Professional Documents

Culture Documents

Fig 950 950G

Fig 950 950G

Uploaded by

AsmaaCopyright:

Available Formats

You might also like

- 002 - ITP Earthworks - Revision 2.0Document12 pages002 - ITP Earthworks - Revision 2.0randyNo ratings yet

- Aci 352r - 02 PDFDocument37 pagesAci 352r - 02 PDFDYGA GramajoNo ratings yet

- Fig-4970-4970G-NEW DESIGNDocument1 pageFig-4970-4970G-NEW DESIGNAsmaaNo ratings yet

- Hattersley Fig 980 CatalogueDocument1 pageHattersley Fig 980 CataloguerkssNo ratings yet

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Document1 pageFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimNo ratings yet

- Fig-970-970G-NEW DESIGNDocument1 pageFig-970-970G-NEW DESIGNAsmaaNo ratings yet

- Brosur Valve Hatersley 2Document1 pageBrosur Valve Hatersley 2Muhamad SuryaNo ratings yet

- Data Sheets Optiseal Wafer Lugged Keystone en en 5445860Document12 pagesData Sheets Optiseal Wafer Lugged Keystone en en 5445860Miyka'el PaunNo ratings yet

- Series 20-21 SS Butterfly ValvesDocument2 pagesSeries 20-21 SS Butterfly ValvesQuangNgocNo ratings yet

- M10S Ball Valve DN " To DN2 ": Full BoreDocument4 pagesM10S Ball Valve DN " To DN2 ": Full BoreTsion GtatiosNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- Imi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"Document2 pagesImi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"SAM AZNo ratings yet

- K Ball EmersonDocument36 pagesK Ball EmersonsiskaNo ratings yet

- Van bươm điều khiển Khi nen AUTOMA ACMDocument1 pageVan bươm điều khiển Khi nen AUTOMA ACMAutoma Viet NamNo ratings yet

- Fig-970-G-OLD DESIGNDocument1 pageFig-970-G-OLD DESIGNAsmaaNo ratings yet

- Fig. 822 & 922 Fig. 810 & 910 Y-Type Strainers: DN50-DN300 DN350-DN600Document1 pageFig. 822 & 922 Fig. 810 & 910 Y-Type Strainers: DN50-DN300 DN350-DN600Manuel CampoyNo ratings yet

- Data Sheets K Ball r110 f190 Ball Valves For Industrial Process Applications K Ball en en 5196762Document36 pagesData Sheets K Ball r110 f190 Ball Valves For Industrial Process Applications K Ball en en 5196762Hedi Ben MohamedNo ratings yet

- Ficha Tecnica Valvula Mariposa Cuerpo H.O - Disco InoxDocument1 pageFicha Tecnica Valvula Mariposa Cuerpo H.O - Disco Inoxlaura giraldoNo ratings yet

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Document2 pagesAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiNo ratings yet

- AVKDocument3 pagesAVKAmirNo ratings yet

- BrooksBank GlobeValve FlangeAbove6Document3 pagesBrooksBank GlobeValve FlangeAbove6T KelvinNo ratings yet

- SISCORBV020 Series Butterfly ValveDocument10 pagesSISCORBV020 Series Butterfly Valveloli2323No ratings yet

- 3way Ball Valve KTMDocument12 pages3way Ball Valve KTMHải Nguyễn ThanhNo ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsRonaldNo ratings yet

- Check Valve - Position IndicatorDocument2 pagesCheck Valve - Position Indicatorunibalaji_05No ratings yet

- Exhaustare in AtmosferaDocument1 pageExhaustare in Atmosferaconstantin.iacomi3837No ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & Benefitsimtz2013No ratings yet

- Data Sheets Optiseal Wafer Lugged Keystone en en 5445860Document9 pagesData Sheets Optiseal Wafer Lugged Keystone en en 5445860oukassou.mohamed10No ratings yet

- Pentair VM FIG GRW y GRL - MTJE KEYSTONE PDFDocument8 pagesPentair VM FIG GRW y GRL - MTJE KEYSTONE PDFFlavio Garcia ValenteNo ratings yet

- Van bướm thường điều khiển khí nénDocument1 pageVan bướm thường điều khiển khí nénAutoma Viet NamNo ratings yet

- SISCORBV030 Series Butterfly ValveDocument10 pagesSISCORBV030 Series Butterfly Valveloli2323No ratings yet

