Professional Documents

Culture Documents

Fastening System 300-1W (Patil Infrasyructure PVT LTD)

Fastening System 300-1W (Patil Infrasyructure PVT LTD)

Uploaded by

Tirumala RaoCopyright:

Available Formats

You might also like

- Scope of WorkDocument60 pagesScope of WorkParesh Tadas100% (1)

- Ac 133Document7 pagesAc 133thirumalaichettiar100% (2)

- Physiotherapy Course PDFDocument156 pagesPhysiotherapy Course PDFMamta100% (2)

- Procedure For Safety Certification and Technical Clearance of Metro Systems by Rdso (Jan-2013)Document51 pagesProcedure For Safety Certification and Technical Clearance of Metro Systems by Rdso (Jan-2013)astor50% (4)

- RDSO PE SPEC AC 0138-2009 Rev 2 or LatestDocument23 pagesRDSO PE SPEC AC 0138-2009 Rev 2 or LatestRajnish KumarNo ratings yet

- Minutes - 10th Extraordinary TSCDocument43 pagesMinutes - 10th Extraordinary TSCcdmNo ratings yet

- Final - Feb-2015 Manual 19.02.2015Document50 pagesFinal - Feb-2015 Manual 19.02.2015Hitesh SrivastavaNo ratings yet

- L1-CHE-SPE-064 Ballast SupplyDocument10 pagesL1-CHE-SPE-064 Ballast Supply4493464No ratings yet

- R GSR612 (E) eDocument68 pagesR GSR612 (E) eVamsiKrishnaNo ratings yet

- TDG 0026 Rev 4 - Final 23042014Document20 pagesTDG 0026 Rev 4 - Final 23042014SunilKumarNo ratings yet

- PNGRB Technical Standard - T4SEDocument44 pagesPNGRB Technical Standard - T4SEVishal AgrawalNo ratings yet

- 15-Saip-50 (Ins. For Conduit - Cable Seals)Document5 pages15-Saip-50 (Ins. For Conduit - Cable Seals)sathish KumarNo ratings yet

- R GSR612 (E) eDocument93 pagesR GSR612 (E) eDevashish SharmaNo ratings yet

- Implementation of Hybrid ETC Letter 27.09.17Document7 pagesImplementation of Hybrid ETC Letter 27.09.17Bhupender YadavNo ratings yet

- MDG 12 Guide For The Construction of Friction WindersDocument23 pagesMDG 12 Guide For The Construction of Friction WindersbenssjNo ratings yet

- CFR 2011 Title49 Vol3 Part195 AppaDocument3 pagesCFR 2011 Title49 Vol3 Part195 AppaAssemNo ratings yet

- Avoiding Holes in RailsDocument2 pagesAvoiding Holes in RailsPrakash budhaniNo ratings yet

- DSC Policy 011221Document8 pagesDSC Policy 011221drhagc2011No ratings yet

- Approved RDSO List Final 2016Document206 pagesApproved RDSO List Final 2016dycmmgncrNo ratings yet

- Mil STD 810gDocument8 pagesMil STD 810gaybidoNo ratings yet

- Nureg 0800 3.6.2 Determination of Rupture Locations and Dynamic Effects Associated With The Postulated Rupture of PipingDocument20 pagesNureg 0800 3.6.2 Determination of Rupture Locations and Dynamic Effects Associated With The Postulated Rupture of PipingFernando DiezNo ratings yet

- Ui Sc180rev4Document9 pagesUi Sc180rev4Maan MrabetNo ratings yet

- Inspection of Electrical Equipment: OISD - STD - 137 For Restricted CirculationDocument45 pagesInspection of Electrical Equipment: OISD - STD - 137 For Restricted CirculationanandpurushothamanNo ratings yet

- Show FileDocument88 pagesShow FileNAVASNo ratings yet

- Installation of Earthing System: Inspection and Test Procedure ForDocument4 pagesInstallation of Earthing System: Inspection and Test Procedure ForJITHIN KRISHNAN MNo ratings yet

- ML18136A762Document14 pagesML18136A762Marcos MaturanaNo ratings yet

- T4S CGD Consolidated 31.12.2016 FinalDocument65 pagesT4S CGD Consolidated 31.12.2016 FinalNikhil SainiNo ratings yet

- OBCMS Final Specifications 1-5-2017Document40 pagesOBCMS Final Specifications 1-5-2017Sahil KumarNo ratings yet

