Professional Documents

Culture Documents

1.6 - Bolting Material

1.6 - Bolting Material

Uploaded by

chilukamariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.6 - Bolting Material

1.6 - Bolting Material

Uploaded by

chilukamariCopyright:

Available Formats

Bolting materials used in Cast Steel Valves are carefully selected and controlled to assure

reliability in service. The following describes the more usual bolting materials (studs and nuts) used

in the bonnet and cover joints of valves.

Steel valves for all temperature services have alloy steel studs. For temperatures up to 875F,

chromium-molybdenum steel conforming to ASTM A193-B7 is normally used, and for higher

temperatures and/or corrosive services, other suitable ferritic (usually ASTM A193-B16) or

austenitic grades are selected from ASTM A193. Nuts for ferritic alloy studs are normally carbon

steel that meets the requirements of ASTM A194 Grade 2H. For low-temperature applications

down to minus 150F, alloy steel studs conforming to ASTM A320-L7 are normally used in

conjunction with alloy steel nuts meeting the requirements of ASTM A194 Grade 4.

Ferritic alloy steel bolting is heat treated to conform to the following minimum mechanical property

requirements:

Tensile strength (psi): 125,000 minimum

Yield Point (psi): 105,000 minimum

Elongation, percent in 2": 16 minimum

Reduction of Area, percent: 50 minimum

In cast iron valves, the bonnet, retainer, and cap joints have carbon steel bolting meeting the requirements of ASTM A307 Gr B. Carbon steel

nuts are used.

In corrosion-resistant valves, the bonnet and gland bolts and nuts are made of austenitic stainless steel.

All bolts are made of Type 304 stainless steel. All nuts are made of gall-resistant austenitic stainless steel of corrosion resistance equal to or

better than Type 303. High strength low alloy bolts, such as ASTM A193-B7 with ASTM A194-2H nuts, are used on 900 lb. and 1500 lb.

valves and for nuclear service.

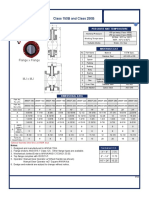

Material Specifications

Temperature

Body Materials

(degrees F)

Bolts Nuts

Cast Iron -20 to 410 ASTM A307 Gr B ASTM A307 Gr 7

Ductile Iron -20 to 650 ASTM A193 Gr B7 ASTM A194 Gr 2H

Carbon Steel (Grade WCB) -20 to 800 ASTM A193 Gr B7 ASTM A194 Gr 2H

Carbon Steel (Grade LCB) -50 to 650 ASTM A193 Gr B7 ASTM A194 Gr 2H

-20 to 800 ASTM A193 Gr B7 ASTM A194 Gr 2H

Carbon Moly (Grade WC1)

801 to 850 ASTM A193 Gr B7 ASTM A194 Gr 7

-20 to 800 ASTM A193 Gr B7 ASTM A194 Gr 2H

1¼Cr-½Mo (Grade WC6)

801 to 1000 ASTM A193 Gr B7 ASTM A194 Gr 7

-20 to 800 ASTM A193 Gr B7 ASTM A194 Gr 2H

2¼Cr-1Mo (Grade WC9) 801 to 1000 ASTM A193 Gr B7 ASTM A194 Gr 7

1001 to 1050 ASTM A193 Gr B16 ASTM A194 Gr 7

-20 to 800 ASTM A193 Gr B7 ASTM A194 Gr 2H

5Cr-½Mo (Grade C5) 801 to 1000 ASTM A193 Gr B7 ASTM A194 Gr 7

1001 to 1100 ASTM A193 Gr B16 ASTM A194 Gr 4

-20 to 800 ASTM A193 Gr B7 ASTM A194 Gr 2H

9Cr-1Mo (Grade C12) 801 to 1000 ASTM A193 Gr B7 ASTM A194 Gr 7

1001 to 1100 ASTM A193 Gr B16 ASTM A194 Gr 4

-425 to 100 ASTM A320 Gr B8 ASTM A194 Gr 8

Type 304 (Grade CF8)

100 to 1500 *ASTM A193 Gr B8 *ASTM A194 Gr 8

-425 to 100 ASTM A320 Gr B8 ASTM A194 Gr 8

Type 347 (Grade CF8C)

100 to 1500 *ASTM A193 Gr B8 *ASTM A194 Gr 8

-325 to 100 ASTM A320 Gr B8 ASTM A194 Gr 8

Type 316 (Grade CF8M)

100 to 1500 *ASTM A193 Gr B8M *ASTM A194 Gr 8M

ASTM A194 Gr 4

-150 to –50 ASTM A320 Gr L7

3½Ni (Grade LC3) With Charpy Test or 8M

-50 to 650 ASTM A193 Gr B7

ASTM A194 Gr 2H

* Alloy steel bolting, A193 bolts and A194 Gr 2H nuts can be used at moderate temperatures

depending on the permissible differential expansion.

