Professional Documents

Culture Documents

K2S-NG01007551-GEN-CG6968-00001 - A01 - Scope of Work For ... Undergrd Survey

K2S-NG01007551-GEN-CG6968-00001 - A01 - Scope of Work For ... Undergrd Survey

Uploaded by

chukudi oguneCopyright:

Available Formats

You might also like

- P RefStd - 4041 - v080201 - EN - HAZIDDocument49 pagesP RefStd - 4041 - v080201 - EN - HAZIDMeoNo ratings yet

- Static Equipment - A Look Inside The How and Why' of SpecificationDocument16 pagesStatic Equipment - A Look Inside The How and Why' of SpecificationmatodelanusNo ratings yet

- How A Polymer Get Dissolves?Document3 pagesHow A Polymer Get Dissolves?Vijay ChaudharyNo ratings yet

- PRM FRM 008 KOM ChecklistDocument13 pagesPRM FRM 008 KOM ChecklistMeoNo ratings yet

- CEPCI CalculationDocument9 pagesCEPCI CalculationChelsea SkinnerNo ratings yet

- LFL Temp MW V% in Air Deg C G/mole 1.7 25 72Document4 pagesLFL Temp MW V% in Air Deg C G/mole 1.7 25 72SHAILENDRANo ratings yet

- Jacobs Calculations 2Document2 pagesJacobs Calculations 2BhattNo ratings yet

- Cefic Solvay Guidelines PDFBR 1770 C-b-1-0602 - H2o2Document48 pagesCefic Solvay Guidelines PDFBR 1770 C-b-1-0602 - H2o2Mark CousinsNo ratings yet

- Bw0404a Sc7 BurnDocument96 pagesBw0404a Sc7 Burnoverlord5555No ratings yet

- P7564 Po127 400 80 Dat 0006 - B1Document246 pagesP7564 Po127 400 80 Dat 0006 - B1NIMISHNo ratings yet

- 1308-306-MEC-DTS-012 - Rev 1 - Vapour Return Blower - UpdateDocument9 pages1308-306-MEC-DTS-012 - Rev 1 - Vapour Return Blower - UpdateAyahKenzieNo ratings yet

- Release RateDocument134 pagesRelease RateSHAILENDRANo ratings yet

- Attachment #1 Otp Check List: Saudi Aramco Commissioning Pre-Check Form Centrifugal PUMPDocument3 pagesAttachment #1 Otp Check List: Saudi Aramco Commissioning Pre-Check Form Centrifugal PUMPzhangNo ratings yet

- 2495 000 JSD 1501 01 - BDocument30 pages2495 000 JSD 1501 01 - BSinaNo ratings yet

- Sabp Z 055Document16 pagesSabp Z 055Hassan MokhtarNo ratings yet

- AMEC Feed Phase Engineering Design IntegrityDocument8 pagesAMEC Feed Phase Engineering Design IntegrityHyeong-Ho KimNo ratings yet

- Calculation of Flash Points and Flammability LimitDocument7 pagesCalculation of Flash Points and Flammability LimitMuhammad Taufiq FathaddinNo ratings yet

- 37 FA10871C J 01 - REV D Design Instruction MechDocument117 pages37 FA10871C J 01 - REV D Design Instruction Mecharunrajmech09No ratings yet

- Spec. Number Suffixes: US Based On US Codes and Standards, ON Applicable For Onshore Projects, M&U Units UsedDocument28 pagesSpec. Number Suffixes: US Based On US Codes and Standards, ON Applicable For Onshore Projects, M&U Units UsedDarshan PanchalNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument20 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Sabp A 003Document83 pagesSabp A 003Maged GalalNo ratings yet

- Numbering System & IdentificationDocument50 pagesNumbering System & Identification4uengineerNo ratings yet

- RAM Planning TemplateDocument7 pagesRAM Planning Templatepradit danielNo ratings yet

- Guidelines For Slurry PipingDocument6 pagesGuidelines For Slurry PipingAatish ChandrawarNo ratings yet

- EDG Failure ModeDocument57 pagesEDG Failure ModeAnonymous a19X9GHZNo ratings yet

- Plant Design and Economics For Chemical EngineersDocument55 pagesPlant Design and Economics For Chemical EngineersMantralaraju KosuriNo ratings yet

- How To Find Energy Savings in Process Plants PDFDocument13 pagesHow To Find Energy Savings in Process Plants PDFCamilo RuaNo ratings yet

- 100 Introduction To Fire PreventionDocument22 pages100 Introduction To Fire PreventionSHAILENDRANo ratings yet

- Viscosity-1 Viscometer-2 Relation Between Viscosity &temperature-3 Vogel Equation-4 Programming ofDocument71 pagesViscosity-1 Viscometer-2 Relation Between Viscosity &temperature-3 Vogel Equation-4 Programming ofDr_M_SolimanNo ratings yet

- Sabp Z 087Document29 pagesSabp Z 087liNo ratings yet

- German and International Cost IndicesDocument25 pagesGerman and International Cost IndicesagueromaNo ratings yet

- Piping Lay OutDocument7 pagesPiping Lay OutNata 1986No ratings yet

- Qot BD 1 22 Me SPC 10364 00Document16 pagesQot BD 1 22 Me SPC 10364 00Hamid MansouriNo ratings yet

- 9.0 Pneumatic Conveying Preface: Bechtel ConfidentialDocument14 pages9.0 Pneumatic Conveying Preface: Bechtel ConfidentialCristhianNo ratings yet

- Chevron LubeWatch Brochure - 2018 PDFDocument20 pagesChevron LubeWatch Brochure - 2018 PDFHaitham YoussefNo ratings yet

- Appendix I - AirDocument155 pagesAppendix I - AirTown of Colonie LandfillNo ratings yet

- Technip Separations PDFDocument10 pagesTechnip Separations PDFProcess EngineerNo ratings yet

- Art's Process Spec SheetsDocument19 pagesArt's Process Spec Sheetsjdaig17No ratings yet

- Safety and Handling: Technical Data SheetDocument15 pagesSafety and Handling: Technical Data SheetRonak MotaNo ratings yet

- SAIC-J-6501 Rev 8Document12 pagesSAIC-J-6501 Rev 8Rashid ArshadNo ratings yet

- Scrubbing Tower DesignDocument10 pagesScrubbing Tower DesignPrathmesh GujaratiNo ratings yet

- 000-SP-PI02-0234 Especificaciones Tecnicas Torque y TensionadoDocument14 pages000-SP-PI02-0234 Especificaciones Tecnicas Torque y TensionadoÀngel RodriguezNo ratings yet

- MARS 2012 - DuPont Design For Reliability FELDocument13 pagesMARS 2012 - DuPont Design For Reliability FELXing Xian AngNo ratings yet

- Chapter - 4-Flow Through Porous MediaDocument36 pagesChapter - 4-Flow Through Porous MediaSata AjjamNo ratings yet

- 19K9 W0110 50 M04 0002 Rev.A3 Equipment Load DataDocument5 pages19K9 W0110 50 M04 0002 Rev.A3 Equipment Load DatasridharNo ratings yet

- O7 08572-TRHT-AE-GN-00-OO-205 - Rev 0Document27 pagesO7 08572-TRHT-AE-GN-00-OO-205 - Rev 0kerkar mohammedNo ratings yet

- Project Deviation RequestDocument5 pagesProject Deviation Request王兆坤No ratings yet

- Tools For Failure Data Analysis - Section1Document19 pagesTools For Failure Data Analysis - Section1Jose GanozaNo ratings yet

- Maintenance & Reliability Initiatives: Intuitive & Common Sense Software Solutions ForDocument16 pagesMaintenance & Reliability Initiatives: Intuitive & Common Sense Software Solutions ForbwelzNo ratings yet

- Equipment EngineeringDocument131 pagesEquipment EngineeringHervéNo ratings yet

- Design of Packed ColumnDocument4 pagesDesign of Packed Columnمنى عبد المنعم صالح رداد منى عبد المنعم صالح ردادNo ratings yet