- Fed STD H28 20BDocument30 pagesFed STD H28 20BAnonymous A5X4rddZPNo ratings yet

- TSS Paper (Final) - StampedDocument11 pagesTSS Paper (Final) - StampedJack ClarkeNo ratings yet

- Netra Final Draft Spec - 14.06.19Document89 pagesNetra Final Draft Spec - 14.06.19RCC PGTNo ratings yet

- Internal Procedure For Operating State GridDocument71 pagesInternal Procedure For Operating State GridSiddharth Bhawsar100% (1)

- GSR612 - PNGRB PDFDocument55 pagesGSR612 - PNGRB PDFBenaknaik S GajannavarNo ratings yet

- RDSO Vendor DirectoryDocument201 pagesRDSO Vendor DirectorySravan CholeteNo ratings yet

- 7-SBS-MST-0218.C Method Statement Joint Pit Installation of 150KV UGC at JP-18 (Cast in Situ) NONODocument116 pages7-SBS-MST-0218.C Method Statement Joint Pit Installation of 150KV UGC at JP-18 (Cast in Situ) NONOAran SimarmataNo ratings yet

- PNGRB T4SDocument56 pagesPNGRB T4SHoney Narang100% (3)

- T4S CGD Consolidated 31.12.2016 FinalDocument65 pagesT4S CGD Consolidated 31.12.2016 FinalcoolmagaNo ratings yet

- Technical Standards PNGRBDocument44 pagesTechnical Standards PNGRBRashid HussainNo ratings yet

- Advisory Circular: Subject: Date: Initiated By: AC NoDocument6 pagesAdvisory Circular: Subject: Date: Initiated By: AC NoriversgardenNo ratings yet

- List of RDSO Approved Vendor PDFDocument176 pagesList of RDSO Approved Vendor PDFYADAVENDRA MAYANK100% (2)

- Nureg 0800 3.6.1 Plant Design For Protection Against Postulated Piping Failures in Fluid Systems Outside ContainmentDocument12 pagesNureg 0800 3.6.1 Plant Design For Protection Against Postulated Piping Failures in Fluid Systems Outside ContainmentFernando DiezNo ratings yet

- STD 137 PDFDocument43 pagesSTD 137 PDFSwarup NayakNo ratings yet

- 730 AaDocument134 pages730 AaRini MathewNo ratings yet

- Guidelines For Setting Up Custody Transfer Metering Station at Entry and Exit Points PDFDocument90 pagesGuidelines For Setting Up Custody Transfer Metering Station at Entry and Exit Points PDFjemorenoa8954No ratings yet

- ETSO-C22g CS-ETSO 0Document2 pagesETSO-C22g CS-ETSO 0rrbo67No ratings yet

- 00 Saip 08Document10 pages00 Saip 08hammad21No ratings yet

- Regulatory Guide 1.90Document23 pagesRegulatory Guide 1.90Luis Juan Trejo CruzNo ratings yet

- MIL-P-9400C Laminate-Sandwich Aircraft StructuresDocument18 pagesMIL-P-9400C Laminate-Sandwich Aircraft StructuresBevanNo ratings yet

- 1.122. Development of Floor Design Response Spectra For Seismic Design of Floor-Supported Equipment or ComponentsDocument4 pages1.122. Development of Floor Design Response Spectra For Seismic Design of Floor-Supported Equipment or ComponentstsvNo ratings yet

- CGD IMS-Original Reg-27. 04.2008Document61 pagesCGD IMS-Original Reg-27. 04.2008Sachin MathurNo ratings yet

- Ogdcl Rig Tor Rm-4573Document8 pagesOgdcl Rig Tor Rm-4573Ahmed Imtiaz RaoNo ratings yet

- D:/IRPWM With cs/ACS To IRPWM/ACS 122Document6 pagesD:/IRPWM With cs/ACS To IRPWM/ACS 122Ajeeth KumarNo ratings yet

- CGD IMS Post Amendment 07.11.2019Document65 pagesCGD IMS Post Amendment 07.11.2019visutsiNo ratings yet

- Saes L 470Document10 pagesSaes L 470abaanNo ratings yet

- Development of The Fmeca Process and Analysis Methodology For Railroad SystemsDocument7 pagesDevelopment of The Fmeca Process and Analysis Methodology For Railroad SystemsGeorgz SimNo ratings yet

