Professional Documents

Culture Documents

Penguard Midcoat

Penguard Midcoat

Uploaded by

firmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Penguard Midcoat

Penguard Midcoat

Uploaded by

firmanCopyright:

Available Formats

Technical Data

PENGUARD MIDCOAT

Product description

Penguard Midcoat is a high solids, low VOC, high build, two-pack epoxy coating. Available with

different hardeners for varying substrate temperatures, Standard (Std) and Cold Climate (CC).

Recommended use

Exclusively as a high build epoxy intermediate coat as a part of a multi layer coating system for

protection of steel structures. The intermediate coat is used to improve the barrier protection for anti

corrosive coating systems in a wide range of environments.

Film thickness and spreading rate

Std Comp. B: Minimum Maximum Typical

Film thickness, dry (µm) 100 250 150

Film thickness, wet (µm) 125 300 185

Theoretical spreading rate (m²/l) 8,2 3,3 5,5

CC Comp. B: Minimum Maximum Typical

Film thickness, dry (µm) 100 200 150

Film thickness, wet (µm) 135 270 200

Theoretical spreading rate (m²/l) 7,5 3,8 5

Physical properties

Colour Buff, Grey, Light Red, Turquoise, White

Solids (vol %)* 82 ± 2 Std Comp. B

75 ± 2 CC Comp. B

Flash point Std Comp. B

25ºC ± 2 (Setaflash)

CC Comp. B

31ºC ± 2 (Setaflash)

VOC Std Comp. B

170 gms/ltr UK-PG6/23(97). Appendix 3

CC Comp. B

210 gms/ltr UK-PG6/23(97). Appendix 3

Gloss Semiflat

Gloss retention Fair

Water resistance Good

Abrasion resistance Very good

Solvent resistance Good

Flexibility Good

*Measured according to ISO 3233:1998 (E)

Surface preparation

All surfaces should be clean, dry and free from contamination. The surface should be assessed and

treated in accordance with ISO 8504.

PENGUARD MIDCOAT Page 1 of 4

Coated surfaces

Should only be applied over clean, dry and undamaged compatible anti-corrosive zinc primer. Zinc

silicate primed surfaces must be fully cured and free of zinc salts and contaminants. Please contact

your local Jotun office for more information.

Other surfaces

The coating may be used on other substrates. Please contact your local Jotun office for more

information.

Condition during application

The temperature of the substrate should be minimum +15°C (Std) (0°C in CC) and at least 3°C

above the dew point of the air, temperature and relative humidity measured in the vicinity of the

substrate. Good ventilation is required in confined areas to ensure proper drying. The coating should

not be exposed to oil, chemicals or mechanical stress until cured.

Application methods

Spray Use airless spray

Brush Recommended for stripe coating and small areas, care must be taken to achieve the

specified dry film thickness.

Application data

Mixing ratio (volume) 4:1

Mixing 4 parts Comp. A (base) to be mixed thoroughly with 1 part Comp. B

(curing agent) for 5-10 minutes prior to use.

Pot life (23°C) Std Comp. B

2 hours. (Reduced at higher temp.)

CC Comp. B

1 hour. (Reduced at higher temp.)

Thinner/Cleaner Jotun Thinner No. 17 (up to 5% for lower film thickness application.)

Guiding data airless spray

Pressure at nozzle 15 MPa (150 kp/cm², 2100 psi.)

Nozzle tip 0.40 - 0.69 mm (0.018-0.027")

Spray angle 40 - 80°

Filter Check to ensure that filters are clean.