- RB - Specifications Piping MaterialsDocument21 pagesRB - Specifications Piping MaterialsFalcon PeregrinusNo ratings yet

- Project Monitoring ControlDocument0 pagesProject Monitoring ControlAnuj GuptaNo ratings yet

- Sabp Z 051Document17 pagesSabp Z 051Hassan MokhtarNo ratings yet

- Control Valve CV CalculationDocument20 pagesControl Valve CV CalculationHadi VeyseNo ratings yet

- Dokumen - Tips Organic Chemistry An Acid Base Approach Second EditionDocument333 pagesDokumen - Tips Organic Chemistry An Acid Base Approach Second EditionQuoc AnhNo ratings yet

- Plant Engineering and Design The Ultimate Step-By-Step GuideFrom EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNo ratings yet

- Advanced Control of Chemical Processes 1994From EverandAdvanced Control of Chemical Processes 1994D. BonvinNo ratings yet

- B-36.021 - Rev A-HVAC Cooling Load Calculation Report-Ground FloorDocument11 pagesB-36.021 - Rev A-HVAC Cooling Load Calculation Report-Ground Floorchukudi oguneNo ratings yet

- Green LightDocument30 pagesGreen Lightchukudi oguneNo ratings yet

- MecaLug HelpDocument31 pagesMecaLug Helpchukudi ogune100% (1)

- 10481-BCL-AKSX-ST-REP-0001 - 1 - IFR - Civil and Structural Design BasisDocument73 pages10481-BCL-AKSX-ST-REP-0001 - 1 - IFR - Civil and Structural Design Basischukudi oguneNo ratings yet

- B-65.221 - BB - Pipe Support Structural Steel Frame Plans and Sections, Reinforcement Details.Document22 pagesB-65.221 - BB - Pipe Support Structural Steel Frame Plans and Sections, Reinforcement Details.chukudi oguneNo ratings yet

- Archictectural Go by of OlEmo ProjectDocument13 pagesArchictectural Go by of OlEmo Projectchukudi oguneNo ratings yet

- 10481-BCL-AKSX-ME-SPC-0002 - A0 - AFC Specification For Pig Launcher & ReceiverDocument22 pages10481-BCL-AKSX-ME-SPC-0002 - A0 - AFC Specification For Pig Launcher & Receiverchukudi oguneNo ratings yet

- 2304-300-47-RD-S-001 - C - Valve Pit Analysis and Design ReportDocument30 pages2304-300-47-RD-S-001 - C - Valve Pit Analysis and Design Reportchukudi oguneNo ratings yet

- 10481-BCL-AKSX-ST-SPC-0003 - 0 - IFR - Specification For PilingDocument16 pages10481-BCL-AKSX-ST-SPC-0003 - 0 - IFR - Specification For Pilingchukudi oguneNo ratings yet

- B-37.734 Rev C - General Layout - Site Roads ParkingDocument1 pageB-37.734 Rev C - General Layout - Site Roads Parkingchukudi oguneNo ratings yet

- 10481-BCL-AKSX-AR-REP-0001 - 4 - IFC - Architectural Design BasisDocument75 pages10481-BCL-AKSX-AR-REP-0001 - 4 - IFC - Architectural Design Basischukudi oguneNo ratings yet

- B-45.355 - CA - Drinking Water Supply Pump P-4504E-Fdn. Plan, Sects & DtlsDocument1 pageB-45.355 - CA - Drinking Water Supply Pump P-4504E-Fdn. Plan, Sects & Dtlschukudi oguneNo ratings yet

- ISD-3675 Building D Wash BayDocument5 pagesISD-3675 Building D Wash Baychukudi oguneNo ratings yet

- B-65.198 - O - Analyzer Panel Shelter Structure Plan Sections and Details Sht1-3Document3 pagesB-65.198 - O - Analyzer Panel Shelter Structure Plan Sections and Details Sht1-3chukudi oguneNo ratings yet

- Site Detail - 2Document33 pagesSite Detail - 2chukudi oguneNo ratings yet

- The Shell Petroleum Development Company of Nigeria LTD.: Project Assa North - Ohaji South Project: EngineeringDocument64 pagesThe Shell Petroleum Development Company of Nigeria LTD.: Project Assa North - Ohaji South Project: Engineeringchukudi ogune100% (1)

K2S-NG01007551-GEN-CG6968-00001 - A01 - Scope of Work For ... Undergrd Survey

K2S-NG01007551-GEN-CG6968-00001 - A01 - Scope of Work For ... Undergrd Survey

Uploaded by

chukudi oguneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K2S-NG01007551-GEN-CG6968-00001 - A01 - Scope of Work For ... Undergrd Survey

K2S-NG01007551-GEN-CG6968-00001 - A01 - Scope of Work For ... Undergrd Survey

Uploaded by

chukudi oguneCopyright:

Available Formats

June 2013 DOCUMENT NUMBER : K2S-

DOCUMENT CHECK PRINT

NG01007551-GEN-CG6968-00001

COPY No. SIGNATURE DUE

ORIGINATOR

(GREEN)

CHECKER

(RED)

Q.A.

(BLACK)

APPROVER

(BLUE)

Shell Petroleum Development Company of Nigeria

Classification Status: Unrestricted

EPC FOR KOLO CREEK TO SOKU GAS EXPORT PIPELINE

SCOPE OF WORK FOR TOPOGRAPHIC, GEOTECHNICAL, BATHYMETRIC AND

UNDERGROUND FACILITIES SURVEY

Proprietary Information: This document contains proprietary information and may not be partly or wholly reproduced without prior written

permission from Shell Petroleum Development Company

The Process Manager for this procedure is the Major Projects General Manager, the Process Owner is the Major Projects Project

Services Manager

Revision Date Description Originator Checker Approver

A01 17.06.13 Issued for Review C. Ekweozor F. Nwogbo L. Ezenwaka

R01 28.02.13 Issued for Review C. Ekweozor F. Nwogbo L. Ezenwaka

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 2 of 44

CHANGE RECORD PAGE

REV. N° Status Description of Revision

R01 IFR Issued for Review

A01 IFR Issued for Review

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 3 of 44

CONTENTS

1.0 PROJECT DESCRIPTION

..........................................................................................................................................................

4

1.1 Purpose of Document

4

1.2 Objectives

5

1.3 Route Description

6

1.4 Work Method Statement

6

1.5 Definitions and Abbreviations

7

1.5.1 General Definitions

7

1.6 Abbreviations

7

1.7 References

8

2.0 ROUTE SURVEY

..........................................................................................................................................................

9

3.0 BASIC SURVEY DESCRIPTION

..........................................................................................................................................................

10

4.0 GENERAL PRE-INSTALLATION ROUTE SURVEY REQUIREMENTS

..........................................................................................................................................................

12

4.1 General

12

4.2 Requirement for Topographical Survey

13

4.3 Pipeline Route Survey Works

14

5.0 SPECIFICATION FOR ONSHORE PRE-INSTALLATION SURVEY

..........................................................................................................................................................

15

6.0 SPECIFICATION FOR NEAR SHORE PRE-INSTALLATION SURVEY

..........................................................................................................................................................

16

7.0 SPECIFICATION FOR PRE-INSTALLATION MARINE SURVEY

..........................................................................................................................................................

16

8.0 SPECIFICATIONS FOR PRE-INSTALLATION PIPELINE APPROACH SURVEY

..........................................................................................................................................................

18

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 4 of 44

9.0 BASIC DESCRIPTION OF SERVICES EXTENT

..........................................................................................................................................................

18

10.0 GENERAL SHORE CROSSING SCOPE ITEMS SERVICES

..........................................................................................................................................................

20

11.0 REPORTING

..........................................................................................................................................................

22

12.0 CAD MAPPING

..........................................................................................................................................................

25

13.0 QUALITY ASSURANCE AND QUALITY CONTROL REQUIREMENTS

..........................................................................................................................................................

