Professional Documents

Culture Documents

OTIS LFT Layout Drawing

OTIS LFT Layout Drawing

Uploaded by

93 Fife ResidenciesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OTIS LFT Layout Drawing

OTIS LFT Layout Drawing

Uploaded by

93 Fife ResidenciesCopyright:

Available Formats

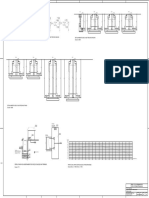

ELEVATOR SHAFT VERTICAL TOLERANCE DETAILS AND ENTRANCE LINTEL DETAILS TO BE PROVIDED

BY MAIN CONTRACTOR / CLIENT

LAYOUT DRAWING OF PASSENGER ELEVATOR NO.1 (15 STOPS)

box section

The requirement of hoistway structure: CONCRETE

≥100 ≥100 ≥100 ≥100

≥120

≥200

≥300

60

HW/HD

≥120

≥120

≥120

VIEW 6-4 VIEW 6-5

≥120

≥120

≥120

≥120

1160

1040

1040

1040

K+25

K+25

K+25

0

0

CLD TLD

VIEW 6-10

iron beam or concrete

girders for landing door

installation by other

≥OP+200

≥300

D

3 ≥100 ≥100

HD/HW HD/HW HD/HW

+25 +25 +35 +35 +50 +50 3

0 0 0 0 0

Rise+25

Rise+25

Rise+25

0 iron beam or

0

Decoration Depth(if available)≤120

concrete girders

Decoration Depth(if available)≤120

D 16# hollow square steel Upper landing door

for landing door

installation

Upper landing door

down mounting beam down mounting beam by other

OPH+100

by other

OP

≥100 DHW

Hoistway wall before filled

OPH+300

OP+200

(For not solid brick wall, hoistway inside wall

100mm width iron beam need to be set

Surface after filled

OPH

at two sides of the door.)

Down landing door

OP upper mounting beam

FINISHED

ROP Down landing door upper

mounting beam

D-D FLOOR

UNFINISHED

FLOOR

S+25

S+25

S+25

FINISHED FLOOR

0

0

16# hollow square steel

≥300

by other

iron beam or concrete girders for

View6-1 Rise≤30m View6-2 30m<Rise≤60m View6-3 Rise>60m landing door installation

by other

hoistway width HOISTWAY WIDTH

VIEW 6-8 VIEW 6-7

inside wall inside wall inside wall inside wall inside wall inside wall。。。。

G1C G2C G3C.........

Otis Elevator Co., Ltd.

PRELIMINARY CIVIL WORKS TO BE DONE INSIDE THE SHAFT AND MACHINE ROOM BY MAIN CONTRACTOR/ CLIENT

1 Elevator work condition: 3 Hoistway

1.1 Machine room temperature should be within 5︒C~+40︒C;1.2The relative humidity of work position should be not exceed 50% when 3.1 In order to ensure the normal operation of the equipment in the hoistway, the hoistway temperature shall be between +5ºC and +40ºC.

The hoistway should be dedicated for elevator, should be not equipped any equipment, cable unrelated with elevator. (In hoi

temperature is 40︒C, when temperature is lower than 40︒C, the relative humidity can be higher than 50%, if the average temperature is 3.2 Hoistway

no higher than 25︒C in one month, the average relat 3.2.1 Construction required the hoistway can help to prevent the frame spread, the hoistway should be enclosed by walls without any hole, root wall

and roof. Only below holes are allowed: a) landing door holes; b) the holes of inspection door, safety door and

1.3 The variation of power supply voltage should be within ±7% compared with rated voltage, power supply system should be three-phase

3.2.2 The wall, root wall and roof of hoist way should have enough strength and be constructed by the material which is strong, non-flammable and not

five wire, system should be with a independent ground wire:TN-S(5 wire=3 phase+Null wire+ground wire). The power supply cable easy to produce dust.

1.4 Ambient air should not contain corrosive and flammable gas, the class of pollution should meet the requirement in GB 14048.1-2006 and 3.2.3 The walls of the well shall have a mechanical strength such that when a force of 1000 N, being evenly distributed over an area of 0,30 m x 0,30

m in round or square section, is applied at right angles to the wall at any point on either face they shall resa)Permanent deformation greater than

no higher than level3 of conduction rule.

1 mm;b)Elastic deformation greater than 15 mm.

