Uses Main Valve Model 100-32)

B (Diameter)

J

100-32

Pressure Ratings (Recommended Maximum Pressure - psi)

Threaded &

Flanged K

Pressure Class

X

H

Valve Body & Cover

C

Flanged Grooved Threaded

(MAX)

Inlet Outlet

ANSI 150 300 300 End‡

Grade Material

Standards* Class Class Class Details G E F

GG

ASTM A536 Ductile Iron B16.42 250 400 400 400

FF

GGG

ASTM A216-WCB Cast Steel B16.5 285 400 400 400

Inlet D

A DD

DDD

UNS 87850 Bronze B16.24 225 400 400 400

AA

AAA

Note: * ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Y

Valves for higher pressure are available; consult factory for details

Materials Z

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

Available Sizes 1" - 6" 1" - 6" 1" - 6" B (Diameter)

Disc Retainer &

J

Cast Iron Cast Steel Bronze

100-32

Diaphragm Washer Grooved

Trim: Disc Guide, Bronze is Standard

K X

Seat & Cover Bearing Stainless Steel is Optional

H CC

Disc Buna-N® Rubber

(MAX)

Diaphragm Nylon Reinforced Buna-N® Rubber

Inlet Outlet

Stem, Nut & Spring Stainless Steel

For material options not listed, consult factory.

EE

Cla-Val manufactures valves in more than 50 different alloys.

GGGG

Inlet DDDD

Model 428-01 Dimensions (In Inches)

AAAA

Valve Size (Inches) 1 1 1⁄ 4 1 1⁄ 2 2 2 1⁄ 2 3 4 6 8

A Threaded 7.25 7.25 7.25 9.38 11.00 12.50 — — —

AA 150 ANSI — — 8.50 9.38 11.00 12.00 15.00 20.00 25.38

AAA 300 ANSI — — 9.00 10.00 11.62 13.25 15.62 21.00 26.38

AAAA Grooved End — — 8.50 9.00 11.00 12.50 15.00 20.00 25.38

B Diameter 5.62 5.62 5.62 6.62 8.00 9.12 11.50 15.75 20.00

C Maximum 5.50 5.50 5.50 6.50 7.56 8.19 10.62 13.38 16.00

CC Maximum Grooved End — — 4.75 5.75 6.88 7.25 9.31 12.12 14.62

D Threaded 3.25 3.25 3.25 4.75 5.50 6.25 — — —

DD 150 ANSI — — 4.00 4.75 5.50 6.00 7.50 10.00 12.69

DDD 300 ANSI — — 4.25 5.00 5.88 6.38 7.88 10.50 13.25

DDDD Grooved End — — — 4.75 — 6.00 7.50 — —

E 1.12 1.12 1.12 1.50 1.69 2.06 3.19 4.31 5.31

EE Grooved End — — 2.00 2.50 2.88 3.12 4.25 6.00 7.56

F 150 ANSI — — 2.50 3.00 3.50 3.75 4.50 5.50 6.75

FF 300 ANSI — — 3.06 3.25 3.75 4.13 5.00 6.25 7.50

G Threaded 1.88 1.88 1.88 3.25 4.00 4.50 — — —

GG 150 ANSI — — 4.00 3.25 4.00 4.00 5.00 6.00 8.00

GGG 300 ANSI — — 4.25 3.50 4.31 4.38 5.31 6.50 8.50

GGGG Grooved End — — — 3.25 — 4.25 5.00 — —

H NPT Body Tapping 0.375 0.375 0.375 0.375 0.50 0.50 0.75 0.75 1.00

J NPT Cover Center Plug 0.25 0.25 0.25 0.50 0.50 0.50 0.75 0.75 1.00

K NPT Cover Tapping 0.375 0.375 0.375 0.375 0.50 0.50 0.75 0.75 1.00

Stem Travel 0.40 0.40 0.40 0.60 0.70 0.80 1.10 1.70 2.30

Approx. Ship Weight (lbs) 15 15 15 35 50 70 140 285 500

Approx. X Pilot System 11 11 11 13 14 15 17 29 31

Approx. Y Pilot System 9 9 9 9 10 11 12 20 22

Approx. Z Pilot System 9 9 9 9 10 11 12 20 22

Model 628-01 (Uses Main Valve Model 100-33)