27

14.0 SPECIFICATIONS FOR GEOTECHNICAL INVESTIGATION SURVEY

..........................................................................................................................................................

28

14.1 Site preparation, logistics and personnel

28

14.2 Topographich survey and positioning

29

15.0 GEOTECHNICAL INVESTIGATION ACTIVITIES SPECIFICATIONS

..........................................................................................................................................................

30

15.1 General

30

15.2 Drilling and Soil Borings

31

15.3 Trial Pits and Shallow Sampling

31

15.4 Deep Sampling in Soil Borings

32

15.5 Static Cone Penetration Test

33

15.6 Presentation of Results

34

16.0 LABORATORY TEST EQUIPMENT AND PROCEDURES – GEOTECHNICAL SURVEY

..........................................................................................................................................................

35

16.1 Laboratory tests performed at the site laboratory during fieldwork

35

16.1.1 Extrusion and Conservation of Samples

35

16.1.2 Schedule of Site Laboratory Tests

36

16.1.3 Tests Performed in the Office Laboratory

37

17.0 EVALUATION AND PRESENTATION OF GEOTECHNICAL PARAMETERS

..........................................................................................................................................................

38

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 5 of 44

17.1 Soil Conditions and Geotechnical Parameters

38

17.2 Design Studies

39

17.3 Final Geotechnical Survey Reports

39

17.4 Final Engineering Report

40

18.0 SCOPE OF WORK FOR UNDERGROUND / BURIED SERVICES SURVEY

..........................................................................................................................................................

41

18.1 General

41

18.2 Deliverables

41

19.0 QUALITY ASSURANCE AND QUALITY CONTROL REQUIREMENTS

..........................................................................................................................................................

41

1.0 PROJECT DESCRIPTION

The primary objective of the project is to sustain gas supplies to NLNG trains 1 to 6. The project

was conceptualized on optimisation of SPDC’s infrastructure usage by utilising spare capacity

that will become available in Soku Gas Plant as from 2014. Non Associated Gas from Kolo Creek

Deep (F1 and F2 reservoirs) shall be bulked in a manifold and evacuated through approx. 20” x

40km bulkline to Soku Gas Plant for processing and onward sales to NLNG trains 1 to 6. The

Kolo Creek field is situated in the southern part of OML-28 in the seasonal flooding fresh-water

swamp area, some 18km southeast of the Gbaran CPF and about 90km west of Port Harcourt. It

is one of SPDC’s Eastern Division fields considered as part of the Gbaran-Ubie nodal

development to provide feed stock gas for the NLNG Trains 1 to 6.

The Kolo Creek to Soku project optimizes SPDC’s infrastructure usage in the short term and

maximizes ullage for both the Soku and Gbaran areas.

The EPC contract scope with NestOil PLC for this project is summarized as follows;

1. Four (4) flowlines from the F2 wells to the new Kolo Creek (intermediate) production

headers with the proper control, safeguarding, metering and monitoring requirements.

2. Three (3) flowlines from the F1 wells to the new Kolo Creek (intermediate) production

headers with the proper control, safeguarding, metering and monitoring requirements.

3. Three (3) intermediate production headers combining the seven (7) F1 and F2 flowlines

into three (3) intermediate bulklines.

4. Three (3) intermediate bulklines with HIPPS and the proper control, safeguarding,

metering and monitoring requirements.

5. One (1) Kolo Creek manifold combining the three (3) intermediate bulklines into the 20-

inch, 40 km long bulkline to the Soku Gas Plant.

6. 20-inch, 40 km long carbon steel pipeline (including the pig launcher and receiver and

proper control, safeguarding, metering and monitoring requirements) from Kolo Creek

NAG manifold to the Soku Gas Plant designed for evacuation of 400 MMscf/d from Kolo

Creek NAG manifold. This pipeline will traverse some communities in Niger Delta, Nigeria

though the intention of the routing was to avoid it as much as possible.

7. Slug-catcher at the Soku Gas Plant and full integration with the existing Soku Gas Plant

including definition of process control and safe guarding systems.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 6 of 44

8. Utilities in Kolo Creek and Soku Gas Plant to ensure safe and cost effective evacuation of

400 MMscf/d from Kolo Creek to Soku.

9. Installation of hardwares for control of facilities at Kolo Creek from Soku control room

10. Installation of a Fibre Optics Cable (FOC) along the length of the pipeline ROW for the

purpose of back-up communication for Kolo Creek Instrumentation Systems.

1.1 Purpose of Document

The scope of work and specification defines all the activities and services to be performed for

the execution of the topographical survey works of K2S Project on the selected project area

inclusive of the selected pipeline route as documented in K2S-TPEF-GEN-LA6958-00001-000.

In addition, it specifies the general requirements for the equipment and procedures applicable to

geotechnical soil survey works necessary for designing and constructing foundations for civil-

engineering structures and/or pipeline construction works for the execution of the Kolo Creek to

Soku Gas Pipeline Project.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 7 of 44

1.2 Objectives

1) To validate all required location, boundary, soil, surface and subsurface data and to provide

any additional information necessary to facilitate CONTRACTOR’S detailed design which

shall include detailed engineering design of foundations required for all equipment and

facilities on this project in the Kolo Creek sites (Manifold & Well location(s)) and Soku Gas

Plant. The extent of survey should be sufficient to cover (or allow reasonable extrapolation

over) the entire project area and should cover facilities sites and the pipelines routes.

2) To carry out detailed investigation on the buried/underground service facilities before

proposing finalised plot plans/equipment foundation layouts. All impacted service lines shall

be completely avoided in the first instance. Where complete avoidance is not feasible,

isolation or relocation shall be considered in that order.

3) Surveys shall be carried out in line with SHELL DEP 34.11.00.10-Gen.

4) To define methodology for obtaining satisfactory and consistent quality in geotechnical soil

surveys, and applies to:

o The definition and purpose of the types of geotechnical survey works as applicable to this

project.

o The equipment and procedures for the performance of the field works, including soil

boring or rock coring, trial pits, soil sampling, in-situ testing or measurements, laboratory

testing on soil samples or rock cores, etc.

o The procedures for the assessment of all results of the soil investigation tests and

measurements, to define the soil characteristics and geotechnical parameters required to

design the foundations and/or earth works as related to the laying of the pipeline, as well

as the presentation of the results, and the reporting to be provided by Contractor.

5) The SURVEY CONTRACTOR may elect, with explicit indication, to execute complete or

partial sections of the above objective in his response.

6) SURVEY CONTRACTOR shall provide everything, including design, engineering, materials

(other than that supplied by COMPANY), services, project management, procurement and

logistics, transportation, administration, for performing the Survey.

7) In meeting that objective, SURVEY CONTRACTOR shall fulfil the obligations and

implement the requirements that are described in the following sections. This document

provides summary details of the specific project requirements for the Kolo Creek - Soku

Pipeline Project. Selection to perform partial sections of the work does not preclude

considerations of all tasks associated for partial completion such as:

the data acquisitions for bottom topography, shallow seabed soils, underwater and

seabed obstructions, existing installations or facilities

metocean criteria like river current profile, tidal effects, depths based on lowest

astronomical tide, river floor bathymetry along laying corridor, etc for marine

surveys

the topographic survey, soils sampling and testing at specified points on the right-of

way, datum identification, location, etc for onshore surveys

River profiling, under River survey, existing pipeline landfalls, etc for near shore

survey

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 8 of 44

and the buildings intended for human occupancy, separate or multiple dwellings,

barriers or limiting factors to human density growth along pipeline, location and

class determination, etc for human occupancy survey.

8) The SURVEY CONTRACTOR can perform the survey in any direction and in any order to

meet the objective.

9) SURVEY CONTRACTOR can also provide explicitly stated modifications to the above

survey objective to optimize cost and schedule.

10) Each SURVEY CONTRACTOR proposing to execute partial survey shall consider having

clear and distinct overlap areas within the different components of the survey work like

onshore, near shore and marine surveys.