- 1.133 US Nuclear RegulatoryDocument7 pages1.133 US Nuclear RegulatoryClaudio FerrariNo ratings yet

- Specification For Piping Erection and TestingDocument44 pagesSpecification For Piping Erection and TestingSanjay SenNo ratings yet

- T4S ONGC IndiaDocument66 pagesT4S ONGC IndiaJk KarthikNo ratings yet

- CoverLetter-EOI-Micro Electro-Mechanical System (MEMS), Nano Electro-Mechanical Systems (NEMS) and MicroOPto Electro-Mechanical Systems (MOEMS)Document2 pagesCoverLetter-EOI-Micro Electro-Mechanical System (MEMS), Nano Electro-Mechanical Systems (NEMS) and MicroOPto Electro-Mechanical Systems (MOEMS)Manoj GowdarNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Licensing Process for the Construction, Commissioning and Operation of Nuclear Power PlantsFrom EverandLicensing Process for the Construction, Commissioning and Operation of Nuclear Power PlantsNo ratings yet

- Functional Outcome Measures in Physiotherapybridging Evidence Based Practice Function and Our Future 2165 7025.1000e106Document2 pagesFunctional Outcome Measures in Physiotherapybridging Evidence Based Practice Function and Our Future 2165 7025.1000e106Tirumala RaoNo ratings yet

- Introduction Section-ExamplesDocument3 pagesIntroduction Section-ExamplesTirumala RaoNo ratings yet

- Research Design (Process)Document8 pagesResearch Design (Process)Tirumala RaoNo ratings yet

- Rehabilitation and COVID-19: How To Take PartDocument4 pagesRehabilitation and COVID-19: How To Take PartTirumala RaoNo ratings yet

- Wheelchair Provision GuidelinesDocument108 pagesWheelchair Provision GuidelinesTirumala RaoNo ratings yet

- MenisectomyDocument3 pagesMenisectomyTirumala RaoNo ratings yet

- Lmrc-c2 Fastening SystemDocument12 pagesLmrc-c2 Fastening SystemTirumala RaoNo ratings yet

- A-III C-2 Fastening SystemDocument4 pagesA-III C-2 Fastening SystemTirumala RaoNo ratings yet

- Pharmacy Made EasyDocument5 pagesPharmacy Made EasyTirumala RaoNo ratings yet

Fastening System 300-1W (Patil Infrasyructure PVT LTD)

Fastening System 300-1W (Patil Infrasyructure PVT LTD)

Uploaded by

Tirumala RaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fastening System 300-1W (Patil Infrasyructure PVT LTD)

Fastening System 300-1W (Patil Infrasyructure PVT LTD)

Uploaded by

Tirumala RaoCopyright:

Available Formats

.l t- !

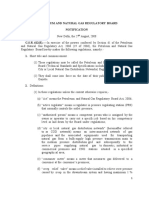

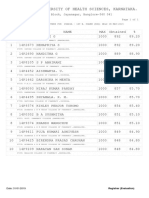

€{.5'r{ {GOVERNMENT OF INDIA)

m etg (RAILUIAY BoARD)

No. 2016/CE-nI/BR/BLT New Delhi, Dated: O1l10/2019

Executive Director/ Track-II

RDSO

Lucknow

Sub: F.astenitlg Systems for Ballastless Track

Ref: RDSO's Letter No.CT/EF/Global EOI-2OI7 lBallastless Track

dated 22.O3.2019

The lastcning system fur ballasliess lrack was under consideraticn in

Board for quite a while. Earlier, Board had approved the fastening sYstems

i.e. "Loarge-336 rail fastening system", "Double Resilient Base Plate

Assembly System", "Deikor Alt- l. fastening" and "Fastening System 336" vide

Board's letters No. 2OO9 lProj/MAS19l2 dt' 19.08.2011, No'

2003/ Proj. / B angalore I 2 I 2(Pt.) dated 07. 1O.2C 1 i, No. 2OO9l Proj . I MAS I 9 / 2

(Vol Ii) d,ated 12.12.2012 and No. 98/Proj. lDLllSOll [Voi. III) dated

24.O I.2O L3 respectively.

2. RDSO vide letter under reference above has sought Board's approvai

for fastening systems namely "sunrui GJ2 resilient Base Plate Assemblies

(GJ2)" and "Fastening System 3O0-1W".