You might also like

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- Astm A193 - Nuts and BoltsDocument5 pagesAstm A193 - Nuts and BoltsgarrybieberNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Ca6nm WPS/PQRDocument22 pagesCa6nm WPS/PQRDeepak0% (1)

- HTTP WWW Pressbolt Com Astm A193 b7, b7m, b8, b8m, b16, A320 l7, l7m, l43 Studbolts HTMLDocument2 pagesHTTP WWW Pressbolt Com Astm A193 b7, b7m, b8, b8m, b16, A320 l7, l7m, l43 Studbolts HTMLMashudi FikriNo ratings yet

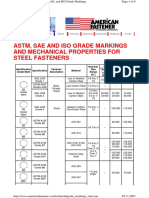

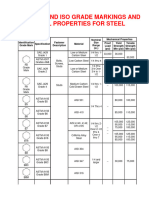

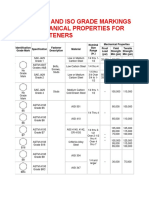

- ASTM & SAE Grade Markings For Bolts and ScrewsDocument2 pagesASTM & SAE Grade Markings For Bolts and ScrewsDavid D'AgostinoNo ratings yet

- Weld Fitting Flange Astm SpecsDocument1 pageWeld Fitting Flange Astm SpecsAZU-OKPONo ratings yet

- Fabory Fasteners ASTM StudboltDocument13 pagesFabory Fasteners ASTM StudboltJohan ConradieNo ratings yet

- PARAFUSOS BANHADOS MADE IN CHINA Threaded-RodDocument58 pagesPARAFUSOS BANHADOS MADE IN CHINA Threaded-RodAMARILDO SUPPLYNo ratings yet

- Hex Bolt Head MarkingsDocument5 pagesHex Bolt Head MarkingscarangoretrepoNo ratings yet

- Valve Materials - Suitability, Performance, Applications & Cross ReferencesDocument16 pagesValve Materials - Suitability, Performance, Applications & Cross Referencesmm tradingviewNo ratings yet

- ASTM A194 - Portland BoltDocument3 pagesASTM A194 - Portland BoltJonathan DouglasNo ratings yet

- Elmac Material SelectionDocument1 pageElmac Material SelectionAnil Krishna JangitiNo ratings yet

- ASTM Bolting Specification Temperature MDocument2 pagesASTM Bolting Specification Temperature Mrazvan65100% (1)

- American FastenersDocument6 pagesAmerican Fastenersashraf elsayedNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationme100% (1)

- Bolts SpacificationsDocument6 pagesBolts SpacificationsSaleem JaradatNo ratings yet

- 4.ASTM A193 B7 Vs A320 L7 Stud BoltsDocument4 pages4.ASTM A193 B7 Vs A320 L7 Stud BoltsO'zSamaNo ratings yet

- Valve Material Application PDFDocument16 pagesValve Material Application PDFSudherson Jagannathan100% (1)

- Pernos ASTMDocument6 pagesPernos ASTMpatricio wachtendorffNo ratings yet

- Astm A194Document3 pagesAstm A194poerwntiNo ratings yet

- FastenersDocument6 pagesFastenersbaburaogtrwNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersCarlos Nina OchoaNo ratings yet

- Material Specification PDFDocument1 pageMaterial Specification PDFneivaprojetosNo ratings yet

- Bolting Material Specifications - PIPING HANDBOOKDocument1 pageBolting Material Specifications - PIPING HANDBOOK최승원No ratings yet

- Sae j429 Vs Astm A354 BD PDFDocument2 pagesSae j429 Vs Astm A354 BD PDFAdam GordonNo ratings yet

- FastnersDocument18 pagesFastnersraghbirNo ratings yet

- Certificado de VictaulicDocument1 pageCertificado de VictaulicsuferrsursacNo ratings yet

- M Catalogue PDFDocument1 pageM Catalogue PDFics companyNo ratings yet

- PosterSAcatIRON 2009Document1 pagePosterSAcatIRON 2009karim3samirNo ratings yet

- ASTM A53 ERW Clarinet Carbon Pipe / ASTM A53/A53M: ProductsDocument4 pagesASTM A53 ERW Clarinet Carbon Pipe / ASTM A53/A53M: ProductsmuathNo ratings yet

- Casting - Forging Eqv.Document2 pagesCasting - Forging Eqv.Saravanan SaranNo ratings yet

- Mechanical Properties For Steel FastenersDocument7 pagesMechanical Properties For Steel FastenersepriyonoNo ratings yet

- A333 Grade 6 Pipe SpecificationDocument10 pagesA333 Grade 6 Pipe SpecificationArmandito ZamudioNo ratings yet

- Astm StandardsDocument15 pagesAstm StandardsAbdouHemmalNo ratings yet

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99No ratings yet

- Astm A194Document3 pagesAstm A194luizz100% (1)

- Steel Fasteners: Materials - Carbon & Alloy SteelsDocument1 pageSteel Fasteners: Materials - Carbon & Alloy SteelsNegro PretoNo ratings yet

- Material AsmDocument6 pagesMaterial Asmrawalepushkar123No ratings yet

- 61c5c696d1f9cDocument1 page61c5c696d1f9cAzifahNo ratings yet

- Common Valve MateriasDocument3 pagesCommon Valve MateriasagrovadoNo ratings yet