1.5 The elevator shall be installed in a place that can protect against the impact of external climate. When the 3.3 Access and emergency doors - Access trap doors - Inspection doors

elevator is installed in the building, the building shall consider the relevant provisions and requirements of fire protection; 3.3.1 Emergency doors: when the distance between consecutive landing door sills exceeds 11 m,should set a intermediate emergency doors which

height is no less than 1.8m, width is no less than 0.5m (exclude the condition with cab safety door); if the hoistway saThere should be an access

1.6 The elevator shall not be installed in the mine or desert environment door where the pit depth exceeds 2,50 m;Access trap doors shall give a clear passage of at least 0,80 m x 0,80 m, and shall be

2 Machine Room counterbalanced;Inspection doors shall have a maximum height of 0,50 m and a maximum width of 0,50 m and shall have sufficient dimensions

to carry out the required work through the door.

2.1 The machine room should be dedicated, can't be for other usage; This room should have a real wall, roof and trap-door, and only

3.3.2 Access and emergency doors and inspection doors shall not open towards the inside of the well.

authorized persons(maintain, inspection and rescue) can get into. Machine room and pulley room can't be for other usage, and al 3.3.3 Trap doors shall not open downwards. Hinges, if any, shall be of a type which cannot be unhooked. Trap doors used only for access of material

2.2 Passageway and passageway gate may be locked from the inside only.

3.3.4 Access and emergency doors and inspection doors should have a lock with key. When door opened, can be closed and locked without key.

2.2.1 Passageway to machine room and pulley should have a permanent light device with an intensity of at least 50 lux.

When door locked, can't be opened in hoistway.

2.2.2 In any conditions the passageway can be used safely and conveniently, and should not need to go through any private room. 3.3.5 Access and emergency doors and inspection doors should set an electrical device to verify the status of door close and open;

2.2.3 The safe passageway to machine room and pulley room should use stairs in advance. If not, can use ladder which meet below 3.3.6 When a trap door is in the open position, precautions shall be taken to prevent the fall of persons (e.g. a guardrail) and prevent the trapdoor from

closing such as to cause a crushing hazard (e.g. by counterbalance).

requirements:

3.3.7 Access and emergency doors and inspection doors should not have any holes, and should have same mechanical strengh as the landing door

(1)The access to the machinery spaces and pulley rooms shall not be situated more than 4 m above the level accessible by stairs; For and meet the requirements of code for fire protection of buildings.

access over 3 m in height by ladder fall protection shall be provided; 3.3.8 Access and emergency doors and inspection doors have a mechanical strength such that when a force of 1000 N, being evenly distributed over

an area of 0,30 m x 0,30 m in round or square section, is applied at right angles at any point from outside the well.

(2)Ladders shall be fastened to the access permanently or at least by rope or chain in such a way that they cannot be removed; 3.3.9 Access trap doors, when they are closed, shall be able to support 2000 N on an area of 0,20 m x 0,20 m at any position.

(3)Ladders exceeding 1,50 m in height shall, when in position for access, form an angle between 65° and 75° to the horizontal and shall 3.3.10 In the case of trap-doors, a permanently visible notice shall indicate to those using the trap-door: “Danger of falling - Reclose the trap-door”

not be liable to slip or turn over; 3.3.1 1Outside of the well, near the access doors and emergency doors, there shall be a notice stating: "Lift well - Danger Access forbidden to

unauthorized persons"

(4)The clear width of the ladder shall be at least 0,35 m, the depth of the steps shall not be less than 25 mm and in the case of vertical 3.4 Hoistway protectionWhere the well contains several lifts there shall be a partition between the moving parts of

ladders the distance between the steps and the wall behind the ladder shall not be less than 0,15 m. The steps shall different lifts by user. If this partition is perforate, EN ISO 13857:2008, 4.2.4.1 shall be respected. The partition shall have sufficient rigidity to

ensure tha

(5)Adjacent to the top end of the ladder there shall be at least one hand hold within easy reach;

3.4.1 This barrier should at least extend as low as 2.5m height from lowest floor surface, the width should prevent on person go through from one pit to

(6)Around a ladder, within a horizontal distance of 1,50 m, the risk of falling by more than the height of the ladder shall be prevented. other pit.