- Valve Weight PDFDocument10 pagesValve Weight PDFPrabha KaranNo ratings yet

- Kunkle MODEL 537Document4 pagesKunkle MODEL 537rubiodegoNo ratings yet

- V15 Series Needle ValvesDocument4 pagesV15 Series Needle ValvesTran Duc DungNo ratings yet

- Cmo Serie AbDocument20 pagesCmo Serie AbrafinhaleocadioNo ratings yet

- Fig 907 Resilient Seated Gate Valve FlangedDocument1 pageFig 907 Resilient Seated Gate Valve FlangedSebastian Andres Quilodran BaquedanoNo ratings yet

- Series: GLV54-55: Specialist .Document3 pagesSeries: GLV54-55: Specialist .Peter KitchenNo ratings yet

- Wheatley Series 500 BRDocument8 pagesWheatley Series 500 BRanuarsgNo ratings yet

- Butterfly Valve CatalogDocument18 pagesButterfly Valve Catalogyash100% (1)

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Fig 1432-1432L-1432C-1432LC Hatt DS 0922Document1 pageFig 1432-1432L-1432C-1432LC Hatt DS 0922Dan HawthorneNo ratings yet

- Data Sheets Series GR Resilient Seated Butterfly Valves Keystone en en 5196336Document12 pagesData Sheets Series GR Resilient Seated Butterfly Valves Keystone en en 5196336sonalpanchal7No ratings yet

- NAF-Torex Butterfly Valves FK 41.42 (11) GB: Primary CharacteristicsDocument8 pagesNAF-Torex Butterfly Valves FK 41.42 (11) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- R 2361 6Document2 pagesR 2361 6Angelo100% (1)

- BV14 Butterfly VDocument6 pagesBV14 Butterfly VFAIYAZ AHMEDNo ratings yet

- Fasani Through Conduit Slab Type Bolted Bonnet ValvesDocument10 pagesFasani Through Conduit Slab Type Bolted Bonnet ValvesFrancis AlmiaNo ratings yet

- Aplicación de Válvulas Macho en La PPIDocument26 pagesAplicación de Válvulas Macho en La PPIPablo Santa CruzNo ratings yet

- Ball Valves 0893ENDocument72 pagesBall Valves 0893ENelmarina compNo ratings yet

- Segmented Ball Valves s19 PB en UsDocument18 pagesSegmented Ball Valves s19 PB en UsMarcos Aurelio Rangel GalvánNo ratings yet

- 400E EngineeringDocument8 pages400E EngineeringDenis Oliveira CostaNo ratings yet

- Piping Class - F1E0U2Document3 pagesPiping Class - F1E0U2AMBYNo ratings yet

- Check Valve Type NRVA: Data SheetDocument8 pagesCheck Valve Type NRVA: Data SheetleticiaNo ratings yet

- Abnt NBR 15514Document20 pagesAbnt NBR 15514Andre alexander dos santosNo ratings yet

- Dembla Resilient Seated Butterfly Valve BrochureDocument8 pagesDembla Resilient Seated Butterfly Valve BrochureArindomNo ratings yet

- Dm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Document1 pageDm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Hasan V SNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- Fig 4923 GDocument1 pageFig 4923 GAsmaaNo ratings yet

- BS 5163 Flanged Resilient OS&Y Gate Valve, Type A, (XZ41X), PN10/16, UL/FM ApprovedDocument13 pagesBS 5163 Flanged Resilient OS&Y Gate Valve, Type A, (XZ41X), PN10/16, UL/FM ApprovedNaresh ANo ratings yet

- Tube Seal Liquid FilledDocument1 pageTube Seal Liquid Filledmota1960No ratings yet

- Investigation On Flow Control Valve by CFD Simulation: Shiva Ram BandariDocument57 pagesInvestigation On Flow Control Valve by CFD Simulation: Shiva Ram BandariDaniele GouveiaNo ratings yet

- EMPUJE DE TIERRAS - Active Earth PressureDocument1 pageEMPUJE DE TIERRAS - Active Earth PressuremistakyNo ratings yet

- Review of Related LiteratureDocument10 pagesReview of Related LiteratureAlbert Martin ReyesNo ratings yet

- Contractor Consultant: Republic of Kenya Ministry of Roads and Public WorksDocument4 pagesContractor Consultant: Republic of Kenya Ministry of Roads and Public WorksGikonyoNo ratings yet