11) Any exclusion shall be explicitly stated in the survey proposal. The objective is more fully

and completely described in subsequent sections.

12) The four survey types required in the proposal are described in section 2 and subsequent

sections.

1.3 Route Description

The Kolo Creek field is situated in the southern part of OML-28 in the seasonal flooding fresh-

water swamp area, some 18 km southeast of the Gbaran CPF and about 90 km west of Port

Harcourt. It is one of SPDC’s Eastern Division fields considered as part of the Gbaran Ubie

nodal development to provide feed stock gas for the NLNG Trains 1 to 6.

The Kolo Creek NAG manifold to Soku gas plant pipeline traverses a wide geographical area.

Although land-take and width of ROWs have been reduced with the philosophy of option for

utilising existing routes (where possible), footprints on the environment are still unavoidable.

Environmental, social and safety factors have therefore been analysed as documented in K2S-

TPEF-GEN-LA6958-00001-000 to establish route corridors with the least potential negative

impact on the natural and human ecology, and also ensure public safety during construction and

operation of the pipelines.

1.4 Work Method Statement

The Contractor shall submit to Company, prior to carrying out any survey activity, a detailed

topographical survey method statement clearly identifying all activities of the survey work to be

performed including the followings as a minimum:

i. Survey methods

ii. Contractor organisation

iii. Logistics for land and water travels

iv. List of instruments and equipment to be utilized

v. Specialised personnel to be employed.

vi. List of the computer programs and the releases that Contractor intends to utilise for

the work.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 9 of 44

1.5 Definitions and Abbreviations

1.5.1 General Definitions

The following definitions shall be applied to the standard terms used throughout this document.

Companyl/Principal/ Shell Petroleum Development Company of Nigeria Limited

Company Representative (SPDC)

Contractor NestOil PLC, The Contractor is the party, which carries out

all or part of the design. The Company may undertake all or

part of the duties of the Contractor.

Engineer Dover Engineering Limited

Survey Contractor is the party (surveyor) which carries out the survey duties

specified by the Contractor

The word ‘shall’ indicates a requirement.

The word ‘should’ indicates a recommendation.

1.6 Abbreviations

ASCII American Standard Code For Information Interchange

ASME The American Society of Mechanical Engineers

ASTM American Society for Testing and Materials

CAD Computer Aided Design

CD Compact Disc

CPF Central Processing Facility

DEP Design and Engineering Practice

DGN Extension name assigned to Microstation file format drawings

DGPS Differential Global Positioning System

DWG Extension name assigned to AutoCAD file format drawings

EPC Engineering, Procurement and Construction

GPS Global Positioning System

HDD Horizontal Directional Drilling

HIPPS High Integrity Pressure Protection System

HSE Health, Safety and Environment

IP Intersection Point

ISO International Organization for Standardization

LLWS Lowest Level Water Spring

MS Microsoft

MSDS Material Safety Data Sheet

MSL Mean Sea Level

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 10 of 44

NAG Non Associated Gas

OML Oil Mining Lease

PC Personal Computer

P/L Pipeline

QA/QC Quality Assurance/Quality Control

ROM Read Only Memory

ROW Row of Way

UTM Universal Transverse Mercator

1.7 References

1. K2S-TPEF-GEN-LA6958-00001-A01 Pipeline Route Selection Report

2. DEP 34.11.00.10 – Gen Onshore and Nearshore Site Investigations

3. ASME B31.8 Gas Transmission and Distribution Piping System

4. ISO 10012 Measurement Management Systems –

Requirements for measurement processes and

measuring equipment

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 11 of 44

2.0 ROUTE SURVEY

The Route Survey and components are completely identified below:

Table 1: Route Survey

Item Survey Description Survey Type

1 Onshore Pipeline Route from Pig Launcher Area to Landfall Onshore Survey

inclusive of Kolo Creek sites (Manifold & Well location(s)) and

Soku Gas Plant

2 Route Approach to major Rivers including River Banks Near Shore Survey

3 Marine Pipeline Route (for all River Crossing) Marine Survey

4 Approach to Facilities: Pig Launchers and Receivers at Terminal Pipeline Approach

Stations and at Intermediate Pig Stations, Valve stations.

5 Onshore Pipeline Route from Kolo Creek to Soku Gas Plant Human Occupancy

Survey

6 Pipeline route, intermediate and terminal stations - determination Geotechnical

of the nature, type and characteristics of the sub soil.

investigation

Note:

1. The extent of survey covers the entire project area both facilities sites (Kolo Creek Manifold &

Well location and Soku Gas Plant) and the pipelines routes.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 12 of 44

3.0 BASIC SURVEY DESCRIPTION

1) The pre-installation Survey Work for the Kolo Creek - Soku Pipeline project, includes the

following types:

Onshore Survey – The areas delineated under the onshore survey include all land

surveys between all pigging, manifolds, well locations, compressor and/or valve

stations.

Near Shore Survey – These includes 100 m to the bank of every River and the

Rivers banks.

Marine Survey – The marine survey shall over lap the river banks on each side and

across the rivers.

Pipeline Approach – The pipeline approach survey shall cover the areas near

each Terminal station, Intermediate Pig Stations, Valve and/or Compressor

stations.

Human Occupancy Survey – The human occupancy survey shall extend on each

side of the ROW.

Geotechnical Investigation Survey – The geotechnical survey shall cover pipeline

route, Kolo Creek & Soku stations, major road crossings, major creek crossing and

major pipeline crossing.

2) The survey route consists of: an approximately 40 km long section onshore, swamp, near

shore and Marine for buried pipeline from the Pigging Station at Kolo Creek to Soku.

3) The COMPANY requires a re-establishment of the existing ROW and an additional 400 m

wide human occupancy survey along the pipeline route.

4) The Objective of the survey shall be to identify topographical features, seabed features,

shallow seabed soil parameters, sea water characteristics, bathymetry, and also identify the

location of any existing pipeline, record and report information on the specified corridor

along the existing pipeline.

5) SURVEY CONTRACTOR shall identify any potential new or previously unidentified hazards

to the proposed pipeline installation and operations; and any submarine, onshore or near

shore wrecks, facilities, mines, debris, rocks and boulders that may interfere with pipeline

installation operations.

6) Considering that there might be a possibility of using HDD for the crossing of the pipeline

across major and busy traffic rivers the SURVEY CONTRACTOR shall also consider some

boreholes within such rivers for acquisition of soil samples to give enough information for

the pipeline burial using the HDD method.

7) SURVEY CONTRACTOR shall mobilize vessels with low drafts (where necessary) for near

shore data acquisition in addition to having to utilize diver and amphibious equipment and/or

teams where the survey vessel is precluded from approach. Current recording buoys shall

also be required to acquire river current and direction data as long as can be allowed for the

period.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 13 of 44

8) A detailed Listing of survey activities include the followings as a minimum:

i. Obtain permit to work from Community chiefs and land owners

ii. Line clearing

iii. Establishing of GPS control point connected to the Nigerian National Geodetic

System (Minna Datum)

iv. Maps

v. Staking of pipeline corridors

vi. Setting out of reference beacons on both side of the R.o.W.

vii. Setting out of reference markers outside the R.o.W. limits

viii. Setting out of control monuments outside the R.o.W. limits

ix. GPS measurements or traversing

x. Levelling of the pipeline route

xi. Ground profile of pipeline route axis

xii. Survey of crossings (roads, watercourses, swamps, above and below ground

services)

xiii. Bathymetric survey at watercourse crossings

xiv. Cross sections transversal to P/L corridor centreline.

xv. Survey of pipeline route (strip map)

xvi. Detail survey of crossings

xvii. Survey of plant areas (wellheads)

xviii. Population density survey

xix. Computation of field data

xx. Drafting of maps and drawings relevant to the crossings

xxi. Pipeline route and profile maps (alignment sheets)

xxii. Contour map of areas

xxiii. Map of crossings including ground profile section of P/L corridor axis

xxiv. Ground profile of P/L corridor route axis

xxv. ASCII files of ground profile along the corridor centerline

xxvi. ASCII files of corridor axis co-ordinates

xxvii. Pipeline drawings in hard and soft copies

Final survey report and final data back up on CD-ROM of all deliverables

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 14 of 44

4.0 GENERAL PRE-INSTALLATION ROUTE SURVEY REQUIREMENTS

4.1 General

The following noted descriptions provide general survey requirements. Detailed description of

each of this requirement is described in the following sections of this document.