2.3 Machine Room 3.4.2 If the horizontal distance between the edge of cab top and moving components of adjacent elevator is smaller than 0.5m, the barrier should

cross all hoistway, the width should be at least equal to the size of moving components or the width of the part

2.3.1 The width of gate of machine room passageway should be no less than 0.6m, the height should no less than 2.0m, and door should not

3.5 Enclosed type hoist way should have ventilation holes(on roof or root typically), the area should no smaller than 1% of hoistway horizontal area,

open to room inside. the door should have a lock with key, and from room inside, the door can't be opened with key. should with protection net.

2.3.2 Machine room light and socket(1) The power of machine room lighting should be sperated with machine power. (2)Machine room should 3.6 Light

3.6.1 The well shall be provided with permanently installed electric lighting, giving the following intensity of illumination, even when all doors are

have a permanent electrical light, the lightness on floor shouldn't be smaller than 200lx. A switch should be set near the entrance(or closed, at any position of the car throughout its travel in the well:a)at least 50 lux, 1,0 m above the car roof within its vertical projection;b)at least

multiple entrances) of machine room at a proper height.(3)Machine room should have at least a 2P+PE type socket. (4)Should have a 50 lux, 1,0 m above the pit floor everywhere a person can stand, work and/or move between the working areas;c)at least 20 lux outside of the

locations defined in a) and b), excluding shadows created by car or components.

switch near the main switch to control the hoist way light, cab light and power of switch.

3.6.2 Near the landing door, the lightness on floor should be no less than 50lx with nature or artificial lighting.

2.3.3 Machine room floor strength and floor surface 3.7 Lower part of hoist way should have a pit, beside the buffer plate, rail plate and drain, the bottom of pit should be smooth, the pit can't use as

(1)The strength of machine room structure should can support the rating load and force. The construction material of machine room sump pit, if have, should be set in the corner of wall; when the rail, buffer and barrier have been installe

3.8 If below the cab and count weight, there is a space which people can reach, the pit floor should at least can support 5000N/mm2 pressure, and

should be durable and not easy to produce dust.

a) install the buffer on a solid pier which extend to the solid ground. or b) with count weight safety. notes: i

(2)The construction marterial of machine room floor should be antiskid, such as smooth concrete, corrugated steel and etc. 3.9 When with concrete sill angle( response by custom), all hoist way wall below landing door sill should meet below requirements a)Should form a

(3)The uneven height of machine room floor should be within 0.5m, if higher than this, should set stairs( response by custom) or step vertical surface between landing door sill, the height should be no less than 50mm plus1/2 unlock area, the width should be no less than inside

width of entrance plus 25mm at each sides .b)This surface should be continuous and constructed by smooth and hard material, such as sheet

with guard rail( response by custom)

metal, it can support a 300N force which distribute evenly on a 5cm2 rounded or square surface :

(4)The holes on machine room floor should be opened followed the layout requirement, the hole should be surrounded by guild frame, 1)permanent deformation greater than 1 mm;

this guild frame should at least 50mm higher than floor surface. 2)elastic deformation greater than 15 mm.c)Any Projections of the hoist way surface should be no higher than 5mm, if with any projection

which is higher than 2mm, the projection should be rounded, the container angle between rounded angle and horizontal surface should be no

(5)If have any pit or trough which depth is bigger than 0.5m and width is smaller than 0.5m, they should be covered. less than 75`。 d)Other, the hoist way wall should:

2.3.4 The machine room should have proper ventilation, and also need to consider that the hoist way need ventilate through the machine 1)connect with next Lintel, or

room, other stale air can't be exhausted directly into machine room.(Suggestion for lighting window and ventilator: ventilat 2)Extend with a smooth and hard declie surface, the container angle between the decline surface and horizontal surface should be no less

than 600 , the area projection shadow on horizontal surface should be less than 20mm2.

2.3.5 The power need be set at the location distribution box of and equipped with a switch with protection and locked. The null wire and ground 3.10 Before the installation of elevator, all door holes should be protected by a safety guild which no lower than 1.2m, and have enough strength.

wire should be separated and the ground resistance should be no bigger than 4Ω. The diameter of machine power wire s 1 After the installation of elevator, custom should pour the machine room, pit, door holes, HBP holes and other reserved holes.

2 All forces which marked in the layout, if without special note, are all be revised for shock, and other forces which wall and pit should support.