- Hydraulic JumpDocument5 pagesHydraulic Jumpsatyam agarwalNo ratings yet

- Wall Inteference Effects - Analysis and Correction For Automotive Wind TunnelsDocument10 pagesWall Inteference Effects - Analysis and Correction For Automotive Wind TunnelsVyssionNo ratings yet

- Bridge Engineering Assignment ReportDocument31 pagesBridge Engineering Assignment ReportChiranjaya HulangamuwaNo ratings yet

- Effective HeightDocument10 pagesEffective HeightmonikaNo ratings yet

- CES 3104 Structural Theory: Work-Energy MethodsDocument59 pagesCES 3104 Structural Theory: Work-Energy MethodsGelord Ray Dumat-olNo ratings yet

- Seminar Report O1-3Document16 pagesSeminar Report O1-3Shailesh NaiNo ratings yet

- Thesis On Hvac SystemsDocument5 pagesThesis On Hvac Systemsoaehviiig100% (2)

- 04-Filling Foundation Concrete Work PlumDocument4 pages04-Filling Foundation Concrete Work PlumBijay Krishna DasNo ratings yet

- Test 1 MKAJ 1033Document4 pagesTest 1 MKAJ 1033Malik Abed100% (1)

- Chapter 4 Torsion Beams + SFD and BMD. (SOM-201)Document99 pagesChapter 4 Torsion Beams + SFD and BMD. (SOM-201)Raushan Jha100% (1)

- Volcanic HeatersDocument6 pagesVolcanic HeatersMarc FazioliNo ratings yet

- Gas Reception Sump: Reducing Gas Pressure Under The BuildingDocument2 pagesGas Reception Sump: Reducing Gas Pressure Under The BuildingRolando CostaNo ratings yet

- Laboratory Analysis - GGU SoftwareDocument2 pagesLaboratory Analysis - GGU Softwareindrajit sodhaNo ratings yet

- Fib Bulletin 57 ContentsDocument2 pagesFib Bulletin 57 Contentshilander2k2No ratings yet

- 1304..mix Design m25 Dalmia Cement... Mes JorhatDocument16 pages1304..mix Design m25 Dalmia Cement... Mes JorhatAbhishek KumarNo ratings yet

- SERVICE LIFT - Option 1Document3 pagesSERVICE LIFT - Option 1Tommy NSGNo ratings yet

- Code: Esm-4 Subject: Civil Engineering - 2: Question PaperDocument4 pagesCode: Esm-4 Subject: Civil Engineering - 2: Question Paperjam jodhpur irri sub dn 6/3No ratings yet

- Seismic Evaluation of Buildings & RetrofittingDocument17 pagesSeismic Evaluation of Buildings & RetrofittingHage Tajang100% (1)

- 1,2.format For Site Visit Report (1) PPRDocument22 pages1,2.format For Site Visit Report (1) PPRpratikrothe13072002No ratings yet

- Hybrid-Masonry-Design-2 13 01 - 12 29 09 PDFDocument6 pagesHybrid-Masonry-Design-2 13 01 - 12 29 09 PDFDennier CHÁVEZ GARRONo ratings yet

- Exposed To All Weather Conditions, Use ABC Gypsum CompoundDocument1 pageExposed To All Weather Conditions, Use ABC Gypsum CompoundCharilyn EcheverreNo ratings yet

- Monocoque & Semio-MonocoqueDocument2 pagesMonocoque & Semio-MonocoquePRIYA mohadNo ratings yet

- Anchor Bolt CalculationDocument3 pagesAnchor Bolt CalculationcordajohnNo ratings yet

- Spanning Space Horizontal Span BuildingDocument651 pagesSpanning Space Horizontal Span BuildingDavoodNo ratings yet

Fig 950 950G

Fig 950 950G

Uploaded by

AsmaaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fig 950 950G

Fig 950 950G

Uploaded by

AsmaaCopyright:

Available Formats

BUTTERFLY VALVES

PN16

Fig. 950 & 950G

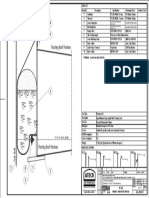

Semi-lugged Wafer Pattern Lever/Gearbox Operated IV

FEATURES & BENEFITS MATERIAL SPECIFICATION

• Robust ductile iron valve body for long life service DRV

Component Material Specification

• Valve body semi-lugged to fit PN10, PN16, or

Class 125 flanges Body Ductile Iron (Epoxy Paint) ASTM A536 64-45-12

• Integrated notch plate for a more compact design Shaft Stainless Steel Type 410 ASTM A276 410