1) The SURVEY CONTRACTOR shall provide an instrumented high resolution marine survey

equipment for existing pipeline; near shore survey shall be a combination of amphibious,

diver and marine capabilities for accomplishing the survey; the onshore survey for the

onshore portions shall have requirements such as topographic, shallow sub soils, crossings

– type data acquisition, interpretation and reporting; and the ROW sides human occupancy

survey shall have requirements such as the number of buildings intended for human

occupancy, separate or multiple dwellings, barriers or limiting factors to human density

along pipeline, location and class determination, etc. The CONTRACTOR’S survey

performed along the proposed pipeline route shall provide sufficient data for the pipeline

installation design related activities.

2) The SURVEY CONTRACTOR shall provide the following for marine geophysical survey:

positioning and navigation of vessels in water depths 0 – 45 meters using positioning

systems; bathymetry recordings; side scan sonars; shallow seabed samplings; sub bottom

profiles, in-situ current profile measuring facility and magnetometer detection.

3) Elevations contours shall be at 0.5 m intervals within the plant area and 1.0 m interval in the

immediate surroundings. In steeply sloping terrain, these contour intervals may be doubled.

Outside this area, a larger contour interval may be used, particularly in rugged country or

over water. Route profiles shall be drawn to an accuracy of 0.1 m in elevation [Ref 2].

4) The SURVEY CONTRACTOR shall consider having to vary the required survey accuracy

along the proposed pipeline route with high resolution in zones of variation, anomalies and

obstructions along with special sub-surface investigations; and standard resolution in other

areas.

5) SURVEY CONTRACTOR shall determine alternate landfall options to proposed route and

landfall based on factors acquired during survey such as: environmental conditions caused

by adjacent coastal features; alternate landfall location to facilitate installation, avoiding

existing, proposed, new or unidentified facilities; and minimizing environmental impact and

notify COMPANY.

6) SURVEY CONTRACTOR shall increase the size of lay corridor if in the course of survey;

structures like rock or boulder obstructions, large pock marks, unstable topography, erosion,

shallow gas, hydrates, scouring of existing pipeline or facilities, new or unidentified facilities

and other geo-hazards are prevalent along the proposed route. This action shall only be

done after prior notification and approval by COMPANY.

7) SURVEY CONTRACTOR shall consider having to identify, locate and count and determine

maximum number of buildings intended for human occupancy along the route of the pipeline

and any information required for pipeline location classification per ASME B31.8. For

multiple dwelling units with separate dwelling, each separate dwelling unit shall be

considered as a separate building intended for human occupancy.

8) SURVEY CONTRACTOR shall consider having to identify any physical barriers or other

factors that may exist in the expansion of population along the pipeline. The SURVEY

CONTRACTOR shall also consider having to identify any facilities having concentrations

greater than 20 people such as: schools, churches, recreational facilities, hospitals, etc and

the facilities frequency of usage along the pipeline route.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 15 of 44

9) SURVEY CONTRACTOR shall state any exceptions in PROPOSAL.

4.2 Requirement for Topographical Survey

The specific requirement for the topographical survey are as follows:

1) Co-ordination and Control

Supervision by skill experienced surveying specialist, qualification/experience,

professional registration etc.

Contractor responsibility for the topographic survey results, establishing the

measurement concept, measurement guidelines, choosing of appropriate measurement

instrument, equipment, the coordination and quality control of the survey work and HSSE.

SPDC has the right to supervise the work at any time and give instructions (This

supervision does not relieve the Contractor of his own responsibility for the execution of

all surveying works).

Handover to SPDC Survey documents and calculations.

2) Instruments and Equipment

- use of modern tropicalised survey instruments and equipment, suitable to obtain the

tolerance required, operated by qualified persons experienced, recently calibrated and shall

be subject to operational regular checks. Calibration report shall be provided to Company

before starting the survey work.

3) Accuracy Requirements for Global Positioning System (GPS)

4) Accuracy Requirements for Conventional Survey

5) Survey Equipment - Setting and Certificates

equipment identification number tag/plate showing Date of the last setting/calibration,

Expire date of the setting/calibration

Contractor shall make available to Company the certificates or calibration report of each

equipment before their utilisation. These certificates shall be part of final survey report.

6) Permit to Survey and Site Security Requirements

7) Progress Report

8) Geodetic parameters and datum

Official Local Datum :

GPS Satellite Datum

Elevation Datum :

Elevations control shall be referenced to the Lagos datum; correlation table for MSL

and LLWS shall be supplied and included in the final report.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 16 of 44

4.3 Pipeline Route Survey Works

The following survey work activitie shall be carried out as a minimum:

1. Line Cutting

2. Staking of Pipeline Route

3. Numbering of Stakes

4. Beaconing

5. Marking

6. Reference Markers

7. Establishment of Control Monument

8. Traversing (alternative to GPS measurements)

9. Setting out of Control Monuments, Reference Markers and Beacons With Global

Positioning System (GPS)

10. Levelling

11. Ground Profile of Pipeline Route

12. Survey of Crossings (Road, Pipeline, Services and Overhead Lines)

Road Crossing

Track Crossing

Pipeline and Other Buried Services

Overhead Line Crossings

13. Watercourses Crossings

General Requirement

Survey Methods

Water Level and Tidal Observations

Stream Velocity Measurements

14. Transversal Sections

15. Detail Survey of Pipelines

16. Detail Survey of Major Road Crossings

17. Detail Survey at Medium River Crossing

18. Population Density Survey

19. Soil Nature and Land Use Evaluation - soil type (i.e. sand, clay, silt etc.), crop and

vegetation information and type shall be observed and included in the route and profile

map drawing (see Attached Sample of Route Map Drawing).

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 17 of 44

5.0 SPECIFICATION FOR ONSHORE PRE-INSTALLATION SURVEY

1) The survey data required in this proposal are for the following facilities: Slug Catcher

location; pig launcher location; onshore pipeline route; pig receiver location; crossings and

types; cathodic protection and connection to pipelines.

2) The SURVEY CONTRACTOR shall consider the development of two key deliverables.

Topographic survey for the proposed Gas pipelines. The Survey shall include a 50

m x 25 m area of section overlap with the near shore survey, extending beach ward

from the landfall. Onshore side of the survey shall also include location of all

underground crossing utilities and pipelines within the right of way. A building and

population density survey shall also be performed along the pipeline route. The

high water line shall also be determined by the survey. Swamps and flooded areas

shall be identified, reported and clearly delineated in the route map in such a way

that there will not be any confusion as to areas where weight coatings shall be

required on the pipeline.

3) The SURVEY CONTRACTOR shall utilize UTM Co-ordinates for survey and provide datum

and translation to TERMINAL STATION ORIGIN CO-ORDINATES

4) The SURVEY CONTRACTOR shall also consider the uncertainty of data provided in the

location of existing facilities along the proposed route and shall proceed with caution during

data acquisition by utilizing reliable equipment and methods to detect any existing facilities,

parallel or crossing pipelines and utilities in the survey corridor.

5) The SURVEY CONTRACTOR shall consider having to perform the survey according to

specifications such as: topographic survey specification, soils resistivity survey specification

and other survey specification.

6) The SURVEY CONTRACTOR shall develop the following topographic survey data such as:

datum and bench marks, co-ordinates and elevations at the pig launcher and receiver,

landfall, any other pipeline and utilities crossings, roads and ground contours at 0.5 m

elevation changes.