2.3.6 Hook used for machine maintenance should be set on top of the machine, the hook should be painted in yellow and marked maximum

3 Do by users if be claimed in lay out, should be finished before installation.

load in red color, one hook for each unit.For machine room less products, hook should be set on top of hoistway. 4 In residential design, the bed room and living room should not be adjacent to the hoist way, and should be far way from the noise source,

should not arrange the machine room above the living space, can use the secondary room such as the closet and bath

5 Hoist way should meet the nation code requirements GB 50300-2001 and GB 50310-2002.

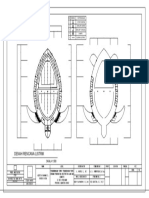

LAYOUT DRAWING OF PASSENGER ELEVATOR NO.1 (15 STOPS) 6

7

Party A shall be provide the elevation line of the final completion plane.

Important parts of the elevator shall be stored in an environment higher than -10 ° C, lower than +45 ° C and the relative humidity shall not

exceed 95% before installation; During the transportation, storage, installation and use of important components, avoid contacting with oil

substances or any other kind of lubricant, prevent the adhesion of water stop, gravel and other impurities, and provide machine rooms and

Otis Elevator Co., Ltd. hoistways with UV protection rate of not less than 98%;

Layout

LAYOUT DRAWING OF PASSENGER ELEVATOR NO.1 (15 STOPS)

HOISTWAY PLAN AND FRONT WALL DETAILS

H3=245 CTCR=855 653 653 / TLD2 / J101 fire rated jamb

GCD

185

210

50

60

PRS Fill back after installation

CWTDBG=1200+3

HD=2600

-0

200 240

CD=2100

CC.

HD=2600

200

L1 L2 L1 L2

520

520

V U

L3 L4 L3 L4

LOWER

L.S.

PES2

CC. T.C.

DF=1091

190 190

Technical parameters

1216

Product name ARISE

NOTE1

UPPER

PES1

60

DOP=100

Duty load(kg)

410

1000

165 V(m/s) 2

30

95

Rise(m) 54

OP=900 HW1=1100 HW2=910

Min. floor height 2700

650 1100 260 HW=2010

H1=416.5 CW=1100 H2=226.5 Door type TLD2

CWOUT=1150 No.of stops See table

62 CARDBG=1243+2 62

-0 Control VVVF

HW1=1100 HW2=910

Roping 2:1

HW=2010

Power supply 400V

HOISTWAY PLAN PIT PLAN Lighting supply 230V 50HZ

System Power(KW) 17

Rated Current(A) 32.4

Start Current(A) 55

PASSENGER ELEVATOR NO.1 (15 STOPS) Heat Release(Kcal/h) 1700

Signature of contact person of Party A

Seal of Party A

Stamp date

Change mark and content Name Date

Otis Elevator Co., Ltd.

Item No: Unit 1 52NER556

Project name: 93 Fife Residence

PL1 - 15 STOPS

NOTE1:The position of PES1 is within 750mm radius from the landing door,and height is 1.1~1.5m above the level of landing door sill. Drawing: Grady Wang Check:

Approval: Date: 2022.10.31

Version: Page number:

Drawing No: D221000577A_ARISE

LAYOUT DRAWING OF PASSENGER ELEVATOR NO.1 (15 STOPS)

MACHINE ROOM ROPE CUTOUT, RCC PLINTH LOCATION,

HOOK LOCATION AND H BEAM VOID DETAILS

CTCR=855 653 855 653

EXHAUST FAN BY OTHERS

BLIND WINDOW BY OTHERS

ARED(IF ANY)

THE DEPTH IS ONLY FOR REFERENCE

THE DEPTH IS ONLY FOR REFERENCE

CONTROLLER

OPERATION SPACE

1384

1384

500x700

B A 460

Te Tf

2-90X90

200 240

200 240

HD=2600

HD=2600

135

260

Tb Td

L2 L2

520

520

L1 L1

L3 L4 L3 L4

Ta Tc 2000KG HOOK 4-150X250

6-250X250

1216

1216

NOTE2

B A

NOTE1

150 150

800 800

EXTENSION 1600

EXTENSION 1600

1000

1000

Trap Door using checkered plate should be provided for Trap Door using checkered plate should be provided for

Machine hoisting purpose by Main Contractor/ Client. Machine hoisting purpose by Main Contractor/ Client.

400

400

1200×2100

240 1100 910

HW=2010

MACHINE ROOM DOOR

HW=2010

THE WIDTH IS ONLY FOR REFERENCE

THE WIDTH IS ONLY FOR REFERENCE

1100 910

MACHINE ROOM PLAN MACHINE ROOM HOLE PLAN

PASSENGER ELEVATOR NO.1 (15 STOPS)

Signature of contact person of Party A

Seal of Party A

500 750

Stamp date

390 210 260 Change mark and content Name Date

50

450

20

Otis Elevator Co., Ltd.