Drying time

Drying times are generally related to air circulation, temperature, film thickness and number of coats,

and will be affected correspondingly. The figures given in the table are typical with:

* Good ventilation (Outdoor exposure or free circulation of air)

* Typical film thickness

* One coat on top of inert substrate

PENGUARD MIDCOAT Page 2 of 4

Std Comp. B

Substrate temperature 15°C 23°C 40°C

Surface dry 6h 4h 2h

Through dry 9h 6h 3h

Cured 10 d 7d 5d

Dry to recoat, minimum 9h 6h 3h

Dry to recoat, maximum 1

CC Comp. B

Substrate temperature 0°C 5°C 10°C 23°C

Surface dry 16 h 8h 4,5 h 1,5 h

Through dry 40 h 20 h 10 h 4,5 h

Cured 14 d 7d 3d 2d

Dry to recoat, minimum 40 h 20 h 10 h 4,5 h

Dry to recoat, maximum 1

1. Provided the surface is free from chalking and other contamination prior to application, there is

normally no overcoating time limit. Best intercoat adhesion occurs, however, when the

subsequent coat is applied before preceding coat has cured. If the coating has been exposed to

direct sunlight for some time, special attention must be paid to surface cleaning and

mattening/removal of the surface layer in order to obtain good adhesion.

The given data must be considered as guidelines only. The actual drying time/times before recoating

may be shorter or longer, depending on film thickness, ventilation, humidity, underlying paint system,

requirement for early handling and mechanical strength etc. A complete system can be described on

a system sheet, where all parameters and special conditions could be included.

Typical paint system

Barrier or Barrier 77 1 x 60 µm (Dry Film Thickness)

Penguard Midcoat 1 x 175 µm (Dry Film Thickness)

Hardtop AS/Hardtop XP 1 x 50 µm (Dry Film Thickness)

Other systems m a y be specified, depending on area of u s e

Storage

The product must be stored in accordance with national regulations. Storage conditions are to keep

the containers in a dry, cool, well ventilated space and away from source of heat and ignition.

Containers must be kept tightly closed.

Handling

Handle with care. Stir well before use.

PENGUARD MIDCOAT Page 3 of 4

Packing size

16 litres Comp. A (base) in a 20 litre container and 4 litres Comp. B (curing agent) in a 5 litre

container and/or

4 litres Comp. A (base) in a 5 litre container and 1 litres Comp. B (curing agent) in a 1 litre

container.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated

conditions. Do not breathe or inhale mist. Avoid skin contact. Spillage on the skin should immediately

be removed with suitable cleanser, soap and water. Eyes should be well flushed with water and

medical attention sought immediately.

For detailed information on the health and safety hazards and precautions for use of this

product, we refer to the Material Safety Data Sheet.

DISCLAIMER

The information in this data sheet is given to the best of our knowledge based on laboratory testing and

practical experience. However, as the product is often used under conditions beyond our control, we

cannot guarantee anything but the quality of the product itself. We reserve the right to change the given

data without notice.

Head Office & Nordic Europe Middle East South East A s i a

Jotun A /S Jotun P aints (Europe) Ltd. Jotun U .A .E Ltd. LLC . Jotun (Singapore) P te. Ltd.

P .O . Box 2021 Stather Road, Flixborough No 11-15, Sixth Lok Y ang

N-3248 Sandefjord North Lincolnshire DN15 A l Q uoz Industrial A rea Road

Norway 8RR P .O Box 3671 Jurong

U nited Kingdom Dubai U .A .E Singapore 628 111

P hone +47 33 45 70 00

Fax +47 33 46 46 13 P hone +44 172 44 00 000 P hone +65 6265 4711

Fax +44 172 44 00 100 P hone +971 4 3 39 50 00 Fax +65 6265 7484

Fax +971 4 3 38 06 66

Jotun is a World Wide company with factories, sales offices and stocks in more than 50 countries. For your

nearest local Jotun address please contact the nearest regional office or visit our website at www.jotun.com

ISSUED 15 DECEMBER 2006 BY JOTUN

THIS DATA SHEET SUPERSEDES THOSE PREVIOUSLY ISSUED

PENGUARD MIDCOAT Page 4 of 4

You might also like

- Coal Tar JotunDocument3 pagesCoal Tar JotunIntan100% (1)

- TDS-ANTIFOULING SARGASSO-EnglishDocument3 pagesTDS-ANTIFOULING SARGASSO-EnglishthirdNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Jotacote UniversalDocument4 pagesJotacote UniversalRidwan BaharumNo ratings yet