Pressure Ratings (Recommended Maximum Pressure - psi)

Pressure Class

Valve Body & Cover

Flanged B (Diameter)

ANSI 150 300

J

Grade Material 100-33

Standards* Class Class Flanged

K

ASTM A536 Ductile Iron B16.42 250 400

X

H C

ASTM A216-WCB Cast Steel B16.5 285 400

(MAX)

ASTM B62 Bronze B16.24 225 400

Outlet

Inlet

Note: * ANSI standards are for flange dimensions only.

F

Flanged valves are available faced but not drilled.

FF

E

Valves for higher pressure are available; consult factory for details EE

Inlet D

A DD

AA

Materials

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze Y

Available Sizes 3" - 8" 3" - 8" 3" - 8"

Disc Retainer &

Diaphragm Washer Cast Iron Cast Steel Bronze

Trim: Disc Guide, Bronze is Standard

Seat & Cover Bearing Stainless Steel is Optional

Z

Disc Buna-N® Rubber

Diaphragm Nylon Reinforced Buna-N® Rubber

Stem, Nut & Spring Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Model 628-01 Dimensions (In Inches)

Valve Size (Inches) 3 4 6 8 10

A 150 ANSI 10.25 13.88 17.75 21.38 26.00

AA 300 ANSI 11.00 14.50 18.62 22.38 27.38

B Diameter 6.62 9.12 11.50 15.75 20.00

C Maximum 7.00 8.62 11.62 15.00 17.88

D 150 ANSI — 6.94 8.88 10.69 12.75

DD 300 ANSI — 7.25 9.38 11.19 —

E 150 ANSI — 5.50 6.75 7.25 8.06

EE 300 ANSI — 5.81 7.25 7.75 —

F 150 ANSI 3.75 4.50 5.50 6.75 8.00

FF 300 ANSI 4.12 5.00 6.25 7.50 8.75

H NPT Body Tapping 0.375 0.50 0.75 0.75 1.00

J NPT Cover Center Plug 0.50 0.50 0.75 0.75 1.00

K NPT Cover Tapping 0.375 0.50 0.75 0.75 1.00

Stem Travel 0.60 0.80 1.10 1.70 2.30

Approx. Ship Weight (lbs) 45 85 195 330 625

Approx. X Pilot System 13 15 27 30 33

Approx. Y Pilot System 10 11 18 20 22

Approx. Z Pilot System 10 11 18 20 22

100-32 Pattern: Globe (G), Angle (A), End Connections: Threaded (T), Grooved (GR), Flanged (F) Indicate Available Sizes

428-01 Inches 1 11⁄4 11⁄2 2 21⁄2 3 4 6 8

Valve

Selection

mm 25 32 40 50 65 80 100 150 200

Pattern G, A G, A G, A G, A G, A G, A G, A G, A G, A

Main Valve

100-32 T, F, T, F, T, F, T, F, F, F, F,

End Detail T T

Gr* Gr Gr* Gr Gr Gr* Gr*

Suggested Maximum 55 93 125 210 300 460 800 1800 3100

Flow

(gpm) Maximum

68 120 160 260 370 580 990 2250 3900

Intermittent

Suggested Maximum 3.5 6 8 13 19 29 50 113 195

Flow

(Liters/Sec) Maximum

4.3 7.6 10 16 23 37 62 142 246

Intermittent

100-32 Series is the full internal port Hytrol. *Globe Grooved Only

100-33 Pattern: Globe (G), Angle (A), End Connections: Flanged (F) Indicate Available Sizes

628-01 Inches 3 4 6 8 10

Valve

Selection

mm 80 100 150 200 250

Pattern G G, A G, A G, A G

Main Valve

100-33

End Detail F F F F F

Suggested

Flow Maximum 260 580 1025 2300 4100

(gpm)

Suggested

Flow Maximum 16 37 65 145 258

(Liters/Sec)

100-33 Series is the reduced internal port size version of the 100-32 Series.