150

Item No: Unit 1 52NER556

Project name:93 Fife Residence

PL1 - 15 STOPS

1.MAIN LINE SW. BOX OF LIFT, BY FACTORY 3P/5W

POWER SUPPLY FOR LIFT. BY OTHERS

Drawing: Grady Wang Check:

2.LIGHT SW.&RECEPTACLE. A 2P+PE type at least)

BY OTHERS Approval: Date: 2022.10.31

NOTE 3.For CODE = EN81_20_2014, WIRELESS ALARM DEVICE

Page number:

device will be shipped, it could laying on top of controller,or Version:

hang on the well of machine room, the cable length is 8m

Drawing No: D221000577A_ARISE

Layout

WELD TO THE MAIN

STRUCTURE FRAME

LAYOUT DRAWING OF PASSENGER ELEVATOR NO.1 (15 STOPS)

200

100

HOOK PLAN

HOISTWAY ELEVATION, LIFT OPERATING PANEL(LOP) HOLE

2000kg HOISTING HOOK OTHERS

PROVISION, MACHINE ROOM HEIGHT, HOOK AND PIT

DETAILS 250

MRH=2600

250

Ø40

4 250 250

1 40 1 40

OPH=2100

OPH=2100

200

2200

2200

1650

500

OP+200=1100 OP+200=1100

1300

1300

OP=900 OP=900

POSITION OF THE LAST

PARAP=1100

GUIDE RAIL BRACKET

K=5000

MAIN FLOOR HALL DOOR HOLE OTHER FLOOR HALL DOOR HOLE

CH+1103

CH=2300

OPH=2100

Spacing of each ring beam=2400

OP=900

HALL BUTTOM(HBP)

400mm HIGH RING BEAM

FOR FIXING LADDER

FIREMAN SERVICE (FSS)

Φ40mm THROUGH HOLE, IN THE MAIN FLOOR

NOTE

R=54000

POSITION OF THE FIRST

Signature of contact person of Party A

GUIDE RAIL BRACKET

1100

Seal of Party A

875

R 5000 FRONT OPENING NO NO

12 3600 FRONT OPENING NO NO

11 3550 FRONT OPENING NO NO

10 3550 FRONT OPENING NO NO

9 3550 FRONT OPENING NO NO Stamp date

8 3550 FRONT OPENING NO NO

7 3550 FRONT OPENING NO NO Change mark and content Name Date

6 3550 FRONT OPENING NO NO

250

5 3550 FRONT OPENING NO NO

250

4 3550 FRONT OPENING NO NO

S=1600

3 3550 FRONT OPENING NO NO

2 6750 FRONT OPENING NO NO

1 3450 FRONT OPENING NO NO

≤250

G 4500 FRONT OPENING NO NO

800

B(基站) 3750 FRONT OPENING NO NO

Nonstop Safety

Floor name Floor height Hall door

floor door

Floor information table Otis Elevator Co., Ltd.

150

Item No: Unit 1 52NER556

ELEVATION

Project name: 93 Fife Residence

PASSENGER ELEVATOR NO.1 (15 STOPS) PL1 - 15 STOPS

Froce(KN) Car side rail CWT guide rail Pit reaction Machine room reaction

PARAMETERS OF BUFFER Drawing: Grady Wang Check:

R=51.7 R=16.5 U=107.3 Ta=24.8 Td=25.5

Approval: Date: 2022.10.31

CAR SIDE CWT SIDE

R1=1.5 R1=1.0 V=86.8 Tb=49.6 Te=24.8 Version: Page number:

STROKE 275 275 R2=1.8 R2=0.2 Tc=12.2 Tf=12.1 Drawing No: D221000577A_ARISE

You might also like

- Vaqif Mustafazade - Bayati SirazDocument1 pageVaqif Mustafazade - Bayati SirazMüşfiq Abdullayev100% (1)

- Introduction To Wireline Log Analysis, Baker Atlas, 2002Document321 pagesIntroduction To Wireline Log Analysis, Baker Atlas, 2002Anonymous Xy309m9Sm967% (3)