- TDS - Penguard Midcoat Mio 80Document4 pagesTDS - Penguard Midcoat Mio 80GunarsyahNo ratings yet

- Penguard FC: Technical DataDocument4 pagesPenguard FC: Technical DataMohamed FarhanNo ratings yet

- Penguard Primer: Technical DataDocument4 pagesPenguard Primer: Technical DataRohit KambleNo ratings yet

- Tds - Penguard HB - English (GB) - Issued.24.06.2005Document4 pagesTds - Penguard HB - English (GB) - Issued.24.06.2005BNo ratings yet

- TDS SAFEGUARD EnglishDocument4 pagesTDS SAFEGUARD EnglishthirdNo ratings yet

- TDS-PENGUARD TOPCOAT-EnglishDocument4 pagesTDS-PENGUARD TOPCOAT-EnglishthirdNo ratings yet

- TDS-PENGUARD HB-EnglishDocument4 pagesTDS-PENGUARD HB-EnglishthirdNo ratings yet

- Jotafloor Damp BondDocument4 pagesJotafloor Damp BondMohamed FarhanNo ratings yet

- Jotafloor Topcoat Technical Data SheetDocument4 pagesJotafloor Topcoat Technical Data SheetTuan ThanNo ratings yet

- Jotafloor Topcoat: Technical DataDocument4 pagesJotafloor Topcoat: Technical DataMohamed FarhanNo ratings yet

- TDS JOTATHANE EnglishDocument3 pagesTDS JOTATHANE EnglishthirdNo ratings yet

- TDS-JOTABAR ZEP-EnglishDocument3 pagesTDS-JOTABAR ZEP-EnglishthirdNo ratings yet

- Chemtech 340Document3 pagesChemtech 340pardissNo ratings yet

- TDS-ANODESHIELD ICCP-EnglishDocument4 pagesTDS-ANODESHIELD ICCP-EnglishthirdNo ratings yet

- Jotacote 5Document4 pagesJotacote 5Ridwan BaharumNo ratings yet

- Tankguard Holding Primer: Technical DataDocument4 pagesTankguard Holding Primer: Technical DataTra ThanhNo ratings yet

- TDS MARATHON EnglishDocument4 pagesTDS MARATHON EnglishthirdNo ratings yet

- Dura MasticDocument4 pagesDura MasticMoh. Emil SyamsudinNo ratings yet

- Penguard SpecialDocument3 pagesPenguard SpecialAbay OchNo ratings yet

- Penguard Midcoat: Technical DataDocument3 pagesPenguard Midcoat: Technical DataMohamed FarhanNo ratings yet

- TDS-JOTACOTE PSO-EnglishDocument3 pagesTDS-JOTACOTE PSO-EnglishthirdNo ratings yet

- Jotafloor Coating: Technical DataDocument4 pagesJotafloor Coating: Technical DataSan CandyNo ratings yet

- Penguard Midcoat MIODocument3 pagesPenguard Midcoat MIOMohamed FarhanNo ratings yet

- Hardtop As ClearDocument4 pagesHardtop As ClearANIBALLOPEZVEGANo ratings yet

- Penguard HB 2005 PDFDocument4 pagesPenguard HB 2005 PDFMuthuKumarNo ratings yet

- TDS - Penguard Midcoat - Issu.26.11.2010 PDFDocument4 pagesTDS - Penguard Midcoat - Issu.26.11.2010 PDFvitharvanNo ratings yet

- TDS-JOTACOTE 5-EnglishDocument4 pagesTDS-JOTACOTE 5-EnglishthirdNo ratings yet

- Jotamastic Plus: Technical DataDocument3 pagesJotamastic Plus: Technical DataMohamed FarhanNo ratings yet

- Jotafloor SealerDocument4 pagesJotafloor SealerSanthosh KarunanithiNo ratings yet

- TDS - Jotaprime Mastic - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Jotaprime Mastic - English (Uk) - Issued.26.11.2010Rajput PratiksinghNo ratings yet