7) SURVEY CONTRACTOR shall provide key supervisors to receive training from COMPANY

plant personnel in safety related matters as it pertains to working inside the plant fence.

These supervisors, in turn, shall train all SURVEY CONTRACTOR and any subcontractor

personnel who will enter the plant facilities.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 18 of 44

6.0 SPECIFICATION FOR NEAR SHORE PRE-INSTALLATION SURVEY

1) The SURVEY CONTRACTOR shall consider the effects of shallow water depths that

usually precludes the use of normal offshore spreads; near shore trenching requirements

that will require soils data from greater depths than normal offshore locations; risk of

sediment mobility; the limitation in the use of land based equipment beyond the low water

mark; the limitation in the use of offshore spreads landward beyond the high water mark; the

use of shallow draft anchored pontoons; small jack-up drilling platforms, and/or the use of

amphibious vehicles to drill, sample and test seabed soil or rock for the PROPOSAL.

2) The SURVEY CONTRACTOR shall utilize UTM Co-ordinates for survey and provide datum

and translation to TERMINAL STATION ORIGIN CO-ORDINATES

3) The near shore survey shall overlap the onshore survey by a 50 m x 25 m wide area

landward and shall overlap the marine survey by a 50 m x 25 m wide area seaward.

4) The SURVEY CONTRACTOR shall use an appropriate combination of instrumented

geophysical survey equipment, diver and other means to acquire data in the near shore

area; in addition to using appropriate methods for grab and core soil samples for shallow

and deep seabed soils; and observing data like wave, current, surface, seabed and sub-

surface features.

5) The SURVEY CONTRACTOR shall provide the following for marine geophysical survey:

positioning and navigation of vessels in shallow water depths 0 – 45 m using positioning

systems; bathymetry recordings; side scan sonar; shallow seabed sampling; sub bottom

profilers and magnetometer detection.

7.0 SPECIFICATION FOR PRE-INSTALLATION MARINE SURVEY

1) The SURVEY CONTRACTOR shall utilize UTM Co-ordinates for survey and provide datum

and translation to TERMINAL STATION ORIGIN CO-ORDINATES.

2) The SURVEY CONTRACTOR shall obtain information on environmental and river bed

conditions along the pipeline routes and as close as possible to landfall locations in terms

of: Bottom topography; Typical shallow seabed soils and strata acquired during marine

survey; River water condition to include individual current velocity distribution and direction;

Obstructions along the routes; Existing installations e.g. pipelines & cables, their location

and bearing, etc.

3) The SURVEY CONTRACTOR shall provide the following details for the PROPOSAL:

Resume of professional and supervisory personnel; Details of marine vessels; Details of

investigative, survey and testing equipment, vessel positioning method; Method Statements

for the marine surveys and geotechnical investigations; Time schedule for completing the

MARINE SURVEYS.

4) The area is expected to be subject to extremes of conditions although a proportion of the

time each year can be expected to be unsuitable for Marine Operations. For the marine

surveys, SURVEY CONTRACTOR will be deemed to have satisfied himself as to the wind,

wave, tide and current and other natural conditions prevailing in the fields and no claim

whatsoever will be entertained arising from these conditions.

5) The SURVEY CONTRACTOR shall provide a reliable Navigation System which can achieve

accuracies better than ± 1 m (2 standard deviations). DGPS is the preferred system over a

medium range radio positioning system.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 19 of 44

6) The SURVEY CONTRACTOR shall provide on-board data computation, reduction and

plotting at specific scale in the form of bathymetric charts.

7) The SURVEY CONTRACTOR shall provide the following for offshore geophysical survey:

positioning and navigation of vessels in shallow water depths 0 – 45 m using positioning

systems; bathymetry recordings; side scan sonar; shallow seabed sampling; sub bottom

profilers and magnetometer detection.

8) The SURVEY CONTRACTOR shall perform seawater sampling at the geotechnical

investigation locations at surface, mid-depth and near seabed, to include: Temperature,

Salinity, and Density.

9) The SURVEY CONTRACTOR shall perform at crossings (if any) for pipelines and cables, a

detailed bathymetric/diving survey of the seabed where the routes cross existing pipelines

and cables, with details of existing pipelines; seabed conditions and at least on seabed soil

samples taken per crossing, providing as a minimum but not limited to the following data:

bathymetry and contours, reflectors, debris and obstructions, soil strata, details of existing

pipelines/other structures and sleepers, details of existing cables, etc. Spot elevation

measurements shall be taken at the theoretical crossing point (for each pipeline) and at 20

m at either side of this point along the existing pipeline, and at 20 m either side of the

existing pipeline.

10) The SURVEY CONTRACTOR shall perform a magnetometer survey along the proposed

pipelines routes and concurrently with an echo sounder survey.

11) The SURVEY CONTRACTOR shall record tidal data for the entire duration of the surveys.

12) The SURVEY CONTRACTOR shall submit a site survey procedure and schedule for

COMPANY approval, and hold a meeting, prior to commencement of each site survey.

CONTRACTOR’s attention is drawn to the fact that the Survey Work shall be subject to

acceptance and approval by COMPANY.

13) The SURVEY CONTRACTOR shall be responsible for providing communications

equipment between the control stations and the survey vessel and between calibration

stations during the provision of positioning and survey services.

14) The SURVEY CONTRACTOR shall submit a work schedule for COMPANY APPROVAL, be

subject to the requirements of the standing instructions for Marine Operations, the safety

regulations relevant to Marine Operations and COMPANY diving regulations. This should

be reflected in the lump sum price.

15) The pipeline routes survey work outlined above shall cover the planned routes. Final routes

will be selected by COMPANY based on reports of the survey performed by the

CONTRACTOR. COMPANY’s Representative on board the survey vessel may instruct

CONTRACTOR for the purpose of the work to sail along different lines within the field.

Provided that the total vessel sailing length as covered by this contract does not change,

this instruction shall not be considered a variation.

16) Based on the survey findings, the SURVEY CONTRACTOR shall consider proposing the

pipeline route for engineering and COMPANY approval.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 20 of 44

8.0 SPECIFICATIONS FOR PRE-INSTALLATION PIPELINE APPROACH SURVEY

1) The SURVEY CONTRACTOR shall utilize UTM Co-ordinates for survey and provide datum

and translation to TERMINAL STATION ORIGIN CO-ORDINATES.

2) The SURVEY CONTRACTOR shall locate major landmarks/facilities in the terminal stations

and indicate them properly on the report and final drawings.

3) Other special features in and around the Terminal Stations and Valve Stations and

Intermediate Pigging Stations shall also be located.

4) All pipeline crossings and existing equipments that may obstruct Pipeline entry into the

facilities shall be properly located and reported.

5) Fences around the Pipeline Approach to Major Stations (Pig launcher and receivers,

Valve/compressor stations) shall be properly detailed with their corner post coordinates

6) Based on the survey findings, the SURVEY CONTRACTOR shall consider proposing the

pipeline route/entry into major facilities for engineering and COMPANY approval, though the

final decision on this shall be taken by the COMPANY after engineering by the

ENGINEERING CONTRACTOR.

9.0 BASIC DESCRIPTION OF SERVICES EXTENT

1) SURVEY CONTRACTOR shall consider all necessary labor, equipment, consumables, and

materials (unless stated to be provided by COMPANY), to perform the Work outlined in this

scope in accordance with the Survey Contract.

2) The SURVEY CONTRACTOR shall be responsible for provision of positioning frequency

licenses, obtaining Government and Marine Department permits for the positioning services

and survey work and for complying with relevant regulation of Government Authorities. All

permits required for the execution of the Site Survey shall be arranged by the SURVEY

CONTRACTOR well in advance, including work permit from the Government of Nigeria, the

COMPANY’s gate pass for access to the operational area and so on.