- BC Window SheetDocument1 pageBC Window SheetSubhankan JainNo ratings yet

- Operations & Maintenance Handbook - LPG Storage Facilities (Propane Research Council)Document176 pagesOperations & Maintenance Handbook - LPG Storage Facilities (Propane Research Council)KannanGKNo ratings yet

- Garment Manufacturing Process Flow Chart PDFDocument6 pagesGarment Manufacturing Process Flow Chart PDFDinesh ViswanathanNo ratings yet

- Ufscar - Curso de Engenharia Civil Projeto de SaneamentoDocument1 pageUfscar - Curso de Engenharia Civil Projeto de SaneamentomichelfibonacciNo ratings yet

- LISTRIKDocument1 pageLISTRIK058 Assyifa Rahmani sebrinaNo ratings yet

- 7dma R9 Covid Cases 20210822Document1 page7dma R9 Covid Cases 20210822Mohrein H. Ismael VINo ratings yet

- Malagueña: Alto SaxophoneDocument2 pagesMalagueña: Alto Saxophonericardosax93gmailcomNo ratings yet

- Christmas Selections For Mixed Clarinet Quartet-Bb Clarinet 2Document1 pageChristmas Selections For Mixed Clarinet Quartet-Bb Clarinet 2Javi Fernández Devesa0% (1)

- Chritsmas Festival - Part - 5Document2 pagesChritsmas Festival - Part - 5fx7b9n69fbNo ratings yet

- Alto Sax Horn 1-2 Transcription WIND WAKERDocument3 pagesAlto Sax Horn 1-2 Transcription WIND WAKERKaden DayogNo ratings yet

- Measure Angles Up To 180°: The Angle Marked Is 30 DegreesDocument2 pagesMeasure Angles Up To 180°: The Angle Marked Is 30 DegreesNida AliNo ratings yet

- Chart of Thermodynamic & Transport Properties of CO2 - ManualDocument34 pagesChart of Thermodynamic & Transport Properties of CO2 - ManualAbdus Saboor KhalidNo ratings yet

- 23.125.90 2000 Kva 11 - 0,4 Ynd 1 Hermetical.r2Document1 page23.125.90 2000 Kva 11 - 0,4 Ynd 1 Hermetical.r2Karim RahmaniNo ratings yet

- Caminos.... Cortada-FlautaDocument2 pagesCaminos.... Cortada-FlautaDiego CabreraNo ratings yet

- II Petrochemicals ENDocument2 pagesII Petrochemicals ENvikrams22No ratings yet

- Anchor Bolt Layout - R02Document4 pagesAnchor Bolt Layout - R02Julfiker Ali RaselNo ratings yet

- Bakalao Salao: Arr. AlvaritoDocument1 pageBakalao Salao: Arr. AlvaritoalvaroNo ratings yet

- Super Mario Bros Sax Quartet-Super Mario Bros Sax Quartet-Tenor SaxophoneDocument2 pagesSuper Mario Bros Sax Quartet-Super Mario Bros Sax Quartet-Tenor SaxophonequchiiiNo ratings yet

- LP3ADocument1 pageLP3ABimo AjiNo ratings yet

- Omori - Duet Spoilers-ViolinDocument1 pageOmori - Duet Spoilers-Violinboblebleu2No ratings yet

- AR Detail 01-07Document1 pageAR Detail 01-07EphremHailuNo ratings yet

- Plan 2Document1 pagePlan 2Muhammad AshrafNo ratings yet

- Christmas Selections For Mixed Clarinet Quartet-Bb Clarinet 3Document1 pageChristmas Selections For Mixed Clarinet Quartet-Bb Clarinet 3Javi Fernández DevesaNo ratings yet

- Danzon N°:02: Trompeta en SiDocument1 pageDanzon N°:02: Trompeta en Sikike_1011No ratings yet

- 8 - FloodLight SMD SquareDocument1 page8 - FloodLight SMD Squaremohamed eltawelNo ratings yet

- Gambar Penampang Memanjang Jalan Trase 2 Skala Vertikal 1: 1000 Skala Horizontal 1: 20.000Document1 pageGambar Penampang Memanjang Jalan Trase 2 Skala Vertikal 1: 1000 Skala Horizontal 1: 20.000Bimo AjiNo ratings yet

- Married Life SaxDocument2 pagesMarried Life SaxJoão Vitor SallesNo ratings yet

- Murisemar To Chatra - P1Document1 pageMurisemar To Chatra - P1Manash BhattacharjeeNo ratings yet