- Astm, Sae and Iso Bolting MaterialDocument7 pagesAstm, Sae and Iso Bolting MaterialSds Mani SNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- Astm A335 Blog 9Document3 pagesAstm A335 Blog 9RELIABLE PIPES & TUBESNo ratings yet

- Opper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Document8 pagesOpper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Mohammed NazeerNo ratings yet

- Nutron TM Trunnion Mounted Ball Valve FlyerDocument2 pagesNutron TM Trunnion Mounted Ball Valve FlyerAlbert RubianoNo ratings yet

- Gate ValveDocument1 pageGate ValvebloggerparthiNo ratings yet

- ASTM Piping Codes PDFDocument6 pagesASTM Piping Codes PDFdablu kumarNo ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- JSC "Zaporizhstal" (Ukraine) : Company's Business ProfileDocument8 pagesJSC "Zaporizhstal" (Ukraine) : Company's Business ProfileCyril J PadiyathNo ratings yet

- Astm A955Document6 pagesAstm A955歐昱辰No ratings yet

- Brchembase LRDocument4 pagesBrchembase LRRavindra PawarNo ratings yet

- Fischer-Tunnel ConstructionDocument20 pagesFischer-Tunnel ConstructionAlem LoajnerNo ratings yet

- E-Waste ManagementDocument28 pagesE-Waste ManagementHarshit VyasNo ratings yet

- C% MN% Si% P% Max S% Max: The Ladle Analysis of The Steel Shall Be Given As BelowDocument2 pagesC% MN% Si% P% Max S% Max: The Ladle Analysis of The Steel Shall Be Given As BelowThennarasu VelloreNo ratings yet

- Lathe Part IDocument151 pagesLathe Part Ishiva100% (2)

- Flux-Cored Arc Welding: A. Process PrinciplesDocument3 pagesFlux-Cored Arc Welding: A. Process Principlessn200709No ratings yet

- What Is Counter Gravity CastingDocument2 pagesWhat Is Counter Gravity Castingmmr315No ratings yet

- Document Cover Sheet: Oyu Tolgoi Underground ProjectDocument12 pagesDocument Cover Sheet: Oyu Tolgoi Underground ProjectGSkoruNo ratings yet

- Slaghog Narrow User ManualDocument11 pagesSlaghog Narrow User ManualMetin AğayaNo ratings yet

- Techalloy 99: Conformances Key FeaturesDocument2 pagesTechalloy 99: Conformances Key FeaturesDaniel Lvqve GarciaNo ratings yet

- Division2 RecordDocument9 pagesDivision2 RecordCelestial ChewiNo ratings yet

- Cold Working of HolesDocument21 pagesCold Working of HolesSwampfootNo ratings yet

- Insoluble Anodes: The Next GenerationDocument4 pagesInsoluble Anodes: The Next GenerationEvangelos PapaioannouNo ratings yet

- 23 82 19 - Fan Coil UnitsDocument4 pages23 82 19 - Fan Coil UnitsLoraine AnnNo ratings yet

- C7025 (英文) ver1 6Document11 pagesC7025 (英文) ver1 6顏健軒No ratings yet

- Project Proposal Sample FormatDocument6 pagesProject Proposal Sample FormatCarl Jerome AustriaNo ratings yet

- PDF 17573Document115 pagesPDF 17573goaltechNo ratings yet

- Expanded Grid by ROCHE MESHMAKERDocument4 pagesExpanded Grid by ROCHE MESHMAKERibrahime mohammedNo ratings yet

- New Highway Code For Italy - Traffic and Road SignsDocument56 pagesNew Highway Code For Italy - Traffic and Road SignsSyed Zillay AliNo ratings yet

- Mechanical SpecificationDocument185 pagesMechanical SpecificationAhmad Saadeldin100% (1)

- NO.20 Product Catalogue: Specialist Architectural Hardware Suppliers To The Door Openings IndustryDocument50 pagesNO.20 Product Catalogue: Specialist Architectural Hardware Suppliers To The Door Openings IndustryCold War YaltaNo ratings yet

- PY - The - M.kekkonen L.holapp - 2000 - Comparison of Different Coal Based Direct Reduction ProcessesDocument47 pagesPY - The - M.kekkonen L.holapp - 2000 - Comparison of Different Coal Based Direct Reduction ProcessesEduardo CandelaNo ratings yet

- Grizzly G4185 Horizontal Boring Machine Instruction Manual ENDocument32 pagesGrizzly G4185 Horizontal Boring Machine Instruction Manual ENRichard RoperNo ratings yet

- Field Inspection ReportDocument14 pagesField Inspection ReportRanjit SinghNo ratings yet

- ESAB 453ccDocument32 pagesESAB 453ccdavid bolivarNo ratings yet

- AA19511Document6 pagesAA19511varshaimpexcoNo ratings yet

- The Child Labour (Prohibition & Regulation) Act - 1986Document38 pagesThe Child Labour (Prohibition & Regulation) Act - 1986Satish MNo ratings yet