• The anti-blow out stem design provides a safe Disc Al Bronze C954 ASTM B148

and secure operation Taper Pin Stainless Steel Type 410 ASTM A276 410

OP

• Fully bonded epoxy paint system for superior Bushes PTFE -

corrosion resistance O-Ring Buna N -

• Suitable for applications where Level 3 C3 Liner EPDM -

(Medium) corrosion protection is required Lever Aluminium Alloy (Epoxy Paint) -

• Maintenance free valve design, reducing downtime Gearbox Cast Iron -

VOCS

Fig. 950 DN50

PRESSURE/ Centring holes.

Aluminium bronze disc.

TEMPERATURE RATING

16 bar from -10 to 130°C EPDM liner. Trigger lever.

Valves DN250 and larger supplied as

TEST PRESSURES standard with fully enclosed gear operator.

Hydrostatic Sizes DN50 to DN300 are suitable forFORV

use

Shell: 24 bar with flanges conforming to BS EN 1092-2

Seat: 17.6 bar PN10 or PN16 and ANSI B16.1 Class 125

Sizes DN350 to DN600 are for PN16 flanges only.

SPECIFICATION Valves may be used for flow regulation.

Conforms to BS EN 593:

Face to face conforms to BS EN 558.

Ductile Iron body epoxy coated.

DIMENSIONS & WEIGHTS DIMENSIONAL DRAWINGS

h H

Fig. 950 LEVER FOCS

Nom Fig. 950 E Fig. 950G E

Size mm 50 65 80 100 125 150 200 LEVER GEARED

A mm 109 131.5 134 163 169 179 224 4PMV

ØF

A1 mm 246 278.5 294 343 359 392 465

M

D

D

B mm 72 82 95 115 125 142 170 FLANGE

C mm 43 46 46 52 56 56 60 SLOT FLANGE

A

A

D mm 32 32 32 32 32 40 40 SLOT

A1

E mm 212.5 212.5 212.5 212.5 212.5 245 378

F mm 100 120 127 156 190 212 268

G mm 52.9 64.6 79 104.4 123.5 155.8 202.7

B

B

Kv*** 98 167 258 512 872 1347 2675

Flange slots PN16/2" PN16/2.1/2" PN16/3" PN16/4" PN16/5" PN16/6" PN16/8"

C F C

to suit CL125 CL125 CL125 CL125 CL125 CL125 CL125

CFC

Weight kg 2.4 3.3 3.6 4.5 6.3 8.4 13.4 G G

Fig. 950G GEARED 18

Nom 16

Size mm 50 65 80 100 125 150 200 250 300 350 400 450 500 600

14

A mm 109 131.5 134 163 169 179 224 264 299 368 400 422 479 562

12

B mm 72 82 95 115 125 142 170 215 240 264 305 317 352 444 DOC

Pressure bar

C mm 43 46 46 52 56 56 60 68 78 78 86 105 130 154 10

D mm 32 32 32 32 32 40 40 40 40 - - - - - 8

E mm 157 157 157 157 157 157 238 238 223.5 223.5 277 325 325 340

6

F mm 150 150 150 150 150 150 300 300 300 300 450 450 450 450

G mm 52.9 64.6 79 104.4 123.5 155.8 202.7 250.7 301.9 334 390 441 492 597 4

H mm 45 45 45 45 45 45 45 63 78 78 78 185 185 185

h mm 54 54 54 54 54 54 81 81 81 81 81 160 160 160

2 TRV

0

M mm 39 39 39 39 39 39 39 41.5 38.3 46.5 39 120 120 126 0 20 40 60 80 100 120 140

Kv*** 98 167 258 512 872 1347 2675 4555 7037 6003 8885 10419 13613 17801 Temperature ˚C

Flange slots PN16/2” PN16/2.1/2” PN16/3” PN16/4” PN16/5” PN16/6” PN16/8” PN16/8” PN16/12” PN16/14” PN16/16” PN16/18” PN16/20” PN16/24”

to suit CL125 CL125 CL125 CL125 CL125 CL125 CL125 CL125 CL125 CL125 CL125 CL125 CL125 CL125 BS* for bareshaft