- Anode Support DesignDocument1 pageAnode Support DesignBethelSilasNo ratings yet

- Dessin 1Document1 pageDessin 1Jules DumontNo ratings yet

- Qari2at AlfinjanDocument21 pagesQari2at Alfinjanhijazi hamoodNo ratings yet

- 1812c-Violonchelo 3Document3 pages1812c-Violonchelo 3miansama3505No ratings yet

- Bald Eagle Park MapDocument1 pageBald Eagle Park MapEliza MarstellerNo ratings yet

- Wildcat Mountain Trail MapDocument1 pageWildcat Mountain Trail MapJesica HelgrenNo ratings yet

- Я Свободен (Ya Svoboden)Document2 pagesЯ Свободен (Ya Svoboden)cyril.ghosttownNo ratings yet

- Haydn Concerto - For - TumpetDocument5 pagesHaydn Concerto - For - TumpetВаня АбраменкоNo ratings yet

- TimpaniDocument1 pageTimpaniIsac Ciconha de OliveiraNo ratings yet

- San Pelayo-Fandango-Trompeta en Sib 2Document2 pagesSan Pelayo-Fandango-Trompeta en Sib 2Trump TruNo ratings yet

- Practica-Perfiles-Mapa-Doblecarta (1) RDocument1 pagePractica-Perfiles-Mapa-Doblecarta (1) RJose Manuel JimenezNo ratings yet

- Site Plan: NeighborDocument1 pageSite Plan: NeighborMAN ENGINEERINGNo ratings yet

- Active Glass MediaDocument2 pagesActive Glass Mediaehden.emadNo ratings yet

- CMYK Test Form SRA3 US PortraitDocument1 pageCMYK Test Form SRA3 US PortraitEconotintas del ValleNo ratings yet

- CMYK Test Form SRA3 US PortraitDocument1 pageCMYK Test Form SRA3 US PortraitWatcharapon WiwutNo ratings yet

- Menara TCM Infra Coordination PlanDocument1 pageMenara TCM Infra Coordination Planmaurice86No ratings yet

- Silt Trap Details-1Document1 pageSilt Trap Details-1MahindaNo ratings yet

- 18 606000 1100001344 Asb Civ SHD 115152 - 01Document1 page18 606000 1100001344 Asb Civ SHD 115152 - 01Mahmudul Alam kanakNo ratings yet

- Radar Road-Plan and ProfileDocument8 pagesRadar Road-Plan and ProfileRockstarNo ratings yet

- Ax001 PDFDocument1 pageAx001 PDFAl Fakhamah LiftsNo ratings yet

- Carbon Dioxide: Pressure - Enthalpy Diagram: R 90 0 Sity 7 00 KG/MDocument1 pageCarbon Dioxide: Pressure - Enthalpy Diagram: R 90 0 Sity 7 00 KG/MJackNo ratings yet

- La Fastin brass-טובהDocument1 pageLa Fastin brass-טובהליאור סבגNo ratings yet

- Pramod Permission PlanDocument1 pagePramod Permission PlanInspire BuildersNo ratings yet

- 43 Columns Walls, Stairs 01Document1 page43 Columns Walls, Stairs 01Riham AdelNo ratings yet

- 74-27a-Section View of Furnace Charging Roller Table Billet Charging Pusher-ModelDocument1 page74-27a-Section View of Furnace Charging Roller Table Billet Charging Pusher-Modelsol manNo ratings yet

- Highlights From "Frozen": Percussion 2Document1 pageHighlights From "Frozen": Percussion 2FaniFaNo ratings yet

- Shaman Fairy Tale-Violino 1Document2 pagesShaman Fairy Tale-Violino 1Renata BenficaNo ratings yet

- Sectorizacion PDFDocument1 pageSectorizacion PDFSOVEYDA AVILA ESPICHANNo ratings yet

- 02 Retaining Wall Type 2 - Road 3 Typical Reinforcement (Nf1, Nf2&Nf3) Elevation For - (Rw-Type2-Wall) Section 01-01Document1 page02 Retaining Wall Type 2 - Road 3 Typical Reinforcement (Nf1, Nf2&Nf3) Elevation For - (Rw-Type2-Wall) Section 01-01Ahmed MandorNo ratings yet

- LA RAZA CUMBIA-Trompeta - en - Sib - 2-1Document1 pageLA RAZA CUMBIA-Trompeta - en - Sib - 2-1FRANCISCO EDUARDO HERNANDEZ PEREZNo ratings yet