- Futura AS: Technical DataDocument3 pagesFutura AS: Technical DataMohamed FarhanNo ratings yet

- TDS - Penguard Primer - Issued.26.11.2010Document4 pagesTDS - Penguard Primer - Issued.26.11.2010vitharvanNo ratings yet

- Cmp0000410 Dc1 Jotamastic 87Document5 pagesCmp0000410 Dc1 Jotamastic 87Akhiruddin AbasNo ratings yet

- Antifouling Seaquantum FBDocument3 pagesAntifouling Seaquantum FBMoh. Emil SyamsudinNo ratings yet

- TDS - Penguard Topcoat - English (Uk) - Issued.26.11.2010 PDFDocument4 pagesTDS - Penguard Topcoat - English (Uk) - Issued.26.11.2010 PDFNPTNo ratings yet

- Penguard HB: Technical DataDocument4 pagesPenguard HB: Technical DataMohamed FarhanNo ratings yet

- Penguard Primer: Technical DataDocument3 pagesPenguard Primer: Technical DataMohamed FarhanNo ratings yet

- Spec Peinture BacDocument2 pagesSpec Peinture BacSalah JallaliNo ratings yet

- Megayacht Royal AntifoulingDocument3 pagesMegayacht Royal Antifoulingasjoben1002No ratings yet

- Hardtop Flexi: Technical DataDocument3 pagesHardtop Flexi: Technical DataMohamed FarhanNo ratings yet

- Muki EPS: Technical DataDocument3 pagesMuki EPS: Technical DataMohamed FarhanNo ratings yet

- Jotafloor SF PrimerDocument3 pagesJotafloor SF PrimerMohamed FarhanNo ratings yet

- Antifouling Seaquantum LLLDocument3 pagesAntifouling Seaquantum LLLMoh. Emil SyamsudinNo ratings yet

- Jotashield Alkali Resistant PrimerDocument3 pagesJotashield Alkali Resistant PrimerRaviyanantham RishabananthanNo ratings yet

- Conseal PrimerDocument3 pagesConseal PrimerpardissNo ratings yet

- Antifouling Seaquantum ClassicDocument3 pagesAntifouling Seaquantum ClassicRidwan BaharumNo ratings yet

- J HB TDS PDFDocument4 pagesJ HB TDS PDFwey5316No ratings yet

- Jotamastic Smart PackDocument4 pagesJotamastic Smart PackMohamed FarhanNo ratings yet

- Antifouling Seaquantum ClassicDocument3 pagesAntifouling Seaquantum ClassicMoh. Emil SyamsudinNo ratings yet

- Antifouling Seaquantum PlusDocument3 pagesAntifouling Seaquantum PlusMoh. Emil SyamsudinNo ratings yet

- ALKYDPRIMERDocument3 pagesALKYDPRIMERMoh. Emil SyamsudinNo ratings yet

- Penguard Stayer - English (Uk) - Issued.06.12.2007Document3 pagesPenguard Stayer - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- TDS - Penguard Midcoat MIO - English (Uk) - Issued.26.11Document4 pagesTDS - Penguard Midcoat MIO - English (Uk) - Issued.26.11Karthik ChannamsettyNo ratings yet

- Hardtop PS5 PDFDocument3 pagesHardtop PS5 PDFMohamed FarhanNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- Navbelt and GuidecaneDocument11 pagesNavbelt and GuidecaneSwathi Bhattiprolu100% (1)

- Architectural Design 9 Thesis Research Writing: 3 Proposal DraftDocument7 pagesArchitectural Design 9 Thesis Research Writing: 3 Proposal DraftVANESSA DELA TORRENo ratings yet

- BTech Thesis Student AttendanceDocument24 pagesBTech Thesis Student AttendanceJohn Pecson100% (1)

- CCI, MACD, ZIG ZAG Trading System - Forex Strategies - Forex Resources - Forex Trading-Free Forex TraDocument6 pagesCCI, MACD, ZIG ZAG Trading System - Forex Strategies - Forex Resources - Forex Trading-Free Forex TraJames LiuNo ratings yet