3. Having considered the above, Board (ME) has approved the fastening

systems "sunrui GJ2 resilient Base Plate Assemblies (GJ2)" offered by M/s

Ked Sati Iron & Steel Rrt. Ltd., Kolkata, in associalion with M/s Luoyang

Sunrui Rubber & Plastic Science and Technolory Cc. Ltd., Luolra-ng, Herar,

China and "300- lW" offered by M/s Patil Rail Infrastructure Pvt. Ltd.,

Hyderabad, subject to the following conditions:

a. The Metro Rail Administration (MRA) should verify the authenticity of

the system proposed to be used by them vis-d-vis the performance certifrcate

submitted by the offering firms during tender stage as per Para 4.1 (ii) of

"Procedure for Safety Certilication and Technical Clearance of Metro systems

Annexure C-2".

b. MRA need to ensure t}lat actual components us'ed in the fastening

system are matching with assembly drawing which has been examined by

RDSO.

,:r."

ili

t{t

r..,,,.."/.

\iF,,-*\ r'1

c. Before the fastening system is installed in the track, .MIiA Should

by_ conducting fresh tests from anilindependent

lltt 9*selves,

rlDolarory on sample selected by MRA, that the fastening system meets ttre

physical parameters requirements raid down in the

"procldure

Certilication and Technical Clearance of Metro systems Annexure for safetjr

C_2".

d. MRA needs to ensure and veri$r compliance to' the dimensional

o.lvarious pa-ram€ters oi comp-lete fastening assembly

lol*31...^ e*"

a'2 "" f.. of

Qvl of "Procedure for safety certification and rechnica,i clearance

Metro systems Annexure C_2".

e. MRA to ensure the compliance to all aspects of the performance

criteria as laid down in the "procedure for safetSr certification

Clearance of Metro systems Annexure C_2". and

rechnica_l

f' MRA should arso satiss themserves the credentiars of the prospective

suppliers of the offered fastening system.

g' since the system w i be used in India for the first

time, as and when

used, this will be kept under rnonitoring of RDSO

for two years.

1

h. The repair anci. maintenance methods for the fastening

system shall be

detaiied in the Maintenance Manuar f.r ill;;tr;s

Track structure by MRa.

4. RDSO is advised to circulate the details of ail types

of approved

Fastening System for ballastless track consolidated

in one letter to all

concerned.

lnraaeep'uffilJ

Director Civil Engg.(pfg.l

Railway Board

You might also like

- Scope of WorkDocument60 pagesScope of WorkParesh Tadas100% (1)

- Ac 133Document7 pagesAc 133thirumalaichettiar100% (2)

- Physiotherapy Course PDFDocument156 pagesPhysiotherapy Course PDFMamta100% (2)

- Procedure For Safety Certification and Technical Clearance of Metro Systems by Rdso (Jan-2013)Document51 pagesProcedure For Safety Certification and Technical Clearance of Metro Systems by Rdso (Jan-2013)astor50% (4)

- RDSO PE SPEC AC 0138-2009 Rev 2 or LatestDocument23 pagesRDSO PE SPEC AC 0138-2009 Rev 2 or LatestRajnish KumarNo ratings yet

- Minutes - 10th Extraordinary TSCDocument43 pagesMinutes - 10th Extraordinary TSCcdmNo ratings yet

- Final - Feb-2015 Manual 19.02.2015Document50 pagesFinal - Feb-2015 Manual 19.02.2015Hitesh SrivastavaNo ratings yet

- L1-CHE-SPE-064 Ballast SupplyDocument10 pagesL1-CHE-SPE-064 Ballast Supply4493464No ratings yet

- R GSR612 (E) eDocument68 pagesR GSR612 (E) eVamsiKrishnaNo ratings yet

- TDG 0026 Rev 4 - Final 23042014Document20 pagesTDG 0026 Rev 4 - Final 23042014SunilKumarNo ratings yet

- PNGRB Technical Standard - T4SEDocument44 pagesPNGRB Technical Standard - T4SEVishal AgrawalNo ratings yet

- 15-Saip-50 (Ins. For Conduit - Cable Seals)Document5 pages15-Saip-50 (Ins. For Conduit - Cable Seals)sathish KumarNo ratings yet

- R GSR612 (E) eDocument93 pagesR GSR612 (E) eDevashish SharmaNo ratings yet

- Implementation of Hybrid ETC Letter 27.09.17Document7 pagesImplementation of Hybrid ETC Letter 27.09.17Bhupender YadavNo ratings yet