- Christmas Selections For Mixed Clarinet Quartet-Bass ClarinetDocument1 pageChristmas Selections For Mixed Clarinet Quartet-Bass ClarinetJavi Fernández DevesaNo ratings yet

- Planning For The Next Global PandemicDocument6 pagesPlanning For The Next Global PandemicCOproduções Culturais e ArtísticasNo ratings yet

- ResourcesDocument5 pagesResourcesvarunNo ratings yet

- Second Periodical Test in Mathematics Vi S.Y. 2019-2020Document7 pagesSecond Periodical Test in Mathematics Vi S.Y. 2019-2020Jessmiel Labis100% (1)

- Searchq Elbow+Mercury+Steering+Pressure&Rlz 1CDGOYI EnAE911AE911&Hl en US&Ei 8kFNZNmIPNmB9u8P1ZaV2Ac&OqDocument1 pageSearchq Elbow+Mercury+Steering+Pressure&Rlz 1CDGOYI EnAE911AE911&Hl en US&Ei 8kFNZNmIPNmB9u8P1ZaV2Ac&Oqt8fn5ykc84No ratings yet

- Rhapsody: Actual Design Area: 1" X 2"Document1 pageRhapsody: Actual Design Area: 1" X 2"Anonymous Y2qwEuANo ratings yet

- ATT2100 & 2200 ManualDocument52 pagesATT2100 & 2200 ManualFranco SNo ratings yet

- Catia Important Interview QuestionsDocument40 pagesCatia Important Interview QuestionsHarshwardhan Singh0% (1)

- Natural Proiduct QuizDocument39 pagesNatural Proiduct QuizLaraib FatimaNo ratings yet

- Isr4321 k9 DatasheetDocument6 pagesIsr4321 k9 DatasheetSail DMNo ratings yet

- TabernacleDocument126 pagesTabernacleVal100% (8)

- Production and Operations ManagementDocument178 pagesProduction and Operations ManagementRavi KumarNo ratings yet

- BEJE2242VA Block Diagram 1670405Document1 pageBEJE2242VA Block Diagram 1670405David RomeroNo ratings yet

- Contoh Format SoalDocument3 pagesContoh Format SoalAinol mardiyahNo ratings yet

- Elco 345Document3 pagesElco 345fernandez_jhon4987100% (1)

- Gotco Operation ManualDocument251 pagesGotco Operation ManualBrett KingNo ratings yet

- Panasonic Broadcast AJ-D455 Mechanical ArtsDocument26 pagesPanasonic Broadcast AJ-D455 Mechanical ArtskarkeraNo ratings yet

- FILE 20210720 230205 Ôn-Tập-TACNDocument9 pagesFILE 20210720 230205 Ôn-Tập-TACNVăn KhánhNo ratings yet

- SN1 Vs SN2 PDFDocument1 pageSN1 Vs SN2 PDFHeather UyNo ratings yet

- Assignment 2 (Co3co4)Document4 pagesAssignment 2 (Co3co4)jiwa remajaNo ratings yet

- Geared Motor Device 100/130V E1/6-T8Document2 pagesGeared Motor Device 100/130V E1/6-T8seetharaman K SNo ratings yet

- Operators GuideDocument380 pagesOperators Guideswapon kumar shillNo ratings yet

- Theory and Application For The Scanning Tunneling MicroscopeDocument4 pagesTheory and Application For The Scanning Tunneling MicroscopeIgor LukacevicNo ratings yet

- Berger Paint ProjectDocument144 pagesBerger Paint ProjectMukesh Kumar100% (2)

- The Rhodax® Process For Dry Mix Preparation in Anodes PlantsDocument37 pagesThe Rhodax® Process For Dry Mix Preparation in Anodes PlantsGupta AnacoolzNo ratings yet

- Petzl Sport Catalog 2010 GBDocument81 pagesPetzl Sport Catalog 2010 GBPatrascu Lucian0% (1)

- Demeter & Stoicescu 2008 PDFDocument21 pagesDemeter & Stoicescu 2008 PDFAbigail CicortNo ratings yet

- Guided Revision: Section-I Single Correct Answer Type 14 Q. (3 M (-1) )Document8 pagesGuided Revision: Section-I Single Correct Answer Type 14 Q. (3 M (-1) )Archisha DasNo ratings yet