GB** for gearbox

Wgt BS* kg 2.1 3.0 3.2 4.2 6.0 7.8 12.7 28.4 41.0 - - - - - Kv*** coefficient denotes valves

Wgt GB** kg 7.1 7.9 8.2 9.1 10.9 12.7 19.6 38.8 54.0 56.2 88.4 110.2 160.5 260 in fully open position

141119

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Hattersley Ltd assumes no responsibility or

liability for typographical errors or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

Technical Helpline UK: 0845 604 1790 MEA: +971 4 816 5800 27

Email UK: tech-enquiries@hattersley.com

MEA: mena-techenquiries@hattersley.com

You might also like

- 002 - ITP Earthworks - Revision 2.0Document12 pages002 - ITP Earthworks - Revision 2.0randyNo ratings yet

- Aci 352r - 02 PDFDocument37 pagesAci 352r - 02 PDFDYGA GramajoNo ratings yet

- Fig-4970-4970G-NEW DESIGNDocument1 pageFig-4970-4970G-NEW DESIGNAsmaaNo ratings yet

- Hattersley Fig 980 CatalogueDocument1 pageHattersley Fig 980 CataloguerkssNo ratings yet

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Document1 pageFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimNo ratings yet

- Fig-970-970G-NEW DESIGNDocument1 pageFig-970-970G-NEW DESIGNAsmaaNo ratings yet

- Brosur Valve Hatersley 2Document1 pageBrosur Valve Hatersley 2Muhamad SuryaNo ratings yet

- Data Sheets Optiseal Wafer Lugged Keystone en en 5445860Document12 pagesData Sheets Optiseal Wafer Lugged Keystone en en 5445860Miyka'el PaunNo ratings yet

- Series 20-21 SS Butterfly ValvesDocument2 pagesSeries 20-21 SS Butterfly ValvesQuangNgocNo ratings yet

- M10S Ball Valve DN " To DN2 ": Full BoreDocument4 pagesM10S Ball Valve DN " To DN2 ": Full BoreTsion GtatiosNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- Imi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"Document2 pagesImi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"SAM AZNo ratings yet

- K Ball EmersonDocument36 pagesK Ball EmersonsiskaNo ratings yet

- Van bươm điều khiển Khi nen AUTOMA ACMDocument1 pageVan bươm điều khiển Khi nen AUTOMA ACMAutoma Viet NamNo ratings yet

- Fig-970-G-OLD DESIGNDocument1 pageFig-970-G-OLD DESIGNAsmaaNo ratings yet

- Fig. 822 & 922 Fig. 810 & 910 Y-Type Strainers: DN50-DN300 DN350-DN600Document1 pageFig. 822 & 922 Fig. 810 & 910 Y-Type Strainers: DN50-DN300 DN350-DN600Manuel CampoyNo ratings yet

- Data Sheets K Ball r110 f190 Ball Valves For Industrial Process Applications K Ball en en 5196762Document36 pagesData Sheets K Ball r110 f190 Ball Valves For Industrial Process Applications K Ball en en 5196762Hedi Ben MohamedNo ratings yet

- Ficha Tecnica Valvula Mariposa Cuerpo H.O - Disco InoxDocument1 pageFicha Tecnica Valvula Mariposa Cuerpo H.O - Disco Inoxlaura giraldoNo ratings yet

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Document2 pagesAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiNo ratings yet

- AVKDocument3 pagesAVKAmirNo ratings yet

- BrooksBank GlobeValve FlangeAbove6Document3 pagesBrooksBank GlobeValve FlangeAbove6T KelvinNo ratings yet

- SISCORBV020 Series Butterfly ValveDocument10 pagesSISCORBV020 Series Butterfly Valveloli2323No ratings yet

- 3way Ball Valve KTMDocument12 pages3way Ball Valve KTMHải Nguyễn ThanhNo ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsRonaldNo ratings yet

- Check Valve - Position IndicatorDocument2 pagesCheck Valve - Position Indicatorunibalaji_05No ratings yet

- Exhaustare in AtmosferaDocument1 pageExhaustare in Atmosferaconstantin.iacomi3837No ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & Benefitsimtz2013No ratings yet

- Data Sheets Optiseal Wafer Lugged Keystone en en 5445860Document9 pagesData Sheets Optiseal Wafer Lugged Keystone en en 5445860oukassou.mohamed10No ratings yet