- MDG 12 Guide For The Construction of Friction WindersDocument23 pagesMDG 12 Guide For The Construction of Friction WindersbenssjNo ratings yet

- CFR 2011 Title49 Vol3 Part195 AppaDocument3 pagesCFR 2011 Title49 Vol3 Part195 AppaAssemNo ratings yet

- Avoiding Holes in RailsDocument2 pagesAvoiding Holes in RailsPrakash budhaniNo ratings yet

- DSC Policy 011221Document8 pagesDSC Policy 011221drhagc2011No ratings yet

- Approved RDSO List Final 2016Document206 pagesApproved RDSO List Final 2016dycmmgncrNo ratings yet

- Mil STD 810gDocument8 pagesMil STD 810gaybidoNo ratings yet

- Nureg 0800 3.6.2 Determination of Rupture Locations and Dynamic Effects Associated With The Postulated Rupture of PipingDocument20 pagesNureg 0800 3.6.2 Determination of Rupture Locations and Dynamic Effects Associated With The Postulated Rupture of PipingFernando DiezNo ratings yet

- Ui Sc180rev4Document9 pagesUi Sc180rev4Maan MrabetNo ratings yet

- Inspection of Electrical Equipment: OISD - STD - 137 For Restricted CirculationDocument45 pagesInspection of Electrical Equipment: OISD - STD - 137 For Restricted CirculationanandpurushothamanNo ratings yet

- Show FileDocument88 pagesShow FileNAVASNo ratings yet

- Installation of Earthing System: Inspection and Test Procedure ForDocument4 pagesInstallation of Earthing System: Inspection and Test Procedure ForJITHIN KRISHNAN MNo ratings yet

- ML18136A762Document14 pagesML18136A762Marcos MaturanaNo ratings yet

- T4S CGD Consolidated 31.12.2016 FinalDocument65 pagesT4S CGD Consolidated 31.12.2016 FinalNikhil SainiNo ratings yet

- OBCMS Final Specifications 1-5-2017Document40 pagesOBCMS Final Specifications 1-5-2017Sahil KumarNo ratings yet

- Fed STD H28 20BDocument30 pagesFed STD H28 20BAnonymous A5X4rddZPNo ratings yet

- TSS Paper (Final) - StampedDocument11 pagesTSS Paper (Final) - StampedJack ClarkeNo ratings yet

- Netra Final Draft Spec - 14.06.19Document89 pagesNetra Final Draft Spec - 14.06.19RCC PGTNo ratings yet

- Internal Procedure For Operating State GridDocument71 pagesInternal Procedure For Operating State GridSiddharth Bhawsar100% (1)

- GSR612 - PNGRB PDFDocument55 pagesGSR612 - PNGRB PDFBenaknaik S GajannavarNo ratings yet

- RDSO Vendor DirectoryDocument201 pagesRDSO Vendor DirectorySravan CholeteNo ratings yet

- 7-SBS-MST-0218.C Method Statement Joint Pit Installation of 150KV UGC at JP-18 (Cast in Situ) NONODocument116 pages7-SBS-MST-0218.C Method Statement Joint Pit Installation of 150KV UGC at JP-18 (Cast in Situ) NONOAran SimarmataNo ratings yet

- PNGRB T4SDocument56 pagesPNGRB T4SHoney Narang100% (3)

- T4S CGD Consolidated 31.12.2016 FinalDocument65 pagesT4S CGD Consolidated 31.12.2016 FinalcoolmagaNo ratings yet

- Technical Standards PNGRBDocument44 pagesTechnical Standards PNGRBRashid HussainNo ratings yet

- Advisory Circular: Subject: Date: Initiated By: AC NoDocument6 pagesAdvisory Circular: Subject: Date: Initiated By: AC NoriversgardenNo ratings yet

- List of RDSO Approved Vendor PDFDocument176 pagesList of RDSO Approved Vendor PDFYADAVENDRA MAYANK100% (2)

- Nureg 0800 3.6.1 Plant Design For Protection Against Postulated Piping Failures in Fluid Systems Outside ContainmentDocument12 pagesNureg 0800 3.6.1 Plant Design For Protection Against Postulated Piping Failures in Fluid Systems Outside ContainmentFernando DiezNo ratings yet