3) Mobilization and demobilization of SURVEY CONTRACTOR’s various spreads including

survey vessel, survey vessel equipment, material transportation barges, shore crossing

support equipment, onshore survey equipment, personnel, support vessels, anchor handling

tugs, diving and survey support vessels, subcontract services and all other equipment,

spare parts, consumables and specialized services necessary for the completion of the

Work.

4) SURVEY CONTRACTOR shall review all COMPANY provided survey and geotechnical

information, sketches, acknowledge acceptance, and perform all additional route survey

work necessary to ensure pipeline integrity and safe pipe laying operations to

CONTRACTOR’s installation equipment.

5) SURVEY CONTRACTOR shall conform to all contract, government, local regulations,

Industry accepted specifications and practices for the execution of this project.

6) SURVEY CONTRACTOR shall purchase materials, fabricate, test and transport all required

equipment to CONTRACTOR’s staging site. CONTRACTOR shall install all provided

assemblies in accordance with the drawings and specifications.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 21 of 44

7) SURVEY CONTRACTOR shall mobilize suitable and approved vessels/barges, personnel,

security forces, subcontract services and all other materials, equipment and personnel to

complete all required marine survey.

8) SURVEY CONTRACTOR shall mobilize suitable and approved equipment, personnel,

subcontracted services and all other materials necessary to complete the required surveys.

SURVEY CONTRACTOR shall provide all utility services to complete Work. SURVEY

CONTRACTOR shall assume these services are not available from the existing plant.

9) SURVEY CONTRACTOR shall supply suitable marine equipment, fuel, personnel, diving

services and survey services for pipeline crossing or near shore survey.

10) SURVEY CONTRACTOR shall submit for COMPANY approval all required chemical MSDS

sheets for chemicals to be used. CONTRACTOR shall purchase and transport to location all

required chemicals for Work and properly dispose of all unused chemicals upon completion

of the Work per COMPANY’s HSE requirements. MSDS sheets shall be located on site.

11) SURVEY CONTRACTOR shall document the “as-built” condition of existing pipeline

segment and launcher and receiver tie-ins.

12) SURVEY CONTRACTOR shall calibrate all testing and recording instruments prior to

mobilization. COMPANY at its option may witness these calibrations.

13) SURVEY CONTRACTOR shall immediately advise COMPANY of any known damage or

alleged claims to local fishing (or other) equipment caused by CONTRACTOR’s equipment.

14) SURVEY CONTRACTOR shall identify key personnel for the project including qualifications

information.

15) COMPANY/CONTRACTOR shall perform a marine vessel audit and inspection and must be

satisfied equipment is in safe and good condition prior to mobilization. SURVEY

CONTRACTOR shall give COMPANY/CONTRACTOR adequate notice to allow proper

planning to minimize impact to mobilization schedule. “Company Vessel Inspection Form”

shall be utilized. COMPANY/CONTRACTOR shall be given opportunity to inspect all other

marine vessels or survey equipment prior to mobilization.

16) SURVEY CONTRACTOR shall present a logistics plan that includes liaison with the

designated port and/or inland waterways authorities prior to transit.

17) COMPANY/CONTRACTOR shall provide the names and contact information of Survey

team personnel that are familiar with the shore crossing and onshore pipeline routing who

will be available to accompany SURVEY CONTRACTOR for any desired field visits. The

coordination of field trips should be made through these individuals and their availability

may be limited.

18) SURVEY CONTRACTOR shall also consider having to provide quarters, meals, offices,

subsistence, phone, and fax for all COMPANY/CONTRACTOR representatives/inspectors

on SURVEY CONTRACTOR’s mobilized vessels and work sites. SURVEY CONTRACTOR

shall accommodate the following minimum personnel requirements:

Onshore Operations: 1 COMPANY inspectors/representatives and 1

CONTRACTOR inspectors/representatives

Marine Operations: 1 COMPANY inspectors/representatives and 1 CONTRACTOR

inspectors/representatives

This is in addition to all required Government and/or SURVEY CONTRACTOR security

personnel.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 22 of 44

10.0 GENERAL SHORE CROSSING SCOPE ITEMS SERVICES

In addition to the requirements identified for consideration in section 8 above, the following

general shore crossing scope items shall be considered for developing the survey cost estimate

and schedule:

1) SURVEY CONTRACTOR shall be responsible for coordinating any marine activities with

any shore crossing subcontractor to ensure no delays are encountered.

2) SURVEY CONTRACTOR shall provide qualified subcontractors, equipment, and personnel

to survey the shore crossings.

3) SURVEY CONTRACTOR shall be responsible for mobilizing all shore crossing equipment

to location. Any work required to construct / rehabilitate any roads to obtain access to the

shore crossing site is the responsibility of the SURVEY CONTRACTOR.

4) SURVEY CONTRACTOR shall present for COMPANY’s review through the ENGINEERING

CONTRACTOR a detailed security plan. All security while on site (both on land and

offshore) to protect SURVEY CONTRACTOR’s personnel and equipment shall be supplied

by SURVEY CONTRACTOR.

5) SURVEY CONTRACTOR shall be responsible for the disposal of all waste products per

COMPANY requirements.

6) SURVEY CONTRACTOR shall present in the project execution plan the effects of its

activities on the watercourses, wetlands and sedimentation in the area of operation. All

shore crossing trenches shall ensure no salt water intrusion into onshore mangrove or other

environmentally sensitive areas.

7) SURVEY CONTRACTOR shall supply all expendable materials and chemicals.

8) SURVEY CONTRACTOR shall verify all accesses to and from the shore crossing site. Any

required road or bridge crossing permits will be obtained by SURVEY CONTRACTOR.

9) SURVEY CONTRACTOR shall satisfy the requirements of appropriate regulatory agencies

by providing a means to contain, monitor, and abate turbidity while performing shore

crossing work. SURVEY CONTRACTOR shall propose measures specifically designed to

minimize turbidity.

10) In addition to turbidity monitoring and abatement, the entire area surrounding the crossing

exit locations may require spoil containment. Any soil removed for the crossing work shall

be uniformly distributed across the area so no mounds of soil build-up are produced.

11) SURVEY CONTRACTOR shall provide the following at the onshore and shore crossing

locations:

All required water either from local sources or self-drilled wells.

All electrical power, fuel and lighting shall be supplied by SURVEY CONTRACTOR.

All required security measures for personnel and equipment

Suitable communications between all site locations and marine support vessels

Lodging and meals for SURVEY CONTRACTOR’s personnel.

Lands other than permanent right of way.

Camp sites if required. Survey Contractor shall advise during tendering its plans for

utilization of camp sites.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 23 of 44

12) Additionally SURVEY CONTRACTOR shall provide the following services at the shore

crossing location:

Perform a site accessibility program.

13) SURVEY CONTRACTOR shall provide the following additional services:

All personnel travel, catering and lodging arrangements

All equipment operating permits

All permits for equipment to enter and exit Nigeria

All training programs for locally utilized labour force.

All personnel protective equipment for SURVEY CONTRACTOR personnel

14) SURVEY CONTRACTOR shall be subject to attend on-site meetings between COMPANY

and CONTRACTOR to periodically discuss safety, community relations, etc as needed to

enforce the concept of incident and injury free operations.

15) SURVEY CONTRACTOR shall minimize environmental damage at the Work Site due to

their equipment and shall remediate all work locations to near their original condition upon

completion of Work.

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 24 of 44

11.0 REPORTING

1) The SURVEY CONTRACTOR shall provide key deliverables such as: objectives, method

statements for topographical reports, drawings, equipment used, settings and work to be

performed within 7 days of contract award; preliminary reports within 10 days of

demobilization. Project Execution Plan shall be included in the proposal.

2) The final Report shall consist of a Route Topographical Survey Report and Route Map

Drawing. The report shall record factors affecting the accuracy and reliability of the results

reported, e.g. [Ref 2]

Type(s) and accuracy of survey method(s), including the use of correction factors;

Control points used;

Atmospheric and other environmental conditions;

The nature of the ground surface or seabed, in particular where this consists of soft

ground;

Geohazards (land slide areas);

Land use (e.g. crops); etc

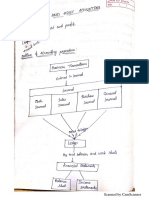

3) A sample Route Map Drawing is Attached below.