- 1,023,695, Patented Apr. 16, 1912.: G. WaltherDocument3 pages1,023,695, Patented Apr. 16, 1912.: G. WaltherdfdfsdNo ratings yet

- Q9. A Proforma Cost Sheet of A Company Provides The Following ParticularsDocument2 pagesQ9. A Proforma Cost Sheet of A Company Provides The Following ParticularsGourav SharmaNo ratings yet

- Apparel Internship Report 12Document118 pagesApparel Internship Report 12Ankita RanjanNo ratings yet

- Atomic Hydrogen WeldingDocument2 pagesAtomic Hydrogen WeldingDavid TurnerNo ratings yet

- Drug Schedules and Prescription Writing Clifford M. Knapp, PH.DDocument36 pagesDrug Schedules and Prescription Writing Clifford M. Knapp, PH.DEman ElzeftawyNo ratings yet

- Module 2 Solar EnergyDocument140 pagesModule 2 Solar EnergyMuhammad Ahad Rahman MiahNo ratings yet

- Wednesday, January 07, 2015 EditionDocument16 pagesWednesday, January 07, 2015 EditionFrontPageAfricaNo ratings yet

- DSA Weekly PlanDocument3 pagesDSA Weekly PlanJatin0% (1)

- Technical Proposal 1Document2 pagesTechnical Proposal 1syed khalilNo ratings yet

- Motion To Reconsider-Vacate-Modify Order, C.a.11 No.13-11585-BDocument62 pagesMotion To Reconsider-Vacate-Modify Order, C.a.11 No.13-11585-BNeil GillespieNo ratings yet

- Module 2 SOUND RECORDING AND REPRODUCTIONDocument92 pagesModule 2 SOUND RECORDING AND REPRODUCTIONRenz Dela Cruz ArellanoNo ratings yet

- Ra 8800 - FaqDocument3 pagesRa 8800 - FaqNeil OrtileNo ratings yet

- GR 190080Document9 pagesGR 190080Arvi MendezNo ratings yet

- Zara Case Study20191029 42781 f73lj1 With Cover Page v2Document17 pagesZara Case Study20191029 42781 f73lj1 With Cover Page v2Amrutha RPNo ratings yet

- G.R. No. L-48176 PDFDocument7 pagesG.R. No. L-48176 PDFAj SobrevegaNo ratings yet

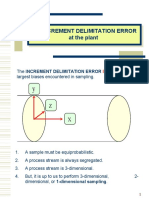

- K Delimitation Error at Plant (New)Document30 pagesK Delimitation Error at Plant (New)ricardo cruzNo ratings yet

- Liberian Daily Observer 11/20/2013Document24 pagesLiberian Daily Observer 11/20/2013Liberian Daily Observer NewspaperNo ratings yet

- Unisab III Engineering - 2009 06Document293 pagesUnisab III Engineering - 2009 06Marildo CominNo ratings yet

- Traxxas v. Namero, LLC D/b/a Redcat RacingDocument4 pagesTraxxas v. Namero, LLC D/b/a Redcat RacingPatent LitigationNo ratings yet

- AnneCecile RABINE - PortfolioDocument20 pagesAnneCecile RABINE - PortfolioAnne-Cécile RabineNo ratings yet

- Etkin 2016Document64 pagesEtkin 2016rindi atikahNo ratings yet

- 042 Myrmidon (Elf Class)Document3 pages042 Myrmidon (Elf Class)VikshadeNo ratings yet

- Drawing System With Dobot Magician Manipulator BasDocument20 pagesDrawing System With Dobot Magician Manipulator BasAnshika SainiNo ratings yet

- Studentzone 02 2017Document3 pagesStudentzone 02 2017YahiaEl-obidyNo ratings yet

- Understanding Economics and How It Affects BusinessDocument7 pagesUnderstanding Economics and How It Affects BusinessHuynh Thi Hong NhungNo ratings yet

- PMP NotesDocument3 pagesPMP Notesjay2kay5793No ratings yet