- STD 137 PDFDocument43 pagesSTD 137 PDFSwarup NayakNo ratings yet

- 730 AaDocument134 pages730 AaRini MathewNo ratings yet

- Guidelines For Setting Up Custody Transfer Metering Station at Entry and Exit Points PDFDocument90 pagesGuidelines For Setting Up Custody Transfer Metering Station at Entry and Exit Points PDFjemorenoa8954No ratings yet

- ETSO-C22g CS-ETSO 0Document2 pagesETSO-C22g CS-ETSO 0rrbo67No ratings yet

- 00 Saip 08Document10 pages00 Saip 08hammad21No ratings yet

- Regulatory Guide 1.90Document23 pagesRegulatory Guide 1.90Luis Juan Trejo CruzNo ratings yet

- MIL-P-9400C Laminate-Sandwich Aircraft StructuresDocument18 pagesMIL-P-9400C Laminate-Sandwich Aircraft StructuresBevanNo ratings yet

- 1.122. Development of Floor Design Response Spectra For Seismic Design of Floor-Supported Equipment or ComponentsDocument4 pages1.122. Development of Floor Design Response Spectra For Seismic Design of Floor-Supported Equipment or ComponentstsvNo ratings yet

- CGD IMS-Original Reg-27. 04.2008Document61 pagesCGD IMS-Original Reg-27. 04.2008Sachin MathurNo ratings yet

- Ogdcl Rig Tor Rm-4573Document8 pagesOgdcl Rig Tor Rm-4573Ahmed Imtiaz RaoNo ratings yet

- D:/IRPWM With cs/ACS To IRPWM/ACS 122Document6 pagesD:/IRPWM With cs/ACS To IRPWM/ACS 122Ajeeth KumarNo ratings yet

- CGD IMS Post Amendment 07.11.2019Document65 pagesCGD IMS Post Amendment 07.11.2019visutsiNo ratings yet

- Saes L 470Document10 pagesSaes L 470abaanNo ratings yet

- Development of The Fmeca Process and Analysis Methodology For Railroad SystemsDocument7 pagesDevelopment of The Fmeca Process and Analysis Methodology For Railroad SystemsGeorgz SimNo ratings yet

- 1.133 US Nuclear RegulatoryDocument7 pages1.133 US Nuclear RegulatoryClaudio FerrariNo ratings yet

- Specification For Piping Erection and TestingDocument44 pagesSpecification For Piping Erection and TestingSanjay SenNo ratings yet

- T4S ONGC IndiaDocument66 pagesT4S ONGC IndiaJk KarthikNo ratings yet

- CoverLetter-EOI-Micro Electro-Mechanical System (MEMS), Nano Electro-Mechanical Systems (NEMS) and MicroOPto Electro-Mechanical Systems (MOEMS)Document2 pagesCoverLetter-EOI-Micro Electro-Mechanical System (MEMS), Nano Electro-Mechanical Systems (NEMS) and MicroOPto Electro-Mechanical Systems (MOEMS)Manoj GowdarNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Licensing Process for the Construction, Commissioning and Operation of Nuclear Power PlantsFrom EverandLicensing Process for the Construction, Commissioning and Operation of Nuclear Power PlantsNo ratings yet

- Functional Outcome Measures in Physiotherapybridging Evidence Based Practice Function and Our Future 2165 7025.1000e106Document2 pagesFunctional Outcome Measures in Physiotherapybridging Evidence Based Practice Function and Our Future 2165 7025.1000e106Tirumala RaoNo ratings yet

- Introduction Section-ExamplesDocument3 pagesIntroduction Section-ExamplesTirumala RaoNo ratings yet

- Research Design (Process)Document8 pagesResearch Design (Process)Tirumala RaoNo ratings yet

- Rehabilitation and COVID-19: How To Take PartDocument4 pagesRehabilitation and COVID-19: How To Take PartTirumala RaoNo ratings yet

- Wheelchair Provision GuidelinesDocument108 pagesWheelchair Provision GuidelinesTirumala RaoNo ratings yet

- MenisectomyDocument3 pagesMenisectomyTirumala RaoNo ratings yet

- Lmrc-c2 Fastening SystemDocument12 pagesLmrc-c2 Fastening SystemTirumala RaoNo ratings yet

- A-III C-2 Fastening SystemDocument4 pagesA-III C-2 Fastening SystemTirumala RaoNo ratings yet

- Pharmacy Made EasyDocument5 pagesPharmacy Made EasyTirumala RaoNo ratings yet