4) The CONTRACTOR shall submit a daily work report including a vessel movement (where

such is used) log during each site survey.

5) The SURVEY CONTRACTOR shall provide key deliverables in preliminary report on

features discovered. The SURVEY CONTRACTOR shall submit reports and drawings

including daily, preliminary and final reports.

6) Prior to demobilizing his survey spread and staff, the SURVEY CONTRACTOR shall submit

three (3) sets of the interim survey reports and hold a meeting to present for the

COMPANY’s information, the results of each survey and the outline of data logging

gathered during his investigation.

7) The SURVEY CONTRACTOR shall provide 5 copies of bound final reports, chart and data

sets on CD ROM that contains executive summary, introduction, technical background,

results of interpretation and analysis, field activities summary, QA/QC procedures, errors,

and conclusion and recommendations; and final drawings with title block indicating: project

and location, survey date and scope, datum, translation numbers and references.

8) All the documents other than CAD files shall be prepared by means of Microsoft Office

package approved by the Company. Soft copies of all deliverables and of final survey report

shall allow Company to print easily each survey report section if needed.

9) Final report shall be submitted only after having incorporated Company’s comments.

SURVEY CONTRACTOR shall include in the final report the description of survey methods,

survey data computation and presentation, list of personnel, equipment and the following as

a minimum shall be captured in the report:

I. General P/L route key map on report cover

II. Instruments data specifications, type and certificate / calibration reports

III. Station description, co-ordinates and source of all control points used for the

survey

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 25 of 44

IV. Monograph of the triangulation, GPS control beacos or traverse stations

V. Original record book of the survey data

VI. Summary of the zenith directions (if any)

VII. Calculations and adjustments of triangles, quadrilaterals and traverses

VIII. Calculations and adjustments of the co-ordinates for all triangulation or traverse

stations

IX. GPS data processing compute and diagrams of satellites observations and

conversion formulas.

X. Conversion formulas between co-ordinates systems and datum

XI. Graphic of the observations and of the sides measured plotted at 1:20.000 scale.

XII. List of all pipeline route intersection points with relevant co-ordinates, progressive

kilometres (according to the soil feature and identification number)

XIII. List of all beacons installed at ROW boundaries with relevant co-ordinates

elevations and identification numbers

XIV. Monograph of traverse beacons of intersection points

XV. Monographs of beacons at all major crossings

XVI. List of reference markers installed along the pipeline route, with relevant co-

ordinates elevation and identification number

XVII. Monographs of the reference markers

XVIII. Population density spread sheet

XIX. Stream velocity measurements results

XX. Swamp areas report

XXI. Result of Quality Control on survey data, using procedures and software

approved by Company

10) Final survey report format shall be split into sections per the content of the final survey

report suggested below as a minimum:

1. General

1.1 Introduction

1.2 Scope of work

1.3 Survey organisation, personnel and equipment

1.4 Data of survey

1.5 Survey operations

1.6 Recce survey

1.7 Cutting and staking

1.8 GPS survey of control points

1.9 Pillaring and numbering

1.10 Levelling

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 26 of 44

1.11 Detail survey

1.12 Bathymetric survey of major river

1.13 Stream velocity measurements results

1.14 Swamp areas report

2. Traversing

2.1 GPS Network and Control Points

2.1.1 General

2.1.2 Survey procedure

2.1.3 GPS data processing and conversion table to Nigerian Grid System

2.1.4 Results

2.2 Traverse on pipeline axis

2.2.1 General

2.2.2 Survey procedure

2.2.3 Data processing

2.2.4 Results

3. Levelling

3.1 Reference bench marks and pillars

3.2 Correlation between MSL, LLWS and Lagos Datum and compensation

3.3 Tidal variation along major rivers and creeks

3.4 Elevation at different site locations

3.5 Levelling and profiling

4. Appendix

APPENDIX "A" LIST OF TOPOGRAPHIC DELIVERABLES (MAPS, CROSSING, ETC)

APPENDIX "B" FINAL LIST OF COORDINATES (PL CENTRE LINE PEGs AND BENCH

MARKERS)

APPENDIX "C" TABLES OF PIPELINE DATA AND INFORMATION

APPENDIX "D" GEODETIC PARAMETERS AND DATUM

APPENDIX "E" GPS STATION DESCRIPTION AND MONOGRAPHY

APPENDIX "F" DIARY OF EVENTS

APPENDIX "G" LIST OF PERSONNEL

APPENDIX "H" LIST OF EQUIPMENT

APPENDIX "I" INSTRUMENTS SPECIFICATION

APPENDIX "J" TRIMPLAN PREDICTION DIAGRAM (IF ANY)

APPENDIX "K" TRAVERSE LOOPS DIAGRAM

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 27 of 44

11) SURVEY CONTRACTOR shall maintain survey record books for field and office works. All

records shall be available for inspection by the Company or Company representative during

and at completion of the work for at least 5 years. All the soft files shall be backup on

magnetic media suitable for preserving and storing data for long time on CD-ROM media.

12) Pipeline axis profile shall be issued to Company per section, as soon as pipeline section

has been surveyed, tied-in to monuments, adjusted and verified.

12.0 CAD MAPPING

All topographic data shall be translated to topographical drawings and maps, to be produced, to

the following extent:

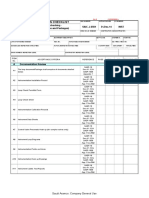

Table 1: CAD Mapping

Drawing Content Scale Format

Route Maps Final route, topography, cadastral 1:10,000 / 1:25,000 A0 / A4

boundaries, crossings

Profile Longitudinal profile of pipeline 1:2,000 / 1:500 A0 / A4

Drawings

Special Points Road , River, Swamp, Pipeline 0.388888889 Varies

Drawing crossings

Onshore – Detailed topography (min. 30 m x 30 0.128472222 A2

Offshore m)

Tie-in into Detailed topography (min. 30 m x 30 0.128472222 A2

existing m)

stations

Notes:

1) All survey data and files (soft copy) shall be of magnetic media (CD-ROM readable by

generic CD-ROM driver windows system compatible.

2) Survey maps ( plant areas and of pipeline route maps) and drawings shall be in Autocad 2000

(or latest ) file format (*.DWG)

3) The data for groundbed profile and coordinates shall be in MS Excel (*.XLS)

This document is controlled electronically and is uncontrolled when printed

EPC for Kolo Creek to Soku Gas Export Pipeline

Scope of Work for Topographical, Geotechnical, Bathymetric and

Underground Facilities Survey

K2S-NG01007551-GEN-CG6968-00001 Page 28 of 44

The content of the drawings / CAD Mapping should include the followings::

1) Pipeline Route and Profile Maps: the drawing shall include the following informations:

East and North co-ordinates, co-ordinate grid and co-ordinate system reference, spheroid and

datum parameters;

Axis of the pipeline with all points of intersection (PIs),

All concrete beacons and reference markers;

2) Pipeline Route Profile: A sample is provided in the attachement, it should contain the

following information described with the title at the left side:

(a) Ground profile data,

i) Survey reference

ii) P/L Direction changes

iii) Ground elevation (m)

iv) Partial Horizontal distance (m)

v) Progressive Horizontal distance (m)

(b) Terrain Information

i) Soil nature

ii) Vegetation / cultivation

(c) Population density information:

i) Crossings

ii) Number of buildings

iii) Class location;

(d) Legend, this shall show all survey symbol used including notes

(e) Geodetic and Cartographic Parameters

i) Datum

ii) Spheroid

iii) Length of semi major axis

iv) nverse flatting

v) Projection system

vi) Central meridian

vii) Latitude of origin

viii) Zone Number (if any)

ix) False Easting

x) False Northing

xi) Scale factor