- Pentair VM FIG GRW y GRL - MTJE KEYSTONE PDFDocument8 pagesPentair VM FIG GRW y GRL - MTJE KEYSTONE PDFFlavio Garcia ValenteNo ratings yet

- Van bướm thường điều khiển khí nénDocument1 pageVan bướm thường điều khiển khí nénAutoma Viet NamNo ratings yet

- SISCORBV030 Series Butterfly ValveDocument10 pagesSISCORBV030 Series Butterfly Valveloli2323No ratings yet

- Valve Weight PDFDocument10 pagesValve Weight PDFPrabha KaranNo ratings yet

- Kunkle MODEL 537Document4 pagesKunkle MODEL 537rubiodegoNo ratings yet

- V15 Series Needle ValvesDocument4 pagesV15 Series Needle ValvesTran Duc DungNo ratings yet

- Cmo Serie AbDocument20 pagesCmo Serie AbrafinhaleocadioNo ratings yet

- Fig 907 Resilient Seated Gate Valve FlangedDocument1 pageFig 907 Resilient Seated Gate Valve FlangedSebastian Andres Quilodran BaquedanoNo ratings yet

- Series: GLV54-55: Specialist .Document3 pagesSeries: GLV54-55: Specialist .Peter KitchenNo ratings yet

- Wheatley Series 500 BRDocument8 pagesWheatley Series 500 BRanuarsgNo ratings yet

- Butterfly Valve CatalogDocument18 pagesButterfly Valve Catalogyash100% (1)

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Fig 1432-1432L-1432C-1432LC Hatt DS 0922Document1 pageFig 1432-1432L-1432C-1432LC Hatt DS 0922Dan HawthorneNo ratings yet

- Data Sheets Series GR Resilient Seated Butterfly Valves Keystone en en 5196336Document12 pagesData Sheets Series GR Resilient Seated Butterfly Valves Keystone en en 5196336sonalpanchal7No ratings yet

- NAF-Torex Butterfly Valves FK 41.42 (11) GB: Primary CharacteristicsDocument8 pagesNAF-Torex Butterfly Valves FK 41.42 (11) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- R 2361 6Document2 pagesR 2361 6Angelo100% (1)

- BV14 Butterfly VDocument6 pagesBV14 Butterfly VFAIYAZ AHMEDNo ratings yet

- Fasani Through Conduit Slab Type Bolted Bonnet ValvesDocument10 pagesFasani Through Conduit Slab Type Bolted Bonnet ValvesFrancis AlmiaNo ratings yet

- Aplicación de Válvulas Macho en La PPIDocument26 pagesAplicación de Válvulas Macho en La PPIPablo Santa CruzNo ratings yet

- Ball Valves 0893ENDocument72 pagesBall Valves 0893ENelmarina compNo ratings yet

- Segmented Ball Valves s19 PB en UsDocument18 pagesSegmented Ball Valves s19 PB en UsMarcos Aurelio Rangel GalvánNo ratings yet

- 400E EngineeringDocument8 pages400E EngineeringDenis Oliveira CostaNo ratings yet

- Piping Class - F1E0U2Document3 pagesPiping Class - F1E0U2AMBYNo ratings yet

- Check Valve Type NRVA: Data SheetDocument8 pagesCheck Valve Type NRVA: Data SheetleticiaNo ratings yet

- Abnt NBR 15514Document20 pagesAbnt NBR 15514Andre alexander dos santosNo ratings yet

- Dembla Resilient Seated Butterfly Valve BrochureDocument8 pagesDembla Resilient Seated Butterfly Valve BrochureArindomNo ratings yet

- Dm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Document1 pageDm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Hasan V SNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- Fig 4923 GDocument1 pageFig 4923 GAsmaaNo ratings yet

- BS 5163 Flanged Resilient OS&Y Gate Valve, Type A, (XZ41X), PN10/16, UL/FM ApprovedDocument13 pagesBS 5163 Flanged Resilient OS&Y Gate Valve, Type A, (XZ41X), PN10/16, UL/FM ApprovedNaresh ANo ratings yet

- Tube Seal Liquid FilledDocument1 pageTube Seal Liquid Filledmota1960No ratings yet