Important Notice: Do Not Oversize

Pilot System CFM9 When Ordering,

Remote

Specifications Please Specify

1.8"

Float

2.81

3.38

Control

2.38

Temperature Range

1. Catalog No. 428-01

Water: to 180°F

2.63 MAX (1.25)

FLOAT UP

(2.50)

or No. 628-01

Materials: 2. Valve Size

1.38

2.00

In contact with operating fluid: Bronze, 3. Pattern - Globe

6.25

.78

Stainless Steel, Monel, with Buna-N® or Angle

1.19

Rubber seals.

1.38

4. Pressure Class

Float linkage: Brass,

.50 A

DRAIN

Base plate: Enameled Steel 5. Materials Desired

1/2" NPT

2X .44 .68

Float: 304 Stainless Steel 6. Threaded or

.52

8.00 MIN.

Float Rod: Standard - Two 12" sections of Flanged

FLOAT UP

PVC rod, with 12" extension increments.

3.63

7. Valve Closing or

SUPPLY

6.31 1/2" NPT

UPPER

Valve Opening on

3.75

Float Rod: Optional - 24" stainless steel

LIQUID LEVEL

30.50

Rising Water Level

Float

rod, with 24" extension increments.

Down

8. Desired Options

A larger counterweight is required if float

5.38

1.00

rod length exceeds 4'. Consult factory for

TO

.38 19.00

details.

ADJUST

RANGE

LOWER

LIQUID LEVEL

CLA-VAL 1701 Placentia Ave • Costa Mesa CA 92627 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

Cla-Val 2021 • Printed in USA • Specifications subject to change without notice.

© Copyright

E-428-01/628-01 (R-03/2021)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- E-36 - Series NEWDocument1 pageE-36 - Series NEWjpalauguillemNo ratings yet

- Wire CV TransferDocument1 pageWire CV TransferjpalauguillemNo ratings yet

- Electronic Surge Control Panel: ModelDocument2 pagesElectronic Surge Control Panel: ModeljpalauguillemNo ratings yet

- General 04 Fixed Flow Pump To Three TanksDocument13 pagesGeneral 04 Fixed Flow Pump To Three TanksjpalauguillemNo ratings yet

- Maintrac Group Vineyard Product Guide 2022Document24 pagesMaintrac Group Vineyard Product Guide 2022jpalauguillemNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument6 pagesSafety Data Sheet: 1. IdentificationjpalauguillemNo ratings yet

- Maintrac Group Bird Control Guide VineyardsDocument24 pagesMaintrac Group Bird Control Guide VineyardsjpalauguillemNo ratings yet

- C208-96 Elbow Dimensions For Fabricated Steel Water Pipe FittingsDocument1 pageC208-96 Elbow Dimensions For Fabricated Steel Water Pipe FittingsjpalauguillemNo ratings yet

- Durability of Titanium Dioxide Photocatalytic Laye-1Document10 pagesDurability of Titanium Dioxide Photocatalytic Laye-1jpalauguillemNo ratings yet

- FRESNO 36 Inch FLAP GATE-F062-36011ADocument1 pageFRESNO 36 Inch FLAP GATE-F062-36011AjpalauguillemNo ratings yet

- F-25 Medium Duty Drainage GateDocument3 pagesF-25 Medium Duty Drainage GatejpalauguillemNo ratings yet

- Cheng Fluid Systems, Inc. - Pump CavitationDocument3 pagesCheng Fluid Systems, Inc. - Pump CavitationjpalauguillemNo ratings yet

- API 686-Suction Line Slopes and ReducersDocument1 pageAPI 686-Suction Line Slopes and ReducersjpalauguillemNo ratings yet