- Investigation On Flow Control Valve by CFD Simulation: Shiva Ram BandariDocument57 pagesInvestigation On Flow Control Valve by CFD Simulation: Shiva Ram BandariDaniele GouveiaNo ratings yet

- EMPUJE DE TIERRAS - Active Earth PressureDocument1 pageEMPUJE DE TIERRAS - Active Earth PressuremistakyNo ratings yet

- Review of Related LiteratureDocument10 pagesReview of Related LiteratureAlbert Martin ReyesNo ratings yet

- Contractor Consultant: Republic of Kenya Ministry of Roads and Public WorksDocument4 pagesContractor Consultant: Republic of Kenya Ministry of Roads and Public WorksGikonyoNo ratings yet

- Hydraulic JumpDocument5 pagesHydraulic Jumpsatyam agarwalNo ratings yet

- Wall Inteference Effects - Analysis and Correction For Automotive Wind TunnelsDocument10 pagesWall Inteference Effects - Analysis and Correction For Automotive Wind TunnelsVyssionNo ratings yet

- Bridge Engineering Assignment ReportDocument31 pagesBridge Engineering Assignment ReportChiranjaya HulangamuwaNo ratings yet

- Effective HeightDocument10 pagesEffective HeightmonikaNo ratings yet

- CES 3104 Structural Theory: Work-Energy MethodsDocument59 pagesCES 3104 Structural Theory: Work-Energy MethodsGelord Ray Dumat-olNo ratings yet

- Seminar Report O1-3Document16 pagesSeminar Report O1-3Shailesh NaiNo ratings yet

- Thesis On Hvac SystemsDocument5 pagesThesis On Hvac Systemsoaehviiig100% (2)

- 04-Filling Foundation Concrete Work PlumDocument4 pages04-Filling Foundation Concrete Work PlumBijay Krishna DasNo ratings yet

- Test 1 MKAJ 1033Document4 pagesTest 1 MKAJ 1033Malik Abed100% (1)

- Chapter 4 Torsion Beams + SFD and BMD. (SOM-201)Document99 pagesChapter 4 Torsion Beams + SFD and BMD. (SOM-201)Raushan Jha100% (1)

- Volcanic HeatersDocument6 pagesVolcanic HeatersMarc FazioliNo ratings yet

- Gas Reception Sump: Reducing Gas Pressure Under The BuildingDocument2 pagesGas Reception Sump: Reducing Gas Pressure Under The BuildingRolando CostaNo ratings yet

- Laboratory Analysis - GGU SoftwareDocument2 pagesLaboratory Analysis - GGU Softwareindrajit sodhaNo ratings yet

- Fib Bulletin 57 ContentsDocument2 pagesFib Bulletin 57 Contentshilander2k2No ratings yet

- 1304..mix Design m25 Dalmia Cement... Mes JorhatDocument16 pages1304..mix Design m25 Dalmia Cement... Mes JorhatAbhishek KumarNo ratings yet

- SERVICE LIFT - Option 1Document3 pagesSERVICE LIFT - Option 1Tommy NSGNo ratings yet

- Code: Esm-4 Subject: Civil Engineering - 2: Question PaperDocument4 pagesCode: Esm-4 Subject: Civil Engineering - 2: Question Paperjam jodhpur irri sub dn 6/3No ratings yet

- Seismic Evaluation of Buildings & RetrofittingDocument17 pagesSeismic Evaluation of Buildings & RetrofittingHage Tajang100% (1)

- 1,2.format For Site Visit Report (1) PPRDocument22 pages1,2.format For Site Visit Report (1) PPRpratikrothe13072002No ratings yet

- Hybrid-Masonry-Design-2 13 01 - 12 29 09 PDFDocument6 pagesHybrid-Masonry-Design-2 13 01 - 12 29 09 PDFDennier CHÁVEZ GARRONo ratings yet

- Exposed To All Weather Conditions, Use ABC Gypsum CompoundDocument1 pageExposed To All Weather Conditions, Use ABC Gypsum CompoundCharilyn EcheverreNo ratings yet

- Monocoque & Semio-MonocoqueDocument2 pagesMonocoque & Semio-MonocoquePRIYA mohadNo ratings yet

- Anchor Bolt CalculationDocument3 pagesAnchor Bolt CalculationcordajohnNo ratings yet

- Spanning Space Horizontal Span BuildingDocument651 pagesSpanning Space Horizontal Span BuildingDavoodNo ratings yet